Filson Diesel Coalescer Filter

- 150psi welded steel ASME code construction(stamp on request)

- Available in hydrophobic barrier media and hydrophilic coalescing media

- Epoxy-coated interior for corrosion resistance and polished exterior

- Decrease economy loss, reduce engine downtime and improve efficiency

- High quality carbon steel, borosilicate and epoxy resin material

- Less than 50ppm separation level for free water removal from diesel

- Specifications

- Send Us Inquiry

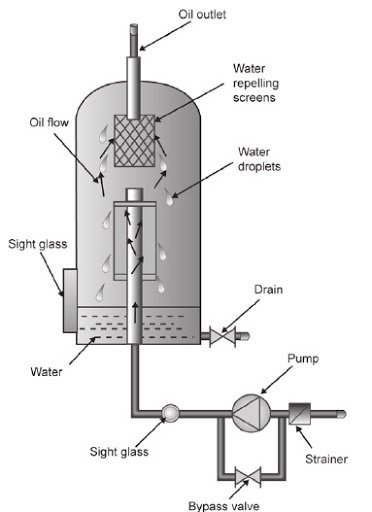

Filson diesel coalescer filter is a dewatering unit which is suitable for diesel fuel with densities of less than 950kg/m3. The working principle of Filson diesel coalescing filter is that small water droplets are combined into larger drops and separated from the diesel by force of gravity.

- Raw material: stainless steel, carbon steel

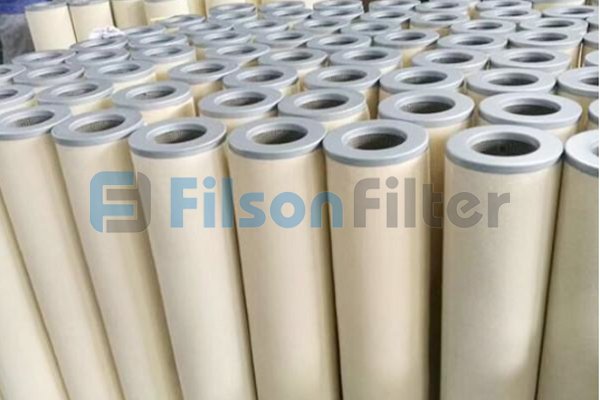

- Filter cartridge material: silicone cellulose, fiberglass, borosilicate, epoxy resin

- Dimension: customized

- Cartridge length: 22 inch, 33 inch, 44inch, 56 inch or customized

- Filter media type: pleated or depth type media

- Applicable medium: liquid liquid separation

- Micron rating: from 5 to 25 micron

- Flow capacity: 1800L/min

- Max flow rate: up to 7950lpm

- Working temperature: ranging from -75 ℃ to 200 ℃

- Maximum pressure differential: 145 psig

- Construction standard: 150psi welded steel ASME code construction(stamp on request)

- Connection mode: NPT thread, flange and weld end connection

- Accessories: automatic air vent, pressure relief valve, differential pressure gauge, water interface control, water sight glass, sampling probes, manual drain valve, water slug valve, sump heater

Note: listed above are for reference purpose, please consult Filson for customization.

Send Your Inquiry Today

Filson Diesel Coalescer Filter

Your Dependable Diesel Coalescer Filter Manufacturer in China

Since impurities such as water vapor and aerosols in diesel can wear the engine injection nozzles and injection pumps, you should use a coalescer to reduce this damage by dewatering. As a leading diesel coalescer filter manufacturer in China, Filson is your best choice.

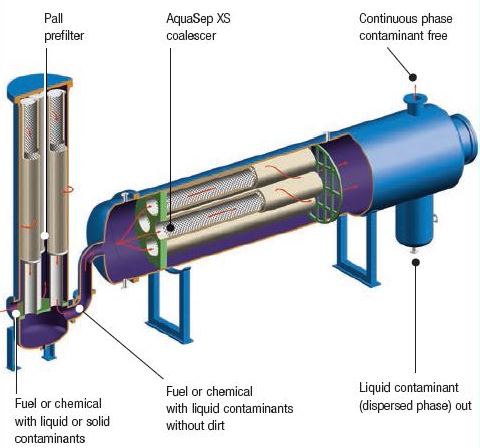

By installing pre-filters, you can eliminate large contaminants from diesel, and also protect coalescer. Filson high performance diesel coalescer filter remove tiny and finely distributed free water to less than 50ppm levels.

The most typical filter element found in Filson diesel coalescer filter is hydrophobic barrier media, such as silicone cellulose. Water in the diesel is rejected and beads on the upstream. As more water is rejected, beads coalesce into large drops and drained into a collection.

Another media is hydrophilic depth coalescing media, such as glass micro-fiber. As water in the diesel encounter the media, it associates with the glass fiber and grows into massive droplets. The droplets falls into port by gravity, while dry diesel rise out Filson diesel coalescer filter outlet.

Any other questions? Click Here for more information.

Diesel Coalescer Filter: The Ultimate FAQs Guide

If you’re looking for any information about diesel coalescer, you will find it here.

It covers everything, from applications, components, working principle, to replacement, amongst other aspects.

So, if you want to be an expert in diesel coalescer filter, read this guide.

What is a Diesel Coalescer Filter?

This is a device which removes particulate and water impurities found in diesel fuel.

It ensures that the diesel used meets the cleanliness standards specified by the OEMs.

You will use this device to protect the system components and sensitive pumps and injectors from wear and blockage caused by solid contaminants.

Similarly, they also protect the system from corrosion and diesel combustion complications that can arise as a result of water contamination.

Fuel coalescer filter

What is the Working Principle of a Diesel Coalescer Filter?

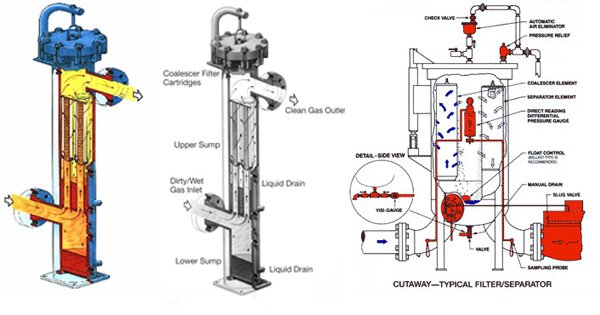

A diesel coalescer filter removes contaminants in two steps.

The diesel is filtered in inside to outside flow.

During the first step, it removes the particulate contaminants through different mechanisms including impaction, interception and diffusion.

In the second step, it removes water molecules found in diesel through combining the droplets into large drops which can drain away into sump collection through gravity.

What are the Components of a Disease Coalescer Filter?

A diesel coalescer filter is made up of different components that perform different functions.

They include:

Air eliminator: It automatically opens to allow the release of trapped air when the vessel is filling and opens to release it once full.

Check valve: It blocks the ingression of air into the vessel through the air eliminator.

Pressure relief valve: It opens at a pre-set pressure level to allow for the escape of system generated pressure as a result of thermal expansion under stagnant fuel condition.

Coalescing Element: The medium traps particulate impurities and amalgamates water droplets from the diesel stream.

Separator element: This is optional inclusion but mandatory when very high diesel cleanliness standards is a prerequisite.

It removes the tinier droplets from the diesel through repulsion hence releasing clean and dry diesel on the output port.

Slug valve: Shuts down diesel flow through the system in the event of excessive buildup of water in the sump.

Drain: It allows for daily removal of wastewater and diesel samples from the sump. You will also use it to drain off diesel in the vessel during changeouts of elements.

Pressure gauge: It indicates the condition of elements through measuring differences in pressure across its inlet and outlet.

What Applications require Diesel Coalescer Filter?

You can use diesel coalescer filters in turbines, vehicles operating diesel engines and other large mobile machinery or engines.

The following industries require diesel coalescer filters for their process applications.

· Mining

Most of the electronic engines common in modern mining industries require extreme pressure and sizes of injection nozzles as tiny as 2 microns.

Therefore, installing a diesel coalescer filter will ensure that the cleanliness of diesel meets the required standards for bulk storage, transfer and dispersion.

· Terminals/Refinery

Contaminants can find their way into the diesel fuel during transportation, refining, storage or distribution.

Consequently, using a good filter will ensure that the quality of diesel delivered to the consumer meets the cleanliness requirements of the OEM.

· Power Generation

The diesel coalescer filter help in the delivery of high-quality diesel fuel free of particulate and water contaminants in diesel-powered plants.

These plants require large amounts of clean diesel in reservoir tanks which must be available on demand.

· Transport

The transportation sector heavily relies on clean and quality diesel for optimum operation.

The quality of engine diesel you use for transporting trucks will affect the maintenance cost and intervals, fuel costs and efficiency and overall transportation cost.

· Retail

Diesel retailers require to supply high-quality fuel which meets all the cleanliness specifications of ISO 4406 to their customers.

Installing a diesel coalesce filter will enable the retailers to get rid of any particulate or water that might have contaminated the fuel during transportation.

What Type of Contaminants are removed by a Diesel Coalescer Filter?

There are different types of contaminants which can contaminate the diesel fuel at different stages.

The common types of contaminants you will find in the diesel include:

· Water

Water contaminates the diesel fuel in the bulk storage tanks.

You have to remove the water because it will cause problems in fuel combustion and corrosion of the filtration and piping system.

It will also reduce diesel lubricity henceforth causing significant system component damage.

· Solid Contaminants

Debris and particulate contaminants ingress the diesel on transit between two storage tanks as well as system wear particles.

The contaminants include pipe scales particles, dust and silica particles.

Large quantities of unfiltered solid contaminants will damage the nozzles of fuel injectors as well as disruption of the diesel combustion in the engine.

· Microbes

Bacteria can proliferate in the water at the fuel interface

· Paraffin and Wax

These contaminants are associated with chilly weather conditions.

· Fuel Degradation Products

These are the bi-products which are come as a result of oxidative and thermal destabilization of the diesel before combustion.

· Air

Air bubbles will ingress and contaminate the diesel from connection joints and cracks or leakage in the piping or filters.

· Asphaltenes

These contaminants are natural components of the crude oil and trace amounts can contaminate the refined diesel fuel.

What are the Benefits of a Diesel Coalescer Filter?

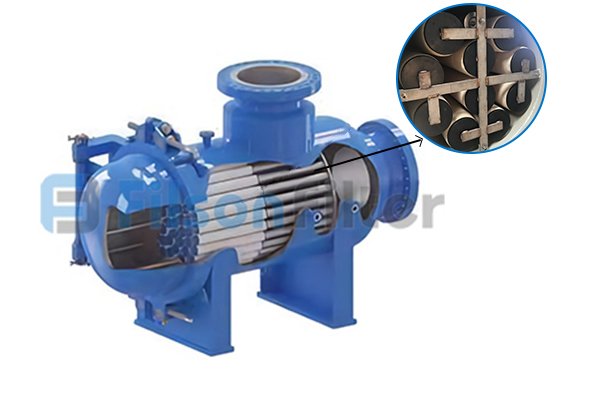

Coalesce skid

You need clean diesel to smoothly operate the modern engines.

Some of the key benefits of using a diesel coalescer filter include:

- Reduced operating and maintenance cost

- Reduced machinery failure and repairs

- Increased machinery uptime

- Efficient and performance of the fuel injector

- Improved fuel consumption efficiency

- Reduced waste emissions into the environment

What are the Characteristics of a Good Diesel Coalescer Filter?

A good diesel coalesce filter must have the following qualities:

- Material for the construction of all filtration components should be chemically compatible with diesel

- Filter out water to achieve up to 1 micron

- Remove water to below 50 ppm in downstream diesel

- Should withstand a wide pH range.

- The filter elements must withstand the operating temperature, pressure and flow rate of the process

What are the Quality Standards for Diesel Fuel Cleanliness?

The fuel cleanliness standards enable manufacturers of diesel to coalesce skid to make a filter that can achieve the level of diesel cleanliness specified by equipment manufacturers.

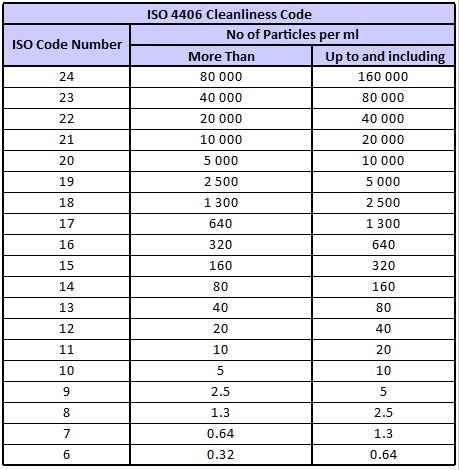

The requirements of diesel fuel cleanliness standards are specified under ISO 4406 contamination codes.

These codes provide the cleanliness requirements of diesel fuel by measuring both the size and number of particulate contaminants.

ISO Cleanliness code

Under the ISO 4406 contamination codes, three code numbers are provided.

The code numbers correspond to the number of particulate contaminants present in the diesel for particle sizes including and above 4 microns, 6 microns and 14 microns.

The code numbers should range from 1 to 28 and are usually divided by the slash sign.

Individual code numbers represent counts of particles ranging from 0.01 to 2, 500, 000.

For instance, the number 11/5/8 correspond to codes for particles including and larger than 4, 6 and 14 microns in the respective order.

How can you Monitor Contamination in a Diesel?

You can use different types of diagnostic equipment to help you detect the presence of particulate and water in the diesel fuel.

You can use electronic particulate counters to detect levels of solid contamination in diesel.

The devices are either mounted online or come portable for both online and offline use.

The devices use laser detection technology to produce precise and reproducible results.

Dual analyzer equipment can detect and count the number of solid contaminants down to 4 microns as well as dissolved water in parts per million.

This kind of contamination monitoring devices uses two separate sensor technology to detect both water and particulate contaminants.

What are the Benefits of a Portable Diesel Coalescer Filter?

Portable diesel filters offer benefits beyond the traditional fuel filtration with an inherent impact on long term performance of fuel systems.

These advantages include:

- Easy to move around with only a single operator

- Easy and fast filter change out

- Does not require extra hardware

- Reliable and durable over a long time

- They can be used with numerous models of filters that meet the cleanliness standards

- The centre of gravity is low to provide more stability

- Can contain additional ports which aid in flexible operations

What test Determine Efficiency in Diesel Filtration?

You can perform some tests under the specifications provided by industry standards such as SAE, ISO, ASTM, and ANSI.

The test ensures that diesel coalescer filter will give you the best filtration results under the designated working conditions.

Some of the important tests you should consider include:

· Retention Test

The test is guided by the specifications of ISO 19438:2003 standards.

You will use it to determine the efficiency of the diesel filter to retain particulate contaminants.

You will use a multi-pass test through a continuous supply of known quantity and size of particulate into the test diesel at a constant flow rate.

You use an online particulate counter to determine the number of particulate impurities upstream and downstream.

Use the figure acquired to work out a Beta ratio which indicates the filtration efficiency of the filter.

This test will give you the particulate removal properties, capacity and differential pressure of the filter.

· Media Migration Test

You should conduct this test to ensure that the dirt retained in the media does not find its way downstream to contaminate the clean filtrate.

You should modify your test conditions to mimic the real-life operating condition to factors such as mechanical vibration, reverse flow and fluctuating flow rates.

Continuously pass a clean fluid through the filter so that you can collect the migrated impurities then draw a graph depicting loss rates against flow rate and time.

· Dirt holding Capacity Test

You will conduct this test to determine the service life of a diesel coalescer filter element.

Continuously supply the system with clean diesel fuel while adding a known amount of dirt at specified time intervals upstream.

Record the differential pressure across the filter element and draw a graph that shows a curve of the amount of dirt added against the differential pressure.

This will allow you to determine the maximum contaminants that can be retained in the filter at specific differential pressure.

· Collapse Test

You will use this test to determine the structural integrity of a filter after it has reached the dirt holding capacity.

Continuously force a contaminated diesel using a pump through the filter at a controlled flow rate and temperature.

Allow for continuous flow of the diesel to a differential pressure at which the element disintegrates.

· Emulsified Water Coalescing Test

The test will determine the efficacy of a filter to remove emulsified water found in diesel.

You can adopt specifications of SAE JI488 when filtering diesel in processes with high flow rates and ISO 4012 when filtering diesel in low flow rates.

For SAE JI488 test procedures, you should use diesel which is 0.25% water concentration while for ISO 4020, the concentration should be 2%. You will inject the water before the system pump.

· Course Water Coalescing Test

You can conduct the test as per the guidelines of ISO/TS 16332 and SAE J1839 standards.

The test uses water that is injected after the system pump without any intense mechanical shear.

According to SAE J1839 standards, the droplets of course water range from 180-260 um and is therefore easily removed by a repellant medium.

What Factor Determines the Service Life of a Diesel Coalesce Filter?

The service life of a diesel coalescer filter element is the length of time which you can use a filter element in your system before it reaches its terminal pressure drop.

The following contaminants related factors will affect the service life of diesel coalescer filter.

Oil coalescer system

· Filtration Efficiency of the Filter

Diesel coalescer filter with very high filtration efficiency also has a short service life because they retain ore dirt and the small pore sizes easily block.

· Flow Rate

Process application with high flow rates also reaches maximum dirt holding capacity compared to processes with lower flow rates.

· Diesel Velocity

The fluid viscosity is dependent on either the level of solid impurities or the nature of diesel.

The higher the viscosity, the lower the filtration rate.

When the diesel fuel is highly polluted, the viscosity increases and the period required to reach the dirt holding capacity of the filter is greatly reduced.

When the contamination of the diesel fuel is light, then the service life of the filter will be extended because the time to maximum dirt holding capacity will also be prolonged.

· Type of Contaminants

The size of particles and their distribution in contaminated diesel has a profound effect on the service life of a filter.

Particulate contaminants whose sizes equate to that of the filters will clog the filter pores faster compared to small of larger particles.

Larger particulate contaminants can drastically increase the service life of a fine size diesel coalesce filter compared to fine particles.

On the contrary, large size particles will reduce the dirt holding capacity of a course size filter faster than ultra-fine particles.

· Change Out Pressure

This is a predetermined pressure beyond which the efficiency of the filter is compromised.

The pressure is based on the dirt holding capacity of the filter medium and the differential pressure.

It indicates the amount of energy required to pass the diesel through the filter.

What is the Best Material for Diesel Coalesce Filter Media?

The filter media represents the core foundation of filtration technology and therefore selecting the most suitable material for construction is key to proper filtration.

You use the following materials for construction of the filtration media for oil filtration systems:

· Silicone Treated Cellulose

The treated cellulose media is constructed using cellulose that has been treated with silicone to effectively remove water and particulate contaminants.

You can use the media to remove impurities on the suction side of diesel systems

· Polyester and Cellulose Media

The media is constructed using two layers constituting a layer of synthetic polyester and cellulose.

The double-layered has increased particulate retention and water removal capacity.

You can use this kind of media for critical operations that require extended service intervals.

It is suitable for use on both pressure and suction diesel systems.

· Synthetic (Fibreglass) and Cellulose

This is a high-performance media which is suitable for secondary fuel filtration and enhances the systems components and engine protection.

The media can extend the service life of a filter up to triple the period of traditional filter media.

· Pure Synthetic Media

You can also select any single synthetic media for making the media of a fuel filter.

Such media is usually used for high-performance filtration and are more suitable for secondary diesel filtration.

How can you Maintain Diesel Coalescer Filter?

Drain off the wastes collected in the sump daily and test the sample for any discolored water and contamination [articles.

Routinely inspect and record the pressure drop across the housing vessel under normal filtration conditions daily.

Schedule routine inspection, repair and cleaning of the diesel storage tanks.

Constantly monitor the pressure drop indicator and schedule element change out once the recommended has been reached.

You should consider testing the filtration efficiency of a filter yourself before settling on a specific brand.

When conducting the routine maintenance, you should follow these simple steps to avoid any mishaps.

- Open the air eliminator to speed up the processes of draining the diesel off the filter housing during the change out. Ensure that you remove all the diesel from the vessel.

- Avoid touching the elements during replacement. You can achieve this by inserting the elements together with the polybag cover then removing the cover slowly to avoid static charge one element is in place. Otherwise, put on a clean rubber or cotton glove if you have to touch the elements.

- Do not use diesel to lubricate the gasket because it can result in bunching and pinching of the gasket making it prone to leakage.

- Use a clean diesel or diluted bleach to clean the housing bowl. Avoid using detergents and other types of fuels.

- Ensure that you shut all the drain valves before reconnecting to the piping.

How does the Orientation of a Diesel Coalescer Filter determine its Operation?

The diesel coalescer filter can be hosted in a vertical or horizontal vessel.

The filtration principles are similar for both vessels.

However, vertical housing is suitable where the floor space is limited since the horizontal model takes up much floor space.

On the other hand, a horizontal diesel coalescer filter usually has bigger internal space and can accommodate more internal devices and high flow capacity.

Vertical and horizontal oil coalescer

How can you Increase the Filtration Efficiency of a Diesel Coalescer Filter?

You can increase the target collection efficiency of a diesel coalesce filter through:

· Increasing the Velocity of the Droplets

At a higher droplet velocity, the momentum of the droplets also increases.

The high momentum increases the probability of the smaller droplets to impact the medium rather than flow around it.

However, ensure that you do not exceed the upper limit of the velocity.

Beyond the upper limit, the velocity will develop a drug force which can prematurely pull the droplets off the media to the outlet stream before they settle.

· Reducing the Continuous Phase Viscosity

Principally, you can achieve a reduction by increasing the operating temperature.

The reduction will lower the drag force which reduces the settling time through permission for the rise and fall of droplets at a higher settling velocity.

However, you must consider the limits beyond which the temperatures will inhibit the separation due to an increase in mutual phase solubility.

· Decreasing the Target Diameter

Reducing the target diameter will lower the turbulence target/media and allow the flowing stream to carry the smaller droplets into the media.

Can you Clean and Reuse a Diesel Coalescer Filter Elements?

Yes, depending on the type of material used to construct the elements.

You can clean elements constructed using synthetic material while you will not be able to clean and reuse the once made from the natural cellulose of paper.

How much can a Diesel Coalesce Filter Cost?

The price of a diesel coalescer filter will greatly vary depending on the application.

For instance, a portable diesel coalescer filter can cost $ 15000 while a simple truck diesel coalescer filter will cost between $2 and $5.

When should you Replace Diesel Coalesce Filter?

You should change the filter cartridges when the differential pressure reaches the filter changeout level recommended by the filter manufacturer at the rated flow.

However, the change out pressure differential will be affected by the flow rate at which the filter is operating.

If your process application is operating below the flow rate at which the filter is designed, then the change out differential pressure will also drop.

You should, therefore, understand the characteristics of the pressure differentials of lower flow rates to avoid using a filter which has already surpassed its service life.

How does Diesel Coalescer Filter compare to Normal Filters?

A diesel coalescer filter can have additional separator cartridge which is absent in normal coalesce filters.

The separating cartridge ensures that the suspended coalesced water droplets do not contaminate the diesel on the outlet ports.

With this information, am sure you can get high quality and reliable diesel coalescer filter.

For standard or custom diesel coalescer filter designs, you can contact us now.