Efficient and Economical Liquid-Gas Separation Solution

Filson demister pad is an optimal and effective device for your liquid entrainments separation from various gases, commonly acts on over 3μm droplets. Typical types of Filson mist eliminators can be divided into mesh type and vane type, among the mesh type is more popular since the better tiny entrainment filtration performance.

For 18 years, Filson has served hundreds of companies from more than 40 countries and regions around the world with their approval. A series of ISO 9001, CE, etc. certificates are our pride and extensive expertise is our strong backing.

Demister Pad

Why Filson Demister Pad

- Experienced – extensive expertise, years of experience, constant technical updates

- Professional – 30+ expert R&D engineers, a variety of production and test equipment

- Economical – own factory, complete production workshops, competitive factory price

- Fast – set up a good relationship with logistic companies, delivery from factory directly

- Considerate – sincere and enthusiastic service, 7/24 consultation throughout the trading

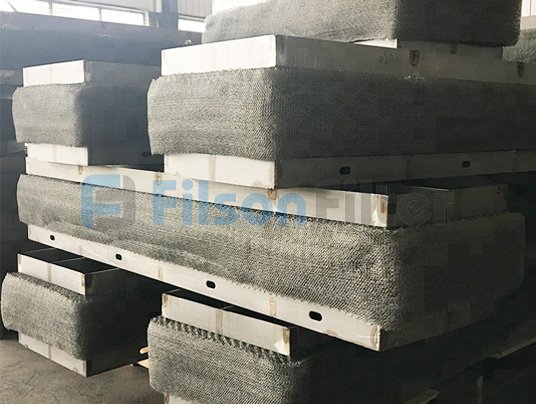

- Safe – complete package, wrapping with plastic film, customized wooden case outside

Filson: Your Demister Pad Manufacturing Specialist in China

Filson demister pad, also named mist eliminator, can effectively clean, dry, distillate, separate the liquid drop from gas. In usual applications, it easily protects downstream equipment to avoid expensive maintenance.

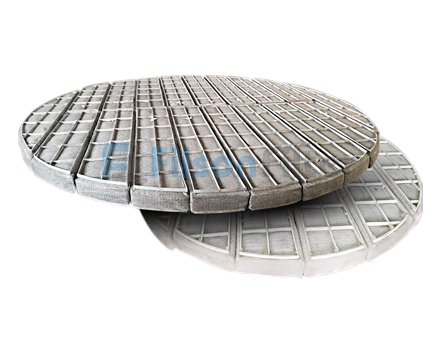

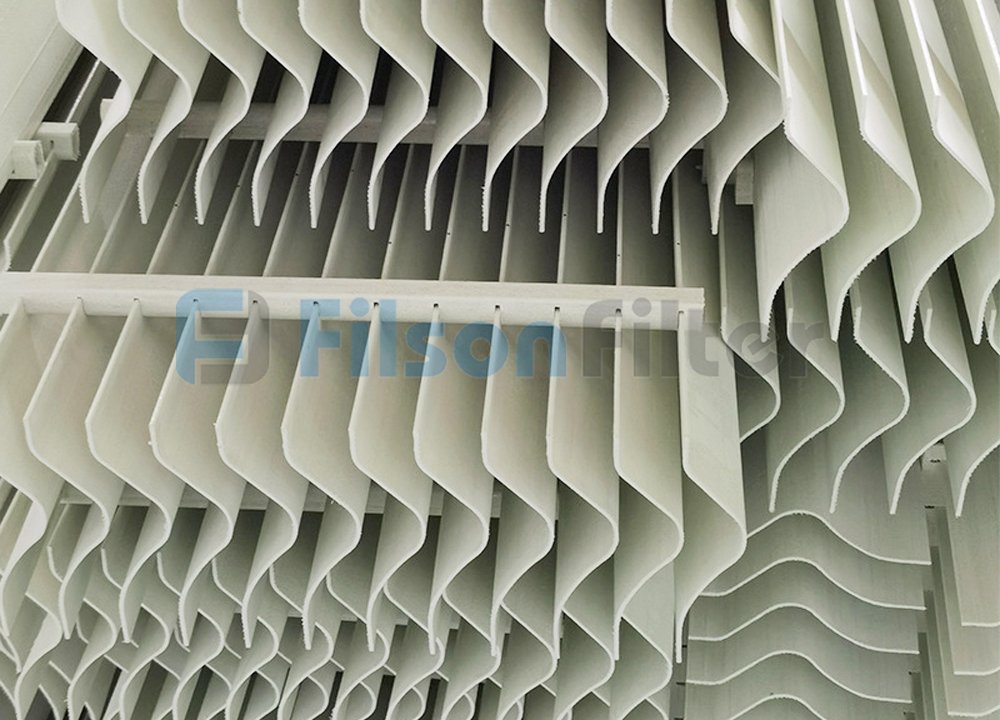

Filson demister pad is constructed with knitted wires and support grids, available in integral style or separate style. Depending on your existing or new system, pads can be designed to be round, rectangular, ring-shaped, wave shapes. Certainly, vane type is also provided.

From refineries, sulfuric acid plants, petrochemical plants, to gas absorption systems, flue gas desulfurization, Filson demister pads are always your best partner with economical cost and safe operation. Both metallic demister pad and plastic demister pad types are your choices.

Filson metallic demister pads are mainly manufactured in SS 304/304L, SS 316/316L, SS 904L, Monel-400, Titanium, Hastelloy, Nickel, or Inconel-625 materials, with high strength and superior mechanical performance. Plus, they feature excellent corrosion and rust resistance, are very suitable for various chemical environments.

For metallic Filson demister pads, each batch of raw materials will be strictly detected with a Spectrograph for ingredient compliance. In addition, each finished mist eliminator will experience a series of filtration accuracy, pressure, quality & safety tests before delivery.

And if you need Filson plastic demister pads, PP(polypropylene), PE(polyethylene), PVC(polyvinyl chloride), PTFE(polytetrafluoroethylene), etc. materials all available. Plastic types are more economical than metallic types with lighter weight, easier to install and ship.

Filson is capable of designing and manufacturing mesh type and vane type of demister pads. Among mesh demister pad can effectively remove liquid entrainment larger than 3 micron, while vane type mist eliminator performs very well for 8-40 microns droplets and particles removal.

Of course, other filtration accuracy customization are allowed, just send your unique application or existing drawing to us. Our professional technicians will help you pick the most appropriate demister pad.

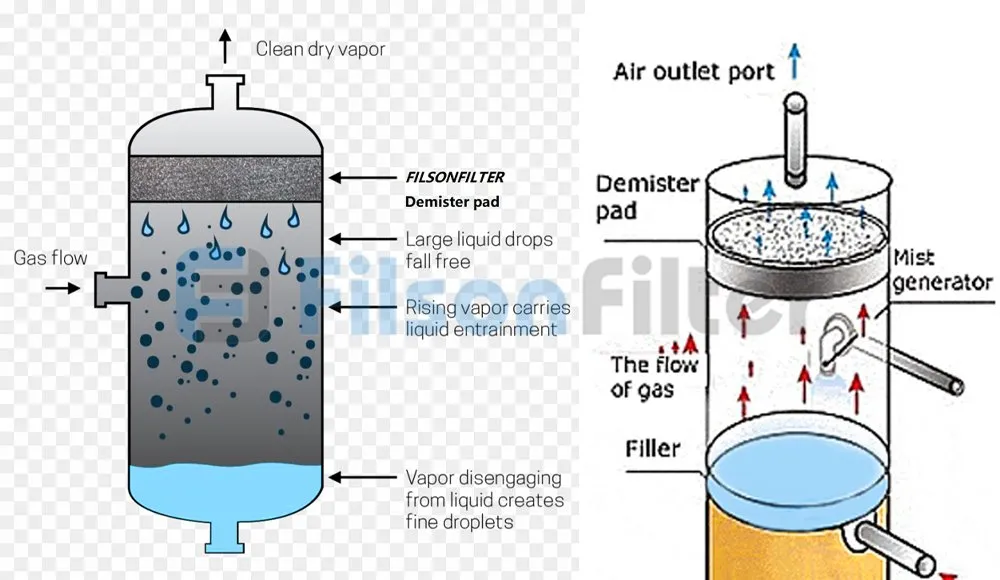

Filson demister pad is usually installed to the top of packed column, cooling tower, distillation column, and suitable for both vertical and horizontal installation directions. Moreover, such as demister pad in heat exchanger, demister pad in steam drum are also available.

As one of the most professional demister pad manufacturers in China, Filson can totally provide an independent demister pad design for your special application. We always support CAD drawings and demister pad sizing calculations advisory service.

ODM/OEM service is our speciality. No matter you have any requirement of demister pad material, demister pad type, demister pad function, or any replacement need of Koch Glitsch demister, Otto York demister, Filson mist eliminator is always your preferred choice.

We promise to sincerely serve you from pre-sale to after-sale, any pre-sale enquiry or after-sale assistance is provided. An instruction manual in English will arrive with your demister pads, and your exclusive representative will be online 24/7 for your filtration problem.

Filson always aims to assist you reduce your overall costs without losing mist eliminators quality. We can provide the most competitive demister pad price due to we achieve the integration of production and sales.

If any doubt of demister design calculation, demister pad sizing calculations, demister pad use, demister pad price…, please fell free to use our contact forms:

Call: 86-157 3695 8886

Email: sales@filsonfilters.com

What is Demister Pad?

Demister pad is an essential device in various packed columns, rectifying columns, separation columns, cooling towers, etc., generally located at the top. It is used for removing specified size liquid entrainments from gas streams.

Mainly consist of knitted wire mesh and support grids, demister pads can be manufactured in stainless steel, nickel, monel, hastelloy, inconel, PP, PE, PVC, PTFE(Teflon) or other required materials. And for different application and installation needs, it can be designed into various shapes like standard round, rectangular, ring types or special wave-shaped. Vane-type is also available.

How do demister pads work?

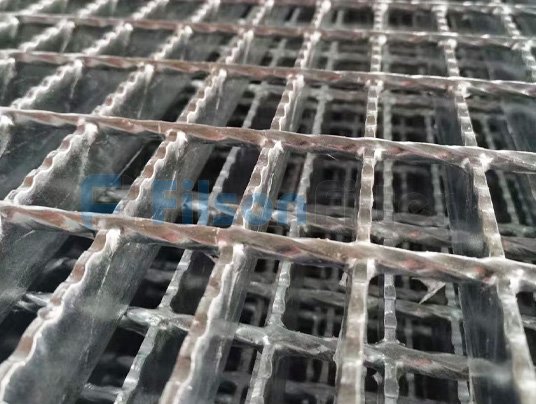

The main principle of demister pad is coalesence by inertia. When tiny liquid entrainments passing through the tortuous path of demister pad, they collide with each other between the gaps of knitted wires and condense into larger liquid droplets. Weight gain, droplets drop down. Thus the mist will be separated from gas streams and you can obtain the pure gases.

How to clean a demister pad?

Regular and proper maintenance of demister pad is important. After a period of using, your demister pad may be clogged by the particles in the gas and pressure drop will increase, then you need to clean it. Various cleaning methods will be mentioned here including spray with cleaning liquids, boil, soak… to help you regain a clean demister pad while recovering its high filtration efficiency.

Please be more careful when you cleaning the demister pad, and carefully check for damage after each cleaning. Measure its wire diameter with a micrometer to confirm if there is any change compere to the brand new. In addition, a spare demister pad is necessary before you start cleaning.

Filson Demister Pad Features:

- High collection efficiency and low pressure drop of 100-400 Pa

- Fully annealed with maximum corrosion resistance

- Easy to install and remove with a simple construction

- Uniform pore size and firm knit with stable structure

- Perfect welding of support grating with precise knitted mesh

Filson Demister Pad Specification:

- Raw Material: SS 304/316/904L, 2205, 2507, PE, PP, PVC, PTFE(Teflon/F4), Nickel, Titanium, Monel 400, Hastelloy, Inconel 625, FRP(fiberglass reinforced plastic)

- Pad Diameter(mm): 300-6000

- Wire Diameter(mm): 0.1-0.3

- Thickness(mm): 20-500

- Filtration Accuracy(μm): 3-10

- Filtration Efficiency(%): 99.9

- Pressure Drop(Pa): < 250

- Shape: round, ring, rectangular, wave-shape

- Type: mesh type, vane type

Note: listed above are standard reference, please consult for customized.

Filson Demister Pad Applications:

- Petrochemical Plants

- Chemical Industries

- Marine Industries

- Pharmaceutical Companies

- Fertilizer Plants

- Fine-chemical Industries

- Desalination Plants

- Oil Refineries

- Air Compressor Systems

- Gas Companies