An Efficient & Dependable Solution for Fluid Filtration

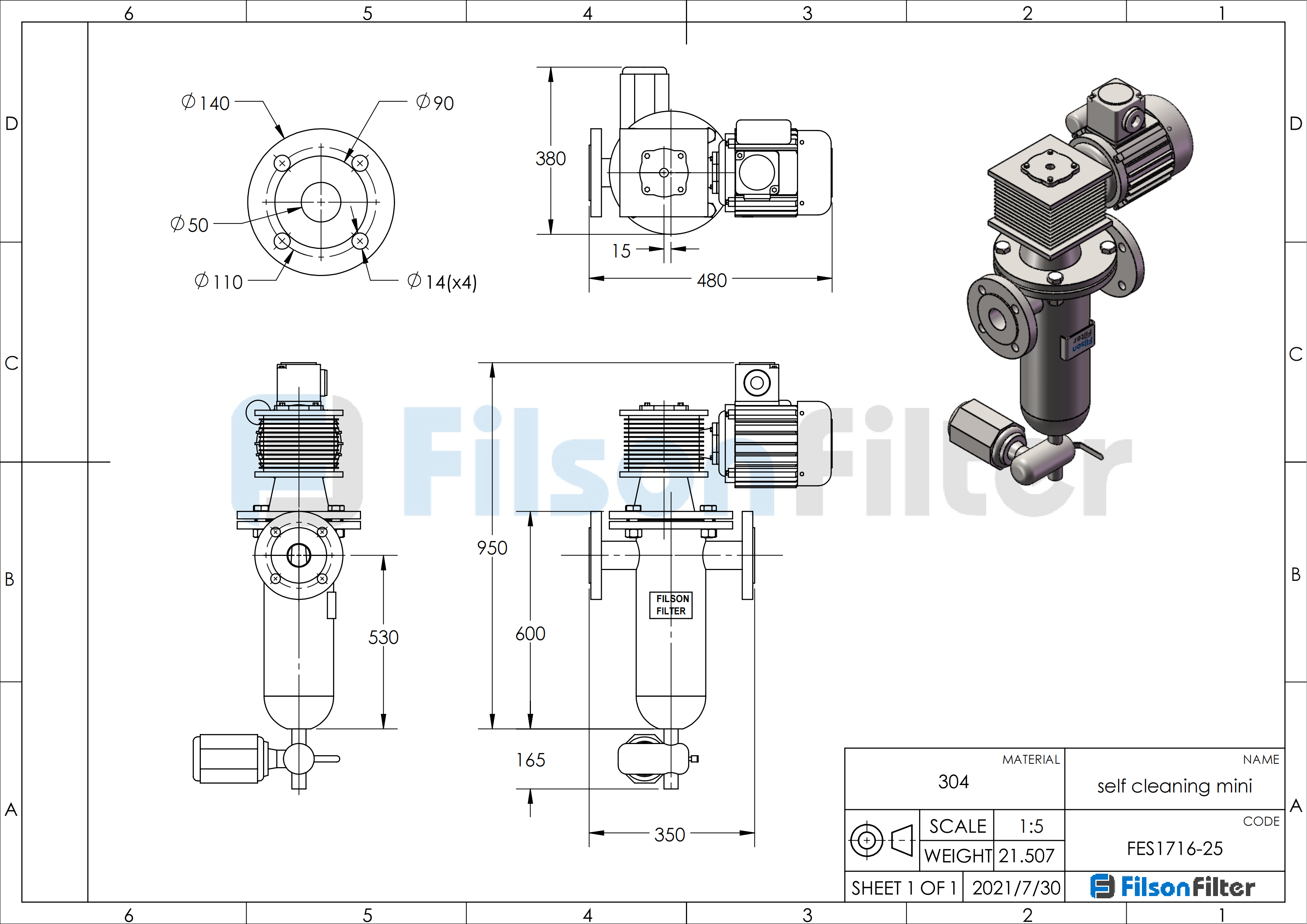

Filson self cleaning filter is specially designed for fluid filtration with continuous operation, saving the downtime and maintenance costs. It is generally manufactured by quality 304/316L stainless steel material, and nickel or titanium alloy can also be available for high-corrosion sea water applications.

If you need an economical and reliable fluid filtration system, Filson self cleaning filter will be your optimal choice. With precision size design, strict quality control and perfect after-sale service, Filson has become one of the best self cleaning filters manufacturers in China.

Self Cleaning Filter

Why Trust Filson?

For 18 years, Filson may always be a strong performer in self cleaning filter manufacturing and designing field. We promise you to solve your complex water filtration problems, with our innovative self cleaning filter production technology and experienced engineer team.

Of course, according to your special application requirements, our technicians will help you design an appropriate OEM solution of self cleaning filter. Plus, we are known for prompt and thorough service to provide quick quote and professional installation guidance.

Filson: Your Industrial Leading Self Cleaning Filter Manufacturer in China

Filson self cleaning filter, also called self cleaning strainer, automatic self cleaning filter, is an innovative industrial filtration unit to help you easily remove contaminants from your needed liquid. It has a unique self cleaning system design to allow continuous flow without downtime.

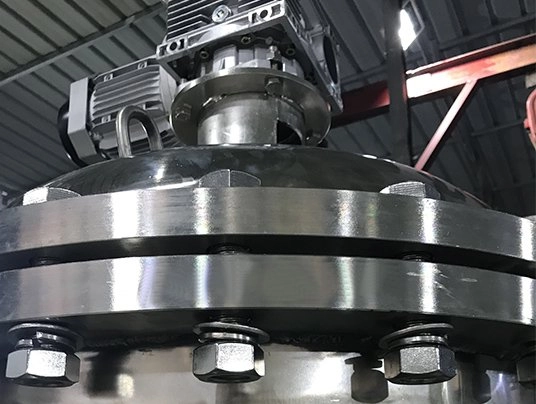

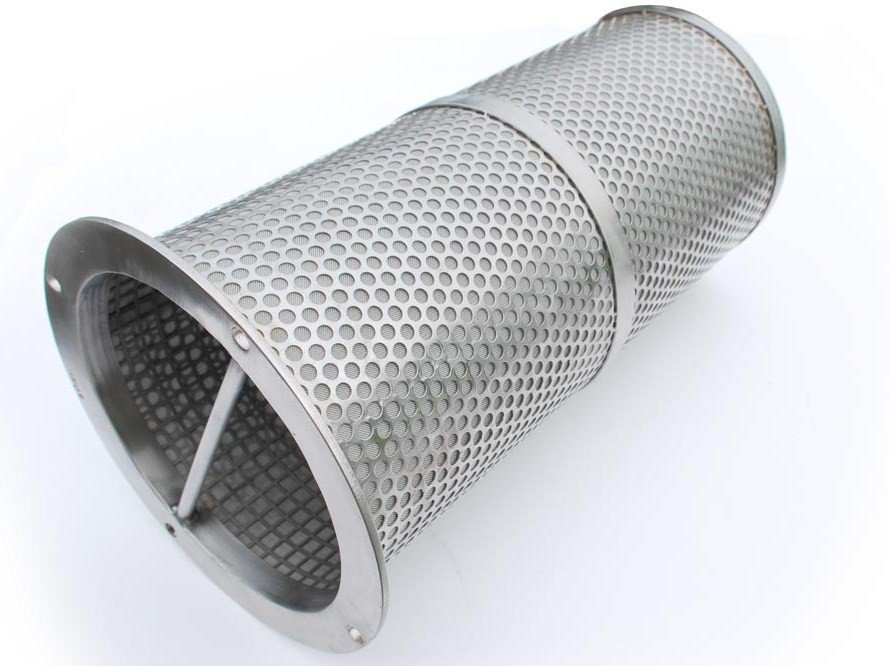

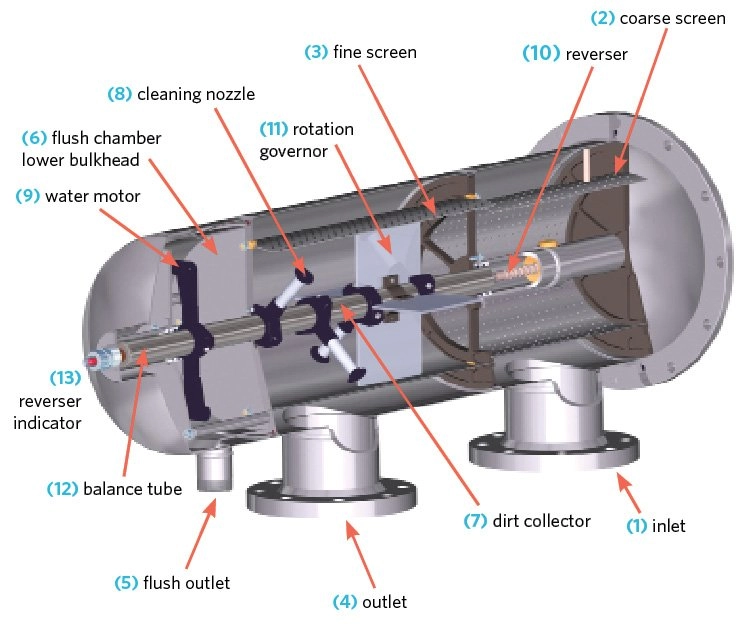

Filson self cleaning strainer mainly consists of a drive motor, a reusable screen filter element, and stainless steel brush for brushing type or suction nozzles for suction type. Among the filter element options include wedge wire filter element, wire mesh filter element, sintered mesh filter element and perforated mesh filter element.

With excellent corrosion resistance, Filson self cleaning filter is a highly versatile machine to filter effectively from chocolate and honey to water and oil. We commonly supply several types, such as self cleaning water filter, self cleaning air filter, self cleaning oil filter.

When you prepare to select a self cleaning strainer, you should pay more attention to the temperature requirement of operating environment. Filson self cleaning filter can withstand 0-65℃ as usual, or higher temperature can be achieved by high-heat resisting materials.

Filson automatic self cleaning filters are available in the filtration rating of 50-3000 micron, you can pick depending on your liquid filtering condition. Certainly, your special micron rating need is always permitted, please consult our technicians.

No matter for a high or low flow rate of your application, Filson self cleaning filter will be your best candidate with a wide range of flow rates from 15m3/hr to 4200m3/hr. Moreover, it can adopt both vertical and horizontal installation types to meet most installation space and requirements.

You can choose both differential pressure control and PLC timing control two types for the self cleaning process of Filson automatic self cleaning filter. When reaches your set time or differential pressure typically around 7psi, it will clean itself in 12-18 seconds.

Compared to conventional manual cleaning filters, Filson self cleaning filters can offer an uninterrupted filtration process to improve production efficiency. Therefore, it is a cost-effective option that can easily replace the simplex or duplex manual strainers.

Filson self cleaning filters benefits to a variety of applications like petrochemical, pulp, and paper, irrigation system, power plants… Furthermore, we arrange a specialized production line to meet strict health and safety regulations of food&beverage or pharmaceutical industries.

We recommend you to install Filson self cleaning filter at the place where close to the pressure source, ensuring proper pressure of the inlet for normal use. Standard working pressures of Filson self cleaning filter are 1.0Mpa, 1.6Mpa, 2.5Mpa, or other unique selections upon your need.

As one of the most expert self cleaning filter manufacturers in China, Filson has supplied our self cleaning filters to plenty of overseas customers in Australia, America, and many European countries. Over the last 18 years, Filson has cooperated with more than 1000 partners.

In addition, even you have an urgent or large quantity order, we are capable of satisfying your needs by our sufficient self cleaning filter inventory. And OEM pricing is available upon quantity purchase agreements.

Filson can also provide customized service according to your drawings. Or you may just send us your independent flow rate, working pressure, temperature, and micron rating requirements, we will assist you to design the most suitable self cleaning filter.

If you have any other questions about Filson self cleaning filters, please consult our engineers or sales. Call at +86 157 3695 8886 or email sales@filsonfilters.com! We will reply to you within 12 hours!

Can not find what you need? Filson also has rich experience in manufacturing sintered metal filters, wedge wire filters, sintered wire mesh filters, stainless steel basket filters, high flow filter cartridges, etc. Contact us today!

Filson Self Cleaning Filter Working Principle:

The Filtration Process

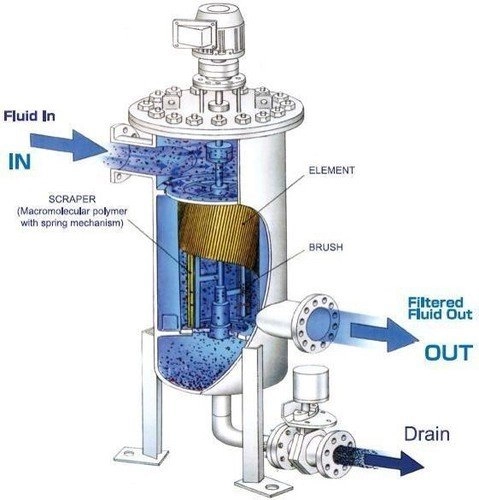

The liquid enters filter body from the inlet and then passes through the screen filter element inside to start the filtration process. Various dirt, particles in the liquid will build up gradually on the inner screen surface to cause a filter cake, with an increased differential pressure across the screen. Typically, when the inside pressure reaches to the pre-set value of 0.05Mpa(7 psi), control system will receive the signal, the self cleaning process begins.

The Self Cleaning Process

At the beginning of self-clean, the flushing valve will be opened with a portion of filtered liquid(less than 1%) reenters the filter body. In 12-18 seconds, the motor may drive suction nozzles(for suction scanning type) or stainless steel rotating brush(for brushing type) to efficiently remove the contaminants deposited on the screen surface. During the entire self cleaning period, normal filtration part will be continuous with very low flow rate fluctuation.

Filson Self Cleaning Filter Features:

- Wide flow rate range with high filtration rating

- Large dirty holding capacity for long service life

- Superior raw material for high filtration performance

- Low maintenance without frequent replacement

- Uninterrupted production process to save downtime

- Self cleaning ability without any manual operation

Filson Self Cleaning Filter Specifications:

- Raw material: SS 304, SS 316L, 2205, CS, nickel, titanium alloy

- Filtration rating:50-3000 micron

- Single unit flow: 15-4200m3/h

- Working pressure: 0.25-2.5Mpa

- Cleaning differential pressure: 7psi (0.05Mpa)

- Operating temperature: 0-65℃

- Connection type: flange

- Self cleaning time: 12-18 seconds

- Self cleaning flow: <3% of filtration liquid flow

- Control method: differential pressure control, PLC timing control

Filson Self Cleaning Filter Applications:

- Pulp and paper industry

- Water&Wastewater treatment

- Primary metal industry

- Power plant

- Petrochemical industry

- Pharmaceutical industry

- Irrigation system

Self-Cleaning Filter: The Ultimate Guide

Are you tired of cleaning clogged filters?

How much time and money do you spend during any downtime while cleaning clogged filters?

Well, here is a perfect solution for you – go for a self-cleaning filter.

In today’s guide, you’re going to learn about every aspect of self-cleaning filters – from the basic definition, technology, benefits, working principle, etc.

Guess what, by the end of this guide, you’ll be a self-cleaning filter expert.

Let’s get started:

- What is a Self-Cleaning Filter?

- Benefits of Self-Cleaning Filter

- Applications of Self-cleaning Filters

- Basic Self-Cleaning Filter Terminologies

- Classification of Self-Cleaning Filter

- Parts of Self-Cleaning Filter

- Self-cleaning Filter Working Principle

- Key Considerations when Buying Self-cleaning Filters

- Conclusion

What is a Self-Cleaning Filter?

Self-cleaning filters are special systems that automatically get rid of clogged particles or dirt after a period of time.

That is, once the filter holds or traps unwanted particles, it is set in such that it flushes or removes unwanted material.

Actually, self-cleaning filters come in different configurations.

For example, it allows clean fluid to flow through the system and removing dirt or particles from the system.

In short, as the name suggests, this is a filter system that cleans itself after a period of time.

Benefits of Self-Cleaning Filter

There are many benefits that you will derive from the use of a self- cleaning filter.

Either directly or indirectly, this equipment will benefit you in the following ways.

1. Continuous filtration

The advantage you have with a self- cleaning filter is that you don’t have to stop the filtration process.

This is important especially in applications that require continuous filtration of your fluid.

You don’t have to stress yourself with stopping the operations to clean the filter element.

As the filtration continues, the filter element cleans itself.

2. Cost efficiency

When you compare a self- cleaning filter with other kinds of filters, you will notice it is effective regarding cost.

The maintenance cost such as cleaning and repairing cost is less which saves you money.

You are therefore able to use these resources for other functions that filtration will require.

3. Ease of operation

The use of a self- cleaning filter only needs basic operational skills to be able to run it.

You will, therefore, find it an easy device to use on your application.

Basically, once you have installed in on your application, it is good to go.

Also, removing the components for repair and maintenance only requires you to go through the manual.

Basket strainer

4. Easily available

The advantage you have with a self- cleaning filter is that you can easily find them in the market.

This is partly due to their relatively affordable price and also since different manufacturers manufacture them.

Also, you have the upper hand since they come in different sizes.

You can, therefore, pick the size that fits your application.

By having different sizes of their filtration element, you can choose the level of filtration that you want of your fluid.

5. Contaminant holding area

Most self- cleaning filters come with a large holding area for the contaminants.

This enables you to operate your application for a long time without disposing of the contaminants.

Polypropylene membrane filter

The advantage you have here is that you can continue with your production for a long time.

Applications of Self-cleaning Filters

There are different applications that you can use a self- cleaning filter.

The choice of which filter to use will depend on which application you want to use.

Some of the common applications for self- cleaning filters include the following.

§ Farming Application

Water circulation on your farm is very important.

There are a lot of applications where you need a continuous flow of water.

Irrigation system

That is why you need a self- cleaning filter on the farm’s water system.

For instance, your animals require clean water to drink.

By using a self- cleaning filter, you will be able to remove contaminants that may pose as a health hazard to your animals.

Since you will be doing less maintenance means that you won’t stress yourself often to repair the filter.

Another area of application is irrigating your farm’s produce.

You will need a lot of water to irrigate your farm which at times may be dirty from its source such as rivers.

As such, you need to remove the contaminants before allowing the water to flow into the farm.

You can achieve this by using a self- cleaning filter which will remove contaminants thereby letting clean water on your farm.

There are various filter sizes that you can use depending on the size of contaminants you want to remove.

§ Sewage Treatment

We all understand how valuable water resource is and the need to conserve and if possible, recycle it.

One way of doing this is by treating wastewater.

Treatment of sewage water involves several steps which work efficiently by using a self- cleaning filter.

A self- cleaning filter minimizes clogging of the waste treatment piping system.

Waste treatment plant

The advantage of this is that there is a continuous treatment of sewage water.

Treatment of sewage water allows for the usage of the water in various applications such as farming.

§ Water Treatment

We all require clean water for consumption and other household activities.

This requires that we treat the water we use before consuming it.

Water treatment plant

By using a self- cleaning filter, you will be able to remove contaminants such as unwanted particles from the water.

Depending on the size of the filter element, you can remove various unwanted particles from the water making it safe to use.

In treatment plants, using a self- cleaning filter ensures that water treatment continues without any disruption.

This is because it can clean itself during the application process.

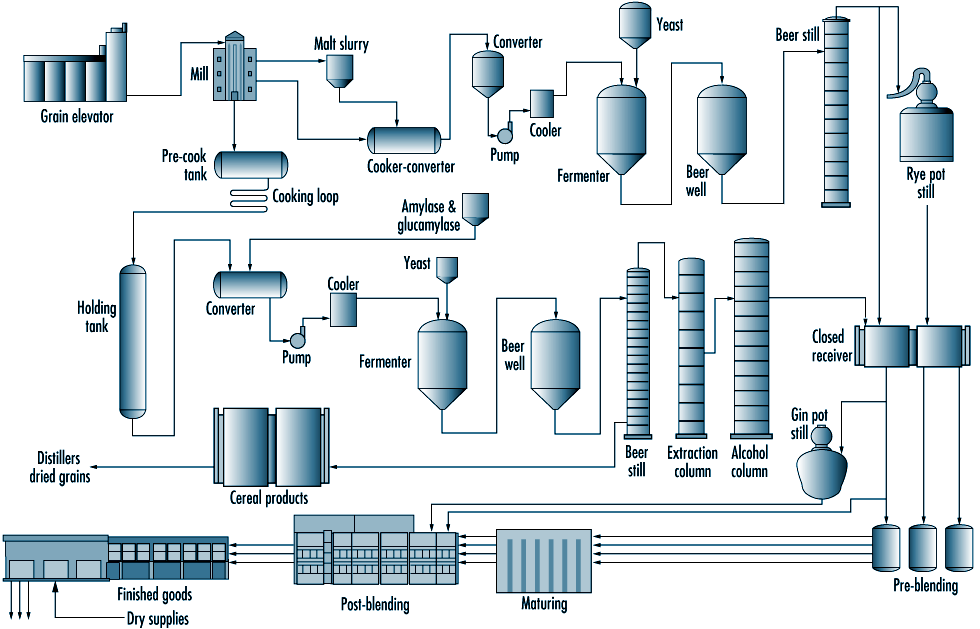

§ Food Processing Industry

To ensure the safety of food during processing, you can use a self- cleaning filter to remove contaminants from the food.

Beverage industry setup

Different foods processing requires different filters which you can use to ensure the removal of contaminants.

§ Electricity Generation

There are different areas of electricity generation where you can use a self- cleaning filter.

For example, in turbines, you need a self- cleaning filter to ensure that the fluid flows efficiently and effectively.

Also, in the electricity generators, you will need a self- cleaning filter to remove contaminants from the oil.

This ensures that you can continuously generate electricity.

Basic Self-Cleaning Filter Terminologies

But wait!

How can we explain what a self- cleaning filtration is without having explained what terminologies you would encounter?

These terminologies are phrases or words that you will frequently use when talking about a self- cleaning filter.

Self-cleaning filter – Photo courtesy: Rotor Flush

Allow me to take you through.

§ Filtration and micro-filtration

Filtration refers to the process of removing unwanted particles from the fluid.

What happens is that you pass the fluid through a porous material known as a filter.

As it passes through the filter, it retains unwanted particles and substances while the fluid flows.

The kind of filter to use will depend on the size of the unwanted particles.

There are three filtration techniques that you can have, that is cold, hot and vacuum filtration.

The choice of which technique to use will depend on the outcome that you want.

Hot filtration is applicable if you want to separate particles from a hot fluid.

This kind of filtration is suitable especially when you want to prevent the formation of crystals in the filter.

Cold filtration involves the use of an ice bath which cools down the fluid rapidly thereby crystalizing it.

On the other hand, vacuum filtration involves the use of a Büchner flask, Büchner funnel and a rubber tubing which connects the filter to the source of the vacuum.

Microfiltration refers to a special kind of filtration process where the fluid passes through a special pore- sized membrane.

By doing this, the pores retain microorganisms as well as microparticles from the fluid.

The major limitation of the performance of microfiltration is fouling.

This is the process of accumulation and deposition of the microparticles within the pores of the filtration membrane.

The occurrence of this is when the parameters of the fluid such as the temperature and pressure are constant during the working process.

When it occurs, there is a reduction in the efficiency of the microfilter membrane.

Even though you can reduce the amount of fouling that occurs, it is impossible to remove the whole of it.

This implies that you will have to replace the membrane often to ensure efficiency.

§ Filtration degree

Filtration degree refers to the size of the pores in the filtration medium which affects the degree of your filtration.

There are different sizes of pores that you can choose for your filtration.

The choice of the filtration degree will depend on the outcome that you want for your filtration.

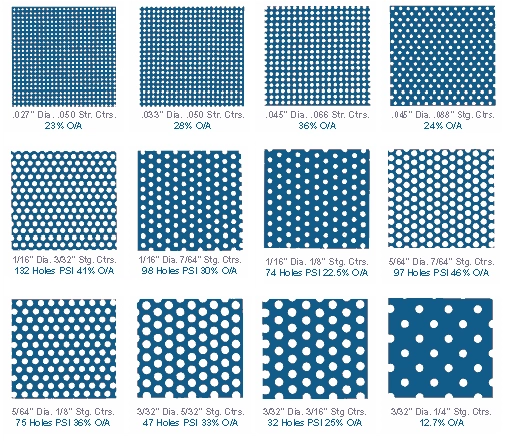

§ Mesh

A mesh refers to an element that can either be of wires or threads that has pores through which your fluid passes through.

There are different mesh sizes that you can have for your filters depending on the outcome you desire.

Mesh patterns for filters

Effective filtration area

Effective filtration area refers to the area of the self- cleaning filter that does the filtration of your fluid.

Different filtration area exists which depend on the size of your filtration element.

By choosing a larger filtration element, you will have a larger filtration area.

Likewise, by choosing a small filtration element, you will have a smaller filtration area.

§ Screen

The screen refers to a cylindrical body that is mainly of metal which holds the contaminants during filtration.

There are two kinds of screens.

That is a wedge-wire screen and a weave-wire screen.

Wedge- wire screen consists of stainless-steel wires that have a trapezoidal shaped cross-section.

These cross-sections are parallel to each other allowing a small gap between them.

You, therefore, find that they have long slots which have nominal filtration width.

These types of screen are useful when removing 3D particles from the fluid which will get stuck in between the spaces during the filtration process.

On the other hand, a weave-wire screen consists of discrete openings.

Basically, 2D square-weave has rectangular openings which when joined in pairs, form a weave-wire screen.

You can have different openings of this screen depending on the size of the rectangular openings.

They are particularly important when you want to remove scaly contaminants from the fluid.

§ Filtration open area

The open filtration area refers to the total area that your filter covers which is usually in square inches or square centimeters.

§ Direct flushing in self-cleaning filters

Direct flushing is the process of cleaning the self- cleaning filters.

This process operates as the fluid flows.

Once the contaminants fill the filter, the direct flushing valve will open up thereby directing the flow of the fluid to the drainage valve.

As it does this, the pressure of the fluid cleans the filter thereby removing the contaminants from the filter element into the drainage valve.

§ Back-flushing in self-cleaning filters

During filtration, solids will accumulate on the filtration membrane which implies that once in a while you will have to remove them.

You can achieve this by using backflushing.

Generally, backflushing is the reverse flow of filtration through a filter.

The process removes the accumulated particles from the filtration membrane.

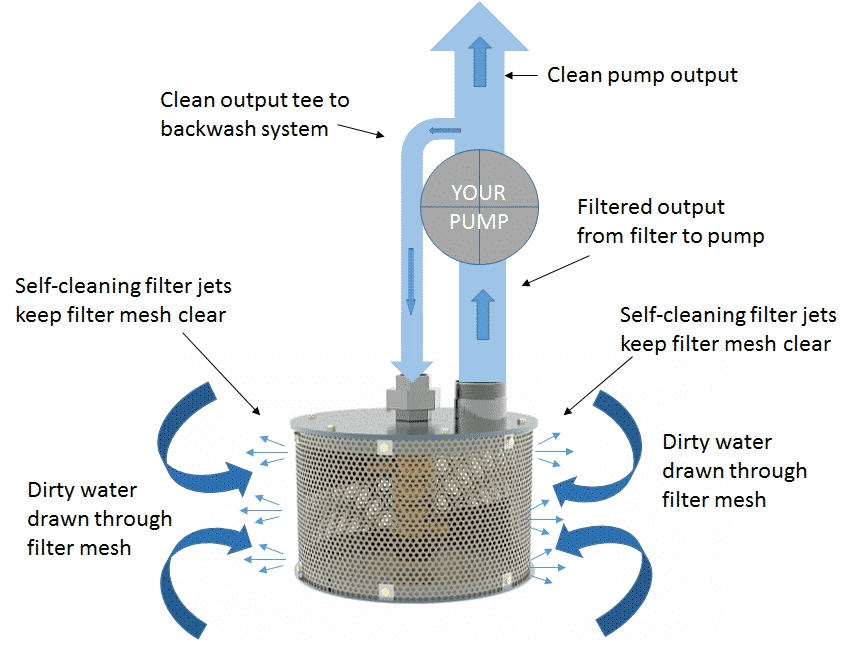

§ Suction scanning or focused back clashing in self-cleaning filters

Suction scanning refers to a suction which is as a result of reversing the flow of the fluid through a tiny section of the screen element and into a nozzle.

The nozzle is normally at the tip of the scanning element which is usually rotating.

Classification of Self-Cleaning Filter

There are different ways that you can classify self- cleaning filter.

The classification depends on the application that you are going to use your self- cleaning filter for.

To be able to understand this, the following are the different classification of self- cleaning filters.

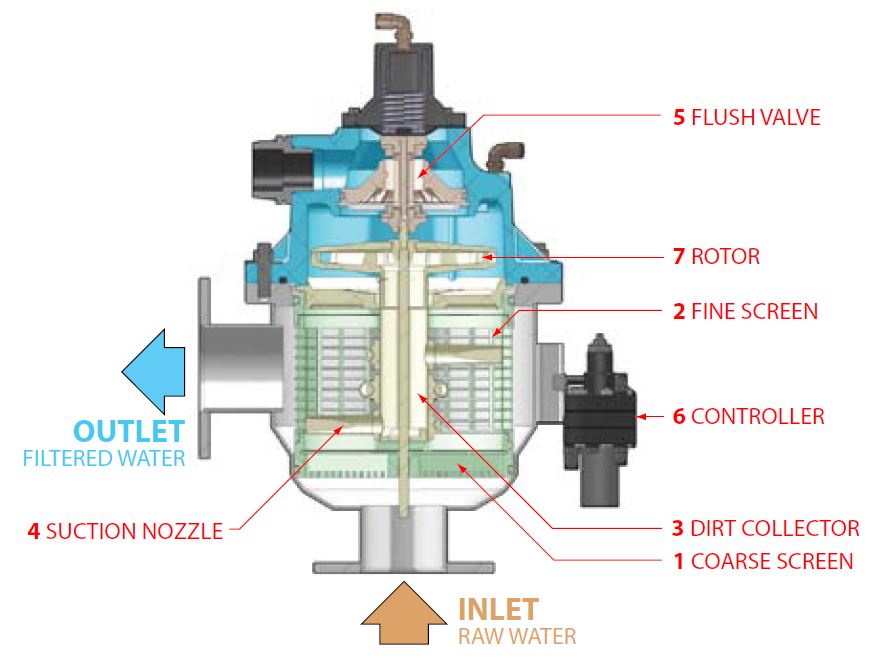

§ Automatic self-cleaning water filters

Automatic self- cleaning filters are a kind of filters that are suitable for the removing of contaminants from water.

You will, therefore, find these kinds of filters in water circulation systems such as sewage treatment plants and water treatment plants.

Automatic self-cleaning filter

These kinds of filters utilize water pressure difference to clean themselves.

What happens in this kind of filter is that water flows through the inlet to the filtration element inside the filter.

At the filter element, trapping of contaminants that are larger than the pores of the filter element take place.

This process continues until there is a difference in pressure of the water.

At this point, air operated valves open up which redirect section of the water flow backward through the pores of the filter elements.

This is normally known as backwashing.

By doing this, the water flushes the contaminants that have accumulated on the element.

This process repeatedly occurs thereby enabling the self- cleaning filter to clean itself.

Self- cleaning water filters are efficient as they only consume less than 1%

§ Automatic self-cleaning air filter

You will find automatic self- cleaning air filter in air cleaning applications.

For example, in air conditioners, these types of filters are important in purifying the air we breathe.

§ Self-cleaning oil filter

In equipment that requires continuous filtration of oil, you can use a self- cleaning oil filter to filtrate your oil.

There are various equipment and machinery that you can use a self- cleaning oil filter.

For example, by using a self- cleaning oil filter ensures that industrial machinery and equipment function continuously.

This enables continuous production while ensuring clean oil.

Another area of application is in the motor industry where you will need a self- cleaning oil filter to filter your oil.

This ensures that you can operate your vehicle efficiently.

Parts of Self-Cleaning Filter

If you are going to use a self- cleaning filter, it is important to get t to understand what the parts that constitute a self- cleaning filter are.

This is crucial especially when you are looking for a spare part, or you need to know the function of a part.

To be able to understand this, here is a look at the parts of a self- cleaning filter.

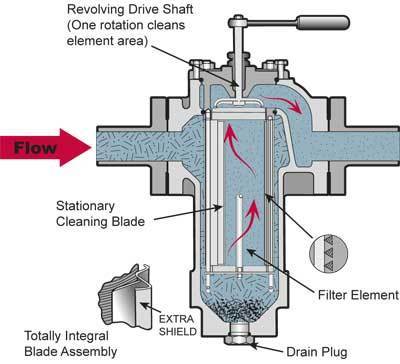

Parts of self-cleaning filter

§ Drain Plug

Drain valve plays an important role in the cleaning of your self- cleaning the filter.

You can locate this component on the lower part of your filter.

The purpose of this component is to remove the contaminants from the filter.

This ensures that your filter is continuously working.

§ Filter Element

Filter element component of your self- cleaning filter that holds the contaminants and the unwanted particles during filtration.

There are different sizes of filter elements which will depend on the quality of filtration you want for your fluid.

Also, you can have different materials making up the filter element.

Since they are the most active part of your filter, you need to check for any maintenance constantly.

§ Suction Nozzle

The suction nozzle ensures the dirt from the filter element and into the dirt collector.

There are different types of suction nozzles depending on the kind of filter you are using.

You can have an air suction nozzle, water suction nozzle, and oil suction nozzle.

§ Dirt Collector

Once the filter accumulates dirt from your fluid during filtration, pumping of the contaminants into the dirt collector happens.

Meanwhile, the dirt collector holds the contaminants until when it is full that you can remove and dispose of.

The purpose of this is that it ensures continuity of the process of the application giving you maximum output.

§ Inlet and Outlet valve

The inlet valve is that part of the self- cleaning filter that lets in fluid during filtration.

There are different sizes of your inlet that you can have depending on the size of your application.

By choosing the right inlet size, you will ensure that there is the maintenance of the flow of the fluid regarding pressure.

On the other hand, the outlet is that part of the self- cleaning filter that allows for the flow of the fluid from the filter.

After filtration, the fluid flows out of the filter from this point.

§ Motor

There needs to be a force of energy that propels the fluid forward ensuring that there is proper working of the filter.

The motor offers this energy for your self- cleaning the filter.

While choosing a motor for your self- cleaning filter, you need to pay attention to the size of your filter and your application.

This ensures that you have sufficient energy to pump your fluid and that your application is not interrupted.

Self-cleaning Filter Working Principle

Of paramount importance in a self- cleaning filter understands how a self- cleaning filter works.

This is so especially when you want to understand the flow of the process.

The flow of the process refers to what happens at each stage when the self- cleaning filter is functioning.

In this segment, I will explain to you the general working principles of a self- cleaning filter works.

Also, I will explain to you how different types of self-cleaning filters work.

Keep reading.

Under normal operations generally, the fluid will flow from the intake through the screen and into the outlet point.

While flowing into the screen, the cleaning disc which is on the upper position of the screen closes.

Also, the rinsing valve will close which will allow for the filtration of the fluid.

As filtration continues, there is foul build up.

Failure to remove foul may result in your filtration not working to the optimum level.

This happens through a reduction of pressure in the fluid.

As a result, you need to clean remove the foul continuously.

You will detect the change in pressure through the control unit which is normally on the side of the self- cleaning filter.

The control unit will initiate the opening of the rinsing valve.

Once the rinsing valve opens, the contaminants around the screen will flow away through this point.

Working of self-cleaning filter

The power unit will initiate the cleaning disc to close down.

This will, in turn, increase the speed of the fluid between the disc and the screen.

As it does this, there will be a decrease in pressure at this point due to the Bernoulli effect.

The decrease in pressure will force the contaminants to be isolated from the screen and drift away upwards.

Once this is complete, the cleaning disc will proceed upwards to an idle position which further cleans the screen.

When the cleaning disc is idle, the rinsing valve will close down which in turn causes the system to resume normal operation.

However, during the entire operation, the fluid will keep on flowing which allows operations to continue undisrupted.

Friction can cause the elements of the filter to wear out quickly.

This implies that you will have to keep buying new components often.

To minimize this, the cleaning disc and the screen do not come into contact with each other.

That is the general working principle of a self- cleaning filter.

However, as you will notice, there are different types of self- cleaning filters in the market.

As such, you need to understand how each type specifically works so that it can be easy when you are using it.

Here is a look at the working principles of the common types of self- cleaning filters.

§ Direct flow self- cleaning filters

The working principle of this type of filter involves the filter mesh retaining all the contaminants.

With this kind of filter, the filter element is cleaned up using the dirty fluid when fouling starts forming.

The results are that you won’t have to replace the element that often.

Usually, the filter element lasts between 1-2 years.

You will also notice that direct flow filters have a drain valve at the bottom end and a ball valve.

The ball valve is the one that opens the drain valve to allow for the contaminants to flow away from the system.

By using a flexible hose or a plastic pipe, you can fit the filter on the fluid system to allow for proper filtration.

§ Backwash self- cleaning filters

The backwash self- cleaning filter consists of an upper section and the main bottom.

During the filtration process, the upper section remains closed as the fluid passes through the bottom section flowing from outside to inside.

The opening of the ball valve allows for the backwash filter to activate and the filter element closes down.

This causes the supply of the fluid to stop thereby diverting it to the small upper section of the filter.

The purpose of this is to allow you to clean the filter.

During this time, water will be flowing back to the backwash filter.

The flow allows the turbines to spin which clean the bottom part of the filter in an inside-outside direction.

By doing so, the bottom section of the filter is always clean during the filtration period.

Closing the ball valve allows for the backwash self- cleaning filter to resume filtration.

Key Considerations when Buying Self-cleaning Filters

The ultimate aim of this guide is to enable you to choose the right self- cleaning filter for your application — a filter that will give you quality service for a long time.

Though there is a variety of self- cleaning filters available, getting one that will work for you can be a challenge.

To assist you in choosing the right filter, here are a few points that you will have to take into consideration.

Self-cleaning filter design – Photo courtesy: Irrigation Direct

Have a look.

§ Kind of contaminant

The first consideration you need to identify is the kind of contaminant that is available on your fluid.

There are different sizes of contaminants that require different self- cleaning filters.

For instance, some fluids have micro contaminants hence you will have to use a micro self- cleaning filter to remove them.

Others have large contaminants that you will have to use a large self- cleaning filter to remove them.

§ The conditions of your application

You also need to check on the condition of your fluid regarding pressure, temperature, and pressure.

By ensuring you have the correct pressure, you will be able to pick the correct self- cleaning filter for your application.

Understanding the flow of your application will enable you to understand where you will place your self- cleaning the filter.

This will ensure the efficiency of your operation

Also, the temperature of your application will determine which type of self- cleaning application you will use.

There are different self- cleaning filters which you can use depending on the temperature of your fluid.

§ Labour and cost

Another factor you need to consider is the labor and the cost of installing and replacing the self- cleaning filter.

This is important especially when you are factoring the cost associated with a self- cleaning filter.

Also, you need to consider the downtime affect your self- cleaning filter is going to have on your application.

Overall, the downtime needs to be as minimal as possible to ensure that there is optimum processing of your application.

§ Contaminant disposal

How will you dispose of off the contaminants to ensure that there is safety in the environment?

That is a factor that you need to bear in mind when choosing a self- cleaning filter for your application.

There are some contaminants which are friendly to the environment hence you can easily dispose of.

However, there are some contaminants especially in industries which can be harmful to the environment.

In such cases, you need to look for proper ways of disposing of the contaminants so that it does not affect the environment.

As you do this, you will have to consider the cost associated with such disposal.

§ The quality of filtration

While choosing your self- cleaning filter, you need to consider the quality of filtration that you require.

Different self-cleaning filters will give you different fluid filtration quality.

§ Nature of the process of your application

Another determinant is the nature of the process of your application.

That is, is your process a continuous one or a batch one?

If it is a continuous process, it will imply that you will have to install a self- cleaning filter which you won’t have to stop the process.

This is so especially when you want to remove the contaminants.

If it is a batch process, you will have to consider the duration of batching to find a filter that will work efficiently during this period.

Conclusion

I hope I have been able to clear all that you need to know about a self- cleaning filter.

The working principle and the terminologies may appear confusing for a start, but with time you will get to understand them.

The important aspect is to find a perfect self- cleaning filter for your application.

If you are looking for a self- cleaning filter that can work for you, get in touch with us today.

We do offer the best quality self- straining filter that will offer the best service for your application.