Your premier simplex Strainer manufacturer

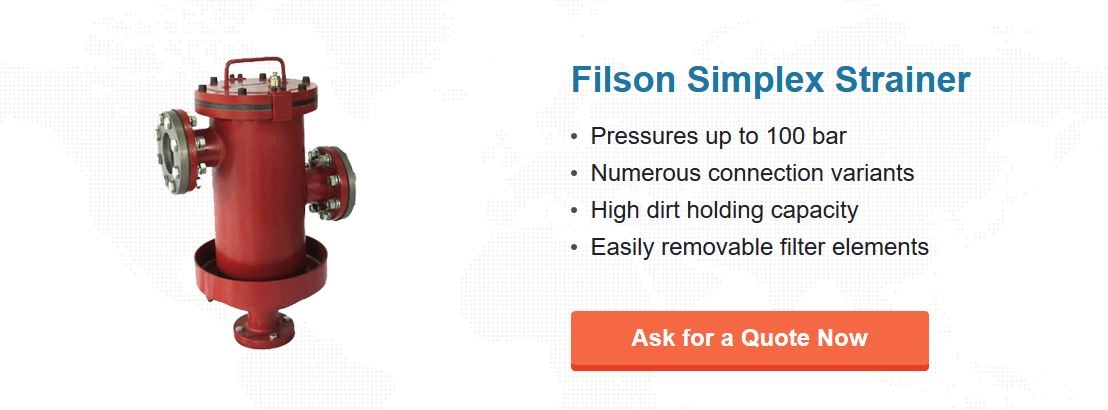

Filson offers a wide variety of standard simplex basket strainers as custom-made filter products for your individual application. Our welded strainer housings permit modifying to fit particular requirements. Additional design and material variants could be offered on request. We manufacture to ASME Code and a host of other construction codes recognized around the world. Filson simplex strainer Covers are easily removed without special tools, and the basket or bag is easily cleaned or replaced. All simplex strainers get through strict air-tight and leak testing. Filson simplex strainers and filters can also handle large flows with the inlet and outlet being in line with the intended connection. Welded versions are available with large flow capacity and pressure capacity of up to 100 bar. Ask a quick quote on our simplex strainers today!

Filson Simplex Basket Strainer: Your Premier Strainer Partner

Filson simplex basket strainer also called simplex filter, it is fully welded basket strainer with the material carbon steel and stainless steel. As the leading simplex basket strainer manufacturer, Filson knows the simplex strainers all details like simplex strainer material, simplex strainer structure, simplex strainer function, simplex strainer benefits and more. Filson simplex strainer can be standard size or customized based on your detailed requirements.

Filson simplex basket strainer also called simplex filter, it is fully welded basket strainer with the material carbon steel and stainless steel. As the leading simplex basket strainer manufacturer, Filson knows the simplex strainers all details like simplex strainer material, simplex strainer structure, simplex strainer function, simplex strainer benefits and more. Filson simplex strainer can be standard size or customized based on your detailed requirements.

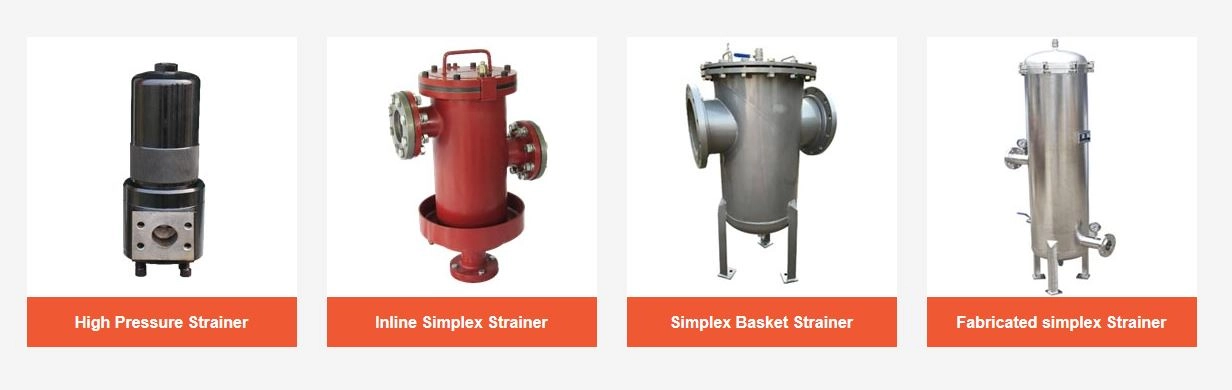

Filson simplex strainers are used in many industries and are used to protect the valves, pipelines, pumps and spray nozzles. Compared to other simplex strainer supplier such Eaton, Filson simplex strainers are much more competitive and more stable.  Filson simplex strainers include simplex inline strainer, simplex suction strainer, simplex return line strainer, high-pressure simplex strainer, simplex spin on strainer, and simplex fabricated strainer. We ensure the 18 months warranty on each Filson products like simplex strainer, duplex strainer .

Filson simplex strainers include simplex inline strainer, simplex suction strainer, simplex return line strainer, high-pressure simplex strainer, simplex spin on strainer, and simplex fabricated strainer. We ensure the 18 months warranty on each Filson products like simplex strainer, duplex strainer .  Each Filson simplex strainer is strictly tested and ensure the best quality strainers in our factory. So if you are looking for simplex strainer supplier, Filson will be your better choice, not just a supplier, you need a partner, let Filson simplex strainer protect your project right now. You can contact us if any questions about our simplex strainers.

Each Filson simplex strainer is strictly tested and ensure the best quality strainers in our factory. So if you are looking for simplex strainer supplier, Filson will be your better choice, not just a supplier, you need a partner, let Filson simplex strainer protect your project right now. You can contact us if any questions about our simplex strainers.

Filson Simplex Strainer video

Filson Simplex Strainer details with Oil Basket Filter

Simplex Basket Strainer Manufacturing in Filson Factory

Filson Simplex Strainers for Marine

This simplex strainer order is for a marine project in Japan, Client ordered 20 Filson simplex basket strainer in our factory. below is an image when we produce the simplex basket strainers.

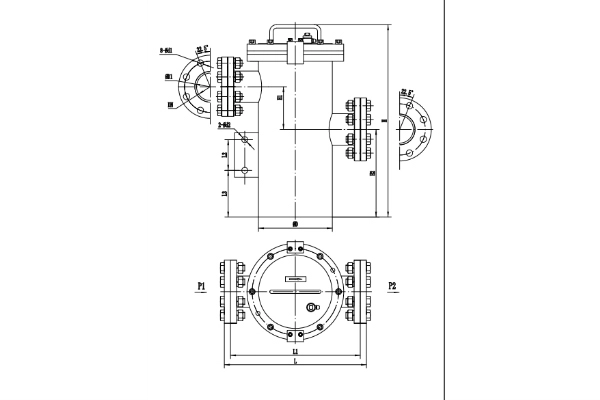

Simplex Basket Strainer: The Ultimate Guide

In today’s guide, I want to discuss 7 critical things about simplex basket strainer. And, why should you learn about them? They will help you choose a suitable simplex basket strainer for your system. But more importantly, you will learn how to maintain the ISO cleanliness levels in your fluid. By the end of this guide, you’ll definitely be an expert in this field.

In today’s guide, I want to discuss 7 critical things about simplex basket strainer. And, why should you learn about them? They will help you choose a suitable simplex basket strainer for your system. But more importantly, you will learn how to maintain the ISO cleanliness levels in your fluid. By the end of this guide, you’ll definitely be an expert in this field.

- What is Simplex Basket Strainer?

- How Simplex Basket Strainer Works

- Simplex Basket Strainer Technical Data

- Function and Purpose of Simplex Basket Strainer in Piping

- Differences Between Simplex and Duplex Basket Strainers

- How to Replace the Basket Element in a Simplex Strainer

- Simplex Basket Strainer Applications

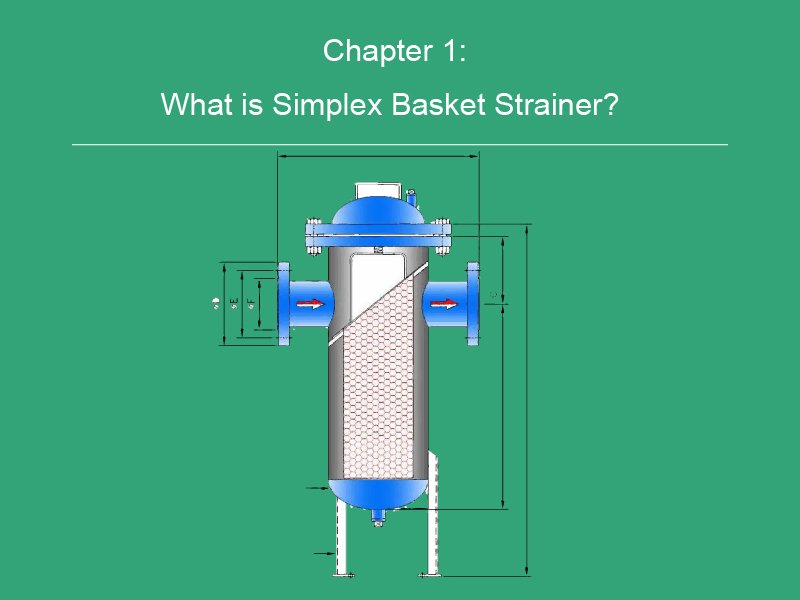

Chapter 1: What is Simplex Basket Strainer?

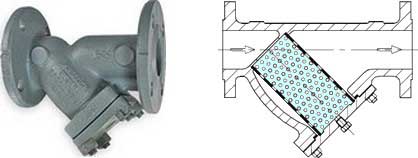

Simplex Basket Strainer is a closed-vessel fitted with a cleaning screen (filter element). The filter element traps and removes all inorganic particles from the flowing fluid. https://youtu.be/EpNRMCar558 Normally, these inorganic particles (impurities) may include:

Simplex Basket Strainer is a closed-vessel fitted with a cleaning screen (filter element). The filter element traps and removes all inorganic particles from the flowing fluid. https://youtu.be/EpNRMCar558 Normally, these inorganic particles (impurities) may include:

- Rust

- Jointing compound

- Scales

- Weld metal in the pipeline

- Dirt

Contaminated water flowing in pipes

Basically, a simplex basket strainer helps to maintain the ISO cleanliness standards of different kinds of fluids. This protects the system from any possible damage due to contamination. Moreover, simplex basket strainer protects the following components and parts:

- Compressors and pumps

- Flow meters

- Regulator and valves

- Ancillary piping-items and instrumentations

- Stream traps

- Heat exchanger and other downstream components in a pipeline system.

The truth is: By protecting these components and parts, you will increase production output. Furthermore, you will increase the lifespan of components. And, by the way, below is an image of a simplex basket strainer:

FilSon Filters simplex basket strainer

Thus, installing simplex basket strainers at strategic positions help prevent damages due to moving solids in a fluid flow.

· Types of Strainers

I know there are many types of strainers in the market today. However, for the scope of this article, I will focus on these two:

- Basket type strainer

- Y-type strainer

Normally, basket type strainers include simplex basket strainers and duplex basket strainers. Generally, basket strainers or pot type strainers have a vertically oriented chamber design. It is seemingly larger than Y-type strainer.

Y-basket strainer

Simplex basket strainers experience less pressure drop across the basket strainers. This makes them suitable for many liquid applications. However, where you need a simplex basket strainer in a steam system, the basket strainer must have a drain plug. Furthermore, it should have steam trap. You’ll use this to remove condensate. Basically, basket strainer designs are for in oil and water systems with:

- Immense high flow capacity

- Larger diameter pipelines

It is because it can trap large quantity of fluid impurities. At the same time, it can take a significant amount loading without collapsing. Let me make it simple for you to understand: Where you use a basket strainer as a secondary filter, it removes impurities that break off from the surface of the pipeline system. You should also note that simplex basket strainer is more suitable for temporary interruption in a batch process. This allows for an easy basket cleaning process.

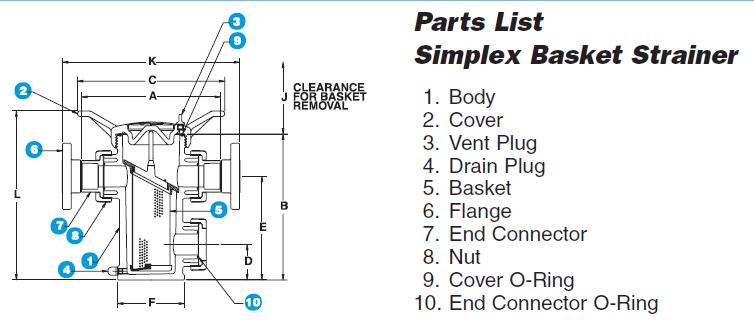

Parts of a simplex basket strainer. Photo Credits: HAYWARD

However, a system that requires continuous and uninterrupted flow – use duplex basket strainers. Do not worry about duplex basket strainer as we will learn more of it in chapter 5. But I know you must be asking yourself this question:

· Why do we Design Simplex Basket Strainer with a Filter Element?

For a fact, the filter media is responsible for fluid filtration in the simplex strainer. It is traps fluid particulates separating it from the stream. So, what is the difference between a filter and strainer? A filter is a permeable media that removes fluid particulates. Most designs are made of disposable material and target specific impurity micron sizes. On the other hand, a Strainer is also a type of filter, however, it uses screen mesh or perforated plate to remove larger particles from flowing fluid process. But, let me make something clear: Strainer basket is reusable – it is one of the main advantages it has over filters. Simply take off the cover and clean it. Different types of simplex basket strainer The basket strainer has three levels of straining, namely:

Different types of simplex basket strainer The basket strainer has three levels of straining, namely:

- Coarse

- Medium; and

- Fine

With that in mind, let’s go a step further to see how simplex basket strainer works.

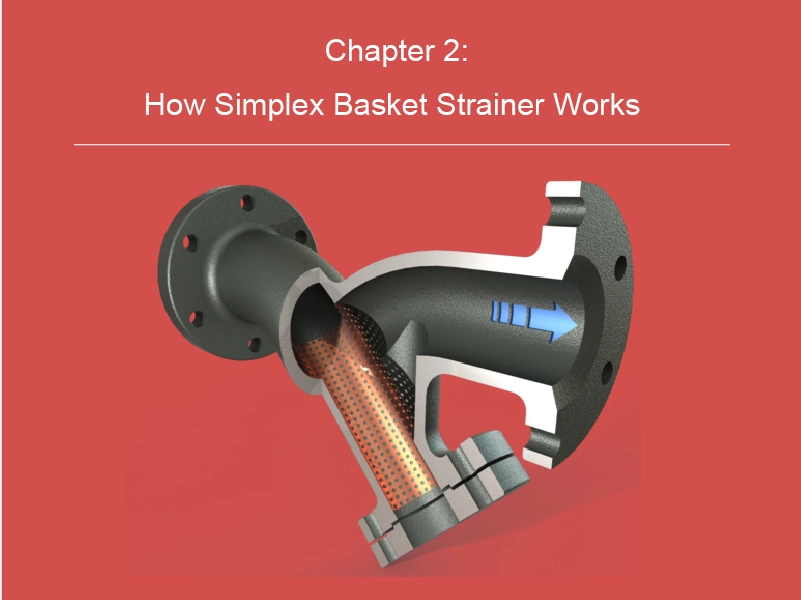

Chapter 2: How Simplex Basket Strainer Works

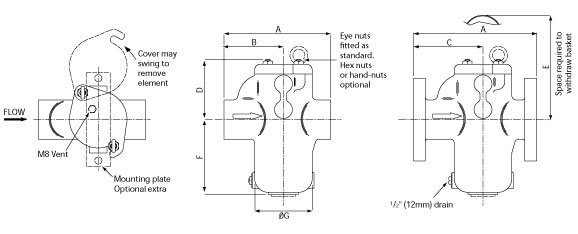

As you can see in the above image, clearly, simplex basket strainers rely on a peripheral inflow method. This enables particle retention on the basket surface and settle at its base. Inside the simplex basket strainer, you will find a basket filter element. It screens the flowing fluid while it goes through it. Here, the contaminated liquid or gas flows through the basket strainer via the inlet (the upper opening on the side of the simplex basket strainer). Here is a simple video of how simplex basket strainer works courtesy of Valve Welco: https://youtu.be/GGk7ZnDndCw The inlet position allows the fluid to flow through the basket element that exists between the inlet and the outlet opening. So here, the fluid stream flows from the exterior of the screen to the interior. Of course, this is due to the cylindrical shape design of the basket element. Now, what happens here? The particles adhere to the surface of the screen as the fluid permeates through the basket element. Separation of the particles from the fluid is the cleaning process. Larger particles than the screen perforations stick on the surface of the simplex strainer. They either stay buoyant in the fluid outside the basket element or settle in the sump. The base of the simplex strainer is also known as a sump. Next, fluid spiral downwards in the basket element of the simplex strainer. The filtered fluid exits through the open outlet specifically designed at a considerably lower level than the inlet. This ensures that the fluid stream goes through screening before exiting the basket strainer. Over time, the filter element becomes dirty and you begin experiencing restricted fluid flow. At the same time, the differential pressure between the inlet and outlet spikes. You can use a differential pressure switch and tap both inlet and outlet pressures to measure the differential pressure across the simplex strainer. Again, I know you are asking yourself this question:

As you can see in the above image, clearly, simplex basket strainers rely on a peripheral inflow method. This enables particle retention on the basket surface and settle at its base. Inside the simplex basket strainer, you will find a basket filter element. It screens the flowing fluid while it goes through it. Here, the contaminated liquid or gas flows through the basket strainer via the inlet (the upper opening on the side of the simplex basket strainer). Here is a simple video of how simplex basket strainer works courtesy of Valve Welco: https://youtu.be/GGk7ZnDndCw The inlet position allows the fluid to flow through the basket element that exists between the inlet and the outlet opening. So here, the fluid stream flows from the exterior of the screen to the interior. Of course, this is due to the cylindrical shape design of the basket element. Now, what happens here? The particles adhere to the surface of the screen as the fluid permeates through the basket element. Separation of the particles from the fluid is the cleaning process. Larger particles than the screen perforations stick on the surface of the simplex strainer. They either stay buoyant in the fluid outside the basket element or settle in the sump. The base of the simplex strainer is also known as a sump. Next, fluid spiral downwards in the basket element of the simplex strainer. The filtered fluid exits through the open outlet specifically designed at a considerably lower level than the inlet. This ensures that the fluid stream goes through screening before exiting the basket strainer. Over time, the filter element becomes dirty and you begin experiencing restricted fluid flow. At the same time, the differential pressure between the inlet and outlet spikes. You can use a differential pressure switch and tap both inlet and outlet pressures to measure the differential pressure across the simplex strainer. Again, I know you are asking yourself this question:

· How does Simplex Basket Strainer Improve a Pressure Circuit Process?

It does not matter what a pressure system runs through chemical products, oil, paint or seawater; there is always solid particles present that pose great risk in the system. This is because of unceasing problem of foreign materials in the pipeline. During the system operation, dirt, clumps of the product and other impurities can clog the pipes or damage condensers. Even fragile components such as pumps, spray nozzle and other fragile components may get damaged. Simplex basket strainer removes foreign solid particles from the fluid stream. And, by the way basket strainers are not expensive as compared to the system components they safeguard or downtime. Now, I hope you know how simplex basket strainers work. Why don’t we look at the technical date of simplex basket strainer? You need this information when shopping for the next filtration equipment.

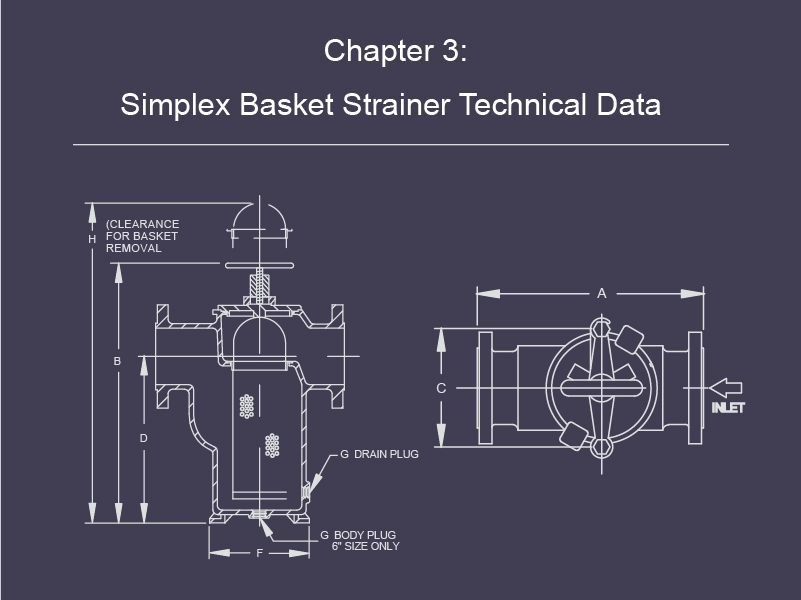

Chapter 3: Simplex Basket Strainer Technical Data

In this chapter, I want to take you through very important points:

In this chapter, I want to take you through very important points:

- Technical features of simplex basket strainer

- Simplex basket strainer terminologies.

But, why do I consider these important? It helps in designing and buying basket strainers. This is even critical in case you wish to customize one for your unique applications. But first, let’s begin by explaining a few common terms in the industry:

· Mesh Microns, Sizes and Capacity

You’ll use these to differentiate different basket strainers in the market. So, let’s dive right in to see what they mean:

i. Mesh Size of Simplex Basket Strainer

Mesh size or screen opening is the number of openings per inch of the screen. And, we refer to the number of openings as mesh size. Therefore, a 6-mesh screen means that there are six little squares in a unit linear inch of the screen. On the other hand, an 80-mesh screen has 80 openings, and so on. As the mesh size increases, the target particle size decreases and vice versa. Please note: Never use mesh size as an accurate standard measure for the size of the particle. You will more often, see a plus (+) and minus (-) signs besides the mesh size number. For example, -100-mesh and +100-mesh. Now, what do these signs mean when stating mesh size? In the -100-mesh it means that all particles smaller than 100-mesh size would go through the screen. On the other hand, +100 mesh implies that all particles of 100 mesh sizes and larger get sieved by the screen surface.

Simplex basket strainer

Simplex basket strainer

Also, for normal operations, the mesh sizes are made with larger dimensions though screen openings vary with application. Besides, different equipment come with particular screen opening specifications.

ii. What is a micron?

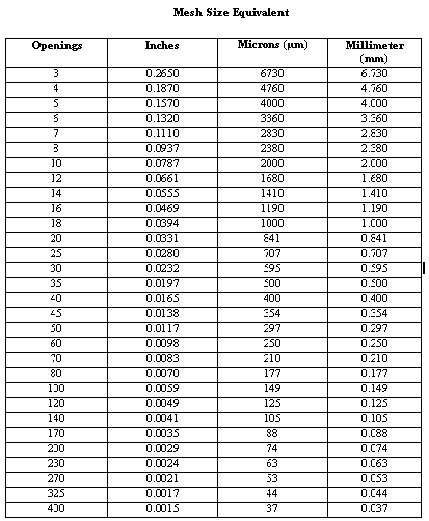

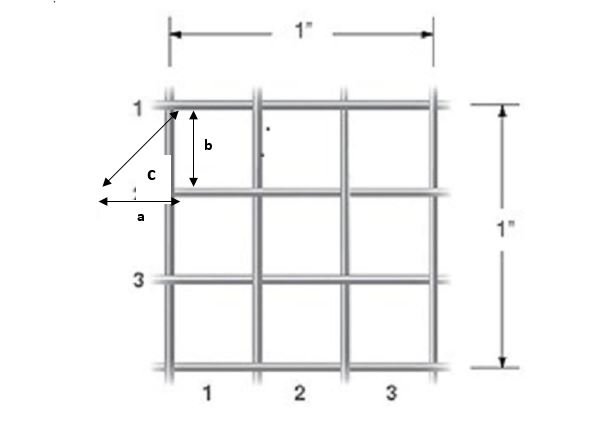

It is a unit of measuring length and is equal to one millionth of a metre. The table below provides mesh size data for typical basket strainer screens as well as their equal dimensions in inches, microns and millimeter:

iii. What is the capacity of basket strainer?

The capacity ratio or rather, open area ratio (OAR)of any basket strainers has influence on the strainer’s operating characteristics. Take for example, the life service of the screening element before cleaning. The open area ratio is the relationship between the open flow area of the cleanable screen; and the internal cross-sectional area of the strainer pipe that forms the straining element. For instance, with a clean basket filter element at 1-to-1 ratio, or 100% OAR; it means you will have an unrestricted flow area same as that in the pipe. However, as the basket filter element clogs the flow becomes inhibited. This means with a 2-to-1 ratio, you would experience a full flow after the strainer gets 50% clogged. So, what’s the bottom line? Large OAR is useful for systems that need straining of much debris from the fluid properties such as viscous liquids.

Simples basket strainer

In chapter 1, we only mentioned types of basket strainer perforations. Here, we are going to expound on these types of strainer screens. But first, you will learn about strainer screens.

· Strainer Screens

What is the screening area? It is the actual area where the unwanted particles get trapped and flushed away. Now, what do you understand by the term free area? The free area is measured as a ratio of the sum of the holes to the total available screening area.

Different types of replacement screens

In case you don’t know – The screening area directly affects simplex basket strainer flow capacity. That is, a coarser screen has a greater free area. Implies that, the basket strainer shall have a much greater flow capacity. Ultimately, it lowers the pressure drop across the screen. Most basket strainer designs have large free and straining area. In fact, those made for gas or steam system easily achieves low pressure drop across the basket strainer element. Let’s dig deep into various types of basket screens found in simplex basket strainers. There are two types of screens in simplex basket strainers:

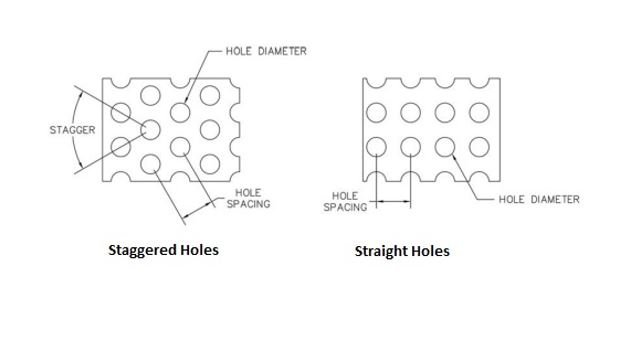

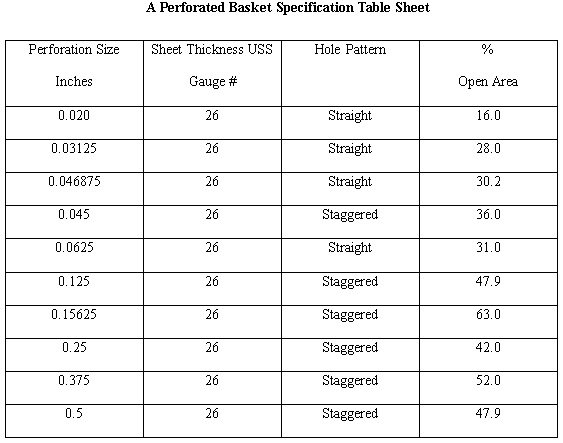

- Perforated Screens

How are the perforations made? You’ll punch an array of holes on a flat material. Use multiple punches to make these holes in a specific pattern. Then roll up the perforated sheet to form a tube, which you can hold together by spot welds. Typically, the hole sizes and coarse screens range from 0.8-3.2 mm. Normally, perforated screens are a perfect choice when you want to remove debris in the pipeline system. Below is a diagram and specification sheet for perforated screen:

Holes Arrangement Diagram

- Mesh Screens

This type of screen combines both the perforated screen and grid or mesh layer formed by fine wire in a specific arrangement. The fine wire arrangement lays over the perforated screen. Therefore, it acts like a mesh support cage. But, why use this arrangement? It will help you to make medium or even smaller hole sizes. It can produce fine screens of 0.07 mm smaller than perforated screens.

Y basket strainer

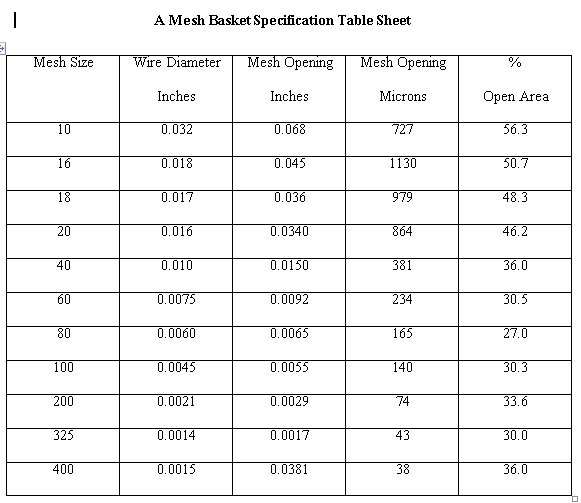

Mesh screens are a perfect choice when you want to eliminate smaller particles. Of course, I am talking about particles that can go through the perforated screen. Most markets specify mesh screens using the total openings in a linear inch of the screen. This is basically measured from the centre line of the wire. Nonetheless, the manufacturer should supply you with this information. In addition, the largest particle size that can go through the mesh screen can be established using geometry. You’ll see that shortly in the image below: For instance, you may have a 200 mesh screen with a 0.076 mm manufacturer’s specification. You can use Pythagoras Theorem to know the largest particle that would pass through the mesh. In this case 0.076 mm represents the dimensions of the mesh:

Mesh Diagram

Where a = 0.076 mm b = 0.076 mm c =? The above mathematical elaboration proves – much smaller hole sizes are easily achieved using a mesh screen than perforated one. This means that much finer filtration is possible with mesh screens as compared to perforated screens. The table below is a mesh basket specification sheet:

· Simplex Basket Strainer Materials

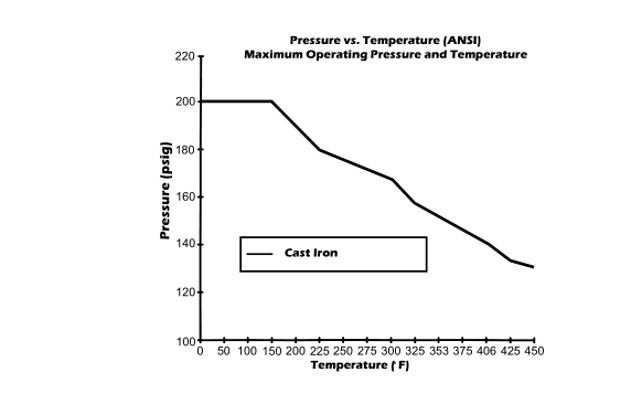

Simplex basket strainer screens are available in a variety of materials. However, the basket material should be made of the same material as the valve trim. Stainless steel is a popular material for this. The strainer’s wall thickness must be exceptionally heavy to withstand immense circuit pressure while under operation. Also, austenitic stainless steel is a popular material for most screens, more so in steam applications. This is because a stainless steel set of simplex basket strainer has a greater resistance to contamination and corrosion. Besides, it’s easy and simple to clean. You can also opt for other materials such as bronze, carbon steel, chrome-moly steel or plastic. All these will depend on the specific applications. Let’s have a quick overview of some of these materials: Bronze—It is suitable for brackish, sea water and saline service. Bronze is normally used in potable water application systems. This basket screen material is twice the cost of cast iron. Cast iron—It is a common and popular strainer housing material due to its affordable initial cost. Cast iron is preferred for systems that do not have high pressure and temperature. This is because, it cannot withstand mechanical shock nor high thermal.

Cast Iron Graph showing Maximum Operating Pressure & Temperature

Carbon steel—Unlike cast iron, this material best suits fluid systems with high pressure and temperature conditions. It is highly resistant to mechanical and thermal shocks encounters. Chrome-Moly steel—This is also another material that can comfortably work under high temperatures and pressure. However, the base of the basket must be precisely machined to get a tight seal. It will prevent by-passing of the system fluid stream. What follows is a basket strainer body/ housing, according to the American Society for Testing and Materials specifications: Body/Housing Description ASTM Specification Iron Castings A126. A278 Ductile Iron Castings A395, A536 Iron-Austenitic Castings A436 Carbon Steel Castings A216, A27 Carbon Steel Pipe A53, A106 Carbon Steel Plate A20, A285, A515, A516 Carbon Steel Forgings A105 Carbon Moly Castings A217, A352 Chrome Moly Forgings A182 Stainless Steel Castings A743, A744, A351

Chrome Moly Plate A387

Chrome Moly Pipe A335 Stainless Steel Pipe A312 Stainless Steel Plate A240 Stainless Steel Forgings A182 Aluminium Castings B26 Bronze Castings B61, B127 Monel B164, B162 Nickel 200 Plate B160, B162 Hastelloy B Castings A494 Hastelloy B Plate B333 Hastelloy C Plate B575 Hastelloy C Pipe B619 Titanium Pipe B337 Titanium Castings B367 Suitable baskets for permanent strainers should be removable. With this, it is easier to disassemble and flush clean during maintenance and operations.

· Pressure Loss

The fact that simplex basket strainers are made of varying configuration and dimensions, they tend to have different pressure drop results. With reputable manufacturers, you can easily find their tested, certified and published pressure drop results.

Different types of simplex basket strainers

When the basket filter element is clogged, the pressure drop across the strainer increases and vice versa. The increase depends on the clogging pattern formed as well as the type of screen strainer. As the basket strainer operates, it clogs with time to a point where the open area ratio (OAR) approaches the cross-sectional area of the pipe. This leads to unpredictable and rapid increase in pressure drop across the basket strainer element. Now, what should you do at this point? It is wise to carry out basket screen cleaning or replacement, or else an enormous differential pressure will build up. You will learn more about basket element replacement in chapter 6 – just keep reading. Remember, your manufacturer will indicate the maximum pressure your screening media can withstand before it collapses. This pressure is also known as burst pressure. Hence, you must be cautious not to allow the pressure drop across the cleanable screen to approach its specified burst pressure. The table below shows pressure drop correction factor for different size basket screens courtesy of Hayward Flow Control:

· Simplex Basket Strainer Design

Just like filter elements, simplex basket strainers also have selection criteria. Suitable designs help to increase the cleaning intervals – it basically reduced possible system downtime. Suitable designs help to increase the cleaning intervals – it basically reduced possible system downtime. Moreover, such designs ensure minimal pressure losses throughout the pressure circuit. As a result, it reduces the power consumption of the system.

· Basket Strainer end connection

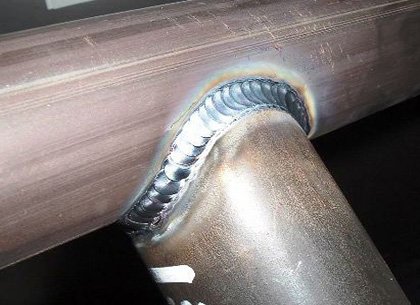

I know you could be thinking out loud – how can you connect the simplex basket strainer to other systems? Typical end connections can be threaded, flanged or welded. Of course, the main priority here is to keep both the inlet and outlet in the correct place and stay stronger. Let’s have a quick overview of these connections: Threaded connections—In most strainers is usually a tapered-female pipe thread, however sometimes male connections are used.

Example of a threaded connection: Photo Credits – SOETE LABORATORY

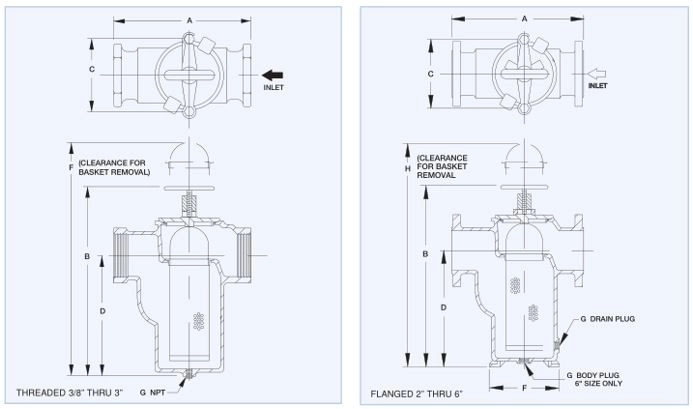

Flanged connections—Simple basket strainers come in different flange rating classes such as 25, 125, 150, 250, 300, 400, 600, 900, 1500 and 2500.

Example of flanged connection

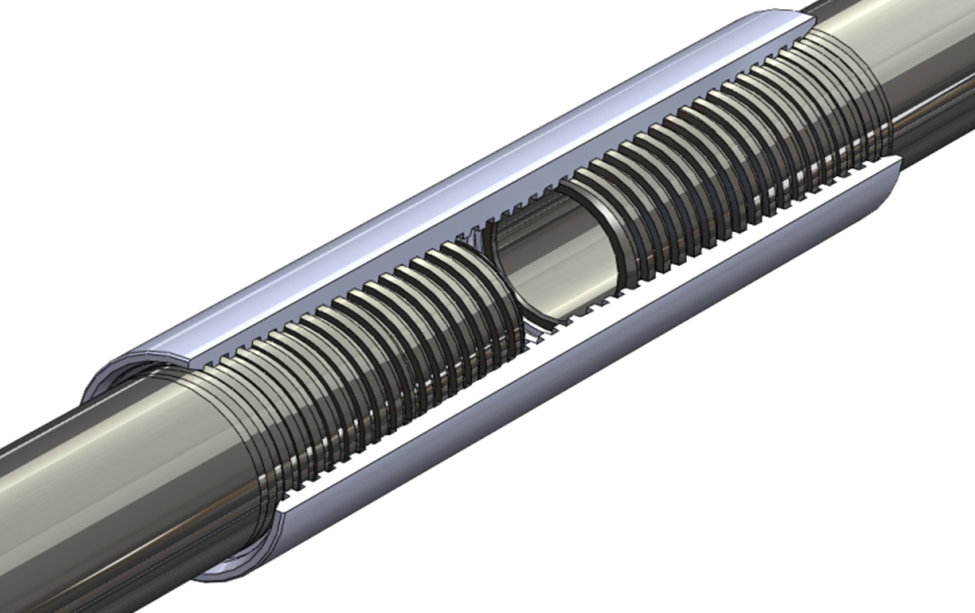

Weld ends connections—Basket strainers with ‘butt weld end’ are as well as available in various dimensions. Here, it’s important that you specify the pipe bore size to the manufacturer to give an equal bore for the basket strainer.

Welded connection

Special ends connection—Supplying details for grooved ends take precedent to secure a matching strainer unit altogether.

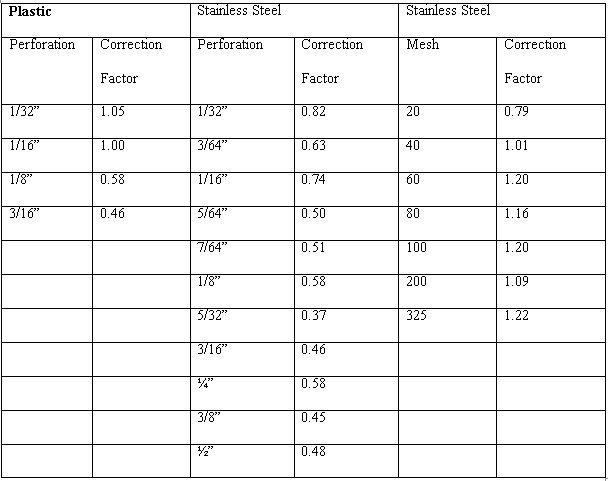

An example of a technical drawing of a Simplex Basket Strainer Courtesy of Hayward

But, this is not everything you need to know here. Let’s look into various flow style designs:

· Flow Styles Designs

There are several flow style designs of simplex basket strainers that fit varying applications:

- Full Outlet Style “FO”

Chambers of the simplex basket strainer designs have a large opening that allows free fluid flow. At the same time, they reduce both pressure loss and time interval during cleaning. Its basket chamber outlet opening should be at least four times the inlet opening. This creates the favorable pressure conditions across the strainer that enhance debris loading for the efficient cleaning process. This specific flow design is suitable for applications where there are large debris in the fluid systems.

- T-Style

T-style basket strainer offers an alternative low-cost cleaning service for pressure systems with relatively light and small debris load with infrequent cleaning intervals. In this design style, the basket chamber outlet is of the same size as the inlet pipe size.

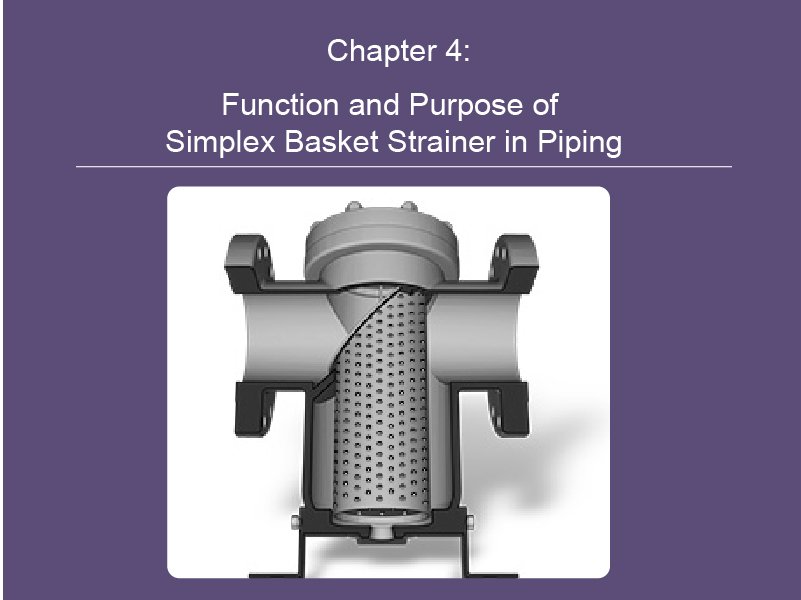

Chapter 4: Function and Purpose of Simplex Basket Strainer in Piping

Normally, most pressure systems have their basket strainers precede pumps to prevent the abrasive wear on the impellers. In most cases, this wear is due to the large particles in the fluid flow. The purpose of preceding basket strainers to pumps is to give protection by:

Normally, most pressure systems have their basket strainers precede pumps to prevent the abrasive wear on the impellers. In most cases, this wear is due to the large particles in the fluid flow. The purpose of preceding basket strainers to pumps is to give protection by:

- Trapping

- Removing larger particles

- Discarding waste, amongst others

From the harmful fluid stream contamination – ensuring proper functioning of the pipeline. However, you should not be overly concerned about the largest sphere dimension allowed for pumps. Why? Because most pump manufacturers offer all the necessary literature to help determine the size using the pump model number. Since simplex basket strainer is a “closed vessel”, it makes it possible to sieve out solid particles from the fluid stream while going through the screen. Also, depending on the screen specification, you can separate a range of fluid particles to enhance performance of the particular pressure system. In essence, with much finer screen, you can retain more than unwanted debris. In fact, some instances totally block the fluid flow. Therefore, you are advised to analyze your pipeline carefully before settling on the type of basket strainer screen. Otherwise, you will unknowingly end up removing even wanted materials which are useful in the later processes. Therefore, simplex basket strainers help promote long service life of the expensive pipeline equipment like: i. Engines ii. Heat exchangers iii. Pumps iv. Valves and many other vital components of the system. When dealing with liquids, using the corrosive resistant materials such as aluminium and copper will equally reduce contamination. This is because some contaminants come from pipe surfaces.

Photo Credits: Oxford Filtration

Also, a simplex basket strainer in a pipeline can be either manually or automatically controlled depending of the design of the basket strainer. Constant use of simplex basket strainer, eventually clogs the screen with the unwanted solid particles that get trapped while fluid continue running. In order to keep the pipeline running, the retained debris in the basket strainer must be flushed clean after a considerable period of usage. I hope we are reading from the same script… With these, allow me to take you a step further and discuss:

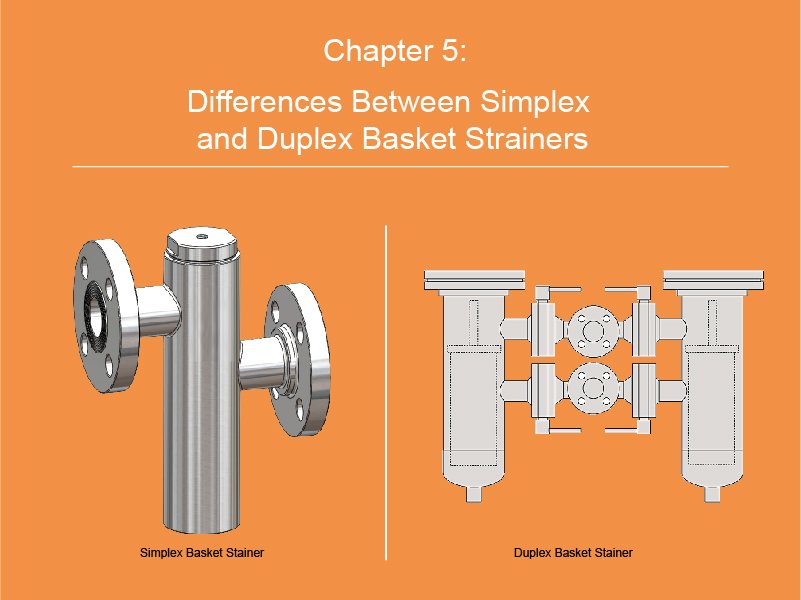

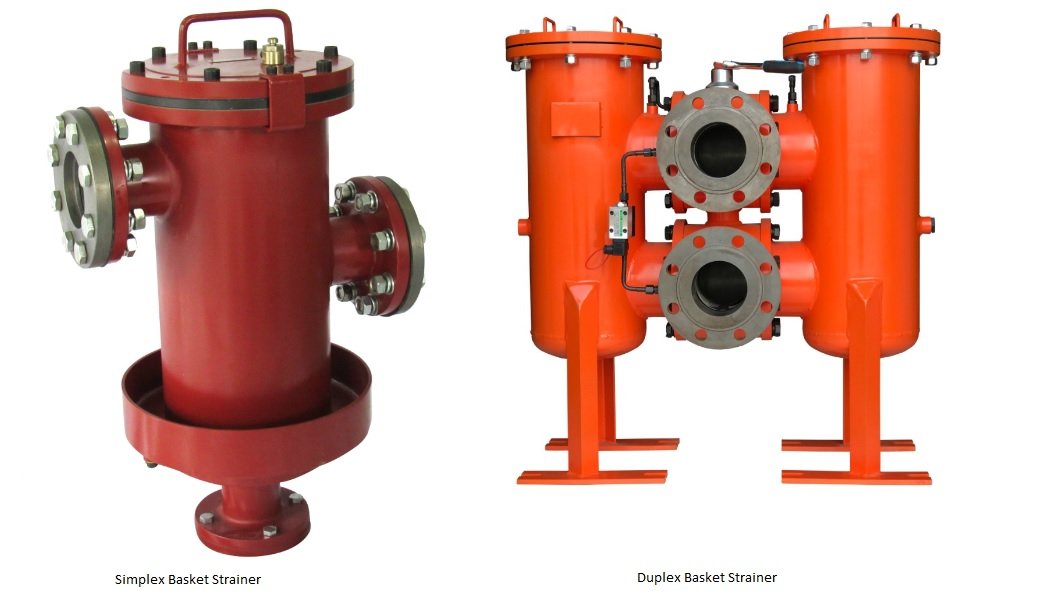

Chapter 5: Differences Between Simplex and Duplex Basket Strainers

In the previous chapters I only mentioned simplex and duplex basket strainers. Here, I will take you a step further to discuss the differences between simplex and duplex basket strainers. The truth is: Basket strainers are integral components in a range of filter applications for fluid systems. Simply put: These are closed pressure vessel with cleanable screen media. They trap solid particles in fluids to prevent possible contaminations. The best part – by installing appropriate basket strainers, you’ll ultimately protect pumps, valves and other fragile machine parts downstream.

In the previous chapters I only mentioned simplex and duplex basket strainers. Here, I will take you a step further to discuss the differences between simplex and duplex basket strainers. The truth is: Basket strainers are integral components in a range of filter applications for fluid systems. Simply put: These are closed pressure vessel with cleanable screen media. They trap solid particles in fluids to prevent possible contaminations. The best part – by installing appropriate basket strainers, you’ll ultimately protect pumps, valves and other fragile machine parts downstream.

Simplex basket strainer vs. Duplex basket strainer

By design, we install basket strainers horizontally. With this design, it is easier to access basket screen for cleaning. Anyway, let’s come back to the main subject of this section – comparing simplex basket strainer and duplex basket strainer.

· Simplex Basket Strainer

It is suitable for processes or fluid systems that can be interrupted. That is, you will shut down the entire system to flush out and clean the simplex basket strainer. The good thing: It is easier to access the basket chamber top cover. Therefore, you don’t have to shut down the system for a long time. Always begin the replacement of cleaning process as soon as the flow stops. At this point you can disassemble the basket strainer into its parts.

Simplex basket strainer

Use vent valve to create a conducive environment for cleaning simplex basket strainer. Once the basket strainer element is clean, you can reassemble it, then resume normal operations. As a rule of thumb, I’d recommend you have an extra basket. Replace this as you take time to clean the clogged basket filter element.

· Duplex Basket Strainer

Unlike the simplex duplex strainer, duplex basket strainers are suitable for systems that MUST NOT be interrupted. That is, the fluid must flow continuously irrespective of whether you’re doing system maintenance or not. Look at this duplex basket strainer:

Duplex basket strainer

Basically, a duplex basket strainer is a combination of two simplex basket strainers, which are connected together with a three-way flow regulator. Unlike simplex basket strainer, duplex basket strainer uses a valve to redirect the fluid flow away from the debris lodged basket chamber to give time for cleaning. Additional, the valve ensures safety as it determines pressurized chambers and empty ones that require maintenance. So, what’s the bottom line? Duplex basket strainers configuration is suitable for continuous duty operations which do not tolerate fluid flow interruption to the basket cleaning. However, you must adhere to a couple of safety rules while preparing to clean duplex basket strainers.

· Valve Designs in Simplex Basket Strainers and Duplex Basket Strainers

While simplex basket strainers designs come with vent valves, duplex basket strainers designs are set up with cast and custom fabricated designs. Duplex strainer only requires a lever to divert fluid flow as its valves is a three-way device. Duplex basket strainer cast designs function in a way that when one side of the valve closes, another side opens to keep up a continuous flow. Alternatively, custom fabricated designs run with four-butterfly valves that can be conveniently linked with a single lever. Nonetheless, you may open or close them independently. Here, the order of valve manipulation really matters. First, begin by opening the inlet valve of the clean basket strainer chamber and then, open the outlet valve of the same chamber. Now, pay attention to the other dirty lodged basket chamber to close the outlet valve, followed by closure of its inlet valve. At the end you will have completely isolated the dirty basket chamber from the flow. It becomes an easy process to get access to and flush clean. This way, there will be no interference with the system flow.

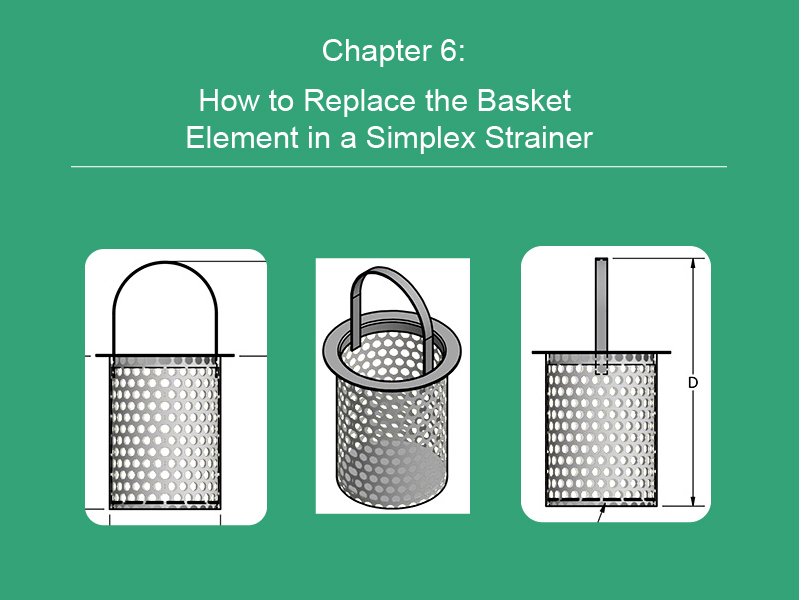

Chapter 6: How to Replace the Basket Element in a Simplex Strainer

In this chapter, you are going to learn how to replace and maintain basket strainer element of simplex basket strainers. Please, read these instructions to the end to replace basket element safely and faster. Also, you should note that these are general instructions for basket element replacement procedure. Therefore, if you are not well-versed in handling a breakdown, recommend some skilled personnel carry out the exercise. https://youtu.be/5KnNVfv_fcw Let me take you through a step-by-step process on how to go about this:

In this chapter, you are going to learn how to replace and maintain basket strainer element of simplex basket strainers. Please, read these instructions to the end to replace basket element safely and faster. Also, you should note that these are general instructions for basket element replacement procedure. Therefore, if you are not well-versed in handling a breakdown, recommend some skilled personnel carry out the exercise. https://youtu.be/5KnNVfv_fcw Let me take you through a step-by-step process on how to go about this:

Step 1: Handling, Unpacking and Inspection of the Product

First, you need to know what to replace. This way, you will choose a basket element that meets your unique specifications and requirements. Second, check the manufacturer’s manual to know the basket element handling procedure. Once you do this, inspect the basket filter element. You should check for scratches, dents or missing parts or features. Remember, with this, you can easily file a claim and return the basket element before using it. Again, you should remember to keep the basket strainer element safely. It should be a clean and dry environment. Just keep it indoors, where no one can interfere with it.

Step 2: Pre-Replacement Checklist

Before the actual basket element replacement, there are a number of genuine concerns that you must address. First, use a solvent-dampened cloth to wipe out any preservatives. Then, remove the protective packing covers, and any loose material on the basket filter element. Check whether the basket strainer element needs replacement or not. You can use pressure gauges on the inlet and outlet of the basket strainer – it is convenient, reliable and safer means. There is nothing complicated here: Simply check for pressure drop across the strainer – that’s enough to tell you whether you need to replace the strainer element or not.

Simplex basket strainer

Now, shut down the system and ensure there is enough support on the pipeline. This will ensure you don’t strain it when doing the replacement. Don’t forget this – you must ensure safety at all times.

Step 3: Replacement Procedure

First cut out the inlet and outlet valves of the simplex basket strainer. Before taking off the basket strainer cover, you must bring down the system pressure to atmospheric pressure. Simply release the pressure at the suction or vent valve. It is an important safety measure – you’ll avoid inflicting bodily injury in the process. Once you equalize the pressure, remove the strainer cover, and make sure you drain off the fluid up to the basket screen seat. Now, you still have another chance to counter check the screening media in operation if it is the exact model of the spare part. You can also use the material safety data Sheet to review other specific technical data. At this point, you can remove the dirt-lodged basket strainer element and clean the basket chamber. Since a replacement spare is available, you can keep the old basket strainer element aside. Replace it with the new clean basket strainer element at its spot. Ensure it squarely seats in the original position. In addition, replace the cover gasket and properly tighten the cover. You are strongly advised to use high pressure steam or water to clean the basket screen. This is to prevent any possibility of banging or hitting it against the pipe or wall. The pressure will help you even remove any sludge or debris lodged in the mesh holes.

· Maintenance

Once the basket element is appropriately replaced, simplex basket strainers need a routine monitoring schedule. You should periodically check the pressure differential across the basket strainer. With this, you will know whether the screen needs cleaning or replacement. I will not lie to you here – this is the truth: Your negligence will let the screen get clogged eventually break down while in operation.

Chapter 7: Simplex Basket Strainer Applications

Here, I am going to take you through a number of simplex basket strainer applications. Below are the common areas where you can use a simplex basket strainer: Figure 23 Photo Credits: Simplex Turbulo

Here, I am going to take you through a number of simplex basket strainer applications. Below are the common areas where you can use a simplex basket strainer: Figure 23 Photo Credits: Simplex Turbulo

· Water Treatment and Supply Systems

Water collection and treatment points take a lot of gravel, sand, etc. Furthermore, given that the treatment environment is open, water may have with insects, leaves other foreign elements. Such debris pose great danger to the system equipment and instrumentation. Simplex basket strainers are important parts of water treatment and supply system. They trap and retain all unwanted material from water. Also, industries use simplex basket strainers to remove materials that can accumulate in the sewer line and cause blockage.

· Marine Industry

Simplex basket strainers play an integral role in the marine industry. You can use them in handling sea water for a range of applications such as in fire control-lines, general cleaning-lines, sanitary lines and cooling lines. Ferries and ships draw ocean, sea or river water to run a number of its systems, and this water has undesirable particle matter. Simplex basket strainers make this water suitable for various uses in the marine industry.

· Food Industry

Simplex basket strainers remove seeds, fiber and other traces of fruit screen during beverage processing in industries. Also, basket strainers are used to take out the wax and lumps from honey and chocolate syrup respectively. Baking industries use basket strainers to strain gristle and bone from molten lard.

· Cosmetic and Pharmaceutical

Lotions, ointments and other similar products usually contain clumps of undissolved or un-dispersed matter. You can easily separate them by passing it through basket strainers. This helps improve product quality.

· Fuel Power Generation

Fuel power generation uses enormous amount of water. To give system equipment protection from unwanted debris in water, simplex basket strainers are installed in the cooling systems. Since it consumes gallons of fuel and transformer oil, basket strainers prevent system clogging, which is potentially dangerous.

· Chemical Processing

This industry has innumerable uses for basket strainers. For a fact, presence of simplex basket strainers means equipment protection, ease solid isolation from fluids, and of course cleaner products.

· Petroleum industry

Processing of petroleum products need basket strainers to remove unwanted matter from gasoline and crude oil. Similarly, fuel oil can carry gums, tars or other foreign dirt that can clog the engine fuel nozzle. Hence, all fuel and oil burners are installed with basket strainers to take out such compounds.

·Paper & Pulp Industry

Presence of lumps in coatings has been an ever-present problem in the paper industry. To make smooth paper finishes, you should use basket strainers in coating lines. It traps and removes the lumps from the pulp.

Conclusion

I hope you have learnt all the fundamental aspects you need to know about simplex basket strainers. Certainly, with this information; you can confidently choose one for your unique application requirements. Also, don’t forget to share this article with your technicians and colleagues. At FilSon Filters, we are always ready to offer free consultation on simplex basket strainers. Just feel free to leave a quick comment below and we will assist you.