Filter Carts: Your Premier Oil Filter System Manufacturer

FilSon filter carts are generally used for filtering, dewatering, degassing and conditioning operating fluids.

We offer various types of portable filtration systems, including vacuum dehydrators, hydraulic filter carts, coalescing filter separators, transformer oil purifiers, handheld filter units and custom oil purification systems.

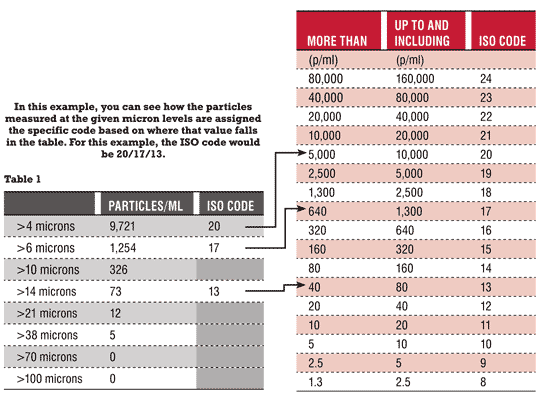

Filson portable filter carts are ideal for use in industrial plants, wind turbines, to help control particulate and water contamination as per ISO 4406.

If you are looking for oil filter carts to purify your oil, Filson filter carts will be your perfect choice. We manufacture all kinds of filter carts to support the global market requirement. Request a quick quote now!

Filson Oil Filtration System

Related Resource about Hydraulic Filter Carts

Your No.1 Hydraulic Filter Cart Manufacturer

Filson hydraulic filter cart also named oil filter cart or oil filtration systems. It was divided into three main part: duplex Basket strainer or simplex strainer, oil filter element, the portable structure, and other parts.

Filson oil filter carts are designed to purify your oil include hydraulic oil, lubricating oil, water based coolants, Synthetic hydraulic fluid, cutting oil, transformer oil, gearbox oil, engine oil and more.

If you google the “Oil filter carts”, you really will not find too many filter carts designs there, you may find the Parker hydraulic filter carts, Donaldson filter carts, or some other brands filter carts, but you will see, most of them have lots of filter cart designs and of course, their filter cart price will be super high.

That’s why Filson filter carts come to the market.

Fison portable hydraulic filter carts are the ideal way to prefilter and transfer fluids into reservoirs or to clean up existing systems.

Filson filter cart is not a standard system, we can custom the filter cart based on your dirt holding capacities. We can put as many filters on the system and Filson also has a wide range of filter elements for you to choose.

Every Filson portable filter cart structure is made with heavy duty frame to avoid damage when working. And all filter carts are with portable designs, so they’re easy to move from place to place.

The most important part for filter cart is the filters and filter element. Because you are buying the filter cart for our oil filtration. Filson filter element is long time to use and this will save you a lot cost of filter element replacement.

When your oil is one low viscosity or high viscosity, Filson oil filter carts can always satisfy your requirements.

Filson filter cart use carbon steel or stainless steel to custom the electrical cabinet, so they are smooth fit our system design.

Request a quick quote and tell us your detailed application by the right contact form.

More Filson Oil Filter Carts

Portable Filter Cart: The Complete Guide

Today, I want to show you how to protect your oil system using a portable filter cart.

First, I will show you how to achieve an ISO 4406 oil cleanliness standards.

Then, I will walk you through the key features, design, working principle, main components, to technical specifications of portable filter carts.

By the end of this guide, you will be able to buy a suitable portable filter cart for your oil system.

Let’s do this:

Chapter 1: What is a Portable Oil Filter Cart

A portable oil filter cart is simply an offline filtration system.

Modern oil filter systems have gradually seen a shift, that is, from reactionary to preventative further relying on predictive maintenance.

In order to attain a comprehensive System Contamination Management (SCM), it must begin at the Fluid Conditioning Products (FCP).

Therefore, a portable oil filter systems remove oil contaminants and water from different variety of oils.

This off-line oil filter system may come with both the mobile filtration unit cart with or without contamination monitoring device, stationary filtration unit (customizable design available).

One important part of the portable oil filter cart is the de-watering function, both coalesce-separation system and vacuum dehydration.

These can also remove both dissolved and free water from fluids.

Chemical elements made from polymers are used for water removal, which characteristically have a very high affinity for water being installed at the outlet filter.

Once the water makes contact with this material, it gets absorbed and accumulated, thus we can drain it from the medium flow.

In addition, the integral units mentioned above can still function better at any flow rates and reservoir size.

Therefore, a portable oil filter cart provides the way to pre-filter and fluid transfer into reservoirs or rather to clean up the existing system fluids.

It is also advisable to filter fluids before being injected into the system.

Note that new fluid is not necessarily contaminant free as most new fluids are actually unfit for immediate use due to the high contamination levels of the storage drums.

For a fact, contamination, both water and particulate, may ingress the new fluids during handling, mixing, processing and storage.

In such an instance, you will need oil filter carts to help replenish and transfer new fluids, as well as flush used fluids with high-efficiency.

What component makes portable filter oil filter cart function as a reliable filtration tool?

In portable oil filter carts, high-capacity filters are preferable to offer long service life together with system protection.

At the inlet, the filter traps large particle impurities and at the outlet, the filter removes water or captures finer fluid particulates.

But I know you could be asking yourself these questions:

· How can a portable oil filter handle enormous oil volumes?

Considering the quantity of fluids to be pre-filtered implies that these portable oil filters are also designed with rugged-industrial gear-pump to fasten the filtration process.

· Why use rely on portable oil filter cart?

It is important to use a portable oil filter for pre-filter and hydraulic fluid cleaning earlier before being put into use.

This is because it provides an economical way to protect your oil system from abrasive wear caused by fluid particulates.

There is an array of various mobile oil filtration units that can meet your industrial filtration requirements.

In particular, portable oil filter carts are ideal for industrial plants and many other applications since they are portable, reliable and versatile.

One great advantage about portable oil filter cart is that it can filter almost all types of hydraulic fluids, coolants, insulating oils and high-viscosity lubricating oils.

Chapter 2: Why you Need Portable Oil Filter Cart

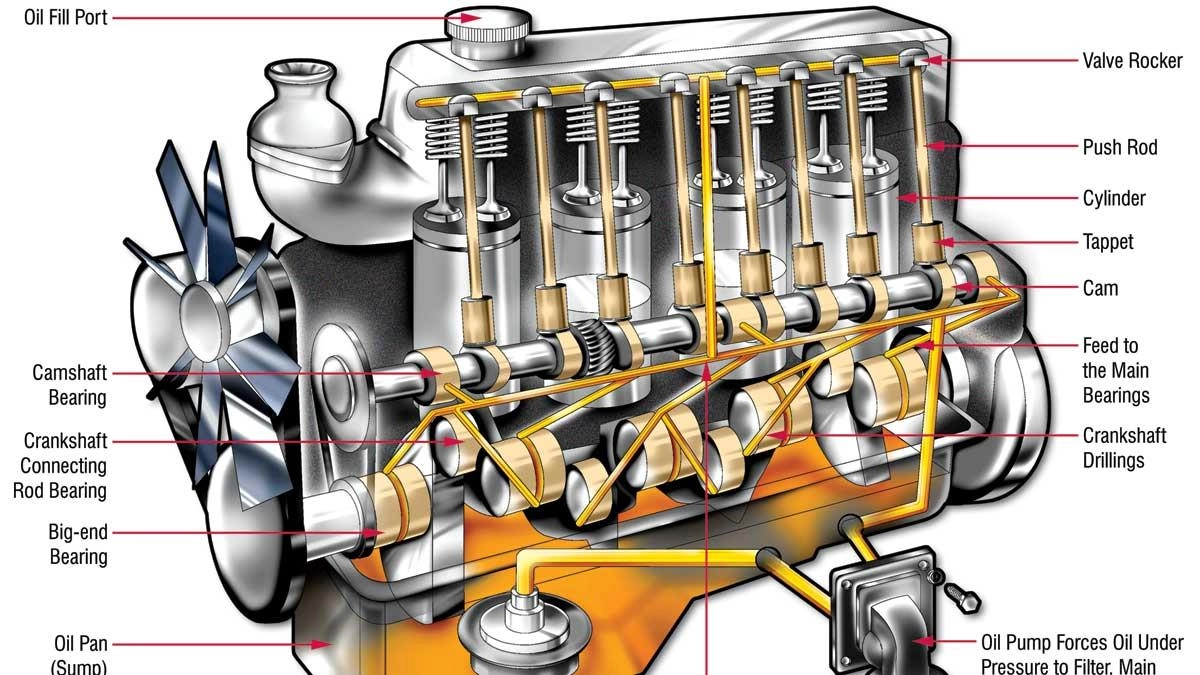

Unless you understand that oil forms the lifeblood of engines, machineries and oil systems, you will not appreciate the usefulness of a portable oil filter cart.

Oil flowing in engines – Photo courtesy: Machinery and Lubrication

Quality for systems begins at pre-filtering of new drum and reservoir oils before circulating into to other critical components and parts.

Thus, portable oil filter cart ultimately helps to promote a reliable machine performance at the same time pre-determines damage on the engines.

Because, filtering oil or reservoir is a sure way of ensuring zero contamination in hydraulic system.

Plus, pre-filter of the fluids improves and enhances its quality and capacity thereby extending its lifespan.

Adoption of portable oil filter in the early stages of fluid management eventually helps curb unnecessary downtime, and ever rising operation costs.

So, it is now clear that portable oil filter cart is vitally important for any machine and oilsystems for refining fluids.

Let’s find out proven practices used along with portable oil filter carts in optimizing oil life for systems and many other industrial machineries:

- Identification of main sources and types of fluid particulates for your system

- Use of effective and reliable oil analysis programs

- Elimination and reduction ingress of contamination by portable oil filter cart pre-filter of the reservoir fluids

- Ensuring the fluid is properly pre-filtered before being introduced into the system

It is advisable to adopt and carry out a proper oil analysis program to enable you to establish the contamination levels and the threat posed to the system.

Professional site assessment, evaluation contributes to good medium storage and injection into the system, but you still need portable oil filter carts for comparison.

This will narrow your search down to the main sources of oil contamination.

And further help you to develop a well-thought out procedure to curb or cut such elements considerably to acceptable levels.

In other words, portable oil filter carts can help manage risk of fluid contamination due to exposure to undesirable elements at the storage facilities.

As long as you pay attention to details on how to overhaul, improve or dispense fluids by using a portable oil filter, you will enjoy smooth operations.

Testing the fluid through the portable oil filter cart also indicates to you the suitability of the medium for its application.

A proper filter media should give you an insight glimpse of the pre-filter results.

Therefore, it really does not matter what quality oil has since during its processing, various contaminants find a way into the product.

Furthermore, the reservoir fluid for system circulations contain oil particulates, however, by using portable oil filter carts can still extend the life of that oil.

Chapter 3: Main Components and Parts of Port Oil Filter Cart

The earlier chapters have expounded on what a portable oil filter cart is as well as comprehensively explained why you need to have one.

In this chapter, we are going to discuss main components and parts that form a single portable oil filter cart.

First, you need to keep in mind that portable oil filter carts are specially designed for specific purposes, more so, for particles orwater removal from oil medium.

Such as water always gets emulsified in hydraulic fluids, thus the conventional methods are less helpful.

The following are integral components and parts of a portable oil filter:

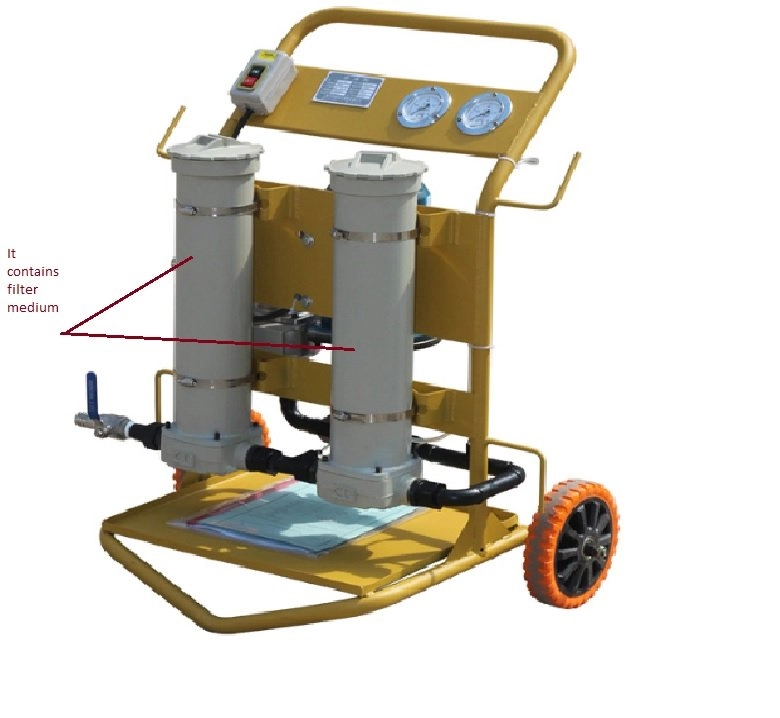

I. Filter Media and Vacuum Switch

A portable oil filter cart uses a special oil cartridge made of filtering element that can absorb water more easily.

Heavily water contaminated hydraulic fluid must be passed through the filter several times for effective removal of water.

Alternatively, a series of different types of oil filter arrangement enables the portable oil filter cart to make fine filtering and high-capacity.

The sturdy construction of the cartridge makes it restrictive.

In order to prevent abrasive wear on the motor and pump, the portable oil filter cart can be installed with a vacuum switch.

Section with filter medium

This switch enables the operator to turn the motor off when the pump draws a predetermined suction.

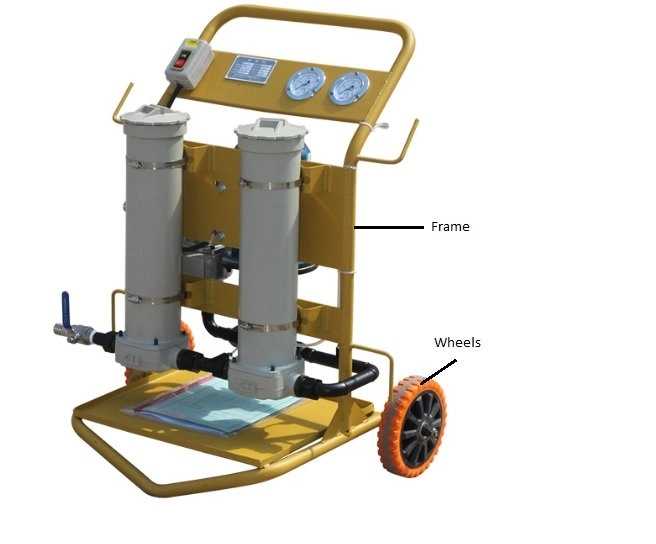

II. Sturdy Cart Framework

This cart framework makes such a filtration system, portable or rather mobile.

The cart is also fitted with rubber tires wheels for the operator to move these units around with ease.

Frame

Hence, you should rather not move equipment or machineries because you can take these filtration units at work site.

III. A rugged Industrial Pump/Motor

Filtration processes work better under high, medium flow rate.

A rugged industrial pump is also mounted on the rigid cart framework.

The type of motor installed depends on the number of filtration units and the mains supply.

For instance, different portable oil filter carts have varying input volt like 110 VAC and 220 VAC.

Also, the motorized pump comes with an on/off switch and properly electrically wired with the right power cables and grounding.

IV. Piping & Extensions

The filtration units are installed with lengthy hoses. The endings of the pipes varying NPT sizes, mostly male threaded.

If the pipes seem to be short for your application, pipe extension is possible, though the extension pipe should be of a smaller cross-sectional area to do the best suction.

A notch is usually made at the suction end to promote good flow.

V. A Control Box

The control box bears functional controls to the units for the operator of portable oil filter cart.

Once the portable oil filter set and ready to use, an operator can simply run the filtration process through accessing the control box.

Control panel

At the control box, there are indicators such as contaminant level, flow rate and other useful parameters that an operator can rely on while using a portable oil filter cart.

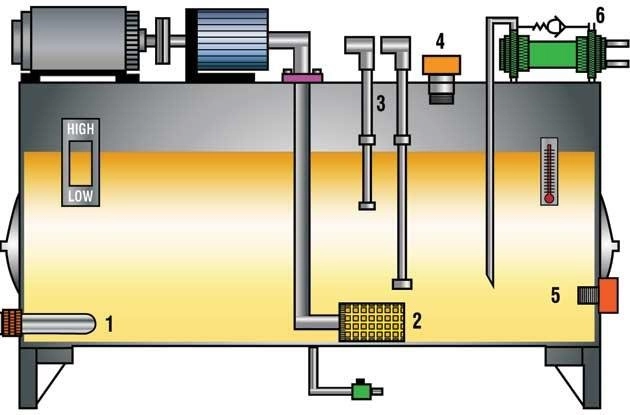

Chapter 4: Working Principle of Portable Oil Filter Cart

The working principle of portable oil filter carts is vitally crucial in maintaining equipment and hydraulic system uptime.

This is because they deliver fluids at the desirable cleanliness levels, and transfer clean oil while machineries run.

Portable Oil Filter 8

How does a portable oil filter cart really work?

The sole role of any filter is to remove contaminants.

Portable oil filter cart designs use a couple of filtration stages where both the filtering units are coupled with a gear pump.

The suction or inlet end is the first filtering stage and operates with a much lower pressure of about 5 psid.

It is specially designed to capture coarse fluid particulates that exceed 150 µm.

The drawn medium is passed through the inlet filter and directed to the second stage.

Contrary to the first stage, the second stage works at a high pressure about 25 psid.

This is the outlet side of the portable oil filter cart.

The filter installed on the outlet is designed to capture minute medium particulates.

It targets impurities less than 5 µm in size, relying upon the filter rating and customization.

The cleanliness level of the ‘start’ and ‘finish’ can be directly attributed to the number of passes the fluid goes through the filter cart.

It also determines the desired cleanliness levels.

The manufacturers of portable oil filter cart offer an array of suitable combination of filter and pump size/type that can cope with your working environment and medium.

Also, the speed of cleanup depends on the pump flow rate, cleanliness rating delta along with the reservoir size.

In case of a centralized and consolidated lubrication systems, it is easier to find the type of portable oil filter cart.

And you can easily set up the right cleanliness needed for such a system.

Chapter 5: Considerations When Buying Portable Oil Filter Cart

By now you should understand why contamination control is a critical aspect of proper management of hydraulic systems and other industrial machineries.

However, in this chapter we shall cover on the considerations that you should take when wanting to buy a new portable oil filter cart.

· Main Uses of Portable Oil Filter Cart

It is wise to discover the main problem that your machine has before embarking on the tedious work of shopping for a portable oil filter cart.

Once you have identified the contamination causes for your equipment, you may have a specific guide on the type of portable oil filter cart that will best suit your environment.

Here, you can run oil analyses for the new oil stock or reservoir oil to find the form of contamination present.

Sample tank for contamination control and oil analysis – Photo credits: Machinery and Lubrication

For instance, particulates, water or gases.

The results should help you set an external routine filtration in which the portable oil filter cart will constantly clean the circulating oil as the system is on-line.

Sometime the portable oil filter cart is preferred for overhauling fluid from a system.

This may call for special features that are not present in a standard filter cart.

During such an exercise you may need a by-pass valve to avoid mixing of clean and contaminated oil through backflow.

If you need sample oil for cleanliness analyses, you’ll have to install a sample valve that lets you access a small amount without necessarily exposing the rest to air.

· Type of Oil

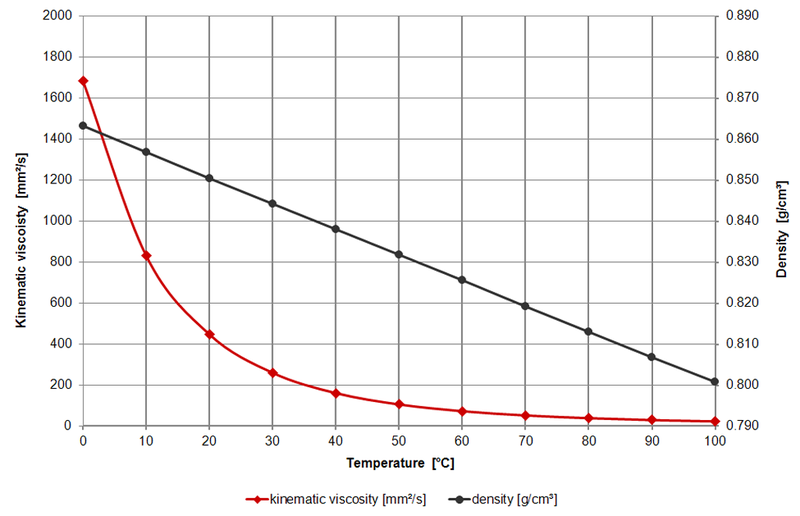

Different types of portable oil filter carts come with varying pump mechanisms that work with different viscosity level of oils.

High viscous oils tend to be thicker and cannot flow quickly as compared to low viscous fluid.

Viscosity of engine oil

Therefore, for viscous oils the motor specification and machine piping have to factor in the type of oil to avoid forming air bubbles when running.

Bubbles can lead to irreversible damages, even cause oil oxidation.

It is essential to understand the ISO VG rating of your system oil.

Besides, you should consult with experts when you decide to filter oil of different viscosity because you may have to use another filtering unit.

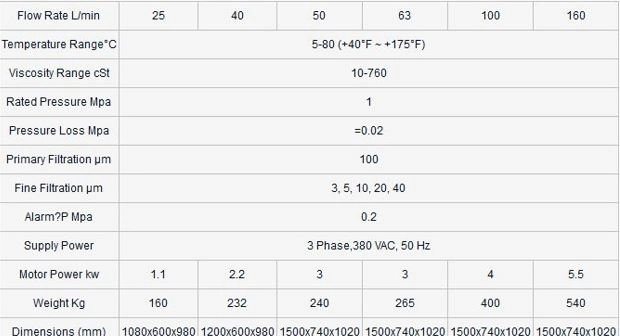

· The Required Flow Rate

Establishing the ideal flow rate is the arduous aspect of picking the correct filter cart.

Portable oil filter cart with powerful specifications will cost you a handsome figure.

Basically, if you go for a higher flow specification than what you need, you may end up overspending.

On the other hand, if the flow rate is too low, you’ll fail to thoroughly clean enough oil in the supposed time leading to premature system failure and potential damage.

The standard rule of a portable oil filter cart should at least pump up to 10% of the reservoir volume in a minute.

· The Target Cleanliness Level

The crucial part of a portable oil filter cart is cleanliness of what it filters out.

Before rushing to buy a filter cart, you should know:

i. Equipment you need to use

ii. Possible forms of contamination it is exposed

iii. Cleanliness levels of oil it requires.

ISO cleanliness – Photo credits: Machinery and Lubrication’s

This information should help you figure out the type of oil, filter and the needed cleanliness level.

Many filter carts are designed with two filter units for effective filtering of both the coarser and finer particulates and moisture.

· Application Environment

Portable oil filter cart model should be convenient for your application environment in terms of mobility while using it.

The physical characteristics of the cart are crucial if it is being used on a machine that is accessible only by wheeling across uneven terrain or ladder.

The power point in your operating environment should be a key factor.

This is because most filter carts use electricity, but in extreme applications like where dust or explosive gases are present then an air-driven motor is suitable.

Design and Structure of Portable Oil Filter Carts

A number of portable oil filter carts come in various designs and structures.

Therefore, they come in different configurations to meet the desired cleanliness levels.

The environment in which the portable oil filter must run affects the structural design of the filter cart.

For example, for applications of dusty settings, the filtering units should be completely encased to prevent further ingress of contaminates during the filtration process.

Let’s look into the various designs and structure of portable oil filter cart that are available at FilSon Filters:

a) High Viscosity Filter Cart

This unique design of filter cart is specially for filtering fluids with high viscosity together with highly contaminated lube or hydraulic oil.

High viscosity filter cart

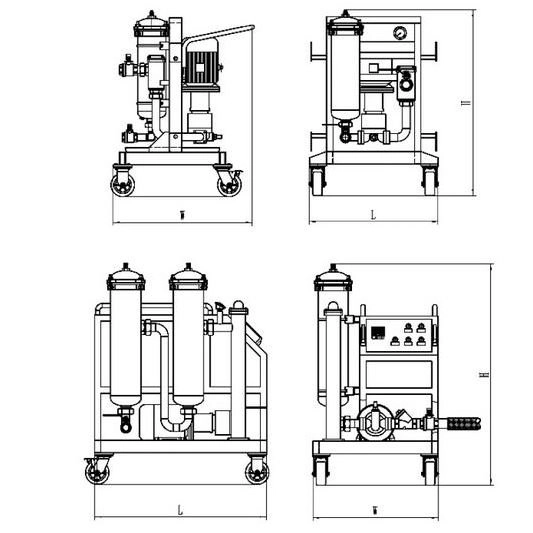

It can attain a peak flow rate of 160 1/min operating with an ambient temperature range of 40-175F.

Higher viscosity oils have poor fluidity and oil taking easy plugging.

But the FilSon High Viscosity Filter Cart uses cycle heating and high pressure pump technology that handles better viscous fluids.

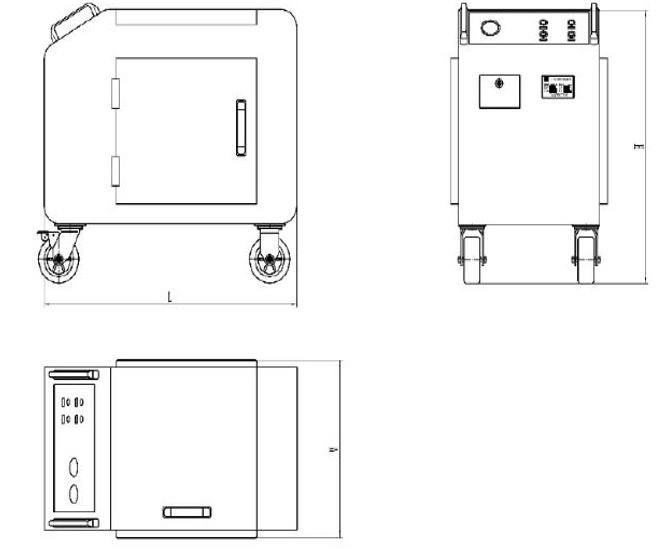

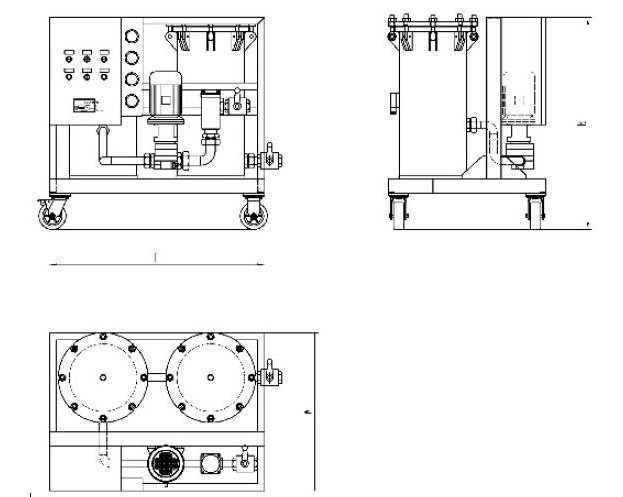

Below is its technical drawing:

Technical drawing of high viscosity oil filter

This high viscosity filter cart is also versatile as it can remove both solid impurities and water or moisture from almost all types of oils.

Besides, you can use it for severe applications like corrosive medium.

· Advantages of High Viscosity Filter Cart

i. It has a sturdy and lightweight body

ii. It can achieve fine filtration and has both high capacity and efficiency

iii. It can work with a broad spectrum of oil viscosities between 10-760 cSt.

iv. Overall cleaning and filter overhaul is easy due to their accessibility.

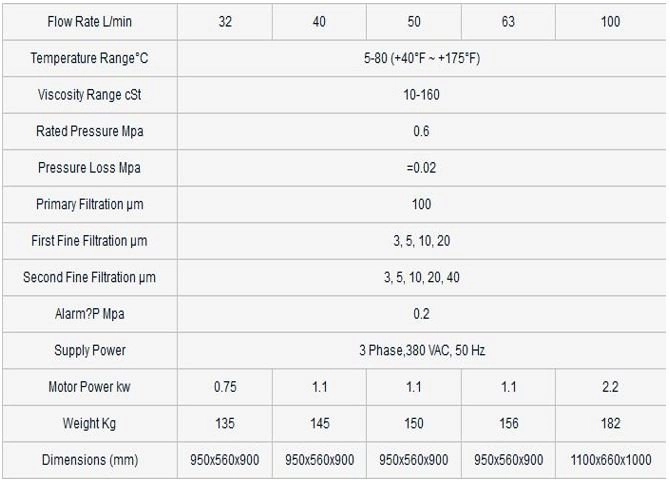

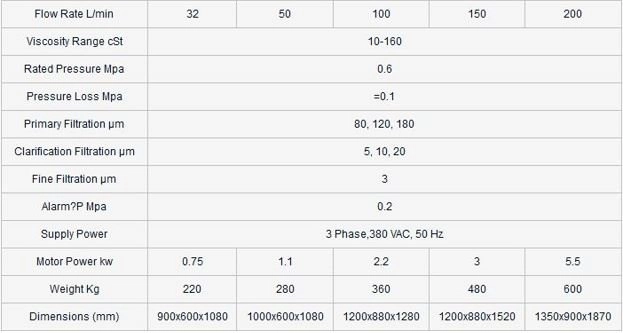

Let’s look at the technical specification data:

Technical specifications of high viscosity filter cart

b) Tote Filter Cart

FilSon Tote Filter Cart comes with a rigid a durable enclosure which impact-resistant.

This design specification makes it provide lubricating and hydraulic system protection.

Of course, this can be in harsh environments.

Tote filter cart

The oil purifier is also made from less dense materials, thus it is light for easy mobility.

It is for this reason that we call it a portable oil filter cart.

What follows is the technical drawing and specification data:

Technical drawing of tote filter cart

Technical specification of tote filter cart

Advantages of Tote Filter Cart

i. It has a two-stage filtering for effective removal of oil contaminates up to 1 micron.

ii. The model of the enclosure provides explosion protection hence all the units are properly secured.

Fully enclosed unit

iii. It has some prolonged oil exchange intervals.

iv. Operator can customize the parameters to meet specific applications during their operations.

v. The enclosure adopts a quick open structure, thus the filtering element can be easily accessed.

Easy to open structure

c) Vacuum Dehydrator

Vacuum Dehydrator is a special filter cart design by FilsonFilters with 90-95% dissolved water and gases removal accuracy.

For instance, in the transformer oil purifier and lube oil purifier.

Vacuum dehydrator

In addition, removal of emulsified water and 100% free from synthetic-based fluids and petroleum.

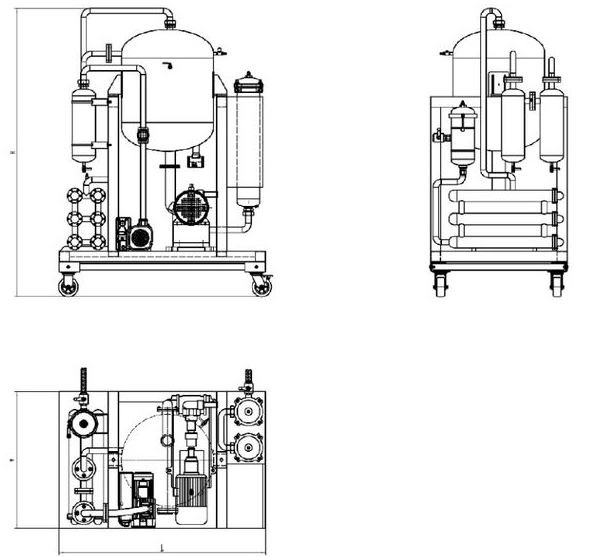

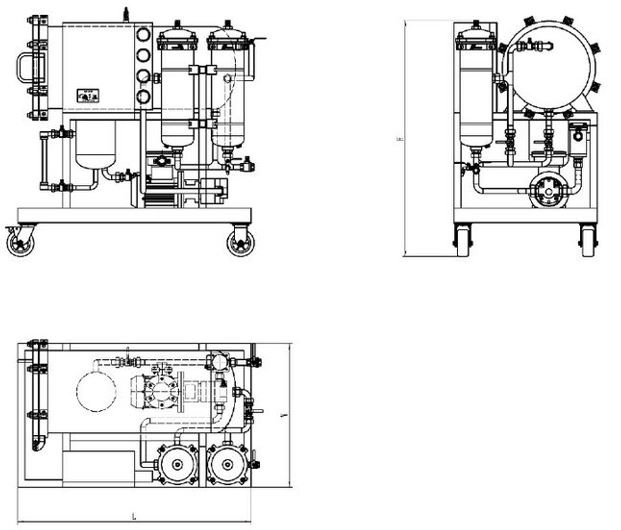

Here is its technical drawing:

Technical drawing of vacuum dehydrators

· Advantages of Vacuum Dehydrator

i. It has a higher water removal efficiency.

ii. It is also highly efficient in the air and dissolved gas filtration.

iii. It is physical characteristics, dimension and arrangement design is flexibility.

iv. Vacuum dehydrator is designed with heater to increase dewatering performance.

v. It comes with a PLC control module for automatic supervision and easy handling

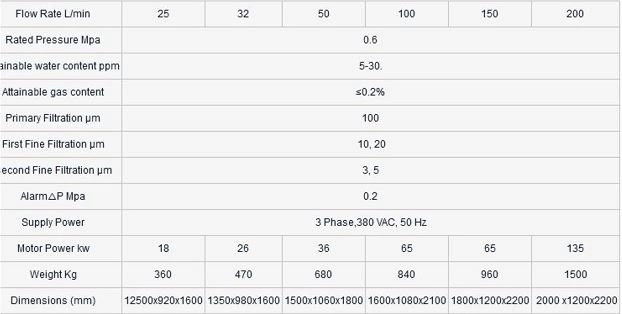

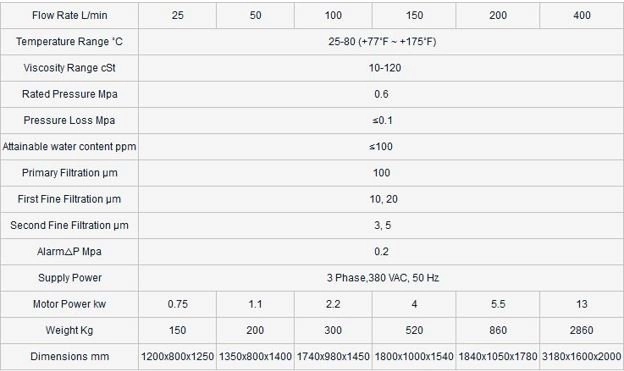

It has the following impressive technical data:

Technical specifications of vacuum dehydrators

· High Solid Filter Cart

This is a special design of filter cart that clean, highly solid contaminated fluid efficiently in a quicker manner.

It can also filter high solid oil.

High solid filter cart

This portable oil filter cart can also filter out ultra-fine particulates with a range of choices from 3, 5, 10 to 20 µm elements.

This filter cart also adopts a specially designed filter media that have high deep-level filtering capacity and reliable separation features.

The filter materials have well-developed openings, chemical stability and surface area.

Technical drawing of high solid filter cart

This special filter cart is suitable for use in the depth filtration and waste oil regeneration.

Its components are tightly coupled to minimize medium leakage during operation.

· Advantages of High Solid Filter Cart

i. Built with a protective frame, rugged for easy transportation

ii. The ideal choice for solid contaminated oils.

iii. It helps save additional maintenance cost and parts replacements

iv. Efficient for removal of suspended sediments, solid particles and rust.

Technical specification of high solid filter cart

d) Hand Held Filter Cart

A Hand Held Filter Cart (HHFC) is also available at FilsonFilters and weighs only 18 kg.

Hand held filter cart

Its design is compact, easy-to-operate lightweight.

It is very instrumental in filtering new oil stocks as well as clean the running fluid in the system to meet the required cleanliness levels.

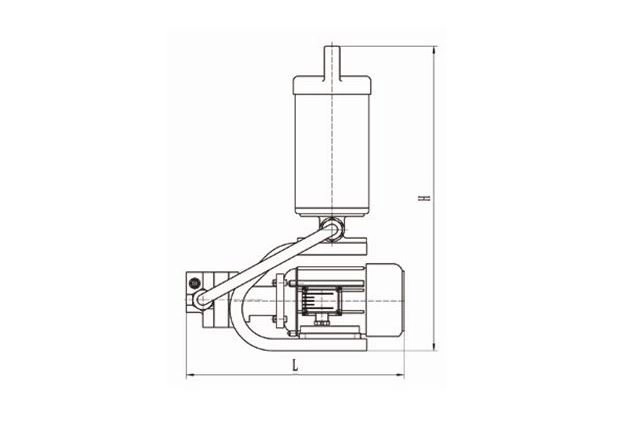

Technical drawing of a hand held filter cart

Further, HHFC is also used to transfer oil from tanks or drums to the reservoir.

This specific type of offline oil filtration system comes with a simple motor/pump and filter unit.

It is convenient and reliable for end-users operate and carry almost anywhere.

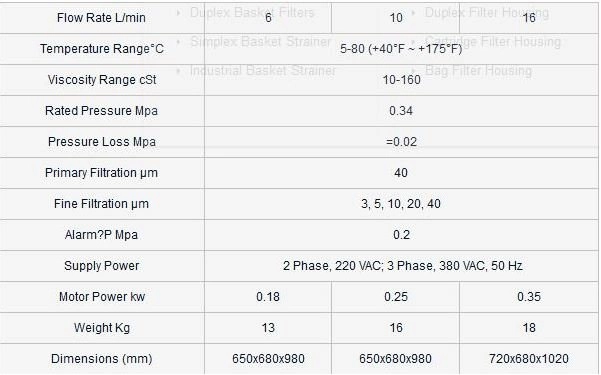

Technical specification of hand held filter cart

· Advantages of Hand Held Filter Cart

i. It allows oil systems to run without any costly downtime.

ii. The oil filtration unit can also remove a water element by radically lowering water contamination in your hydraulicoil

iii. Lightweight thus easily portable without moving on the floor.

iv. It has an array choices of filter element options

v. Low operational noise and work with one person

e) Portable Filter Cart A

Portable Filter Cart A is another excellent product of FilsonFilter carts that consist of a cost-effective pump, filter set and motor.

Portable filter cart A

The thermal relay protection, prevent the motor from damage brought about by overloading.

The filter elements are replaceable for longer machine usage.

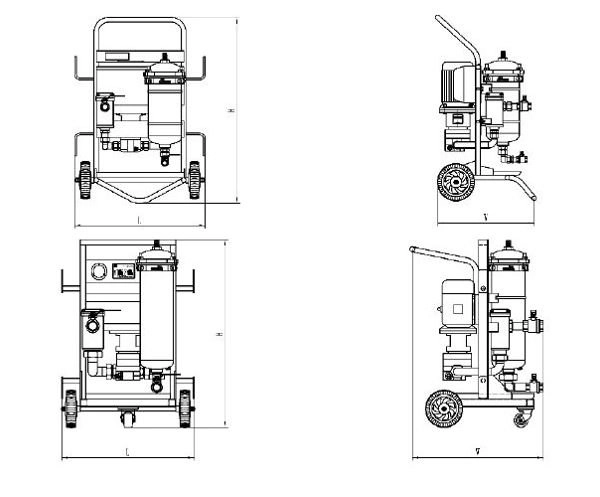

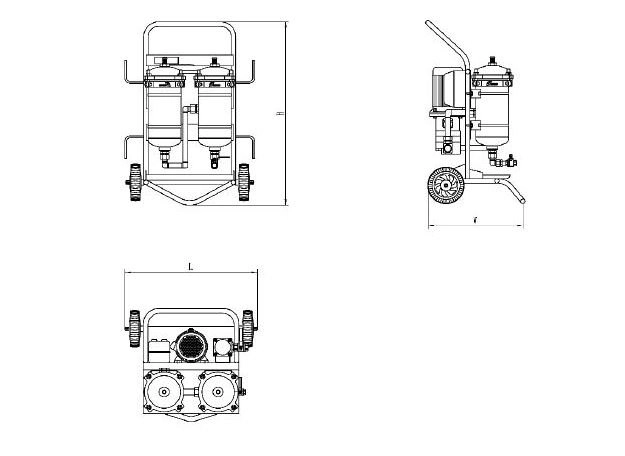

Technical drawing of portable filter cart A

It is ideal for oil transfer, top off and new fill to meet the OEM cleanliness requirements.

It is designed for high filtration performance for a cost and excellent competitive filtration solutions for industries.

Technical specification of portable filter cart A

Coarse filter at the suction orifice protects oil pump and extends the filter cart service life.

· Advantages of Portable Filter Cart A

i. Simple and easy to mount, install and operate

ii. High filtration efficiency

iii. It filters media also have high dirt holding capacity

iv. Guarantees long oil service life

v. It is easily customized

f) Portable Oil Filter B

Filson Portable Oil Filter (PFC-B) it is an ideal to clean oil in existing systems or prefilter and transfer oil into reservoirs.

Even the new oil from manufacturer comes slightly contaminated from processing.

Portable oil filter B

It is simply an effective solution to maintain a clean hydraulic and lubrication systems.

The sophisticated filtration unit helps to meet and maintain the required cleanliness level.

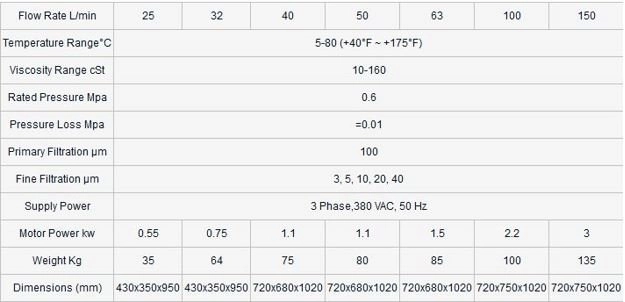

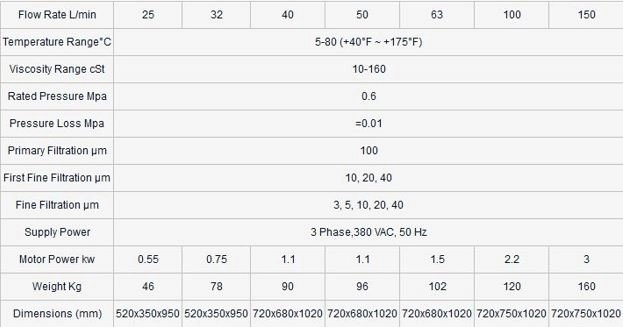

Technical drawing of portable oil filter B

Its design comes with a filtering unit, protection system along with conveniently arranged filter media.

It captures both the coarser and finer oil particulates in one cycle.

The two stage filtration process also removes water contamination.

Technical specification of portable oil filter B

· Advantages of Portable Oil Filter

i. Easy and simple install and operate

ii. The dual-filter system captures water, larger and finer particles

iii. Different filter cartridges available

iv. It can operate at multiple flow rates (25-200 L/min)

v. Cartridge replacement is simple and easy

g) Coalesce Skid

Filson Coalesce Skid is ideal for removal of water and particulates from transformer oil, turbine oil and most hydraulic and lubricating oils.

It is effective because of the five stage filtration process.

Coalesce skid

It comes with a series of units; pre-filter, coalescers, separators and filter elements to attain a higher oil cleanliness level.

Technical drawing of coalesce skid

It is designed with auto-water drain that is PLC controlled and can work automatically and continuously 24/7.

In the following technical data of the coalesce find the outstanding attainable water content while in operation:

Technical specification of coalesce skid

· Advantages of Coalesce Skid

i. It is efficient and effective in the removal of both water particulates.

ii. The auto-water drain feature allows for a continuous operation.

iii. The pre-filter element of the coalescer unit are durable.

iv. Flexible design and dimension to suit a number of applications.

v. The Separator/ coalesce element useful in water removal

vi. Available in various designs and sizes

Chapter 6: Attentions in Operation

In chapter 5, we covered about various FilSon carts and their advantages.

Here, we shall pay attention to details to working precautions and safety measures.

When operating a portable oil filter cart, you should pay attention to the following:

Before turning on the power of the filter cart, it is advisable make sure that the power mains supply voltage matches the specified unit of the filter cart.

Earlier, you learned that filter cart can have a 110 V or 220 V.

A smaller voltage rating of 110 V should never be plugged on a 220 V power supply.

This is because it will damage the electrical part of the filter cart.

Electrical box

To avoid cross contamination of lubricants, specific filter carts should be assigned to a specific cleaning of lubricant and transfer as well.

Carry out a test program with most-utilized or most critical plant-lubricant type.

Always make sure you clean up the unit before and after successful cleaning or transfer operation.

In the process, pay attention to open drip-tray and wand ends around the pump area and the filter base.

It is essential to check the working conditions of filter cart regularly, this will enable you identify oil leakages for timely seal replacement.

Oil exposed to the environment becomes a dirt attractant, therefore, care should be taken during the transfer as the filter cart should be made scrupulously clean.

In fact, the inlet and outlet hoses should be all time covered and kept clean after each cleaning or transfer exercise.

After a lengthy period of using the filter cart, suction becomes difficult due to blockage of the filter.

Noise may occur from the oil pump, at this point the filter media should be cleaned or overhauled immediately.

Most filter carts are fitted with delivery and suction hose ends.

They are designed with open-end transfer wands that fits easily into the supply fluid receptacle/reservoir openings of the recipient and donor reservoirs.

In filtering oil contaminants, this form delivery can pave way for dirt and moisture contamination into the reservoir during the exercise.

What’s the remedy for this?

Conduct a contamination-free process.

Use quick-lock-style couplings to fit the filter cart return/delivery hose ends and drain ports/ reservoir fill.

This will make sure the reservoir is airtight, but also fit a breather or a closed-loop expansion-tank for the larger capacity reservoir.

While the portable oil filter is running, the oil pump can inhale air that may affect the flow rate of the pump.

To avoid such incident, the vent valve must stay open to release the air accumulated in the filter housing, close in time after the discharge.

Kink-resistant should be observed in the delivery and suction hose to prevent cavitation of the pump.

In case the pressure unexpectedly drops, please inspect to decide whether the filter media is damaged.

Carry out a routine preventive-maintenance (PM) check exercise prior to clean up or transfer of oil.

Find out the state of the filter elements before getting into bypass mode due to heavy contamination.

Always remember to contact the supplier of your portable oil filter to consult where you may not be properly enlightened about the filter cart.

Chapter 7: Step-by-Step Process How to Replace Cartridge in Portable Oil Filter Cart

Since you have now understood the importance of paying attention when running the portable oil filter cart, it’s crucial to learn step-by-step process of how to replace cartridge in a filter cart.

It is inevitable as eventually the filter element will get clogged with dirt filtered out of the flowing oil from the reservoir.

Filter Cart – Photo courtesy: TECO Pneumatics

Since you have to dismount some part of the filter cart, it is wise to take precautions.

- Firstly, make sure to cut off the power supply or unplug the power cord from the socket, and close the outlet and inlet ball valves.

- Go ahead to vent the filter housing from the cover and drain the all the medium via the bottom drain.

Remember to make sure that the housing is absolutely vented before taking off the lid or top cover.

A counterclockwise rotation should remove the bolts on the top cover without hustle.

- Carefully, pull out the old cartridge filter and insert/install the new one.

Most spare cartridge filters have technical or 3D drawing in the manual to help you make a proper assembly of parts.

There is usually a rubber washer included in each cartridge filter package, use it to tighten the thumb-screw to a point the rubber washer slightly curls.

- Before tightening the top cover, make sure you clean around the gasket sealing surface and gasket groove, and lightly apply lubricant (petroleum jelly) on the gasket surface.

- However, replace the lid if is deformed and secure it in position with the bolts, continue to rotate the cover clockwise to tight it.

On the exhaust side, slightly loosen the exhaust plug before turning ON the system, but tighten the exhaust once the gas is expelled.

After such a service, run a test program to check whether all fittings and lid have leaks before any major clean up or transfer of oil.

As you can see, this is a simple and straightforward process.

Chapter 8: Application of Portable Oil Filter Cart

As a learner or professional, you should embrace smart lubrication that incorporates the use of effective modern filtration ways and tools to your advantage.

Section of offshore oil rig

Now you know that portable oil filter cart is a crucial tool in any industrial setting that operates hydraulic systems and other machineries with fluid reservoir tanks.

Once you figure out the type of contamination and application environment, a specially customized filter cart can stop a lot oil wastage and extend its service life.

Let’s look at the following applications of portable oil filter carts:

· To Filter New Oil Stock

Portable oil filter cart is used to filter new oil stock before being put into use.

For instance, transport and logistics firms acquire huge volumes of lube, hydraulic, cutting and gear oils for various maintenance and service.

It is true that even the new oil gets contamination during its processing.

Therefore, it’s essential to pre-filter such oils to protect your fleet from contamination damages or downtime.

· In Transfer of Fluid from Reservoir

Transfer fluid from storage tanks or drums in reservoir; diesel locomotives that transverse continents or countries cover a lot of distance.

Thus, locomotives and logistics transporters fit reservoir tanks or systems with all necessary fluids like hydraulic oil, lube oil and many more.

Such oils come in tankers and drums and here filter cart plays the role to pre-filter oils into the reservoir.

· Conditioning Oil in Existing System

Machines and hydraulic system oils overtime get come contaminated with dirt and moisture, but that does not necessarily mean it is spoilt for good.

Such oil can still be conditioned by passing it through a portable oil filter cart to filter out both the solid particulates and water.

The conditioned oil can still be reused as its service life is extended through cleaning up the contaminants.

· Complementing Existing Filtration Systems

Portable filter is a right substitute for an existing filtration system.

This is because you can determine the effectiveness and efficiency of an existing system when there is a filter cart around.

In fact, it can run concurrently with such a system to complement the filtration mechanism.

· Assist During Hydraulic System Overhaul

Changing and filling hydraulic fluid from a system; filter cart is an instrumental filtration tool that carries out oil overhaul in a hydraulic system.

· Use it During Power Flush in Fluid System

It is the process of reducing the fluid level in sumps or tanks and flowing the same medium at extreme velocities across the sump or tank bottom.

This swipes out low-lying solid particulates.

This kind of system drain is best carried out using a suitable filter cart.

· Removes Emulsified Particles

Remove emulsified particles, moisture and water droplets from hydraulic fluids; portable oil filter can also effectively draw out moisture from hydraulic fluids as well as particulates.

Conclusion

Clearly, you can see portable oil filter plays an integral role in modern systems.

And, throughout this article, I have highlighted every essential aspect you should know.

From why you need it, parts, working principle, maintenance to applications.

You must know all these before you buy a portable oil filter.

Now, over to you.

Do you need any filtration system – talk to us today!