Filson duplex basket strainer is composed of two high-flow simplex filters and a 2-position 6-way directional valve. It is installed in low-pressure or return pipelines of hydraulic & lube systems. This duplex basket strainer design is simple in construction and easy to use.

There are a by-pass valve and a contamination indicator in this duplex basket strainer, for protecting the hydraulic system safety.

- The maximum flow rate of 15000 l/min

- Bypass-valve, clogging indicators

- High dirt holding capacity and easy maintenance

- Continuous operation due to duplex change-over filters design

- Filter housing adopts high-quality steel or stainless steel.

- Large ball valve changeovers available

- Details

- Operating Steps

- Attention

- Technical data

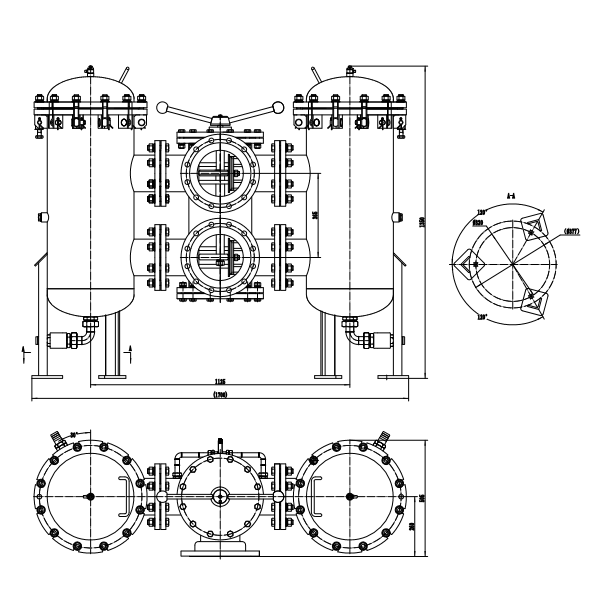

- Drawing

- Vedio

The feature of duplex basket strainer allows for continuous operation when changing elements due to clogging caused by contaminants. After opening the balance valve and turning the directional valve, the other filter begins to work, thus a clogged element should be changed in time.

These series of duplex basket strainer have a high flow range from 1300 l/min to 15000 l/min with maximum pressure 1.6 Mpa. Filson duplex basket strainers are widely used in the hydraulic systems of heavy-duty mining and metallurgical machines.

Note: As the leading duplex basket strainer manufacturer in China, Filson filter can custom any duplex strainers based your detailed requirement.

Operating Steps of Filson Duplex Basket Strainer

- Install the duplex basket filter in the working system.

- After completing filter installation, open the inlet and outlet valves of the filter; the system will start working.

- When the CMS-I alarm turns on (differential pressure is achieved 0.35MPa), please change the switch valve and let the spare filter work.

- Open the vent valve (on the upper cap) and blow-down valve (on the bottom cap); let the dust fluid drain off the filter completely.

- Open its upper can and take out the filter element.

- Clean or change the filter element, then install the filter element and upper cap.

- Close the vent valve and blow-down valve. Make it a spare filter you can use once again for replacement.

You must know the exact positions of our duplex basket strainer – upper is the inlet and lower is an outlet after installation.

- Change the filter cartridges in time when the CMS-I alarm is on and let the filter be in standby state.

- Switch valve must be in place.

- Have the new filter cartridge ready and know when to change it. Reduce the time interval when the internal components of the filter are exposed.

- Ensure the seals are in good-working condition whenever you change the cartridge. Don’t forget to put the seals during installation.

- Don’t let anything fall into the filter after opening the cover.

| Model | Diameter (mm) | Flow Rate (L/min) | Filtration (μm) | Pressure (Mpa) | By-pass setting (Mpa) | Pressure loss (Mpa) | Element Number |

| LFDF-1300 | DN 100 | 1300 | 3,5,10,20,25,50,100 | 1.6 | 0.4 | ≤0.35 | 1*2 |

| LFDF-2600 | DN 150 | 2600 | 2*2 | ||||

| LFDF-3900 | DN 200 | 3900 | 3*2 | ||||

| LFDF-6500 | DN 250 | 6500 | 5*2 | ||||

| LFDF-7800 | DN 250 | 7800 | 6*2 | ||||

| LFDF-9100 | DN 250 | 9100 | 7*2 | ||||

| LFDF-15000 | DN 300 | 15000 | 10*2 | ||||

| LFDN-1300 | DN 40-100 | 1300 | 3,5,10,20,40,50,100,200 | 1.6 | 0.4 | ≤0.35 | 1*2 |

| LFDN-1320 | DN 40-125 | 1320 | 1*2 | ||||

| LFDN-2500 | DN 50-150 | 2500 | 3*2 | ||||

| LFDN-4000 | DN 80-200 | 4000 | 5*2 | ||||

| LFDN-5200 | DN 80-250 | 5200 | 4*2 | ||||

| LFDN-6500 | DN 100-250 | 6500 | 5*2 | ||||

| LFDN-7800 | DN 100-250 | 7800 | 6*2 | ||||

| LFDN-15000 | DN 200-300 | 15000 | 10*2 |

Why Filson Duplex Basket Strainer

Easy-to-operate lever handle

Flexible, lightweight and quiet operation

Duplex filter housing

Industrial quality, ensure continuous operation even during element is changed. Stainless steel models are also available

Quick-opening covers

Fast and easy change of elements that do not require special tools.

Large dirt holding capacity elements

Elements with high differential pressure stability and high surface area

Clogging Indicator

Indicating when to change filter elements

Vent plug

Efficient air purging to ensure pressure equilibration

Inlet (above) Outlet (below)

Inlet and outlet connections are located on the same or opposite side

O-rings

Longer service life, well sealing without oil leakage

Balance Valve

Used for pressure relief, providing smooth changeover when changing elements.

Colors

Variety customizable colors, Industrial powder-coated paint

Clean Side Drain

To remove sediment from filtered oil

Dirt Side Drain

Remove dirt, particles and help to keep the inside working area clean