Your Premier Fabricated Strainer Manufacturer

FilSon fabricated strainers provide more flexibility and design options for any applications.

We offer a large variety of materials and construction designs fabricated basket strainers such as bag filter housing, cartridge filters, automatic self-cleaning filters, stainless steel water filters, Y-type strainers, sea water strainers, filter coalescers, and high temperature & high pressure options. All sizes fabricated strainers feature an O-ring cover seal.

Filson farbicated basket strainers meet the ISO 9001-2008 quality management and offer reduced purged volumes.

Fison has over 10 years manufacturing experience on fabricated strainers include duplex strainers, simplex strainers, basket filter housing and more.

Your Professional Fabricated Strainers Manufacturer

All FilSon industrial fabricated strainers are 100% customized upon request. Our engineers can adjust pressure filters to the flow rates, connection type and installation space that you wish.

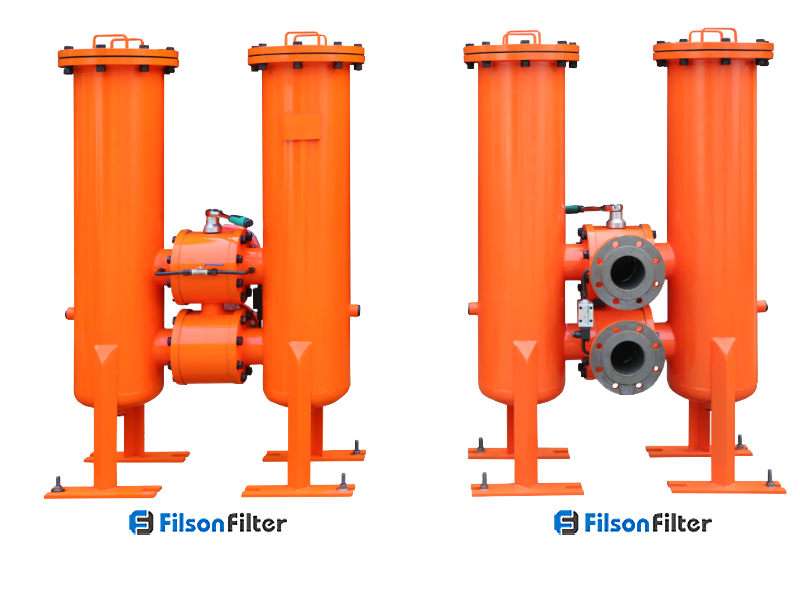

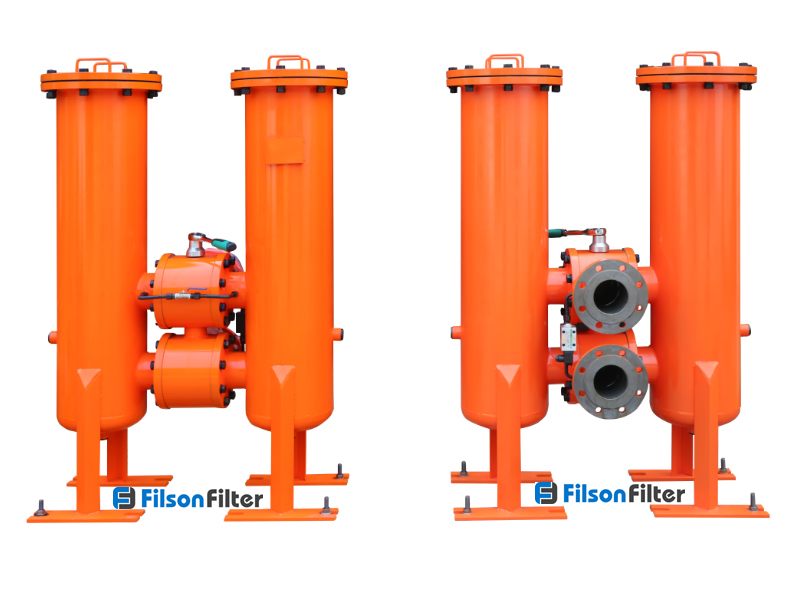

Filson fabricated strainers can be made into duplex strainers and simplex strainers.

Filson fabricated strainers Cast iron & carbon steel filter housings are epoxy painted to provide an increased resistance to rust and corrosion.

Features of Filson Fabricated Basket Strainers

- Good sealing and low maintenance

- Numerous connection variations

- Custom modifications available

- Fineness: 3 – 100 µm (other on request)

- High pressure/flow range can be offered

- Wide variety of filter elements material optional

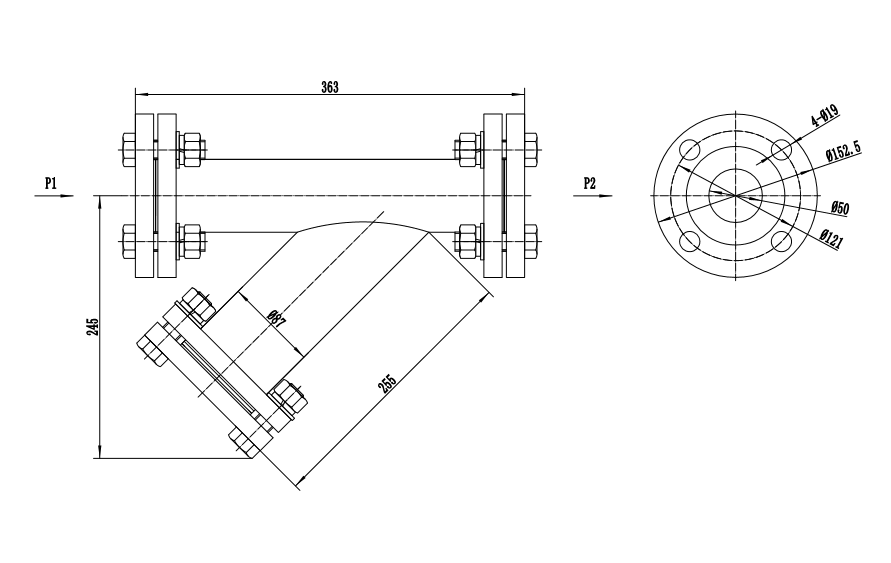

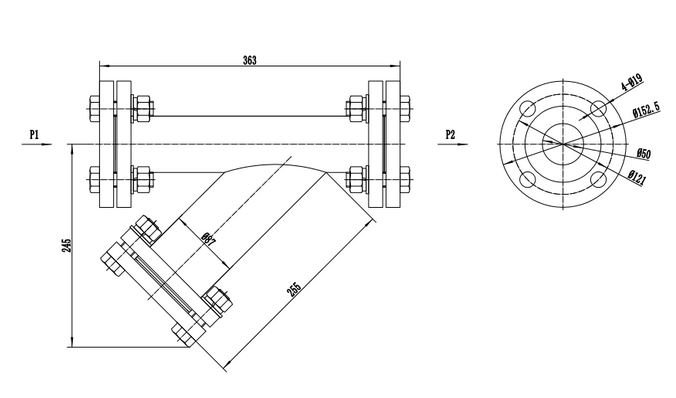

Filson Fabricated Strainer Overall Size

Fabricated Strainer: The Definitive Guide

Impurities will alter the physical and chemical composition of the fluids that you are using in your daily applications.

The best way to get rid of these impurities is by filtering and making sure that the fluids are clean.

You can do this perfectly using a fabricated strainer.

In this guide, I am going to walk you through every aspect of a fabricated strainer – from basic definition, technical specifications, working principle to applications, just to mention a few.

Now, let’s get straight to the main subject of this guide.

What is a Fabricated Strainer?

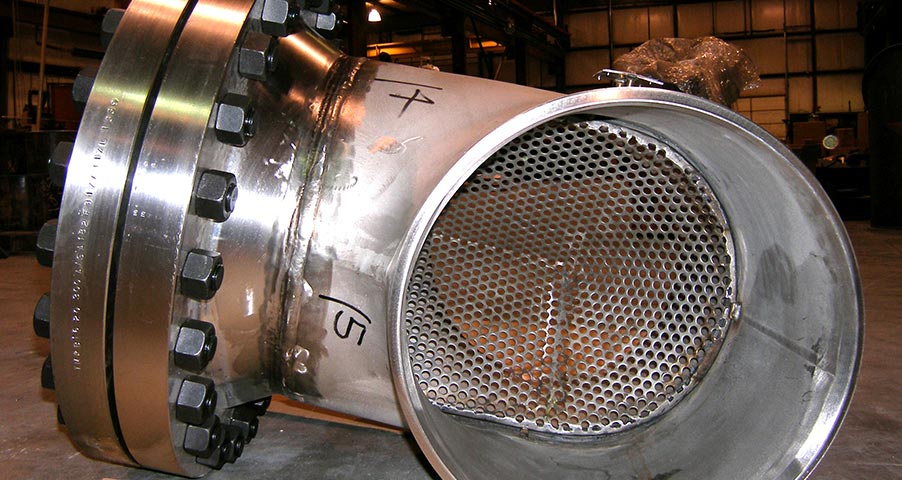

A fabricated strainer is a device that has holes on it, just like a sieve, for keeping the solid matter from liquids.

Fabricated Strainer

It retains any solid piece that may be in a fluid as the liquid flows through it to other destinations.

Normally, it acts as a filter that will sieve and block solid material that you will not need in later stages.

In large industrial applications, manufacturers often fabricate strainers to fit the industrial application.

It is because the industrial applications vary and you might not have a standard strainer to fit all of them.

In that case, fabrication will come in handy to design different types of strainers thus the name fabricated strainers.

Why You Need Fabricated Strainers for Pipelines

A fabricated strainer will work just like a normal strainer, but there are certain modifications to improve its efficiency.

Strainer – Photo courtesy: Weamco

There are specific requirements and settings that you will provide the manufacturer to customize or fabricate a strainer for you.

You will then use it for trapping foreign solid materials in flowing fluids such as sediments and rust materials.

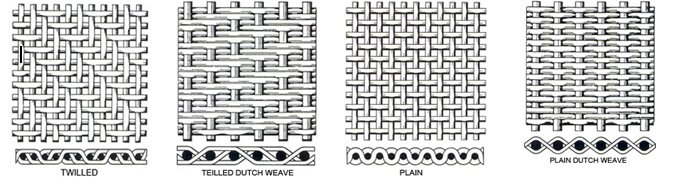

It works best with the aid of perforated metals, wire mesh and wedge wires to keep the solid matter away.

It will be protecting pipe systems, sprinkler heads, pumps, valves, turbines, meters and nozzles from damage from solid impurities.

The devices are costly to acquire so they have to get protection from solid matter that may cause damage.

It will also increase the productivity of the machines it is protecting from any form of damage by the solid matter.

It means that the machines will always be working without interruptions from the solid material that may cause damage.

In the end, it will contribute significantly to the productivity and efficiency of the whole system.

You will also save a lot of money and time especially when you do not need to maintain the machines.

Keeping the solid matter away will reduce damage on the machines that you are using from time to time.

In the long run, you will be using the least amount of money on maintenance, and you will save time.

Apart from that, you can also use it to address application issues that are straining such as:

- Limitations of space

- Special and unique piping connections

- Certain opening systems

- Modifications of cast metal

Clients have a lot of options to choose from especially when they are considering to have fabricated strainers of choice.

The options that are available for you to choose from include:

- Resizing of the strainers so that it can meet the flow process requirements

- Offering comfortable and simple maintenance by creating unique covers

- Making large castings that will save you some money

You will also need a fabricated strainer when you need to use it for specific applications, especially in manufacturing.

At this point, you will take customization seriously and spell out the type and design that you want.

Take note of the temperature requirements, pressure systems of the application and the availability of these designs in the market.

Fabricated Strainer Material

The term fabrication tells a lot about the kind of modifications that a strainer can be taken through.

Manufacturers have been producing fabricated strainers for a long time using different materials.

It means that you are at liberty of choosing the kind of material that will fit the applications you have.

The most common materials that manufacturers use in fabricating strainers are stainless steel, copper, brass, aluminum, cast iron and carbon steel.

Continue reading and find out more about the fabricated strainers manufacturers make out of these materials.

1. Stainless steel fabricated strainers

These are fabricated strainers that you will find with stainless steel as the primary material in use.

Manufacturers will use different types of stainless steel such as 316L, AISI 316, 316Ti, 321 among other types of steel.

Stainless steel strainer

Manufacturers prefer using this type of steel because it does not corrode easily and increases the efficiency of the fabricated strainer.

Apart from resistance to corrosion, stainless steel has the following properties that manufacturers prefer.

- It is very strong and is known to have very high cryogenic strength.

- It has a very high rate of hardening even in the process of using it.

- It is very useful even in varying temperatures, and you can use it at very high temperatures.

- High ductility properties

- Higher hardness and strength and can withstand very high pressure.

- It is even more attractive in appearance.

- It requires very little maintenance thus saving on time and money.

These properties make it one of the greatest material manufacturers look for in fabricating strainers. It can also work in different extremes of both pressure and temperature without damage.

2. Copper fabricated strainers

Manufacturers had the advantage of exploring and finding other material to fabricate strainers such as copper.

It is equally good in comparison to other material, but it has its own unique features that you can consider.

Strainer basket

Despite the good heat and electrical conductivity properties, it is an essential material for fabricated Strainers because of the following:

- It is able to resist corrosion and therefore does not rust making it an appropriate material of choice.

- Has antibacterial properties thus very safe for use even in domestic applications.

- Soft and can easily join with other materials.

- Has ductile properties

- It is a tough material that can withstand pressure and heat

- It is not magnetic

- It is also very attractive and will improve the image of the fabricated strainers.

- It can alloy easily, and you can recycle it for other purposes.

Apart from the properties above, it is also a tough kind of material that you can use for a long period.

It is the most common material in use in pipes for the supply of water and gas.

3. Aluminum fabricate strainers

Aluminum is the other material that manufacturers prefer to use in fabricating strainers.

Chemically and physically, aluminum is just a metal that you can use in making the fabricated strainer just like others.

It has properties that you can manipulate such as melting, casting and can respond well to molding under pressure.

Aluminum fabricated basket strainer

Aluminum has certain properties that make it suitable for use in fabricating strainers which include:

- It is alight material that reduces energy consumption and dead weight while increasing the load.

- It can be made stronger by improving the quality of the constituent alloys.

- It has corrosion resistant properties making it one of the best materials for use in places prone to rust.

- The reflective of the aluminum makes it a better material in the reflection of heat

- It has a low melting point and is ductile making a suitable material for fabrication of strainers.

- It is impermeable and thus does not allow any substance to pass through including smell.

- You are also at liberty of recycling the material for other uses.

4. Brass fabricated strainers

Brass is a material that has come as a result of combining a wide range of zinc and copper alloys.

Brass fabricated strainer

The name brass is generic and was as a result of combining the two types of metals together.

They have quite a number of properties that make them suitable for the fabrication of strainers.

Brass fabricated strainers are a result of fabricating brass to form a strainer. Some of the properties of brass include:

- High tensile strength making it resistant to easy breakages

- Machinability

- Ductility

- High resistance to tear and wear

- It is hard enough to withstand low- and high-pressure systems

- The colors make it very attractive

- Antimicrobial properties make it safe to use

- It is also resistant to corrosion thus keeping rust at bay.

5. Cast iron fabricated strainers

Fabricated strainers are also a result of fabricating cast iron in order to come up with a perfect device.

It is an alloy of carbon and iron and is very popular because of the low cost.

Besides the two metals, there are other metals such as manganese, phosphorous, silicon and sulfur.

Basket strainer

Fabricated strainers that are a result of cast iron exhibit the following properties:

- It is reasonable resistant to corrosion

- It is neither ductile nor malleable and cannot be made as hard as steel

- It has very high melting points with a granular or crystalline fracture.

- The physical properties rely too much on the carbon content of the alloy.

6. Carbon steel fabricated strainers

Carbon steel is another material that manufacturers use in making the fabricated strainer.

It is not a good material, but the cost has made it popular among different people.

Fabricated basket strainer

The properties that make it more suitable for this purpose include:

- Medium resistance to wear and tear

- It is a fairly hard material to deal with depending on the carbon content of the alloy

- It does not distort when it is under heat

Types of Fabricated Strainers for Pipe Systems

Manufacturers at times make different designs of fabricated strainers depending on the application.

This system allows you to get the exact fabricated strainer that will fit the exact application for it.

It will also give you the chance to pay for the fabricated strainer that you will need at particular times.

Manufacturers have the advantage of not starting the fabrication of the strainer from scratch as they can only do modifications.

This is because there are specific designs that are readily available with which they can refer.

Slight modifications to the available designs might involve:

i. Changes on the cover of a particular design

ii. Changing the piping connection or the nozzle of the design

iii. Generation of the vertical or horizontal flow of a particular designs

Clients are at liberty of meeting the manufacturer so that they can discuss the design they need.

Apart from that, there are different types of fabricated strainers available in the market.

Continue reading and find out more about the most common types of fabricated strainers available.

7. Y-strainers

This is a type of fabricated strainer that is in the shape of the letter Y for keeping solids away.

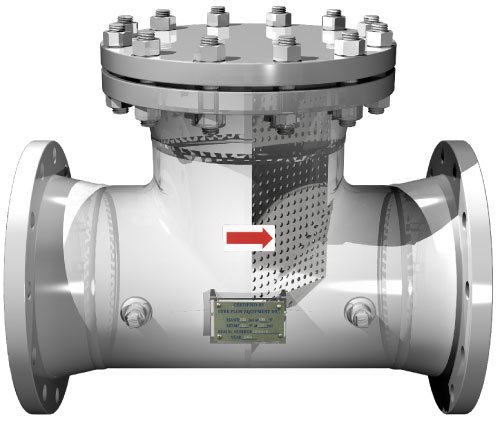

Y Strainer

The Y design of the fabricated strainer makes it have the following features:

- The design is streamlined suitable for low-pressure drops

- It has wide and very large strainer screens within the pipes

- The dimensions are compact from one end to the other end

- It is a result of fabrication during construction

You can find Y fabricated strainers with materials such as bronze, carbon steel, ductile iron, chrome moly and stainless steel.

The end connections can be flat faced, butt weld, raised face, RTJ flanged, threaded or socket weld sweat.

They are available in different sizes according to customers specifications for applications such as:

- Process industries

- Mining and metal industries

- Power industry

- Gas and oil industry

- Waste and water industry

- Chemical industry

8. T Strainers

These are unique types of fabricated strainers that take a T shape.

Manufacturers fabricate them using carbon steel, stainless steel and any other material according to the request.

T Strainers

Most of them have end connections that are either buttweld ends or RF or RTJ flanges.

They are available in different sizes, but the most common are two inches to twenty-four inches.

Manufacturers are able to fabricate larger sizes upon the request of the customer.

You will find the T fabricated strainer in use in:

- Gas, steam, liquid and oil industries

- Process equipment industries

- Waste and water industries

- Mining and metal industries

- Power industry

- Paper and pulp industry

- Chemical industry

The main features are:

- Vertical or horizontal installations

- Standard through bolt covers

- The perforated screen that is stainless

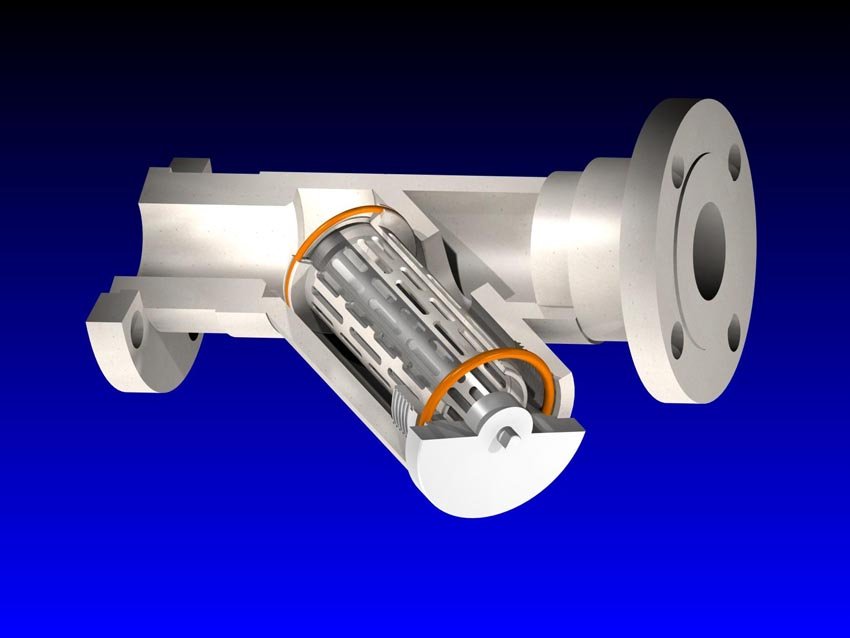

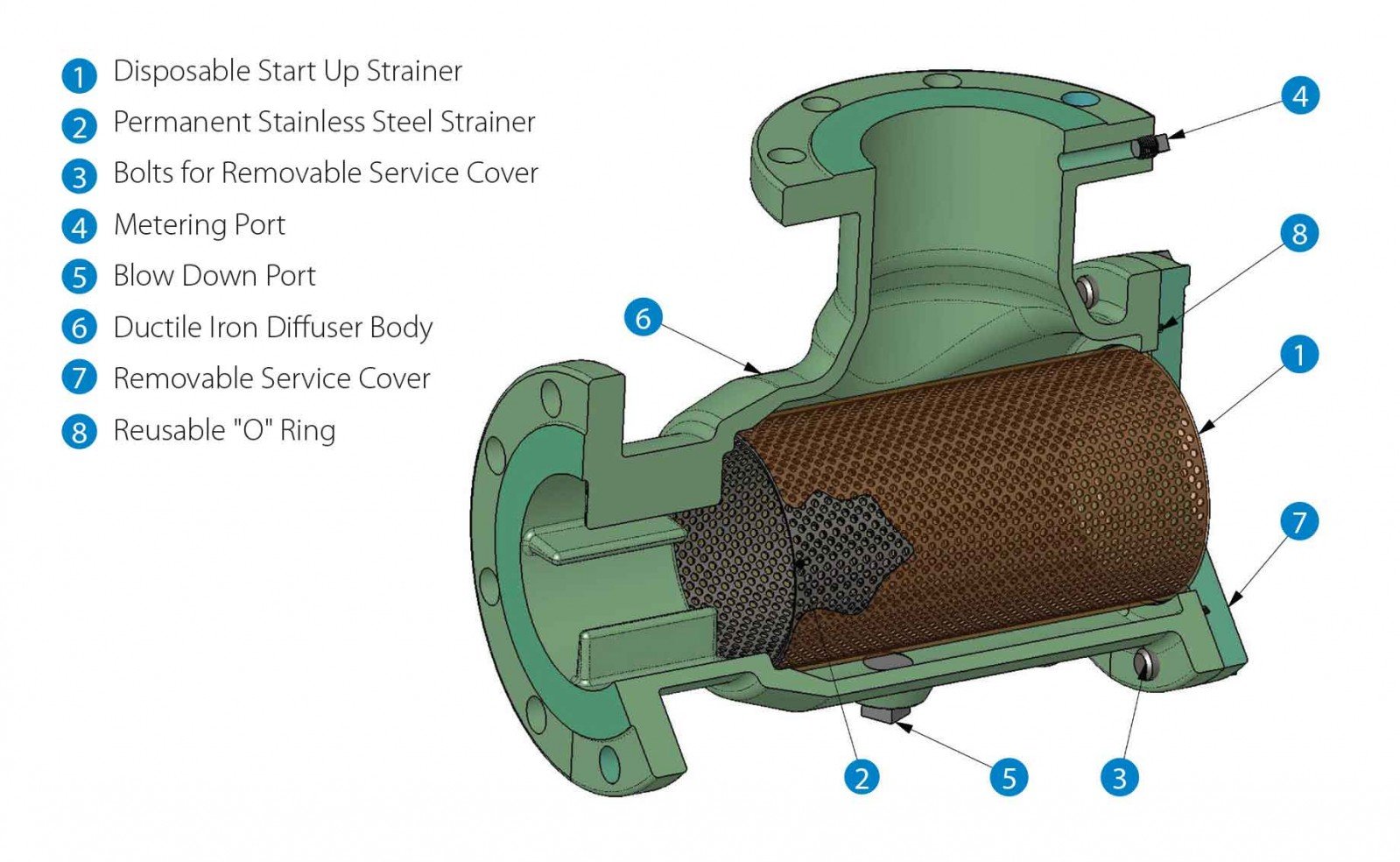

i. Suction diffusers

It is a device that will help in conditioning the flow of fluids into pump suctions to increase pump efficiency.

Suction diffuser – Photo courtesy: State Supply

They have the following benefits and features:

- It has flow cones that eliminate re-circulation zones and directs flow to the pump.

- It improves the condition of the flow and maximizes the efficiency of pump retention.

- You can remove the internals for easier maintenance

- Available in a wide range of sizes

- You can easily remove the end cup and re-use the O-ring

- It has a very fine mesh that ensures very clean fluids at the end.

- Has straight vanes that ensure smooth flow of the fluids.

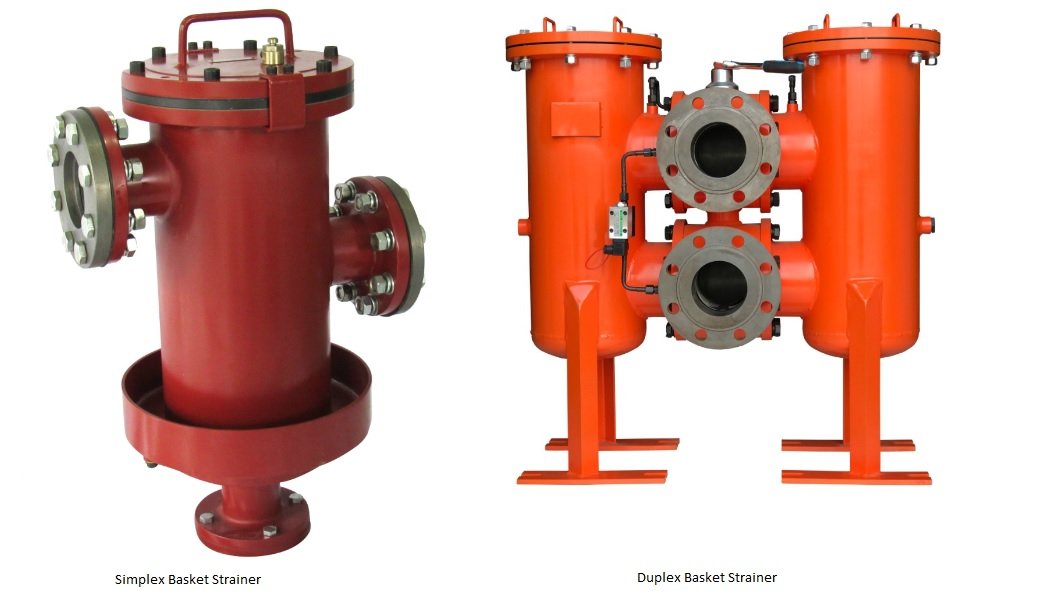

ii. Basket strainer (T-type strainer)

You will find this type of basket strainer in use in chemical industries and other markets.

They are available for customers to make different orders for different applications.

The filters can either be bolted, davit, hinged and others have quick openings.

The connections available are the vents, pressure gauge, drains and differential pressure connections.

It also has special internal and external coatings.

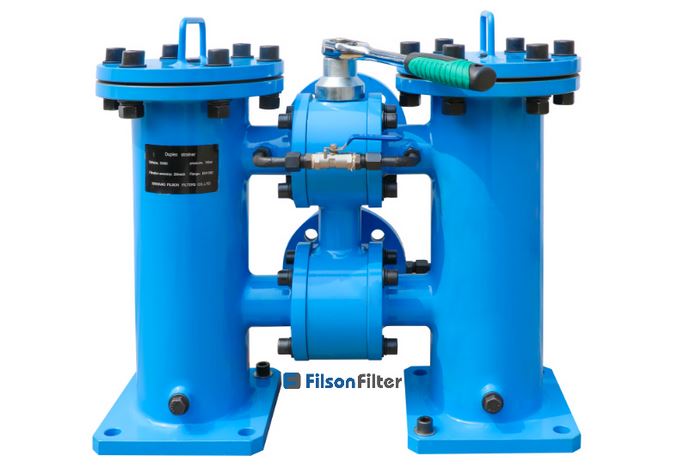

Duplex basket strainer

This type of basket strainer can operate continuously and does not need shutting down for cleaning.

Duplex basket strainer

It has a double basket chamber that often operates differently.

As one basket chamber fills up, the machine switches to the other allowing for clean-up.

Simplex basket strainer

This type of strainer is available in applications where the line is shut down for cleaning purposes.

Simplex basket strainer

You will clean the basket strainer or replace it with another before you proceed.

They are available in different forms and sizes depending on customer specifications.

Working Principle of Fabricated Strainers

The principle behind the operation of the fabricated strainer is the same in all types of strainers.

In this case, we are going to have a look at the principle behind the Y-strainer.

Note that the principle can apply in different types of strainers with slight modifications.

Y strainers are certain devices that you can use to remove solids that are not needed in liquids, steam or gas.

It has perforations and wire mesh elements that block the solid material from passing through.

You are likely to find them in use to protect meters.

Control valves, pumps regulators and other equipment.

It works in applications that will require very small amounts of solid out of the flowing fluids.

This will increase the time that the fluid takes between the filter screens.

You will then stop the machine from operations especially when you want to clean the screens and filters.

Remove the screens carefully from the systems and assess the amount of dirt and solid matter on it.

Clean the solid matter and leave the screens very clean before returning it back.

After that, you can start the machine and allow it to continue working as the screen filters the fluid.

Y strainers have a cylindrical shape that is compact and can withstand great pressure in different applications.

The excess pressure will always be found in certain applications such as that of the steam systems.

Considerations when Buying Fabricated Strainers

As a customer, there are certain things that you should look at when purchasing fabricated strainers.

These are the main parts that need to be in check to ensure that your strainer is in good shape.

You should also speak to the agent available and ask questions about the specific strainer of choice.

In many cases, you should speak directly to the manufacturer for more specifications.

You can as well make an order on the type of strainer that you need depending on the application.

Besides that, you will look at the following specifications whenever you are in need of a fabricated strainer.

· Mesh size for the fabricated strainer

Different applications will require different sizes for the mesh especially when looking at pore size.

You will get a mesh with very small pores when the application has smaller solid material.

In applications with the large solid matter, the pore size can be wider given that it does not allow them to pass.

Strainer basket mesh size

Customization of the mesh is also an option for you to choose from.

Different manufacturers welcome different specifications and are ready to make them for you.

· Type of fluid in pipe systems

You have to know the kind of fluid that will pass through the pipe system before purchasing a strainer.

Water treatment plant

Different fluids require different types of strainers depending on the solid matter that is in them.

The smaller the solid matter, the smaller the mesh pores should be.

Gasses and steam often have minute solid matter in them so you will use smaller mesh.

The type of fabricated strainer should also fit and be able to withstand certain conditions.

It should be able to withstand the pressure and the temperature within the flowing fluids.

· Nature of contaminants

The contaminant or the solid impurities in the fluid is a significant factor to look into before purchasing.

Suppliers will always advise you on the best-fabricated strainer to use in relation to the nature of the contaminant.

Contaminated water

Always speak to the suppliers and let them know the kind of application that the fabricated strainer will do.

The contaminants vary in size and shape; therefore, the fabricated strainers should also fit these variations.

This is the reason why manufacturers have different designs that can fit different applications.

It will also influence the nature of the material of the fabricated strainer to avoid corrosion and even contamination.

· Maximum allowable pressure drops in the pipe system

The pressure drops in the system will also vary accordingly at different intervals.

The material in use when fabricating the strainer should be able to withstand such cases of pressure drops.

You have to specify the application you are working on so that you get the right fabricated strainer.

Pressure drops often influence the type of material that the manufacturer will use.

The material in use has to be strong enough to withstand the drops in pressure.

· Pipeline working temperature and pressure

These are the factors that will greatly affect the kind of material that was in use during fabrication.

High temperatures and pressure systems require very strong materials.

The main materials you can look at for high-pressure material are stainless steel and brass among other strong metals.

The pressure and temperature systems in the pipeline will also influence the thickness of the fabricated strainer.

For very high pressure and temperatures, you should look for thicker materials to withstand such conditions.

Low pressure and temperature systems will not require very thick materials.

· Fabricated strainer housing

The housing on the fabricated strainer will also depend on the application and efficiency of the system.

There are two main systems of housing as follows:

Simplex basket strainer

This type of strainer will require housing that is easy to access the basket strainer inside.

This is because it requires constant cleaning from time to time and should be easily accessible.

The housing should also be strong enough not to allow leakages of the fluid or solid matter.

Duplex basket strainer

The housing on this type of strainer should be able to separate the activity on one side from the other.

Duplex filter housing

This will make it easy for the cleaner to clean one side as the other side is still in operation.

This kind of system will not allow you to switch off the machine for cleaning purposes.

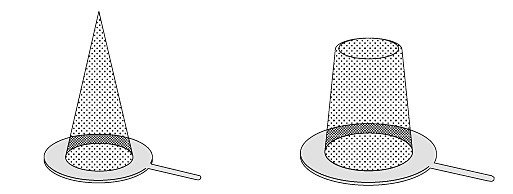

Fabricated screen type

There are two main screen types that you will find in a fabricated strainer as follows:

i. Fabricated strainer with a perforated screen

This type of screen is often available in systems that have solid impurities that are fairly large.

It will be able to contain such impurities well and clean the fluid as it flows through.

The pore sizes also vary depending on the type of application.

In case the perforations on the screens are wide, then the fluid has to have larger solids.

If they are small, then the fluid should have smaller solids and impurities that will not pass through.

ii. Fabricated strainer with a mesh screen

Mesh screens are for the fluids that have very small impurities that will not pass through the mesh.

The fluids are also supposedly gases and steam that contain very tiny pieces of solid matter.

Filters vs. Fabricated Strainers – An Ultimate Comparison

You can use the filter and the strainer in the cleaning of fluids usually liquids, gases and steam.

They work under similar principals, but the size of the impurities they take care of will vary.

Strainers will take care of impurities that are large while the filters will filter the very small sizes of impurities.

Do you want to purchase a device to help you in cleaning fluids in any application?

You should be able to have a clear picture of the size of impurities you intend to filter.

This will help you get a clear picture of the device that you are going to use.

To drive the point home, you should use the strainers for particles that you can see with your eyes.

It is more suitable for particles that are larger than 50 microns in size.

Filters, on the other hand, are suitable for filtering [particles that are smaller than 150 microns.

The design for the pipeline strainers does not have any seals and will ensure retention that is lower than 100 mesh.

If you need retention of particles that are lower than 100 mesh, then look for a filter.

The major difference is in the nominal and the absolute retention factors.

Filters will rely on non-alloy or elastomeric seals to prevent the passing of elements in fluids.

Strainers, on the other hand, will rely on metal to metal type of seal between the housing and the element.

Strainer basket

Membrane filters

These factors mark the greatest differences you will note in the simplest of ways.

The design of the fabricated strainers is very simple and easy to make thus lowering the cost.

The design on the filters is, however, quite complicated and increases the price of the filters.

Many people prefer the fabricated strainers, but you should look at your applications first.

There are certain exceptions when you can use fabricated strainers in particles that are lower than 100 microns in size.

This is the situation when the filter will cause a snarl up in the flow of the fluids causing a block.

It is efficient in applications that have very few impurities that the fabricated strainer can take care of perfectly.

The filters and the fabricated strainers can be left to clean off the impurities automatically especially in duplex designs.

You can apply self-cleaning in situations when the personnel are not enough to replace and clean the elements.

There are different designs available for both filters and fabricated strainers to have minimal differential fluctuations of the pressure.

The designs are also suited for the reduction in loss for the pressure fluids.

FilSon Filters Fabricated Strainers – Your Perfect Partner for Filtration Systems

FilSon filters are one of the best manufacturing companies that available that produce fabricated strainers and supply them all over.

They have some of the best personnel in the world with enough experience in manufacturing fabricated strainers.

The company has trainees working under the guidance of experts to gain the knowledge for future advancements.

It has various publications and booklets which they freely give to customers to learn about their services.

They have a customer care service open 24/7 to assist you with any inquiries on fabricated strainers.

You can also call in and reserve an appointment for a personal talk with their experts on certain ideas.

They are also available online with information on how you can purchase the products they produce.

Information on how you can install and replace the fabricated strainer is also available for free.

Conclusion

You are now in a better position to make the right choice when it comes to purchasing fabricated strainers.

You have the freedom of making a custom design of the fabricated strainer for personal use in different sectors.

Wait no more, pick up your phone and call the manufacturer so that he can meet the demands you have.