Remarkable Stainless Steel Filter Mesh for Filtration and Separation

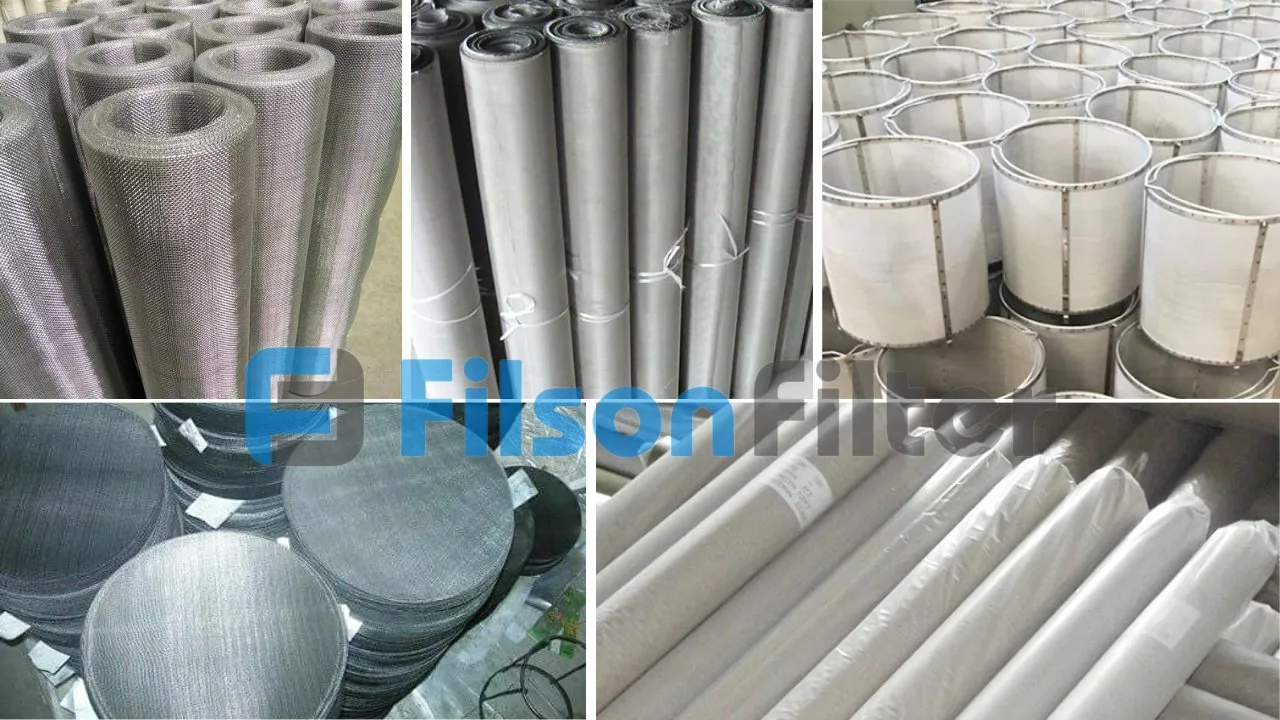

Filson is a professional filter vessel and filter elements manufacturer in China. We strive to provide high-quality products to our customers worldwide. In addition to fine-finished filtration products, we also have semi-finished products for sale, like stainless steel filter mesh.

Filson stainless steel filter mesh, with different patterns, can be applied in a wide range of both domestic and industrial fields, such as food and beverage, chemical and petrochemical industry, pharmaceutical industry, water treatment.

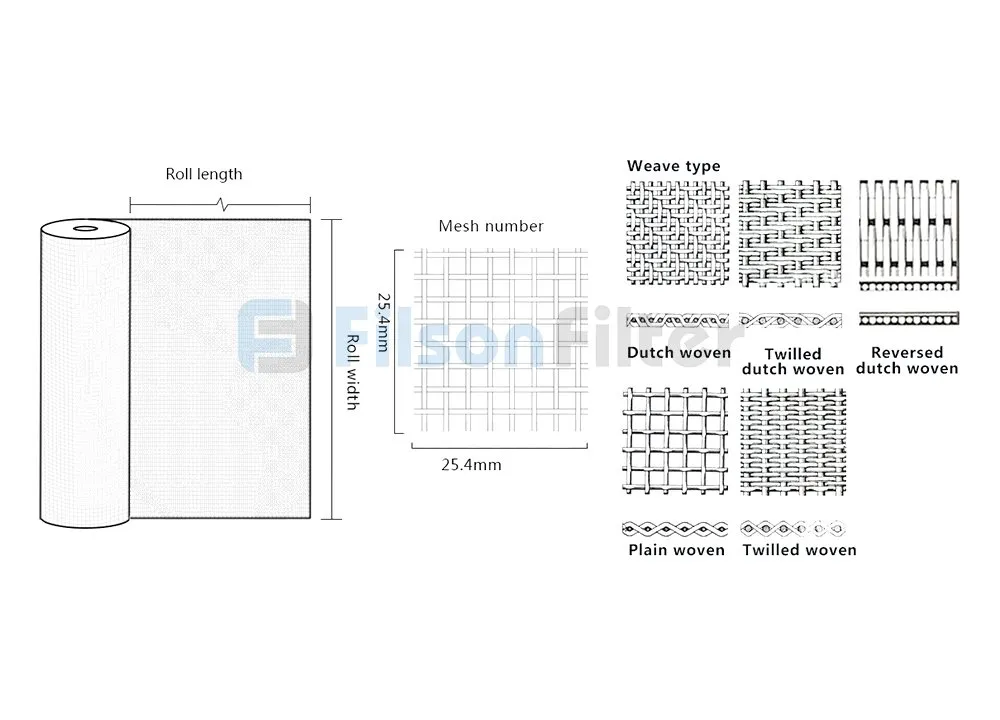

Filson provides stainless steel filter mesh in standard and custom sizes, so it’s available for you to customize filter mesh in different sizes. The size and distribution of the holes are decided by selecting different wire diameters, aperture sizes, mesh layers, and weaving methods of the wire mesh.

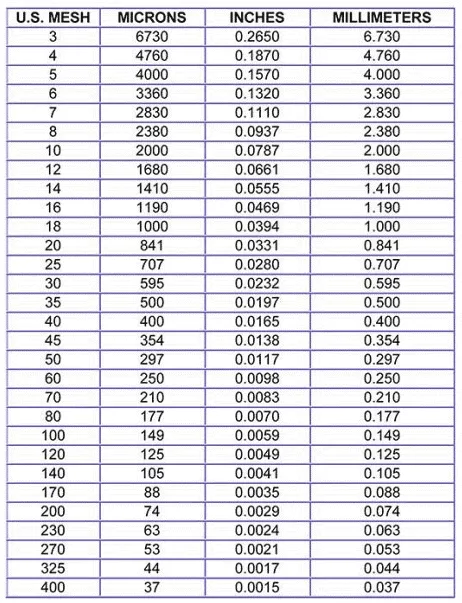

Leave your specifications mentioned above for stainless steel filter mesh, our specialized engineering sales will contact you in 8 working hours. The specific filter mesh size chart is as follows, you can choose the optimal one according to your requirements.

Filter Mesh Size Chart

Stainless Steel Filter Mesh

Why Filson Stainless Steel Filter Mesh

Filson has rich experience in designing and manufacturing in the field of industrial filtration. We have established a complete line of manufacturing and processing to provide professional stainless steel filter mesh for our customers all over the world.

Filson promises to be responsible to every customer from mesh design to operation instruction. All your filtration problems can be solved with the support of our seasoned specialists. Just send us your specifications, Filson will offer you a perfect solution.

Your Reliable Stainless Steel Filter Mesh Supplier in China

Filson has focused on industry filtration and filter elements for over 20 years. During these years, production and development, we have established a complete line of foreign trade. With qualified products and superior service, our products have been exported worldwide to America and Europe Areas and gained great reputation from local customers.

As one of the best stainless steel filter-mesh manufacturers and suppliers in China, Filson is committed to providing products with optimal raw materials. Our most common types of stainless steel mesh used for filter include stainless steel 304, 304L, 316, 316L, 321, 314, 430, and 904L.

Filson Stainless Steel Filter Mesh

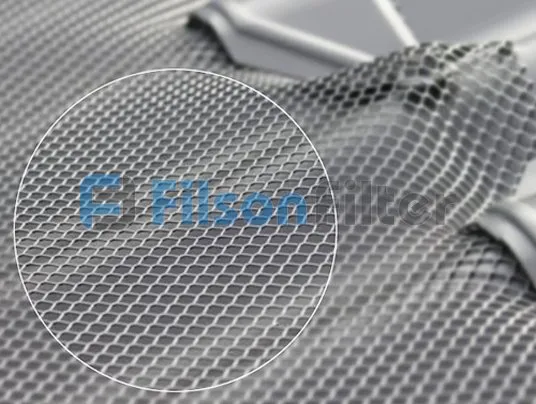

Filson stainless steel filter mesh is used to remove unwanted particles from different types of fluids. The raw material, stainless steel, is an alloy of iron and chromium which has excellent temperature and corrosion resistance. And the chromium in stainless steel can produce an oxide layer on the surface to protect and prevent the filter mesh from further corrosion.

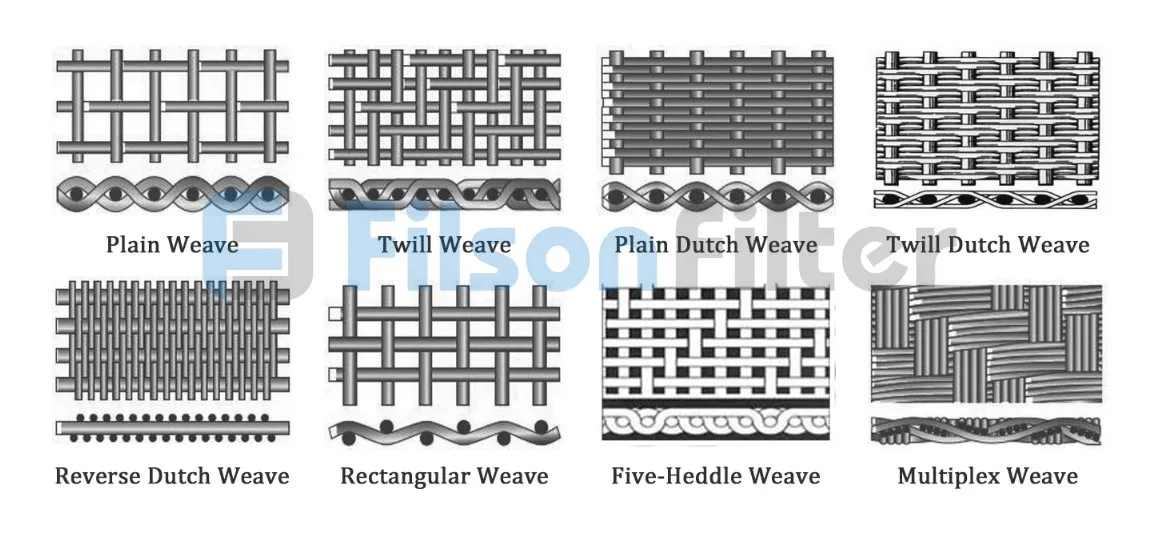

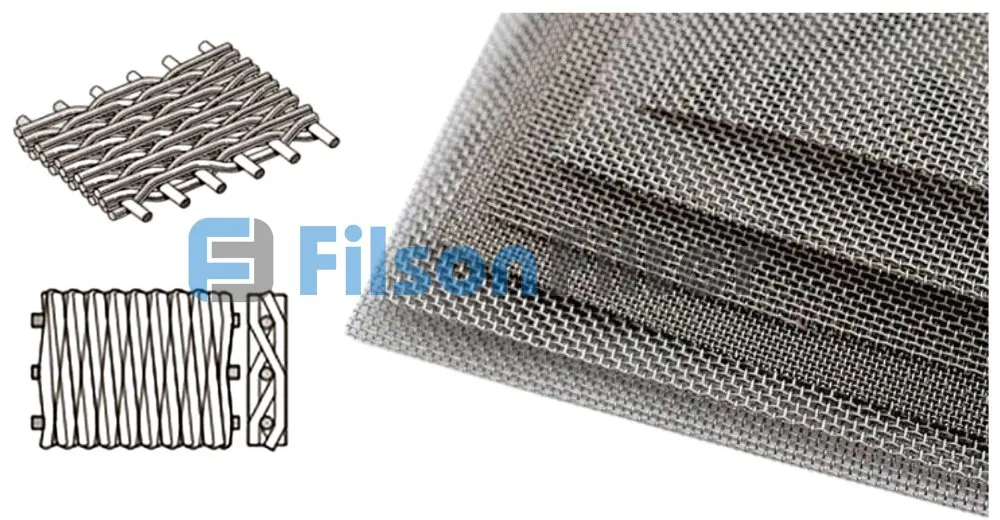

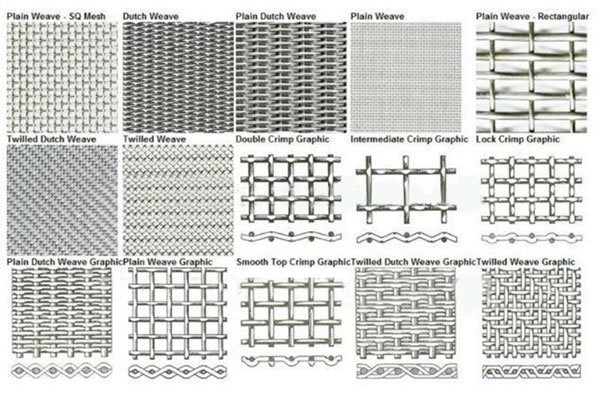

Filson Stainless Steel Wire Mesh Woven Types

Filson provides a variety of weave-type selections for stainless steel filter mesh. The common weaving types include plain weave, twill weave, oblong/broad weave, plain dutch weave, twill dutch weave, reverse dutch weave, 3-heddle weave, 5-heddle weave, and 3-heddle twill dutch weave.

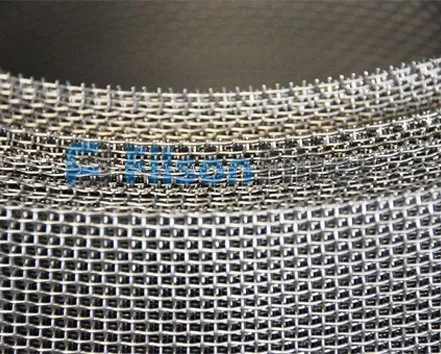

Plain Dutch Weave Stainless Steel Wire Mesh

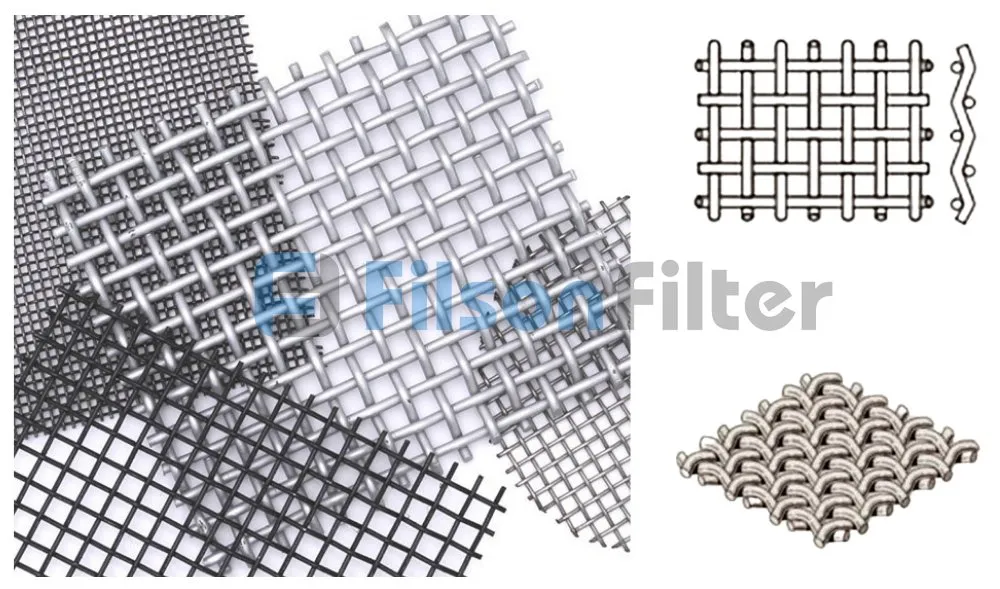

Among those weave types, plain weave is the simplest and most commonly used type with square openings for Filson stainless steel filter mesh. Though all weave types look similar, they are totally different patterns. And the differences in aperture size and wire diameter decide the filtration accuracy of the finished filter mesh.

Plain Weave Stainless Steel Wire Mesh

With various weaving types, Filson stainless steel is made into square weave wire cloth, woven filter cloth, and fabricated mesh. They are widely accepted throughout the industry to block and capture the unwanted contaminants in a filtration system, such as chemical, high viscosity liquids, and food & beverage industries.

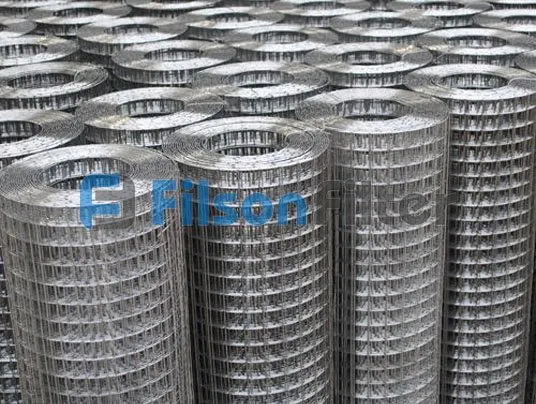

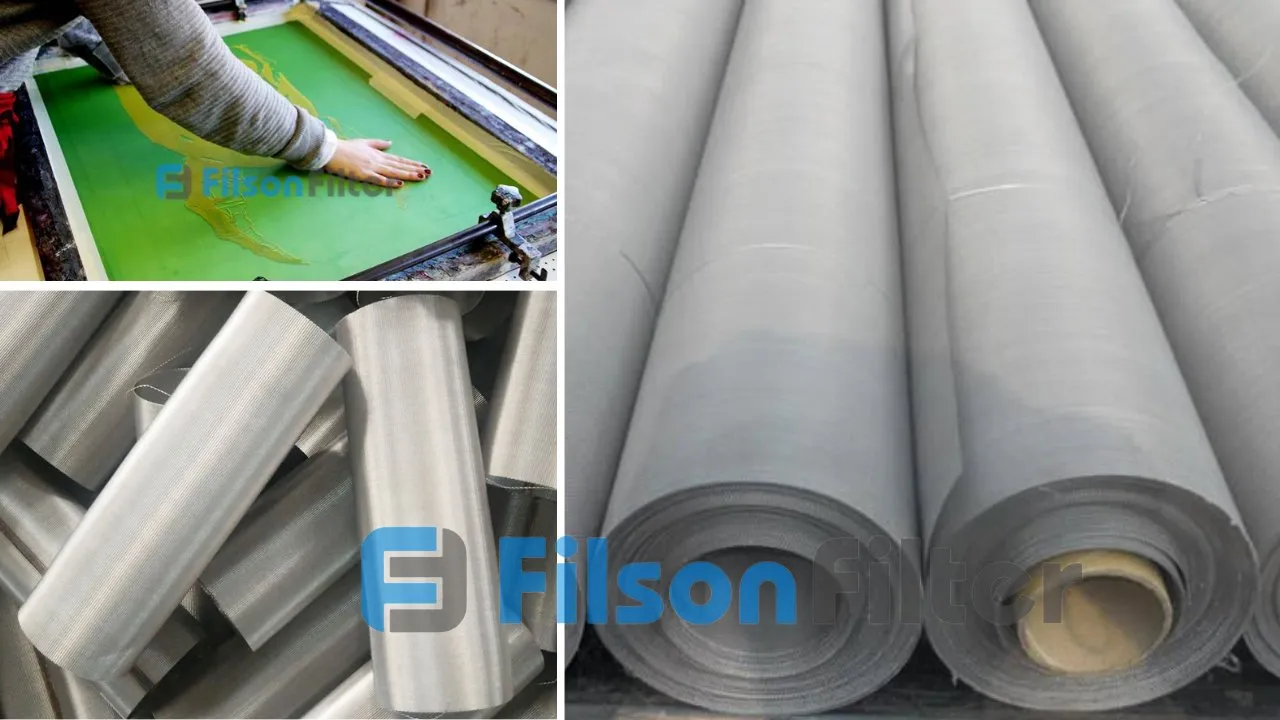

Stainless Steel Filter Mesh Package

Relying on a professional core team and advanced manufacturing technology, Filson produces stainless steel filter mesh with closely spaced wires to offer enhanced mechanical strength and a wide micron rating for industrial applications. You can customize different sizes of filter mesh from Filson for coarse or fine factors of filtration, up to your demands.

Stainless Steel Mesh Workshop and Warehouse

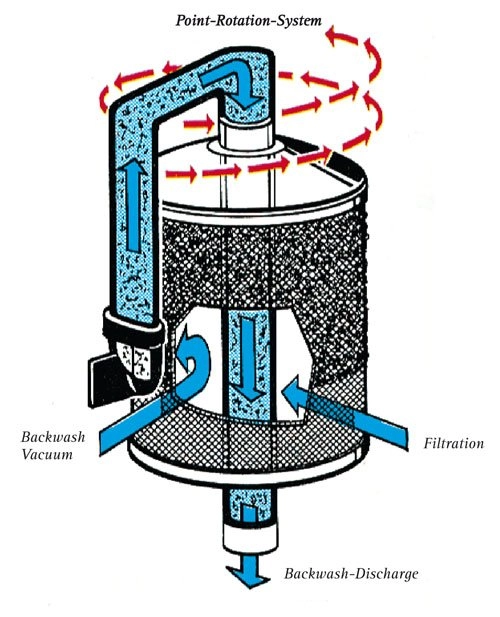

Filson stainless steel filter mesh can be cleaned easily. That ensures the filters have a long lifespan and can be reused for the long term. Besides, a well-designed structure allows the filter mesh to be back washed conveniently.

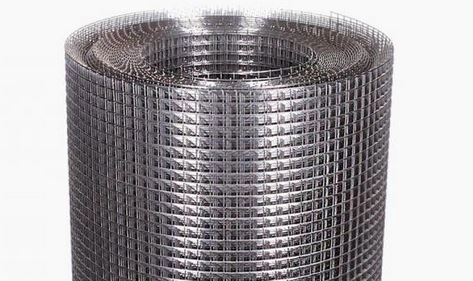

No matter for twill Dutch weave wire mesh or plain Dutch weave wire mesh, 304 stainless steel wire mesh or 316 stainless steel wire mesh, stainless steel sintered wire mesh or stainless steel welded mire mesh, and even for different shapes like stainless steel wire mesh roll or stainless steel wire mesh discs, Filson will always be your premier choice.

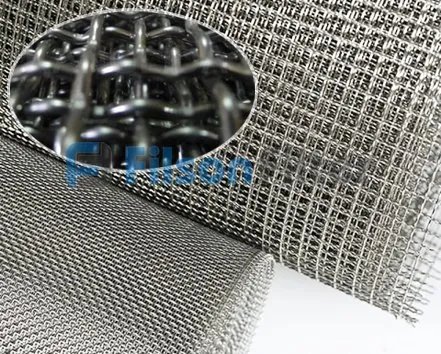

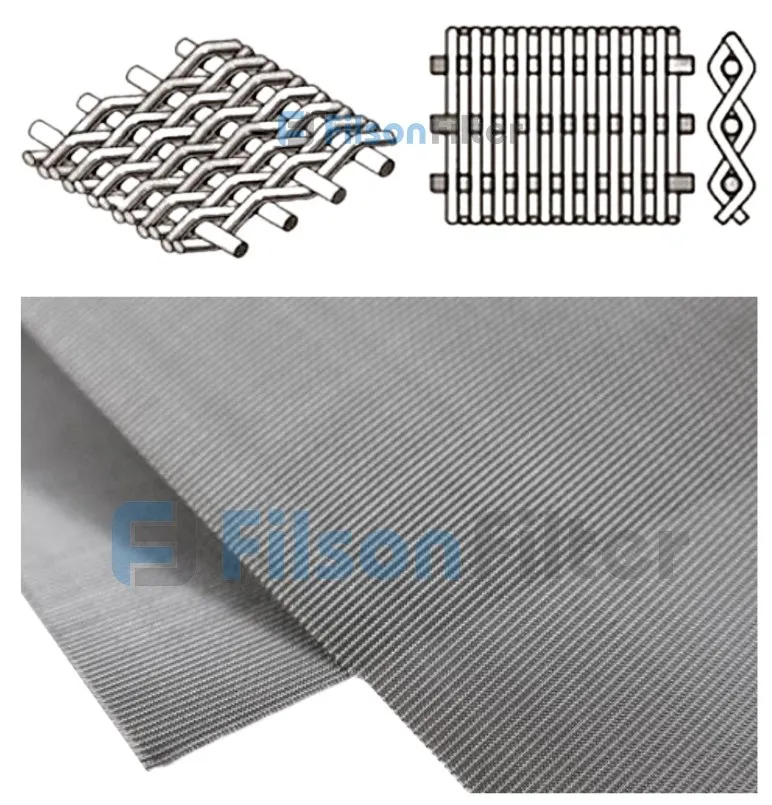

Stainless Steel Twill Dutch Weave Wire Mesh

Through our continuous efforts on production design and technical innovation, Filson has become your ideal stainless steel filter mesh supplier and advisor.

If you are looking for high-quality stainless steel filter mesh at a competitive price, then you are in the right place, contact us now by following ways:

Phone: +86-157 3695 8886

Email: sales@filsonfilters.com

Twill Weave Stainless Steel Wire Mesh

Filson Stainless Steel Filter Mesh Function

- To remove unwanted particles and contaminants from various fluids

- To replace traditional filter mesh under harsh environment

- To complete the filtration process efficiently

- To prevent other equipment in the system from being damaged by pollutants

- To provide different types of stainless steel filter mesh to fit customer request

Filson Stainless Steel Filter Mesh Feature:

- Strict quality control of stainless steel filter mesh passing ISO 9001 certification

- Compact structure for long-term use

- Enhanced mechanical strength with excellent durability

- Applicable under highly corrosive and thermal condition

- Unique designs for versatility in industrial fields

- Wide range of filtration ratings to avoid any size of particles

- Easy to clean and backwash

- Available to be designed and manufactured in custom type

- Aesthetic appeal for your application

Versatile Stainless Steel Filter Mesh from Filson

Filson Stainless Steel Filter Mesh Specification:

- Material: stainless steel 304, 304L, 316, 316L, 321, 314, 430, 904L, monel, hastelloy

- Type: dutch weave mesh, stainless steel sintered wire mesh, stainless steel welded wire mesh, food grade stainless steel mesh, heavy duty stainless steel mesh

- Shape: square, rectangular, circular or special shapes

- Operating Temperature: -200℃—600℃(upon material and request)

- Flitration Ratings: 1μm to 840μm

- Construction method: welded, sintered, woven

- Applicable Medium: oil, stream, water, gas

Filson Stainless Steel Filter Mesh Application:

- Metals and mining industry

- Water and waste management

- Chemical industry

- Pharmaceutical industry

- Food and beverage

- Industrial waste filtration

- High viscosity liquids

- Edible oil industry

- Sea-water desalination

People Also Ask

It refers to a type of filter mesh that is stainless-steel.

Its function is to filter unwanted contaminants from different types of fluids.

Filter Mesh

It is the size of the individual opening of the stainless-steel mesh filter.

It is normally in fractional inches and microns or millimeters.

A micron is twenty-five thousandth inches and a one-thousandth millimeter is one micron.

Filter Mesh Size

Yes.

You can clean a stainless-steel filter mesh.

The process involves choosing an effective detergent that does not react with the stainless-steel filter mesh.

The cleaning process involves the use of the backwashing process.

Backwashing involves the use of pressurized water that flows in reverse, that is, from the output to the input.

As it flows, all the contaminants that are present within the stainless-steel filter mesh flow out via the input.

This ensures that your stainless-steel filter mesh is always clean.

They include the following:

Stainless Steel Filter Mesh

Stainless Steel Filter Mesh

- Durability

Stainless steel mesh filter offers durability to your application.

This is because it does not react with different fluids.

Durability ensures that you have a maximum operation for your filtration process.

You also spend less on purchasing stainless-steel filter mesh.

- Versatility

You have a wide range of applications that you can use a stainless-steel filter mesh.

This is because of the unique features that stainless-steel filter mesh offers.

These features include their operating temperature and pressure, corrosion resistance, and compatibility with different fluids.

- Efficiency

Stainless steel filter mesh offers efficiency in its operation.

Efficiency ensures that you have the desired filtration of your fluid.

- Ease of cleaning

A stainless-steel mesh filter is easier to clean and therefore has a high hygienic property.

This ensures that you can use these filters in sensitive applications such as in the food industry.

The ease of cleaning ensures that the stainless-steel filters are always clean.

A stainless-steel filter mesh offers an aesthetic appeal for your application.

This increases its appearance as well as overall hygiene.

The number of microns that a given stainless-steel filter mesh should have depends on various factors.

These factors include:

Efficiency

The efficiency of your Stainless-steel filter determines the number of microns that it should have.

Having too many microns may affect its efficiency.

Of course, this is a fundamental aspect of all filter elements.

Type of Filtration

The type of filtration that you want for your application will determine the number of microns that your stainless-steel filter mesh should have.

If you are looking for a finer filtration process, you need to have numerous microns on your stainless-steel filter mesh.

Desired Results

The desired results determine the number of microns.

This is in the sense that if you are searching for a fine filtration process, you need to select a stainless-steel filter mesh with numerous microns.

Type of Fluid

Different fluids have different viscosity.

While searching for the number of microns that your stainless-steel filter should have, you need to check on the type of fluid that you are want to filter.

The higher the viscosity, the lower the number of microns that your filter mesh should have.

A stainless-steel mesh filter basket refers to the structure that holds the stainless-steel filter mesh in position during its operation.

They are important components for efficient filtration processes as they hold the filtrate.

You need to consider the following factors when choosing a stainless-steel mesh filter cartridge:

Wire Mesh Filter

Type of Stainless-Steel Mesh Filter Cartridge Material:

There are different types of stainless-steel mesh filter cartridges available.

Each of these types offers different advantages and is ideal for different purposes.

It is therefore important to check on the individual properties of the stainless-steel mesh filter cartridge before you select it for your use.

Such properties include the temperature and pressure limits and the reactivity to other elements and conditions

Mesh Filter Cartridge Number

The mesh filter cartridge number of openings in a stainless-steel filter mesh per inch.

If the mesh number is large, it implies there are many openings per inch of the stainless-steel mesh.

It also implies that the individual size of these openings is small.

The Mesh Filter Cartridge Size

The mesh size refers to the size of the individual opening of the stainless-steel mesh filter.

It is normally in fractional inches and microns or millimeters.

A micron is twenty-five thousandth inches and a one-thousandth millimeter is one micron.

Strand Diameter

The strand diameter is a critical component in selecting a Stainless-steel filter mesh.

If a wire mesh has a thicker strand diameter, it implies that it has small mesh openings.

The large the surface area that the diameter of the strands takes, the higher the mesh number for your stainless-steel filter mesh.

The strand diameter is a percentage of the stainless-steel total surface area.

That is the Percentage Open Area.

If you have a higher Percentage of Open Area, it implies the stainless steel has a great flow.

The Filament Diameter

The filament diameter has an effect on the Percentage Open Area and the mesh opening.

Fluid Compatibility

The stainless-steel filter mesh should be compatible with the fluid that you are going to filter.

This ensures that there is no reaction between the fluid and the stainless-steel filter mesh.

Any reaction affects the quality of the filtration process.

Filter Mesh Form Type

This filter mesh comes in different forms and sizes.

Among the common types include dome, conical and cylindrical filter mesh.

The choice of which stainless-steel filter mesh to select depends on the application and the desired results.

Some of the advantages are:

Stainless Steel Filter Mesh

Durability

Stainless steel mesh filter offers durability to your application.

This is because it does not react with different fluids.

Durability ensures that you have a maximum operation for your filtration process.

You also spend less on purchasing stainless-steel filter mesh.

Versatility

You have a wide range of applications that you can use a stainless-steel filter mesh.

This is because of the unique features that stainless-steel filter mesh offers.

These features include their operating temperature and pressure, corrosion resistance, and compatibility with different fluids.

Furthermore, there are different sizes of stainless steel filter mesh that you can use for your application.

Efficiency

Stainless steel filter mesh offers efficiency in its operation.

Efficiency ensures that you have the desired filtration of your fluid.

Ease of Cleaning

A stainless-steel mesh filter is easier to clean and therefore has a high hygienic property.

This ensures that you can use these filters in sensitive applications such as in the food industry.

The ease of cleaning ensures that the stainless-steel filters are always clean.

Aesthetic appeal

A stainless-steel filter mesh offers an aesthetic appeal for your application.

This increases its appearance as well as overall hygiene.

They include:

Cost

The initial cost of purchasing the stainless-steel mesh filter is relatively high.

This implies that you need to prepare adequately before purchasing one for your use.

Frequent Maintenance

The use of a stainless-steel mesh filter requires frequent maintenance procedures.

This includes frequent cleaning and removal of dirt.

Such a process can be time and resource-consuming.

The common weaving types for Stainless-Steel filter mesh are:

Weaving Types for Filter Mesh

Plain Weave

This type of weaving involves passing wrap wires alternately over and underwires that run traversed through at a right angle to the cloth.

It is a common method of weaving stainless-steel filter mesh as you can use it in a wide range of applications.

Twilled Weave

Twilled weaving involves the passing of the wire strands under and over two warp wires.

This method offers a heavier wire strand count over the plain weave.

It is ideal for greater loads and also if you want a finer filtration solution for your application.

Dutch Plain Weave

The use of course wire strands and fine mesh that has a relatively small wire within the fill.

It features a great-strength stainless-steel filter mesh that has fine openings.

Its primary application is as a filter cloth.

Dutch Twilled Weave

This weaving stainless-steel filter mesh combines both the Dutch plain weave and the twilled weaving methods.

It uses different latitude and longitude threads and also has a different number of wires meshes.

The filter mesh strands alternately pass over and under two warp strands.

This forms a coarse mesh in one direction and a fine mesh in the other direction.

It can support heavier loads than a Dutch plain weave and offers finer openings when you compare it to a twilled weave.

Reverse Weave

This type of weaving utilizes coarse mesh wires strands in wrapping and fine wire mesh wire strands for filling the spaces.

It features great strength and fine openings.

Its primary use as a filter cloth with the positioning and shape of the openings facilitates particle retention while enhancing the filtration process.

Basically, these are some of the weaving methods for filter mesh.

Some of these features include:

i. Water Resistance

A stainless-steel filter mesh has a water resistance feature that makes it waterproof.

This way, there is no contamination of water and the fluid within the stainless-steel filter mesh.

Using it ensures you get quality results for your filtration needs.

ii. Heat Resistance

Given the operational temperature of different fluids, the stainless-steel filter mesh must be able to withstand extreme temperatures.

This feature helps in applications that would have otherwise been impossible to filter.

iii. Chemical Resistance

Different fluids have different chemical components.

An effective stainless-steel filter mesh should not react with the different chemical compounds.

This helps in an efficient filtration process without the need to worry about the reaction of the fluid with the stainless-steel filter mesh.

iv. Corrosion Resistance

The stainless-steel filter mesh should not corrode as a result of a reaction with the fluid that you are filtering.

Corrosion affects the durability of your stainless-steel filer mesh and the final product of your filtration.

v. Durability

Durability allows for the use of your stainless steel for a longer duration without affecting its quality performance.

The inert nature of stainless steel makes it durable for use while ensuring maximum efficiency.

vi. Aesthetic Appeal

The shiny nature of stainless steel allows for the stainless-steel filter mesh to have an aesthetic appeal that attracts individuals.

vii. Easy to Clean

An effective stainless-steel filter mesh should always e clean.

This is because of the sensitive fluids that require filtration.

For example, in the food industry, slight contamination harms the final product.

The ease of cleanliness ensures that the stainless-steel filter mesh always remains clean.

The common areas of application are:

Mining Industry

the use of Stainless-Steel filter mesh plays a critical role in the mining industry.

Its function is to separate minerals from their organic cores.

This allows for the extraction of pure minerals such as gold and diamond.

They also help in filtering the sludge to avoid environmental pollution.

Chemical Industry

In the chemical industry, the importance of Stainless-Steel filter mesh is to allow for proper mixing and filtration of the various chemicals.

This enables the final products to meet the required chemical levels and standards.

Proper chemical filtration prevents the negative effects of having the wrong chemicals on the final product.

Food Industry

Stainless-Steel filter mesh is of common use in the food industry as it aids in the manufacturing of consumer-friendly foods.

In soft drinks, they are used in the filtration of chemicals and fruits to get the required proportions.

In the manufacture of confectionaries, the use of Stainless-Steel filter mesh helps in removing impurities.

Pharmaceutical Industry

Drugs are sensitive substances that require an appropriate manufacturing process.

The use of Stainless-Steel filter mesh helps in the filtering of unwanted particles and compounds in the drug manufacturing process.

Industrial Waste Filtration

Stainless-Steel filter mesh helps in removing harmful chemicals and unwanted particles from the water before allowing it to flow back to the system.

Water filtration offers maximum water usage through recycling.

You need to consider the following parameters when selecting a stainless-steel filter mesh:

Stainless Steel Filter Mesh

The Construction Types

The type of construction for your stainless-steel filter mesh determines which one you are going to select.

The common types include the sintered mesh, photo-etched media, and laminated stainless-steel filter mesh.

The type of application and the desired outcomes determine which stainless-steel construction type to select.

Type of Stainless-Steel material

There are different types of stainless steel available.

Each of these types offers different advantages and is ideal for different purposes.

It is therefore important to check on the individual properties of the stainless steel before you select it for your use.

Such properties include the temperature and pressure limits and the reactivity to other elements and conditions

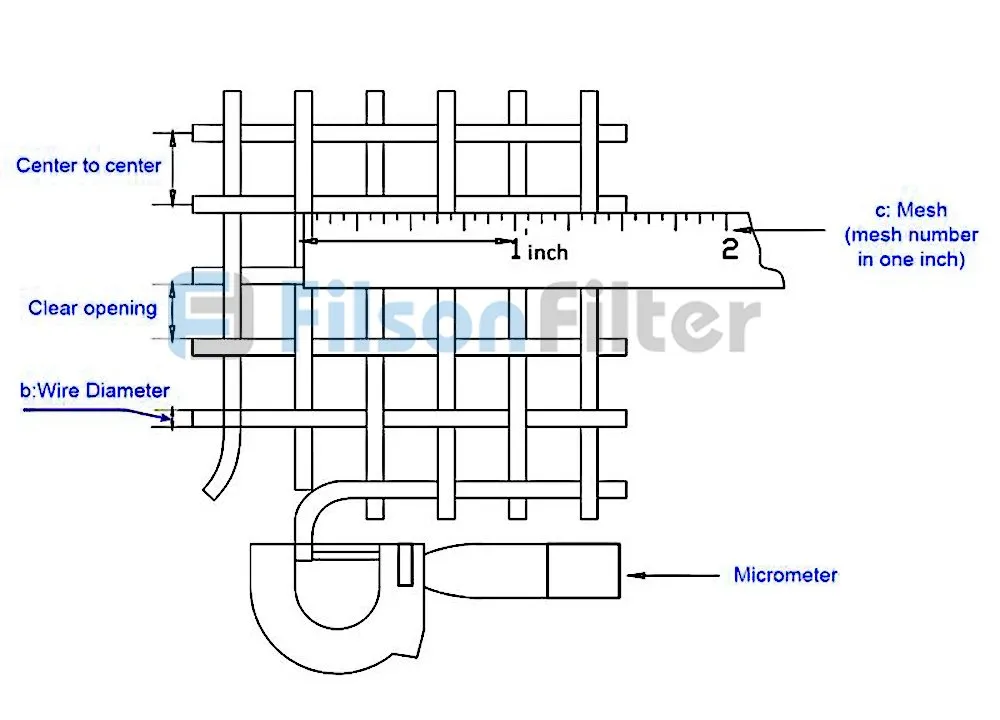

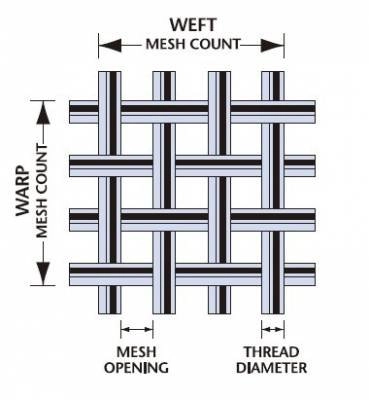

Mesh Number

The mesh number of openings in a stainless-steel filter mesh per inch.

If the mesh number is large, it implies there are many openings per inch of the stainless-steel mesh.

It also implies that the individual size of these openings is small.

The Mesh Size

The mesh size refers to the size of the individual opening of the stainless-steel mesh filter.

It is normally in fractional inches and microns or millimeters.

A micron is twenty-five thousandth inches and a one-thousandth millimeter is one micron.

Strand Diameter

The strand diameter is a critical component in selecting a Stainless-steel filter mesh.

If a wire mesh has a thicker strand diameter, it implies that it has small mesh openings.

The large the surface area that the diameter of the strands takes, the higher the mesh number for your stainless-steel filter mesh.

The strand diameter is a percentage of the stainless-steel total surface area.

That is the Percentage Open Area.

If you have a higher Percentage of Open Area, it implies the stainless steel has a great flow.

The Filament Diameter

The filament diameter has an effect on the Percentage Open Area and the mesh opening.

Fluid Compatibility

The stainless-steel filter mesh should be compatible with the fluid that you are going to filter.

This ensures that there is no reaction between the fluid and the stainless-steel filter mesh.

Any reaction affects the quality of the filtration process.

Stainless-steel Filter Mesh Form Type

A stainless-steel filter mesh comes in different forms and sizes.

Among the common types include dome, conical and cylindrical filter mesh.

The choice of which stainless-steel filter mesh to select depends on the application and the desired results.

Yes.

You can clean a stainless-steel filter mesh.

The process involves choosing an effective detergent that does not react with the stainless-steel filter mesh.

The cleaning process involves the use of the backwashing process.

Backwashing involves the use of pressurized water that flows in reverse, that is, from the output to the input.

As it flows, all the contaminants that are present within the stainless-steel filter mesh flow out via the input.

This ensures that your stainless-steel filter mesh is always clean.

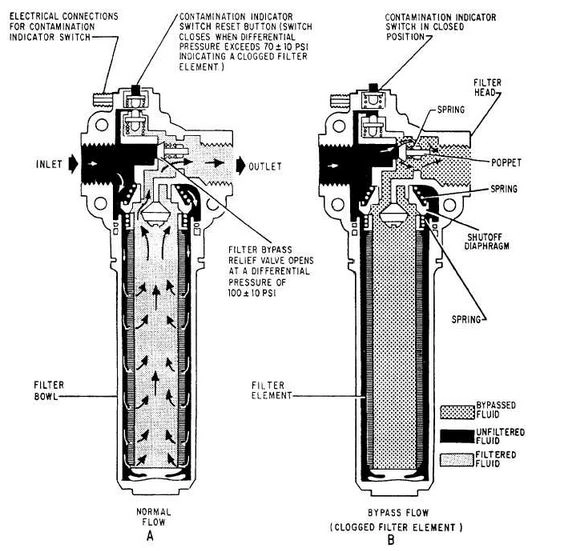

The working of a Stainless-steel filter mesh involves understanding its input and outpoint.

The connection between these two points appropriately is key to ensuring functions appropriately.

Working of Filter System

The fluid for the filtration process flows through the filter casing into a suction segment.

As it flows, the filter mesh traps and holds the unwanted particles.

This process continues until the filter basket is full, and cannot hold more contaminants.

It is at this point that you remove the filter basket and drain off the contaminants.

You can either pause the operation to clean the filter mesh basket or you can clean the basket simultaneously while the operation continues.

This depends on the type of stainless-steel filter mesh that you are using.

The filtered fluid flows out through the outlet and is ready for use depending on your application.

Pressure plays a critical part in ensuring there is effective filtering of the fluid.

The main metal grades for the manufacturing of Stainless-Steel filter mesh are:

- Stainless-steel 304 filter mesh consists of chromium and nickel metals which are non-iron elements.

- Stainless-steel 304L filter mesh has a higher amount of carbon content when compared to stainless-steel 304.

- Stainless steel 316 filter mesh consists of chromium, nickel, manganese, carbon, and silicon elements.

- Stainless steel 316L filter mesh has a lower amount of carbon when compared to stainless-steel 316 filter mesh.

Yes.

Other systems can replace stainless-steel filter mesh in their operations.

However, stainless-steel filter mesh is the best option given its quality and versatile uses.

You need to consider the following factors when selecting a stainless-steel filter mesh housing:

Mesh Filter in The Filter Housing

Construction Material

The different types of stainless steel available offer a wide range to select from depending on the application.

When selecting the type of stainless steel to use, you need to consider the environmental condition, the durability of the material, and its reliability as well as efficiency.

Flow Rate

The flow rate refers to the `rate at which the fluid flows through the stainless steel.

A high flow rate increases the efficiency of your filtration up to a certain level beyond which it will affect its quality.

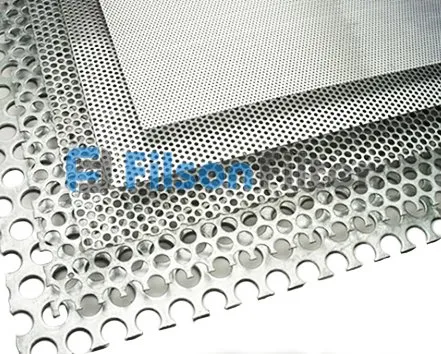

Stainless Filter Mesh Perforations

The perforation of your stainless-steel filter mesh affects the efficiency of your stainless-steel filter mesh.

Perforation comes in different diameters that allow you to select depending on the desired filtration process.

Diameter of the Inlet and Outlets

The diameter of the inlet and outlet of the stainless-steel filter mesh should be compatible with that of your application.

There should be no leakage when connecting during these applications for efficient operation.

Working Temperature and Pressure

Different applications have different working temperatures and pressure.

This can affect the efficiency of the stainless-steel filter mesh.

The temperature and pressure of the stainless-steel filter need to be able to handle the working temperature and pressure of your application.

The manufacturing process for your stainless-steel mesh filter involves the following processes:

Testing of the Materials

This involves testing the quality of materials that you are using for the manufacture of the stainless-steel mesh filter.

These materials include the type of stainless steel that you are going to use.

Wire Testing

Wire testing involves testing the wire strands that you are going to use when weaving the stainless-steel mesh filter.

Channel Regulations

It involves regulating the parameters, including the micron size and number.

It is a process that sets the parameters in place before the manufacturing process begins.

Weaving

There are different methods of weaving, depending on the application of the stainless-steel mesh filter.

The choice of which weaving method depends on the client’s specifications.

Quality Testing

This process involves testing the quality of the stainless-steel mesh filter.

It assures that the product meets all standards and is ready for use.

At this point, am sure you should be able to make an informed decision on the best stainless steel filter mesh you need.

Pay attention to every aspect of these stainless steel filter mesh and you will never regret it.