Filson Indirect Heat Exchangers

- High heat transfer efficiency

- Reasonable structure for long time use

- Easy to clean and repair

- Available to save energy cost

- Specifications

- Send Us Inquiry

Filson has rich experience in designing and manufacturing heat exchangers including indirect heat exchangers. They effectively transfer heat between two kinds of fluids to realize the energy savings.

- Material: stainless steel, carbon steel, duplex stainless steel, cemaric, plastic and more

- Media type: oil, water, air, gas

- Working temperature: under 450℃(up on material and type)

- Working pressure: under 6.4MPa

- Flow rate: 25L/min(depending on fluid type)

- Heat transfer efficiency: 2.80% to almost 100%

- Heat exchange area: 1 – 800㎡

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Indirect Heat Exchangers

Your Best Indirect Heat Exchangers Supplier in China

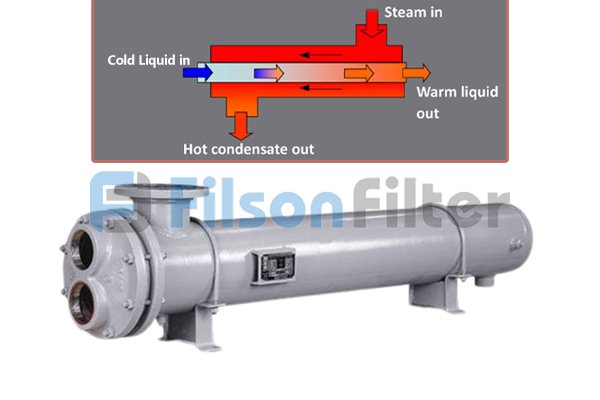

Filson indirect heat exchangers realize a non-contact operation during the heat transfer process. That means the two different fluids with different initial temperature will not contact directly or mix together.

Filson indirect heat exchangers use tubes or plates to implement the indirect contact. The involving types consist of plate heat exchangers, shell and tube heat exchangers, finned tube heat exchangers, double pipe heat exchangers, etc.

Filson, as a professional indirect heat exchanger manufacturer, promises to provide the best quality heat exchangers for our customers.

Contact us today and get an instant quote for an indirect heat exchanger!