Filson Direct Contact Heat Exchanger

- Advanced software for thermal and mechanical calculations

- Simple structure for operation

- Easy cleaning, maintaining and replacing

- Sophisticated CAD design

- Specifications

- Send Us Inquiry

Filson is committed to manufacturing the highest grade quality heat exchangers for our customers all over the world. Basically, Filson heat exchanger can be divided into indirect heat excahnger and direct contact heat exchanger.

- Material: stainless steel, carbon steel, duplex stainless steel, cemaric, plastic and more

- Media type: oil, water, air, gas

- Working temperature: under 450℃(up on material and type)

- Working pressure: under 6.4MPa

- Flow rate: 25L/min(depending on fluid type)

- Heat transfer efficiency: 2.80% to almost 100%

- Heat exchange area: 1 – 800㎡

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Direct Contact Heat Exchanger

Professional Direct Contact Heat Exchanger for the Application

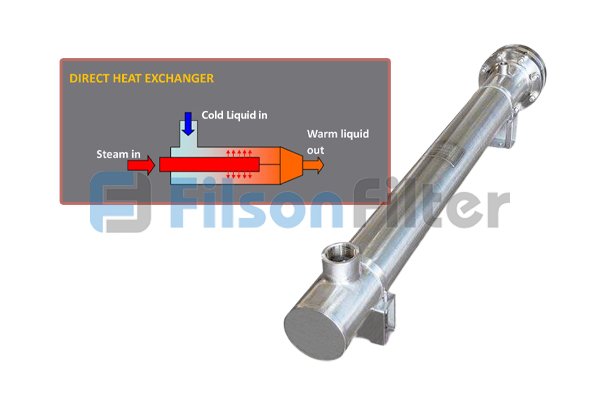

The media in a Filson direct contact heat exchanger must be two immiscible fluids. And during the heat transfer process, they are brought into contact at different temperature. Then, the hotter fluid cools down and the cooler fluid heats up.

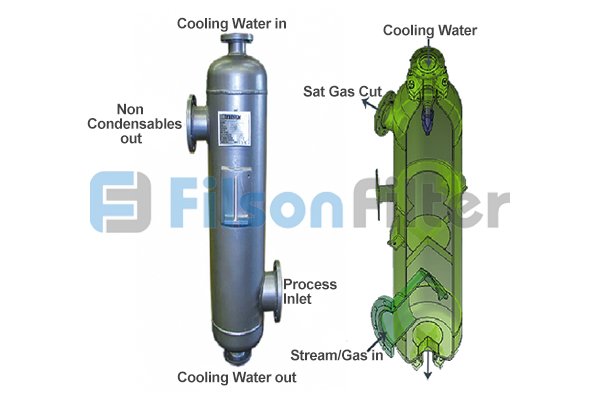

Filson direct contact heat exchanger involves heat transfer between hot and cold streams of two phases without a separating wall. So this kind of heat exchanger can be classified as gas-liquid, immisicible liquid-liquid, solid-liquid and solid-gas.

Filson direct contact heat exchanger is mostly applied to air conditioning, humidification, industrial hot water heating, water cooling and condensing plants.

Don’t hesitate to contact us, our specialists will solve all your problems.