Filson Finned Tube Heat Exchanger

- Increased heat transfer area

- Professional and custom design

- Excellent performance for heat transferring

- Maximum efficiency with minimum energy waste

- Specifications

- Send Us Inquiry

The overall heat transfer efficiency is crucially determined by the surface area of the heat exchanger. Filson finned tube heat exchanger, as well as tube fin heat exchanger, is known for maximizing heat transfer surface area under a perfect design.

- Material: stainless steel, carbon steel, duplex stainless steel, aluminum and more

- Media type: oil, water, air, gas

- Working temperature: up to 450℃

- Working pressure: under 6.4MPa

- Flow rate: 25L/min(depending on fluid type)

- Heat transfer efficiency: 2.80% to almost 100%

- Heat exchange area: 1 – 800㎡

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

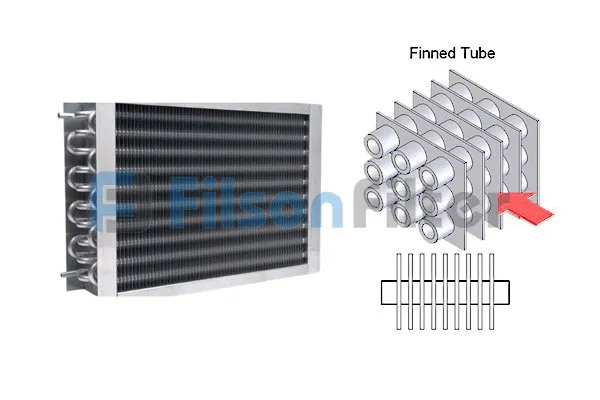

Filson Finned Tube Heat Exchanger

Superior Finned Tube Heat Exchanger for Heat Transfer

Filson finned tube heat exchanger, sometimes also called finned coil heat exchanger, consist of tubes and a dense fin stack surrounding the tubes. Fluid passes through the tubes and conducts heat to the fins, then the air receives the heat from fins.

Generally, Filson finned tube heat exchanger has an effect on air to liquids like air, water, oil or gas. In some occasions, it is used to capture or recover waste heat. It can applied to a broad range of industries such as oil and gas, power plant, marine, etc.

Filson and our highly skilled professional team have two decades of expertise in the design, manufacturing and maintenance of finned tube heat exchanger. We promise to deliver the best quality products for you.

Get in touch with us today to find out more.