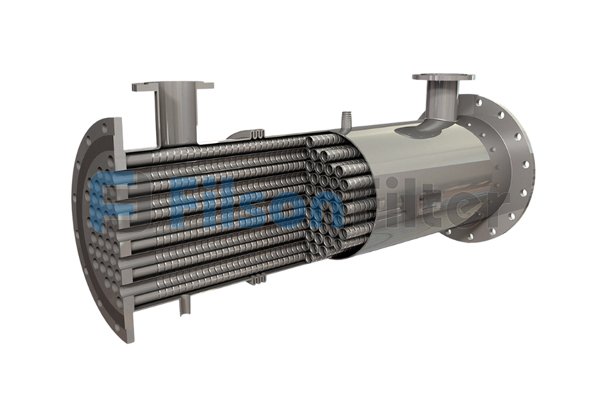

Filson Counter Flow Heat Exchanger

- Higher heat transfer efficiency

- Large flow rate

- Sophisticated CAD design

- Extensive industrial applications

- Easy cleaning and repairing

- Specifications

- Send Us Inquiry

Filson counter flow heat exchanger is also called counter-current flow exchanger. It has the opposite fluid direction for the flows and is classfied based on the flow arrangement. Plate, shell and tube, double pipe, one phase and multi-phase can be counter flow heat exchanger.

- Material: stainless steel, carbon steel, duplex stainless steel, cemaric, plastic and more

- Media type: oil, water, air, gas

- Working temperature: under 450℃(up on material and type)

- Working pressure: under 6.4MPa

- Flow rate: 25L/min(depending on fluid type)

- Heat transfer efficiency: 75-85%

- Heat exchange area: 1 – 800㎡

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Counter Flow Heat Exchanger

The Right Counter Flow Heat Exchanger for the Application

Filson counter flow heat exchanger can be made of different raw materials to meet customer various specifications such as stainless steel 304, stainless steel 316, carbon steel, aluminum, alloys, cemarics and even plastic.

Filson counter flow heat exchanger is the most commonly used flow configurations. It has the highest efficiencies for it allows the greatest amount of heat transference between two fluids resulting in greatest change of temperature. In another word, it has the highest efficiency.

Filson heat exchangers are featured with excellent performance and low cost, if you get interested in our product, please contact us immediately.