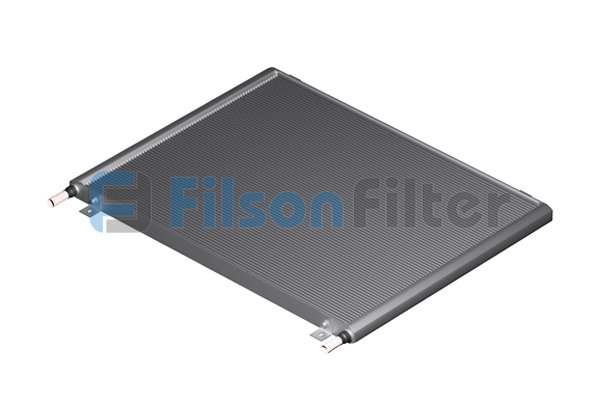

Filson Parallel Flow Heat Exchanger

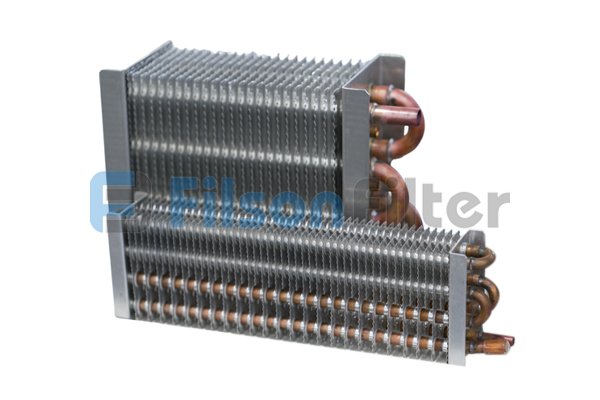

- Fine design to bring two fluids with nearly the same temperature

- Minimal freezing chance

- Custom design solutions to meet specific requirements

- High quality raw materials

- Specifications

- Send Us Inquiry

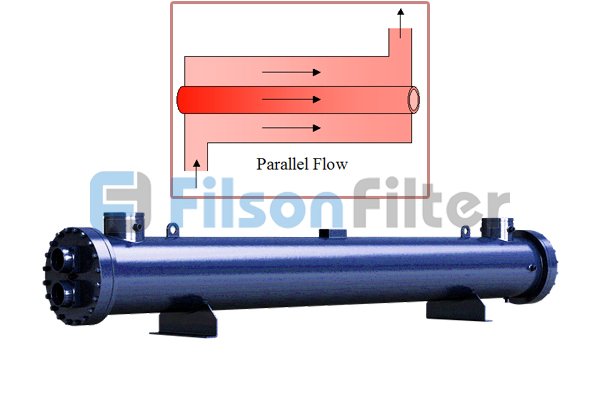

Filson heat exchangers may be extremely different in design and construction, but their operation and heat transfer efficiency is largely determined by the direction of the fluids flowing within the heat exchanger.

- Material: stainless steel, carbon steel, duplex stainless steel, cemaric, plastic and more

- Media type: oil, water, air, gas

- Working temperature: under 450℃(up on material and type)

- Working pressure: under 6.4MPa

- Flow rate: 25L/min(depending on fluid type)

- Heat transfer efficiency: below 70%

- Heat exchange area: 1 – 800㎡

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Parallel Flow Heat Exchanger

Your Best Parallel Flow Heat Exchanger

A parallel flow is the most common arrangement of the flow paths in a Filson heat exchanger, and it’s also called Cocurrent flow heat exchanger. In Filson parallel flow heat exchanger, the two fluids with different initial temperature flow in the same direction.

Generally, Filson parallel flow heat exchanger is less efficient than a counter flow heat exchanger in transferring heat from one fluid to the other. But, there are applications where parallel flow heat exchangers benefit a lot such as when limiting the transfer of heat is required.

Though parallel flow heat exchanger doesn’t perform so well as counter flow heat exchanger, it does provide more uniform wall temperatures.

Whatever your need is a parallel flow, counter flow or cross flow heat exchanger, Filson will try all efforts to satisfy your specifications.