Filson Recuperative Heat Exchanger

- Effective energy saving

- Focused on quality: ISO 9001

- Excellent performance in heat transferring

- Easy installation and cleaning method

- Specifications

- Send Us Inquiry

Filson recuperative heat exchanger is spcial energy recovery heat exchanger designing with counter flow arrangement. It mostly is installed within the supply and exhaust air stream of an air handling system. And sometimes, it is used in an industrial process to recover the waste heat.

- Material: stainless steel, carbon steel, duplex stainless steel, cemaric, plastic and more

- Media type: oil, water, air, gas

- Working temperature: under 450℃(up on material and type)

- Working pressure: under 6.4MPa

- Flow rate: 25L/min(depending on fluid type)

- Heat transfer efficiency: 2.80% to almost 100%

- Heat exchange area: 1 – 800㎡

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Recuperative Heat Exchanger

Certificated Recuperative Heat Exchanger for Whole World

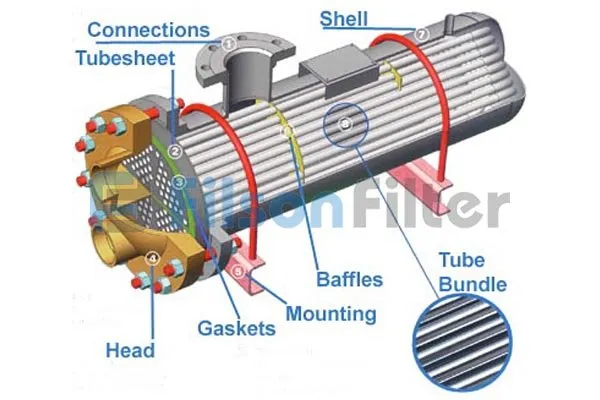

Filson recuperative heat exchanger has another common name as recuperators, is the basic and frequently-used heat exchanger. In a recuperative heat exchanger, each fluid flows simultaneously through its own channel.

Commonly, Filson recuperative heat exchanger is applied to extract and collect heat from exhaust gases, and then put it into use to preheat the air entering the combustion system. By doing this, the waste energy is fully utilized and offsets some of the fuel to save much energy.

Another type of heat exchanger is regenerative heat exchanger, also can be made in high quality by Filson. No matter you need a recuperator or a regenerator, Filson will always be your reliable supplier.