Your Reliable Titanium Filter Manufacturer in China

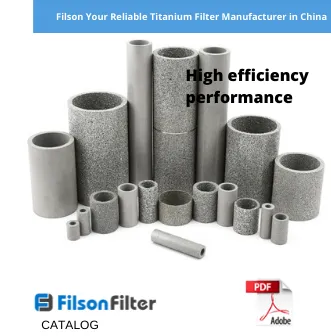

Filson titanium filter is a sintered porous media, sometimes also called titanium metal filter element or micropore titanium filter. It has unique performance and has become a very popular prospective new material currently.

Filson titanium filter, experiencing a series of strict manufacturing processes, has good properties and full capabilities to suit any applications associated with gases, heat, polymers, cryogenics, and aggressive chemicals.

If you are looking for a high-grade titanium filter, Filson has all the practical products you need. And whether you want to get information about the composition, benefits, applications, or other specifications, you will find everything here.

Filson Titanium Filter

Why Choose Filson Titanium Filter?

Filson has been exploring the infiltration field for more than 20 years since its establishment in 2001. We possess long-standing expertise in the manufacture of high precision and excellent performance titanium filters for critical applications.

As a quality-oriented manufacturer in China, Filson fabricates titanium filters in high specification. From the selection of raw material to every step of the production process, Filson gives top priority to the quality and efficiency of the filter.

Filson designs titanium filters totally according to customer specifications. Simply tell us your requirements and you will get an ideal titanium filter fitting your application. Plus, Filson provides the most professional guide for your product design calculation.

Filson core engineering team is always here and ready to help. All our staff including engineers, technicians, and workers are well-trained to support your titanium filter projects. With the powerful capability, we are confident to face all the challenges.

The Premier Titanium Filter Choice Serving Your Application

Filson titanium filter, using high purity titanium as the raw construction material, is a new type of porous filter media in the existing market. This kind of filter is made through a complex technological process including powder classification, molding, sintering, mechanical welding, machining, etc.

Choose the Right Titanium for Your Job

With optimized process conditions and strict quality control, Filson sintered titanium filter is endowed with high porosity of 35 – 50% and high filtration accuracy from 0.22 – 100 micron. And due to their flexible adjustment of them, the device is widely used for lubrication, filtration, separation, catalyzation, thermion, heat exchange, and gas distribution.

Filson exports titanium filters to the whole world to help develop your business. It is so versatile that it can be found in all sorts of industries and even university laboratories, such as the pharmaceutical industry, water treatment, bioengineering, and metallurgical industry.

Customizable Titanium Filter Housing

Filson has huge potential in titanium filter research, design, manufacturing, and testing. With rich experience in filtration, Filson now produces an extensive range of titanium filters including titanium filter mesh, titanium filter cartridge, porous titanium, titanium fiber felt, and titanium frit.

The material of the Filson titanium filter is composed of pure titanium which reaches a high purity of up to 99.6%. The rest 0.4% is titanium alloys, like nitrogen, hydrogen, iron, and manganese. Besides, many grades of titanium can be selected for use in diverse industries and applications, such as grade 1, grade 2, and grade 5.

Filson Titanium Filter Cartridge

Filson provides a custom service for our clients. Not only for the diameter, length, and accuracy but also for the shape can be customized at Filson. Regularly, Filson titanium filter is made into the cylinder. Other types like a disc, plates and rods can be produced by Filson.

The three main types of Filson titanium filter are titanium powder, titanium mesh and titanium felt. When comes to choosing the right filter for your application, take both economic benefits and practical effectiveness into consideration.

Flexible Design for Filson Titanium Filter

Filson titanium filter made of pure titanium powder has higher accuracy and better permeability, but it’s fragile and difficult to clean. As for titanium mesh, it is resistant to high pressure with good mechanical strength. While titanium felt is featured with the largest dirt holding capacity, also it’s the most expensive one.

There are some specific uses of Filson titanium filter listed below:

- Filson titanium filter element can be used as final filtration of infusion, small injection, eye drops, and other solutions in the pharmaceutical industry to ensure security.

- Filson titanium filter plays an important role in impurity removal, raw material decarburization, and fine filtration in the production process of raw materials.

- Filson titanium filter is also applied to ultrafiltration, RO, EDI system security filtration in the water treatment industry.

- Filson titanium filter elements can filter after ozone sterilization and ozone aeration.

- It helps achieve the clarification and filtration of beverages, liquor, beer, vegetable oil, mineral water, soy sauce, and vinegar in the food and beverage industry.

- At the same time, it is widely applied to the chemical industry to fulfill filtration and recovery.

- The equipment supports the crucial step of oilfield return water filtration and security filtration before reverse osmosis in the field of seawater desalination.

- In the dye industry, Filson titanium filter is used for high-temperature decarbonization and filtration.

- Besides, titanium filters can be used to filter steam, compressed air, and catalyst in gas purification.

Sintered Porous Titanium Foam

In addition to titanium filters, Filson provides products with a variety of materials in the sintering industry and filtration fields, such as stainless steel sintering, nickel-based alloys, and other high-temperature sintering materials.

Want a high-efficiency titanium filter? Filson is willing to be your best manufacturer and supplier in China. At Filson, you can find any sintered product you need to completely fit your system. Do not hesitate to contact us TODAY!

Filson Titanium Filter Function

- Solid, liquid, and gas separation and purification

- Final filtration in the pharmaceutical industry

- Contaminants removal in the production process

- Filtration after ozone sterilization, ozone aeration

- Clarification and filtration in food and beverage

- Steam, compressed air, and catalyst filtration in gas purification fields

Sintered Titanium Powder Filter Element for Water Treatment Aeration

Filson Titanium Filter Feature:

- Well constructed entirely of sintered titanium powder

- High corrosion resistance to suit any chemical conditions

- Cleanable and back washable for long time use

- Allowable for re-using to save purchasing costs

- Best filtration efficiency for maximum economy

- High-temperature sintering for compact structure

- Various gasket/o-ring materials and configurations

Filson Titanium Filter Specification:

- Raw material: pure titanium powder and titanium alloy

- Purity: more than 99.4%

- Filtration accuracy: 0.22 – 100 μm

- Working pressure: 0.5 – 1.5MPa

- Working temperature: 500 – 600℃ in the air ( usually 280℃ )

- Porosity: 35 – 50%

- Diameter: 30 – 80mm

- Length: 100 – 1000mm

Titanium Sintered Porous Filter for Water Treatment

Note: specifications listed above are for reference only, please consult Filson for more details.

Filson Titanium Filter Application:

- Pharmaceutical industry

- Water treatment industry

- Food and beverage industry

- Biological engineering

- Chemical industry

- Petrochemical industry

- Metallurgical industry

- Gas purification fields

- Military

People Also Ask

Titanium filter, also known as porous titanium filter or sintered titanium filter, is an industrial device used to filter, classify and purify gases or liquids. It is specially designed for applications involving extreme operating conditions and aggressive fluids.

Titanium filter is made of sintered titanium materials, usually, you can choose different grades of titanium to satisfy your unique application needs. Through a rigorous manufacturing process, the titanium filter is made rugged and stable with a fixed pore structure. The final product is able to withstand high heat, high pressure, high corrosion, and repeated cleaning and backwash cycles.

Filson Titanium Filter

Titanium, as a new well-developed material recently, becomes very popular in many fields. Please view titanium in comparison to other metals, the following characteristics make it so attractive to various industries:

- Titanium has a lighter weight than many other metals. It’s only 60% as dense as steel-based and nickel-based alloys.

- Titanium has extensive tensile strength compared to other materials including austenitic or ferritic stainless steels, especially in alloyed form.

- Titanium material has exceptionally high corrosion resistance which exceeds the resistance of stainless steel in most environments.

- Titanium is non-magnetic.

- Titanium performs well in heat transferring for it has a higher melting point than steel alloys.

- Titanium is cold workable.

According to the properties listed above, it should be no surprise that titanium is a cost-effective material with high quality.

Why Choose Titanium as the Construction Material

Filson is one of the most professional titanium filter manufacturers and suppliers in China. With years of exploration and development, we have carried out a full series of titanium filter products to completely meet all your different applications needs.

Here are some basic titanium filter types produced by Filson:

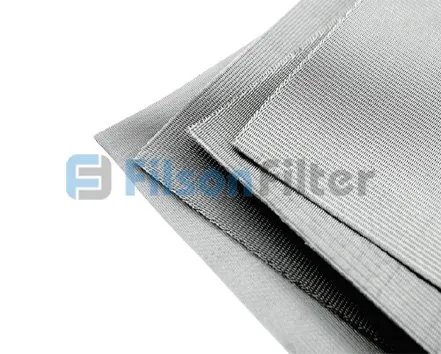

- Titanium filter mesh/titanium mesh screen

- Titanium filter cartridge

- Titanium rod filter

- Porous titanium/sintered titanium

- Titanium fiber felt/titanium fiber mesh

- Titanium frit

These are titanium filters we can supply. We provide custom service for you, so you can get an ideal titanium filter to your unique specifications. Besides, Filson manufactures matched titanium filter housing for your filters. To know more details, simply contact our specialists and you will obtain any information and products you want.

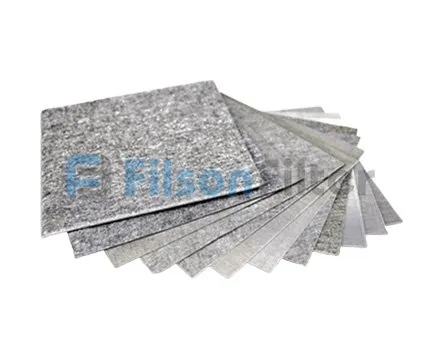

Generally, Filson provides titanium filters in three forms: sintered titanium mesh, sintered titanium powder, and sintered titanium felt. They are all used to realizing the same functions, but with different features, they can be applied to distinct industrial applications.

Next, you will learn something about the main differences among titanium mesh, powder, and felt:

- Sintered titanium mesh has excellent strength and good crushing resistance to withstand high pressure. And it can be made pleated to support a larger flow, further improving your filtration efficiency.

- Sintered titanium powder can be your preferred choice for a titanium filter. Titanium powder has higher filtration accuracy ranging from 0.5 – 50μm and can be made as thin as 0.6mm. Also, a titanium filter made of powder has better air permeability.

( Be aware that products using titanium powder are more brittle and fragile, so remember not to customize your filter too long if you choose titanium powder as your raw material. In addition, you may pay more attention and time to its cleaning. )

- About sintered titanium felt: Filson sintered titanium felt has the largest dirt holding capacity to be used for a longer-term. The micron ratings range from 5 – 80μm and felt can be made very thin to 0.5mm. We don’t recommend ordering felt for too thick due to the high cost ( Sintered titanium powder can replace at this time. )

For hydrogen fuel cells, powder and felt have similar performance, but relatively speaking, sintered titanium powder is more cost-effective. If you don’t know how to choose the right titanium filter, just feel free to consult Filson.

Differences Among Titanium Mesh, Powder, and Felt

The correct cleaning method for a titanium filter, to some extent, influences the service time of your product. To prolong your filter and enhance the filtration efficiency, you can choose both physical and chemical cleaning methods.

Backwashing:

- Degrease your titanium filter. Take solvent degreasing, alkaline degreasing, surface activated degreasing as reference.

- Carefully and gently remove the dirt on the surface by brushing with a soft brush.

- Blow the compressed air from the inside of your filter cartridge.

- Degrease the filter with a clean degreasing agent.

- Use compressed air to blow water for thoroughly washing and finally dry it in natural air.

Chemical cleaning method: ( If can not be completely cleaned by backwashing )

- Wash your titanium filter with mixed acid and treat it with nitric acid. ( Soak for 30 – 60 minutes to reach a better effect. )

- Then, flush the filter thoroughly with water.

- Finally, blow compressed air to remove moisture and air dry it.

Ultrasonic cleaning method:

- Put cleaning solution inside the ultrasonic machine and let titanium filter in.

- The same step is as follows: wash thoroughly and dry the filter.

To achieve a desirable cleaning result, you are recommended to combine all the above cleaning methods. Any question about titanium filter cleaning? Consult Filson for more help!