Filson Plate Fin Heat Exchanger

- Flexible design for fins to handle different situations

- Maximum cleanliness, quality, and reliability

- Compact structure for rugged and leak-free operation

- Expanded heat transfer area

- Specifications

- Send Us Inquiry

When you choose Filson plate fin heat exchanger, you are choosing the best device to bring you higher profits and better return on investment. Our well-performed plate fin heat exchanger will greatly benefit your production line.

- Material: stainless steel, carbon steel, duplex stainless steel, titanium, aluminum alloy, nickel

- Media type: oil, water, air, gas

- Working temperature: under 450℃(up on material)

- Working pressure: under 6.4MPa

- Plate thickness: 0.4 – 3mm

- Heat transfer efficiency: more than 90%

- Heat exchange area: 1 – 800㎡

- Shape of fin: plain, perforated, herringbone, serrated, round-crested, flat-crested, lanced, offset, louvered or wavy

- Fin dimension: height: 2 – 25mm pitch: 0.9 – 8.5mm thickness: 0.1 – 0.6mm

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Plate Fin Heat Exchanger

Top-class Plate Fin Heat Exchanger for Whole World

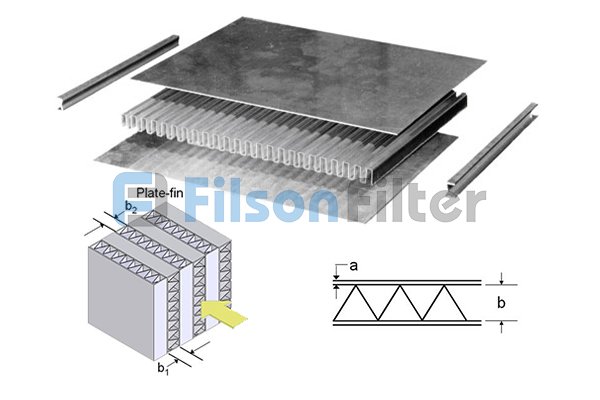

Filson plate fin heat exchanger is manufactured with multiple layers of corrugated sheets which are separated by flat metal plates. These plates are typically made of aluminium to create a series of finned chambers.

During the operation process of Filson plate fin heat exchanger, the hot and cold fluid flow alternately through every layer of the heat exchanger and are enclosed at the edges. The expanded contact surface increases the overall efficiency of the device.

Filson can produce plate fin heat exchanger from large to small scale and take flexible material choices, such as aluminum, titanium and stainless steel, etc. Filson is here to solve all your problems in heat exchanger, just don’t hesitate to contact us!