Filson Semi-Welded Plate Heat Exchanger

- Highest possible efficiency

- Easy to modify heat transfer area to fit various conditions

- Special high pressure version available for heavy duties

- Increased operation safety

- Extensive benifits for all industrial applications

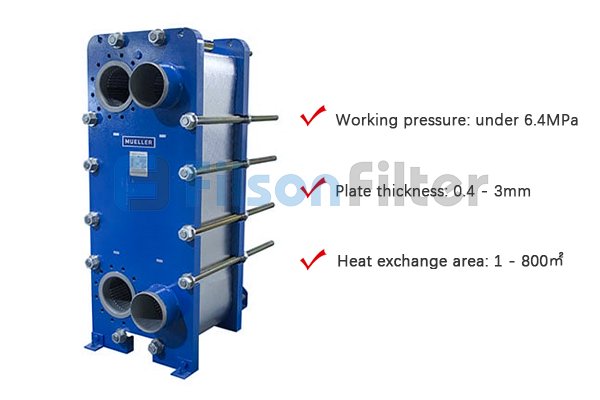

- Specifications

- Send Us Inquiry

Filson designs semi-welded plate heat exchanger for any tasks. Our standard plate can be made into more than 40 different sizes to meet customer requirements. It benifits lots of applications such as petrochemical, refrigeration, oil & gas, power plant, food & beverage, etc.

- Plate material: stainless steel, carbon steel, SMO, hastelloy, titanium, aluminum, nickel(other materials available upon request)

- Gasket materials: EPDM, chemigum, fluororubber(other materials available upon request)

- Media type: oil, water, air, gas

- Working temperature: -25 – 200℃(up on material)

- Working pressure: under 6.4MPa

- Plate thickness: 0.4 – 3mm

- Heat transfer efficiency: more than 90%

- Heat exchange area: 1 – 800㎡

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Semi-Welded Plate Heat Exchanger

Superior Semi-Welded Plate Heat Exchanger for Worldwide

Filson semi-welded plate heat exchanger is constructed by welding every two corrugated plates together, then combining and sealing them with gaskets between each other. The channels between the plates welded together take the higher pressure fluid and the channels between the plates sealed with gaskets take the lower pressure fluid.

Filson semi-welded plate heat exchanger combines the flexibility and advantages of the gasketed plate heat exchanger with the assurance against leakage of the welded heat exchanger. With such careful design, semi-welded plate heat exchanger produces its best possible results.

Get any interests in Filson semi-welded plate heat exchanger? Contact us today and our professional engineering sales are ready to help at all times.