Filson Scraped Surface Tubular Heat Exchangers

- Suitable for high viscosity fluids

- Less fouling on the inside surface of the heat exchanger

- Available for a wide range of industrial applications

- Able to be assembled vertically or horizontally

- Specifications

- Send Us Inquiry

Filson scraped surface tubular heat exchanger is designed and manufactured for the applications where the following problems are required to be settled: one is the drop of the heat transfer efficiency due to fouling, the other one is the low heat transfer rates when fluids are viscous.

- Material: chrome-plated nickel, carbon steel, 316 stainless steel

- Media type: steam, water, cooling brine, viscous media, slurry containing solid particles

- Working temperature: -75 – 250℃

- Working pressure: 2 – 4.0MPa

- Processing viscosity: more than 10,000cP

- Color: grey, blue, silver, brown(based on customer requirements)

- Standard: ASME, ANSI, JIS, GB

Send Your Inquiry Today

Filson Scraped Surface Tubular Heat Exchangers

The Right Scraped Surface Tubular Heat Exchangers for the Application

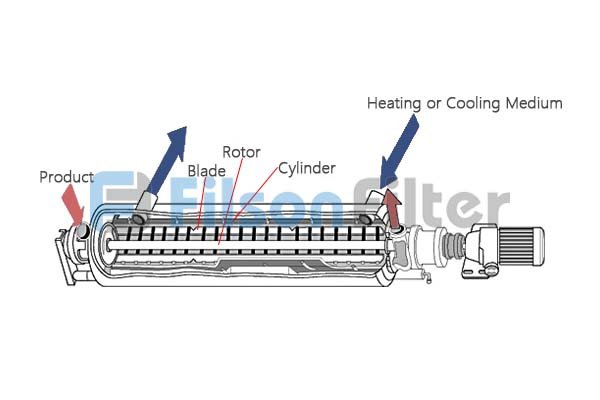

Filson scraped surface tubular heat exchanger consists of a external housing and a inner rotor. The housing part(shell) is composed of an inner cylinder and an outer cylinder. The inner cylinder is the heat transfer cylinder, which passes through the material to be treated (A fluid), while the outer cylinder is the jacket, which passes through the heat exchange medium (B fluid).

The rotor of the scraped surface tubular heat exchanger rotates during operation. The outer edge of the rotor has a scraper used to stir and scrape.

Commonly, the rotor speed of Filson scraped surface heat exchanger is 100 – 800rpm and it varies depending on the viscosity of the media and the size of the equipment diameter. If the fluid has high viscosity and the device has a large diameter, the speed of the rotor should be as low as 10 – 20rpm.

Contact Filson today and get more detailed information about scraped surface tuular heat exchanger.