Pleated Filter Cartridge

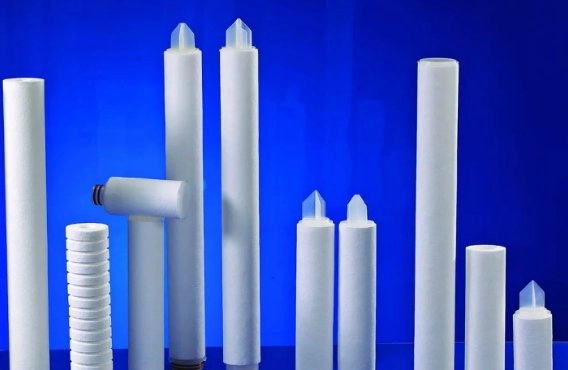

Filson Pleated Filter Cartridges are suitable for pre and final filtration of a wide variety of process liquids and gases, including pleated polyester filter cartridges, pp pleated filter cartridges, fibreglass pleated filter cartridges, 5-micron pleated water filters, and many more.

You can import Filson pleated water filter cartridges by customization, or with standard size.

Filson Pleated Filter Cartridge guaranteed integrity by using the latest thermal bonding technology even in physically demanding applications.

Also, Filson Pleated Filter Cartridge is highly effective at reducing sediment particles down to 0.2 microns.

Pleated Filter Cartridge Manufacturer

Filson Pleated Filter Cartridge also called pleated water filter, pleated sediment filter, pleated water filter cartridge is a process filter cartridge with layers of cellulose, polyester(PE), polypropylene(PP) and glass. It has longlasting filtration and retention efficiency with a large surface area.

Compared to other water filter cartridges, like string wound filter cartridge, spun filter cartridge or melt blown filter cartridge, pleated water filters deliver high dirt-loading capacity at lower differential pressures. Filson pleated filter cartridges are available in nominal 10’’, 20”, 30’’, 40’’ lengths with 2.5” or 4.5” diameters.

- More Details

- Specification

- Application

Filson Pleated Filter Cartridges

With the Filson’sknow-howw in pleated water filters industry, we can help you remain competitive by being your pleated filter cartridge suppliers. Whether for standard, custom or added strength, Filson Pleated Filter Cartridge offers an ideal filtration solution for all market needs.

Features of Filson Pleated Filter Cartridge

- Various endcaps choose to fit in all standard industry housings

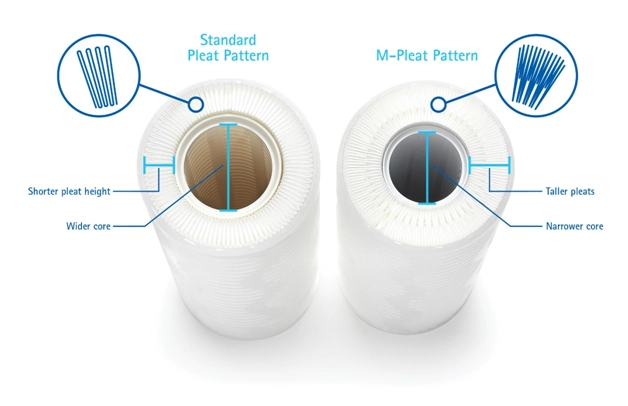

- Contain more surface area than most competitive cartridges

- High retention efficiency provides better protection for downstream filters

- Absolute-rated media provides reliable, consistent and repeatable filtration

- Fixed Pore structure design resists dirt unloading at high differential pressure

- Multiple gasket/O-Ring options for broad application

- Available for food and beverage applications

Types of Filson Pleated Filter Cartridge:

1. Filson Pleated Micro Fiberglass Filter features borosilicate micro fibreglass media construction, it offers an economical filtration solution with exceptional ability to retain both deformable and non-deformable particles.

Filson Fiberglass Pleated Filter Cartridges adopt polyester or polypropylene as the support layer. And the natural positive charge of glass fiber enhances the retention of negatively charged particulates such as colloidal materials. Filson Fiberglass pleated water filters are widely used in broad range of applications with micron ratings from 0.2 to 30 µm.

Filson Fiberglass Pleated Filter Cartridges offer optimized pleat geometry for each micron rating to ensure high stability through good integrity and maximum dirt-holding under the most stringent of processing conditions.

2. Filson Pleated Cellulose Filter Cartridge is economical, yet highly effective for general water filtration purposes. It can capture sediment particulates down to nominal 20 microns in size.

Filson Pleated Cellulose Filter Cartridge is built with a polypropylene core for added strength and an external netted sheath to provide extra support to protect against system pulsating. End caps are fused to the cellulose media preventing bypass and forming a unified endcap and gasket sealing area.

Filson Pleated Cellulose Filter Cartridge provides increased surface area and strength with a double open end or custom design for commercial and industrial filtration applications.

3. Filson Pleated Polyester Filter Cartridge is manufactured by durable, non-woven polyester(PE) media. It can be cleaned and reused with being pleated to maximize its dirt holding capacity and save cost by reducing replacement frequency.

Filson Pleated Polyester Filter Cartridges are widely used in most light industrial applications, such as swimming pool and spa, and well water applications. This PE pleated sediment filter is designed with vinyl plastisol end caps and polypropylene core.

Filson Pleated Polyester Filter Cartridge traps contaminants on their surface. If you are filtering sediment of similar-sized particles like five microns, a 5-micron pleated polyester water filter is the best choice.

4. Filson Pleated Polypropylene Filter Cartridge or pp pleated filter cartridge is manufactured by 100% polypropylene material that ensures an expansive chemical compatibility range for the most demanding applications, especially the filtration of aggressive and viscous chemicals and solvents.

Filson Pleated Polypropylene Filter Cartridge combines continuously graded fiber density with optimised pleating density to provide consistent particle retention and exceptional lifetime performance. Filson pp pleated filter cartridges are available in applications from fluid clarification to general prefiltration with reliable, consistent and repeatable filtration effect.

Filson Pleated Polypropylene Filter Cartridge use a thermal bonding process to seal the media, core, cage and endcaps. This glue-free process eliminates particle bypass for superior compatibility.

Pleated Filter Cartridge: The Complete Guide

You probably consume about one to two liters of water every day, trusting that it is fresh and clean.

Well, you are right because water has to be clean before you get the chance of quenching your thirst.

But first, you need one vital accessory to make it safe – pleated filter cartridge.

And today, I want to help you choose a suitable pleated filter cartridge.

This guide covers everything you should know about pleated filter cartridge.

From basic definition, structure, working principle, classification, technical specification, replacement process, etc. – by the end of this article, you will be an expert in pleated filter cartridge.

Let’s dive right in.

- What is a Pleated Filter Cartridge?

- Types of Pleated Filter Cartridges

- Structure of Pleated Filter Cartridge

- Why you need Pleated Filter Cartridge

- How a Pleated Filter Cartridge Works

- Classification of Pleated Filter Cartridge

- Technical Specifications of Pleated Filter Cartridge

- How to Clean Pleated Filter Cartridge

- A Step-by-step Pleated Filter Cartridge Replacement Process

- Applications of Pleated Filter Cartridge

- Conclusion

What is a Pleated Filter Cartridge?

A pleated filter cartridge is also known as pleated sediment filter, pleated water filter or pleated water filter cartridge.

You can use it on large-scale or small-scale filtration of water, other process liquids and gasses.

Pleated filter cartridge

The process of filtration is possible because the cartridge has:

- Layers of cellulose

- Layers of polyester

- Layers of polypropylene (PP)

- Layers of glass

A pleated filter cartridge has long lasting retention and filtration efficiency with large surface areas.

It a device you can use in the filtration of many varieties of process liquids and gases.

You can use it among other cartridges such as:

- Pp pleated filter cartridges,

- Pleated polyester filter cartridges

- Fiberglass pleated filter cartridges

- 5-micron pleated water filters

You are at liberty of importing a pleated filter cartridge of your standards or that of the standard size.

Modern pleated filter cartridges are capable of reducing sediment particles up to 0.2 microns making it considerably clean.

In comparison to other devices such as spun filter cartridge, string wound filter cartridge, and melt blown filter cartridge.

Melt blown filter cartridge

String wound filter cartridge

The pleated filter cartridge has the capacity to deliver high dirt loading capacity at low differential pressure.

You can find a variety of pleated filter cartridges of 2.5″ or 4.5″ diameters and lengths such as:

- 10″ long

- 20″ long

- 30″ long

- 40″ long

Types of Pleated Filter Cartridges

There are four main types of pleated filter cartridges you can choose from depending on the mode of application.

a) Pleated Micro Fiberglass Filter Cartridge

It has features such as borosilicate “micro fiberglass glass media construction” that offers economical filtration solutions.

Apart from that, it has an exceptional ability that retains both non-deformable and deformable particles.

Pleated micro fiberglass filter cartridge

It adopts polypropylene or polyester as the primary layer of support.

“Natural positive charge” of the glass fiber is an enhancement to the retention to the particulates with negative charges such as colloidal materials.

You can use it in a wide range of applications which have micron ratings of 0.2 to 30 millimicrons.

It optimizes the pleat geometry for every micron rating ensuring high stability.

It does so through maximum dirt holding and good integrity under stringent processing conditions.

b) Pleated Cellulose Filter Cartridge

It is the most economical and highly effective filter you can use for general filtration of water.

It captures sediment particulates that are very small down to “nominal 20 microns”.

It has a polypropylene core and a netted sheath on the outside that improves the strength.

Pleated cellulose filter cartridge

Apart from that, the netted sheath provides extra support that protects the pulsating of the system.

It has end caps that have cellulose media which prevents forming and bypassing the gasket sealing area and the unified end cap.

It has a broader surface area and more strength with custom designs and double open end for industrial and commercial filtration applications.

c) Pleated Polyester Filter Cartridge

This device has non-woven, durable polyester media.

You can clean it and use it again with pleats that maximize the capacity to hold dirt.

This kind of function makes it very efficient, cost-effective and does not require frequent replacements.

You will be using it in light industrial applications, for example, swimming pools, spas as well as well water applications.

Pleated polyester filter cartridge

The polyester media “pleated sediment filter” has end caps made of vinyl plastisol and a polypropylene core.

It can trap contaminants at the surface during the filtering process.

So you have to choose the right water filter depending on the size of the particles you intend to filter.

d) Pleated Polypropylene Filter Cartridge

Also known as the PP pleated filter cartridge, you can use it in filtering aggressive and vicious solvents and chemicals.

It has 100% polypropylene material that will ensure a wide range of chemical compatibility.

It is the method filter you will use in the applications that demand the most from you.

Pleated polypropylene filter cartridge

The filter uses a combination of continuously graded fiber density and optimized pleating density for the best performance.

It provides the best lifetime performance and consistent retention of particles as you filter the solvents.

You can use it in applications such as general prefiltration and fluid clarification with consistent, repeatable and reliable filtration effect.

It uses a thermal bonding process which seals the core, media, end caps and cage.

This kind of bonding makes it the best in eliminating particle by-passes for better compatibility.

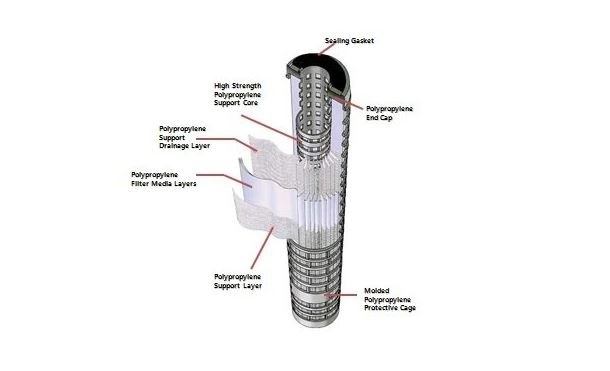

Structure of Pleated Filter Cartridge

The pleated filter cartridge has unique features that make it suitable for the purpose of filtration.

Pleated Filter Cartridge Structure – Photo courtesy: UBOFILTER

The unique features include:

- It has a variety of end cups you can choose from to fit in standard industry houses

- It has a broader surface area in comparison to other cartridges available in the market

- It has high retention efficiency that provides it with better protection to downstream filters

- It has absolute-rated media that offers repeatable, consistent and reliable filtration of liquids and gasses

- It has a fixed pore structure design that resists unloading dirt at high-pressure differentials

- It has multiple O-ring/gasket options for more extensive applications

- It is available for beverage and food applications

The features of the pleated filter cartridge make it the most sort after device you can use for cleaning liquids.

In addition to that, other specifications make it unique to its purpose.

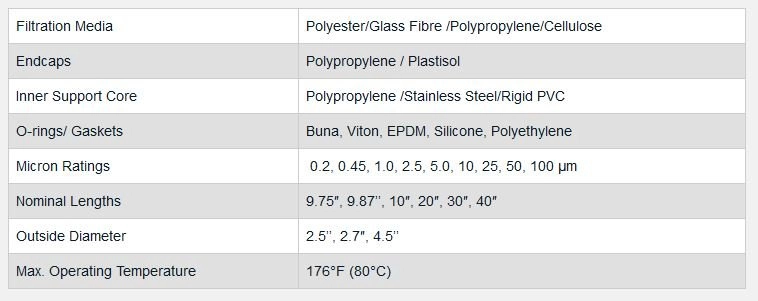

- Filtration Media

- Cellulose/Glass Fiber/Polyester/Polypropylene

- End Caps

- Plastisol/Polypropylene

- Inner Support Core

- Polypropylene/Rigid PVC/Stainless Steel

- Gasket/O-rings

- Buna, EPDM, Polyethylene, Silicone, Vitone

- Micron Ratings such as 0.2, 0.45, 1.0, 2.5. 5.0, 10, 25, 50, 100

- Nominal Lengths such as 9.75″, 9.87″, 10″, 20″, 30″, 40″

- Outside diameter such as 2.5″, 2.7″,4.5″

- Maximum Operating Temperature of about 176 degrees (80 Degrees Celsius)

Why you need Pleated Filter Cartridge

You need pleated filter cartridges for the following purposes:

- Filtering water and other process liquids

- Filtration of gasses

Apart from the things the pleated filter cartridge can perform, it has various advantages such as:

Pleated filter cartridge

- In comparison to spun and wound cartridges, you will prefer to use the pleated filter cartridge. This is because it has a longer life, low-pressure drops and reduces the costs of filtration.

- It does not have any binders or additives which may result in foaming as you filter.

- It has a higher capacity of holding dirt in comparison to other cartridges.

- You will not need to replace the cartridges more often thus making it cost effective as a filtration device.

- The efficiency in which it removes particles is high thus improving its life.

- The cost you will incur in filtering a gallon is lower in comparison to other filters.

Apart from the unique features of a pleated filter cartridge, it is also unique in terms of function and classification.

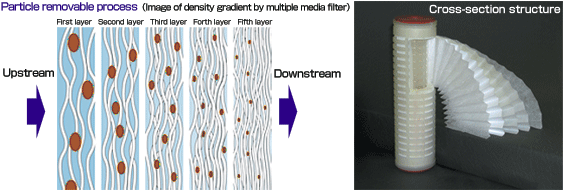

How a Pleated Filter Cartridge Works

A pleated filter cartridge works better than other cartridges such as melt blown, spun, resin bonded and wound cartridges.

You can attribute this to the design and the structure of the cartridge including the pleats and the wide surface area.

The fact that it works best under low pressure also makes it better than the mother types of filter cartridges.

Filter cartridge

The first step in the process of filtering water is the installation of the pleated filter cartridge.

Please note that you can use pleated filter cartridge in different applications to purify water.

In this case, we are going to look at the pleated filter cartridge that to clean water in the house for domestic use.

After successful installation of the pleated filter cartridge, you will make sure that it is working well.

The first step will be confirming if the cartridge is in the right position.

In most cases, the cartridge will be in a canister which should be holding tight in place.

Different sizes of pleated filter cartridge

Allow the water to flow through the pipes and the pleated filter cartridge.

The water will pass through the pleats which have a wide surface area making it cleaner.

Apart from that, make sure that the water flows under low pressure increasing the time it takes in the system.

The pleated filter cartridge has an inner polypropylene core which gives the cartridge its compressive strength.

It is able to compress the water to pass through the microscopic pores leaving the residues behind.

Besides that, the outer filtration layer of polypropylene or polyester will provide the filtration without the media migration.

The more time water takes in the pleated filter cartridge, the more impurities the cartridge will remove.

The synthetic fiber which usually has very small pores such as 5 microns cleans the water better capturing the smallest particles.

The process continues as the water continues to flow through the pleated filter cartridge.

Classification of Pleated Filter Cartridge

Whenever you are looking for a pleated filter cartridge, it is important to focus on the following:

Pleated filter cartridge

§ By End Configuration

The pleated filter cartridge has a wide range of end caps that are available for you to choose from.

Manufacturers have unique designs for end caps fused to the pleated filter cartridges to prevent leakages.

You are at liberty to come up with a unique design for you end cap even with the availability of the standard end caps.

The most common end caps available include:

- Polypro -226

- Polypro core extender

- Open End Stainless Steel – 222

- Flat Open-End Gasket

- Custom End Cap

- Closed-end Stainless steel -222

- Stainless Steel Core Extender

- Flat/Closed Endcaps

- Poly – 222

- Fin End Caps

- Flat/Open Endcaps

- Plastisol Molded Endcaps

By Type of Material

The type of material you will find in a pleated filter cartridge will vary accordingly.

The most common types of cartridges are:

i. Pleated Cellulose Filter Cartridge

The pleated cellulose filter cartridge has a unique design for general water filtration.

They are very economical, highly effective in removing sediment particles down to the size of nominal 1 micron.

The media that is pleated and corrugated increases the surface area and strength of cleaning liquids.

Pleated cellulose filter

It has a long-life extension so you can use it for a very long time without replacing it.

Besides that, the cellulose media are fused to the end caps to prevent bypasses of the liquid.

The fusion also forms a gasket sealing area.

ii. Pleated Cellulose Polyester Filter Cartridge

The unique features of the pleated cellulose polyester filter cartridge include:

- Unique formulations which include polyester fibers and impregnated cellulose

- Has a “Big Blue” filter housing

- Has high wet strength in comparison to other cellulose cartridges

- Media migration and minimal unloading

- Wider surface area of media where the water passes through

You can use the pleated cellulose polyester filter cartridge in cleaning:

- High Purity Chemicals

- Bottled Water

- Cosmetics and Pharmaceuticals

Cellulose polyester filter cartridge

It has unique features which make it have:

- High rates of rejection

- High flow capacities

- Superior quality and helps in saving costs

The cellulose polyester filter cartridge is typical in industrial applications such as:

- Cleaning condensate water and cooling water

- Power generation – for cleaning wastewater

- Chemicals – process water, acids prefiltration, solvents and alcohols

- Oil and gas – prefiltration, refined products, aggressive solvents

- General industrial – cleaning wastewater and metallization bath

iii. Pleated Polypropylene Filter Cartridge

The pleated polypropylene filter cartridge has a 100% solid polypropylene cage and core.

This type of filter will offer broad surface areas and total retention ratings for removal of the particles and impurities.

The end caps of polypropylene filter cartridges are bonded thermally to the media packs thus eliminating the need for adhesives.

Pleated polypropylene filter cartridge

Eliminating adhesives will remove the risk of contaminating the process liquid further.

It also makes sure that the resins do not react with the process liquid you are cleaning.

It is available in many lengths and micron efficiencies to suit different types of applications.

iv. Pleated Polyester Filter Cartridge

The pleated polyester cartridge has bacteria and chemicals resistance that is suitable for cleaning water.

The polyester media makes the cartridges suitable for:

- Cleaning portable water

- Light industrial applications

- Cleaning Spa and Swimming pool water

The polyester fabric is non-woven, durable and you can use it again after cleansing.

The pleats increase the holding capacity of the dirt in the liquid you are cleaning.

It also extends the period in which the water passes through the pleated filter cartridge.

v. PTFE Pleated Filter Cartridge

This type of filter cartridge uses hydrophilic or hydrophobic PTFE membrane for gas or liquid filtration.

PTFE Pleated Filter Cartridge

It produces very clean fluids at very low costs as it is also chemically inert.

It is free of resins, surfactants, adhesives and blinders making it very effective.

It is a great choice for use in pharmaceuticals, semiconductors and other applications that require strict supervision.

The advantages and features of the PTFE pleated filter cartridge include:

- The chemical compatibility is broad

- Has a broader surface area which increases the rate of flow.

- Has pore sizes that are evenly distributed for increased retention

- Thermally welded end caps for better integrity

- It has the options of changing the seals and end caps

vi. Pleated Paper Filter Cartridge

You can use the pleated paper filter cartridges for lubricants, fuel and hydraulic fuel filters to provide contamination control.

Pleated paper filter cartridge

It has three filtration layers which include:

- Outer layer for cellulose media for filtration of course material

- The intermediate layer of glass-media for micro-filtration

- The inner layer of cellulose media for improved support

Pleated paper filter cartridges with single layers are suitable for general filtration because of the economic advantages.

It has disposable cartridges, and urethane ends that mould in different sizes.

The main applications include:

- Refrigeration compressors especially to clean the coolants and the lubes

- It cleans gas in the gas turbines

- The centrifugal lubricated couplings

- Test stands

- High-pressure fluid filtration

viii. Fiberglass Pleated Filter Cartridge

It uses advanced borosilicate micro glass fiber media in the cleansing of the process liquids that pass through it.

Fiberglass pleated filter – Photo courtesy: Filter Fine Vn

The fiberglass pleated filter cartridge has other names such as:

- GF pleated filter cartridges

- Glass fiber pleated water filters

The fiberglass pleated filter cartridge uses polypropylene or polyester media to support the glass membrane layer.

Apart from that, it improves the shapes of pleats and the direction and flow of water.

The stringent standards and pore sizes of the filter medium offer a uniform matrix for better performance.

- The features of the fiberglass pleated filter cartridge include:

- It has a higher filtration efficiency

- The 100% thermal bonds eliminate particle bypass

- It has a structure that has three layers of membranes

- It has a wide area of filtration

- The pressure, in this case, is low

The releasing media which is non-fiber has minimal extractables that provide filtrates of high purity

The applications of the fiberglass pleated filter cartridge include:

- Chemical filtrations

- Standard or Domestic treatment of water.

- Beverage and food industry

By Purpose

You will classify the pleated filter cartridges according to the purpose it will be performing.

Manufacturers design pleated filter cartridges depending on the application you will be using it for.

This is the point where the cartridges will be in different categories such as:

You can classify them into groups terming them as cartridges suitable for:

- Food and beverage cartridges

- Electronics cartridges

- Pharmaceutical cartridges

- Water cartridges

- Chemical cartridges

- High-pressure filtration cartridges

- Gas and Oil filter cartridges

- Fossil fuel cartridges

The list is endless because there are a lot of applications where the pleated filter cartridge will perform well.

The application where the filter will perform will determine the type and size of the filter you will need.

You can make a design of the filter you would like so that the manufacturers can make it for you.

Pleated Filter Cartridge for Liquids

With the liquid efficiency ranging between 0.5 microns to 100 microns, pleated filter cartridges can remove solids efficiently.

Every cartridge has a pleated pore media that maximizes the effective area while preventing fiber migration and particle unloading.

Customers are in a position to get a wide variety of cartridges that will fit the functions they intend to perform.

To clean liquids, you will need filter cartridges such as:

- Pleated Filter Cartridge for Oil

- Pleated Filter Cartridge for Water, etc.

- Pleated Filter Cartridge for Gases

- Pleated filter cartridges for gasses include:

- Silo – top collectors

- Pleated bag collectors,

- Horizontally mounted cartridge collectors

- Vertically mounted cartridge collectors

- First cell filter collector

There are quite a number of pleated filter cartridges for gasses that you can use in various industries.

You can use the filters in toxic, abrasive and explosive types of dust in different industries.

The dust from metal, cement, chemicals and woodwork among other applications are taken care of by some of these filters.

Technical Specifications of Pleated Filter Cartridge

Pleated filter cartridges have special specifications that enable them to perform well.

Without these components then the cartridges would not perform as good as they are.

Continue reading and you will learn more about the specifications that make the best-pleated filter cartridges.

Technical specifications

§ Filtration media

This is anything that you can put in a filter so that it changes the properties of water by cleaning.

The most common filtration media you can find in a pleated filter cartridge include:

- Granular carbon with very high purity

- Carbon cartridges to remove odours and colour

- Roll media that you can dispose of

- Bag filtration media

- Coalescing media

- Horizontal disc filter aid and papers

The filtration media vary according to the kind of application you intend to use it for.

This is the reason why you will find many filtration media in the market.

§ End caps

There are many types of end cup configurations that you will come across as you will be using the filter cartridges.

There are two main types of filter cartridge end caps you might come across which classifies them as:

- Double open-end cap – You can use it in medium to coarse filtration and not for sterile or very fine filtrations.

- Single open-end cap – it employs a double O – ring on the open side of the filter cartridge. The other end can either be closed or it might be the fin type/

Apart from the above classifications, you will come across end cap configurations such as:

- Open

- Spring PP pore extension

- 213 internal core ring end caps

- Flat cap

- Fin end cap

The list is very long, and you will be able to learn more about end caps as you use them.

§ Inner support core

Pleated filter cartridges have inner support cores that help in making everything to stand in the right place.

The inner support core is of different things depending on the type of pleated filter cartridge.

Without the inner support core, the material on the outside would crumble and fall.

§ Gasket type and material

A gasket is a seal that you can use in sealing the space between two different parts you join together.

It comes in handy to prevent any leakages into and out of the combination you had put together while under compression.

You can get a gasket seal that is made unique for the kind of application or filter you are using.

Gasket seals that you can use in pleated filter cartridges include rubber, metal or plastic and other elastomers.

Apart from that, you can get gasket seals with materials such as nylon, polyester and dacron among others.

The type of material on a gasket will depend on the type of filter you are using.

§ Micron rating

Micron rating is the unit of measuring the diameter of a particle you will remove using the filter cartridges.

The micron rating of the pleated filter cartridge will depend on the kind of work the cartridge will perform.

As an example, a filter rated twenty microns means that the filter is capable of cleaning particles that are larger than 20 microns.

You can measure micron ratings through the following methods:

- Nominal Micron rating

- Absolute Micron rating

- Multipass Beta ratio Testing

§ Working temperature

The working temperature of pleated filter cartridge will depend on the application you are using it for.

Manufacturers always advise on the temperature limits where you will operate the cartridge.

In case the working temperature exceeds, the cartridge might malfunction.

Filtration – Photo courtesy: FDPP

You should always look at the instructions which will guide you on the best conditions for operation.

In case the temperature is too high or too low, the cartridge might not work well.

§ Nominal length

Pleated filter cartridges are available in different nominal lengths from which you can choose from.

The nominal lengths of the cartridges will depend on the kind of application you ate working on.

The dimensions on nominal length can either be in inches or in millimeters.

§ Outside diameter

You can measure the outside diameter of the pleated filter cartridge in inches.

The cartridges are of different sizes meaning that the outside diameter will vary accordingly.

Wider cartridges have longer diameters as compared to others.

How to Clean Pleated Filter Cartridge

A pleated filter cartridge is a unique type of filter that you can replace when it is not functioning well.

On the other hand, the design of the pleated filter cartridges gives you the chance to clean and replace it.

Continue reading and get more details on how you can clean and replace the pleated filter cartridge.

Pleated filter cartridges are of different types depending on the type of application you are using it for.

Inner section of pleated filter cartridge

In this case, we are going to have a look at the filter cartridge you use in cleaning water in your swimming pool.

The first step is collecting all the relevant tool s that you will need for the job and turning off the flow of water.

After that, remove the pleated filter cartridge from the place where you had made the installation.

It will probably have a cover or a canister to protect it from external damages.

Remove the cover so that the filter cartridge can be exposed and easy to access.

Remove the filter cartridge from the canister in case it was attached to it and inspect the level of dirt on it.

Using a garden hose pipe, rinse any form of debris that might be on the pleated filter cartridge before it dries up.

If it is allowed to dry, the debris may settle on the filter cartridge making it difficult to clean later.

You can now place the filters in bright sunlight so that they can dry up thoroughly.

Sunlight has algaecide properties that are very important in the cleaning process of the filter cartridges.

After that, remove the loose particles from the filter using an air compressor or simply shaking.

You can also remove the loose particles from the cartridge by tapping it against a surface or using a brush.

Cleaning one pleated filter cartridge is not economical so you will collect a number of cartridges and clean them together.

Place the cartridges in a bucket before bringing in and pouring the cleaning agent into the bucket.

You will use a chlorinator to clean the cartridges so prepare the solution well.

The solution will require “one-part pool chlorinator to six parts water” for the soaking of the filters.

Pour the solution in the bucket and cover the lid to allow it to soak properly.

Soaking the filters will kill all the micro-organisms and break down any form of organic contaminants on the cartridge.

You will soak the cartridges in the solution for a period of three to five days to get the best results.

Remove the pleated filter cartridges from the solution and rinse in clean and fresh water.

Hang the filters in sunlight and allow them to dry thoroughly, then, shake off any dust particles on the cartridge.

After that, soak the filters again in water and muriatic acid solution to dissolve minerals in the filter media.

Immerse the cartridges in the solution and ensure that the solution is not bubbling any more before rinsing it in water.

Bubbling is the indication that the solution is reacting with the acids thus proof that it is cleaning.

Use plenty of fresh water to help you in rinsing the cartridges.

Allow the cartridge to dry up then shake off any dirt on it before reinstalling it to its normal position.

A Step-by-step Pleated Filter Cartridge Replacement Process

The process of filtration will require you to make certain adjustments to increase the efficiency of the device.

Filtration process – Photo courtesy: DAIDO MACHINES

Among the changes, you will be making include the replacement of the pleated filter cartridge.

Continue reading as I explain to you the process of replacing a pleated filter cartridge.

The wide surface area of the pleated filter cartridge makes it have a longer life serving as a filter.

The manufacturers make it in such a way that you can wash and use it again.

At some point, you will have to replace the pleated filter cartridge especially if it is damaged.

The process of replacing the pleated filter cartridge will depend on the application you were using it for.

In this case, I will take you through the process of restoring a pleated filter cartridge you use in your houses.

First, you will have to prepare well for the whole process of doing replacements.

You can do this by having a checklist of all the materials you will need as you replace the filter cartridge.

Go through the list checking out all the elements that you have in place till you confirm everything is in order.

The preparations will include turning off all the waterways in the house preventing the flow of water out of proportion.

The materials you are to have at hand include a filter wrench, strap wrench, replacement filters, silicon grease among others.

Do not forget to have a replacement O-ring, Teflon tape, a bucket and some rags for cleaning in case of a spill.

The second step is usually turning off the water and releasing the pressure within the system and the pipes.

Fill up a bucket or a sink with water which you will use in rinsing the other parts of the cartridge you are replacing.

The third step will involve opening the canister where the canister is using the filter wrench to expose the filter.

Many have had problems opening the canister but when it is done carefully, it will open up easily.

Make sure you release the water pressure in the canister that may make it very tight and difficult to open.

After opening the canister, you will expose the pleated filter cartridge thus making the work of replacements easier.

Inspect the old cartridge making sure that it requires replacements or not because others may need cleaning.

You will clean the canister to rid it of the impurities that may accumulate during the filtration process.

Apart from that, make sure that the cartridge is worn out and will require replacements.

If not, will clean the cartridge well and put it back to its original position for further use.

If it is worn out and you cannot use it again, you will have to replace it with another cartridge.

While you are at it, scrutinize the O-ring and replace it according to the right specifications.

The O-ring is unique because it is the seal between the filter and canister helping in the prevention of licks.

Be careful when inspecting the O-ring and try not to stretch it because you might end up using it again.

Pleated filter pattern – Photo courtesy: BIOPHARMA

After that, put the plumber tape around the threads surrounding the neck of the canister that will contain the cartridge.

The process is not as important, but it can help you especially if you are running into accidental leaks.

Make sure you do it well the first time because you will have to repeat the whole process if it fails.

Before you put back the canister, you should replace the old cartridge with the new cartridge if need be.

Perfectly center the cartridge in its normal place making it easier for you to put back and to increase its functionality.

After that, put back the canister to its original position and tighten using your hands making sure it sticks well.

Finally, pressurize the whole system again so as to enable the whole system to run well.

After that, you can open up the water again to allow it to flow through the filters.

As the water flows through the filter, it becomes clean and therefore good for domestic use.

Applications of Pleated Filter Cartridge

You will use the pleated filter cartridge in other applications such as:

- Water Purification

- Electronics

- Magnetic Media

- O membrane

- Coolants

- Photographic

- Petrochemicals

- Food and Beverage

- Cosmetics

- Bottled water

- Pharmaceuticals

- Chemicals

Conclusion

You are in a better position to decide on the type of pleated filter cartridge you will require to use.

You are also able to make a call and order a custom-made pleated filter cartridge from the manufacturer.

Remember that pleated filter cartridges are replaceable, so you don’t have to purchase new ones all the time.

At FilSon Filters, we have a range of pleated filter cartridge for a range of applications.

Talk to us today – FilSon Filters team will help you choose a suitable filtration system.

| Filtration Media | Polyester/Glass Fibre /Polypropylene/Cellulose |

| Endcaps | Polypropylene / Plastisol |

| Inner Support Core | Polypropylene /Stainless Steel/Rigid PVC |

| O-rings/ Gaskets | Buna, Viton, EPDM, Silicone, Polyethylene |

| Micron Ratings | 0.2, 0.45, 1.0, 2.5, 5.0, 10, 25, 50, 100 µm |

| Nominal Lengths | 9.75″, 9.87’’, 10″, 20″, 30″, 40″ |

| Outside Diameter | 2.5’’, 2.7″, 4.5’’ |

| Max. Operating Temperature | 176°F (80°C) |

- Water Purification

- Magnetic Media

- Coolants

- Petrochemicals

- Food and Beverage

- Bottled Water

- Cosmetics

- Pharmaceuticals

- Electronics

- Photographic

- Chemicals

- R.O. Membrane