Filson Metal Sintered Fiber Felt

- High dirt holding capacity for depth filters

- Low pressure drop with uniform high porosity

- Easy to clean with several cleaning methods

- High temperature and corrosion resistance

- Excellent mechanical strength by sintering process

- Longer service life than traditional wire meshes

- Specifications

- Send Us Inquiry

With high porosity of 85% and filtration rating down to 0.1 micron, Filson sintered metal fiber can provide higher filtration effect than conventional wire meshes. Besides, it features good cleanability by various cleaning methods like ultrasonic cleaning, dipping in chemical solution, etc.

- Raw material: stainless steel, monel, hastelloy, inconel …

- Filtration rating: 0.1-100 micron

- Porosity: up to 85%

- Operating temperature: upon material

- Standard size: 48”×48”

- Thickness: 0.3-1.2 mm

- Shape: sheet, disc, tube, cartridge

Note: Different dimensions available. Consult Filson.

Send Your Inquiry Today

Filson Sintered Metal Fiber

Your Premium Sintered Metal Fiber Manufacturer in China

Filson sintered metal fiber is created from randomly laying short metal fibers through sintering and boding processes. It offers exceptional dirt holding capacity and flow characteristics, meanwhile with superior viscosity fluid filtration performance.

Many materials can be selected to manufactured Filson sintered metal fiber, such as stainless steel, Nickel, Hastalloy, Inconel. The most commonly used material is SS 304/316L. Additionally, other specifications of Filson sintered metal fiber are available in customization.

As a factory with extensive experience in sintering filter design and manufacturing, Filson can not only provide you with high performance sintered metal fiber felt, but also producing sintered wire mesh, sintered powder filter and other forms, to meet your various filtration needs.

If you are interested in Filson sintered metal fiber, please contact us without hesitation!

Sintered Metal Fiber Felt: The Ultimate FAQ Guide

Whether you want to import or learn more about sintered metal fiber felt, all information you’re looking for is right here.

Keep reading if you want to be an expert in sintered metal fiber felt.

What is a Sintered Metal Fiber Felt?

It is a non-woven media-constructed through the randomly laying short metal fibers then subjected to sintering and bonding.

Sintered metal fiber felt is best suited for use in applications that operate under very high pressure, high temperature, and corrosive environments.

The fleece of the metal fiber can comprise different layers of fiber.

They can be compressed together to a suitable thickness then sintered to fuse the respective single fibers.

The resulting material is a highly porous fiber that is very strong, resistant to corrosion, high temperature, and fracture.

Furthermore, it has excellent permeability and can last longer compared to common media.

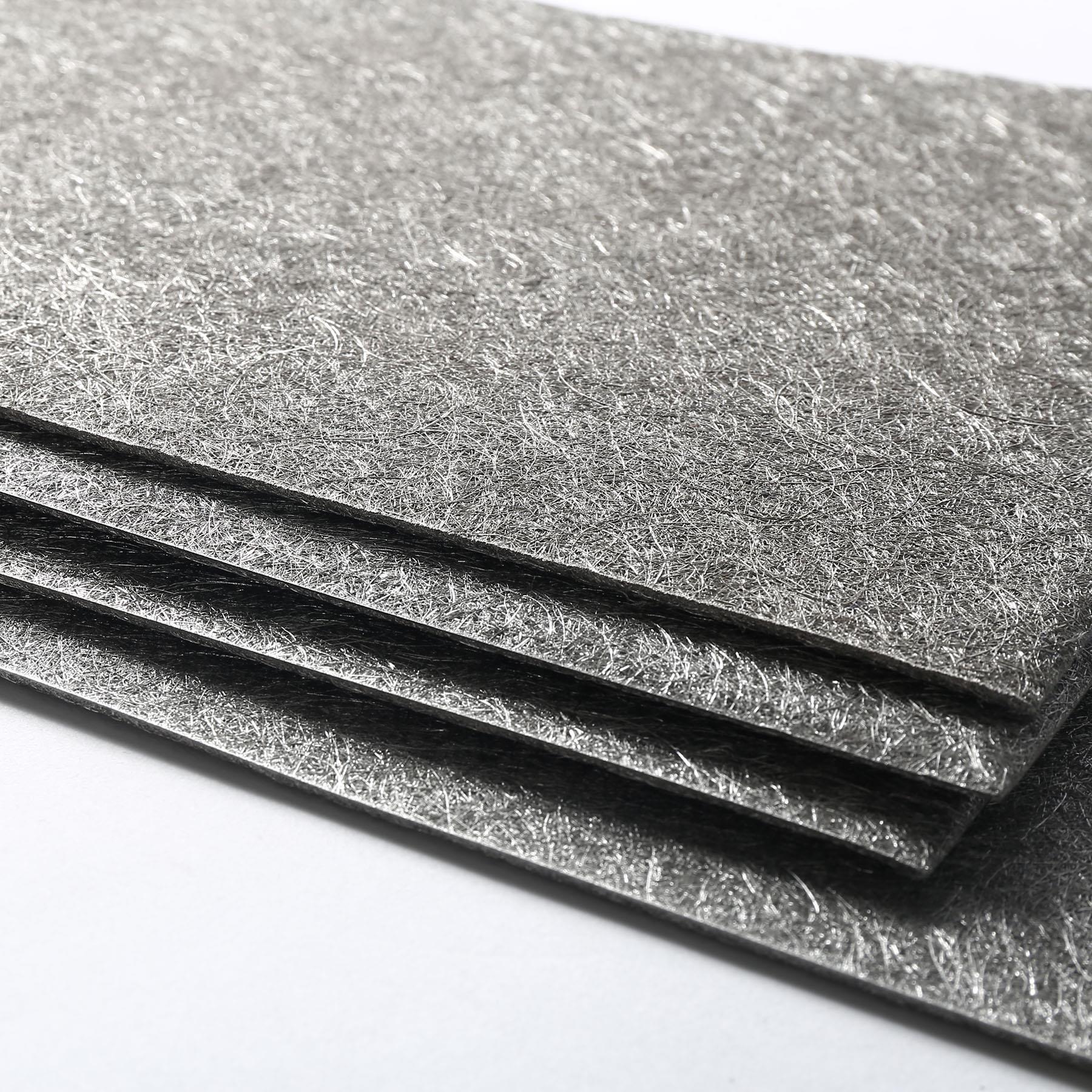

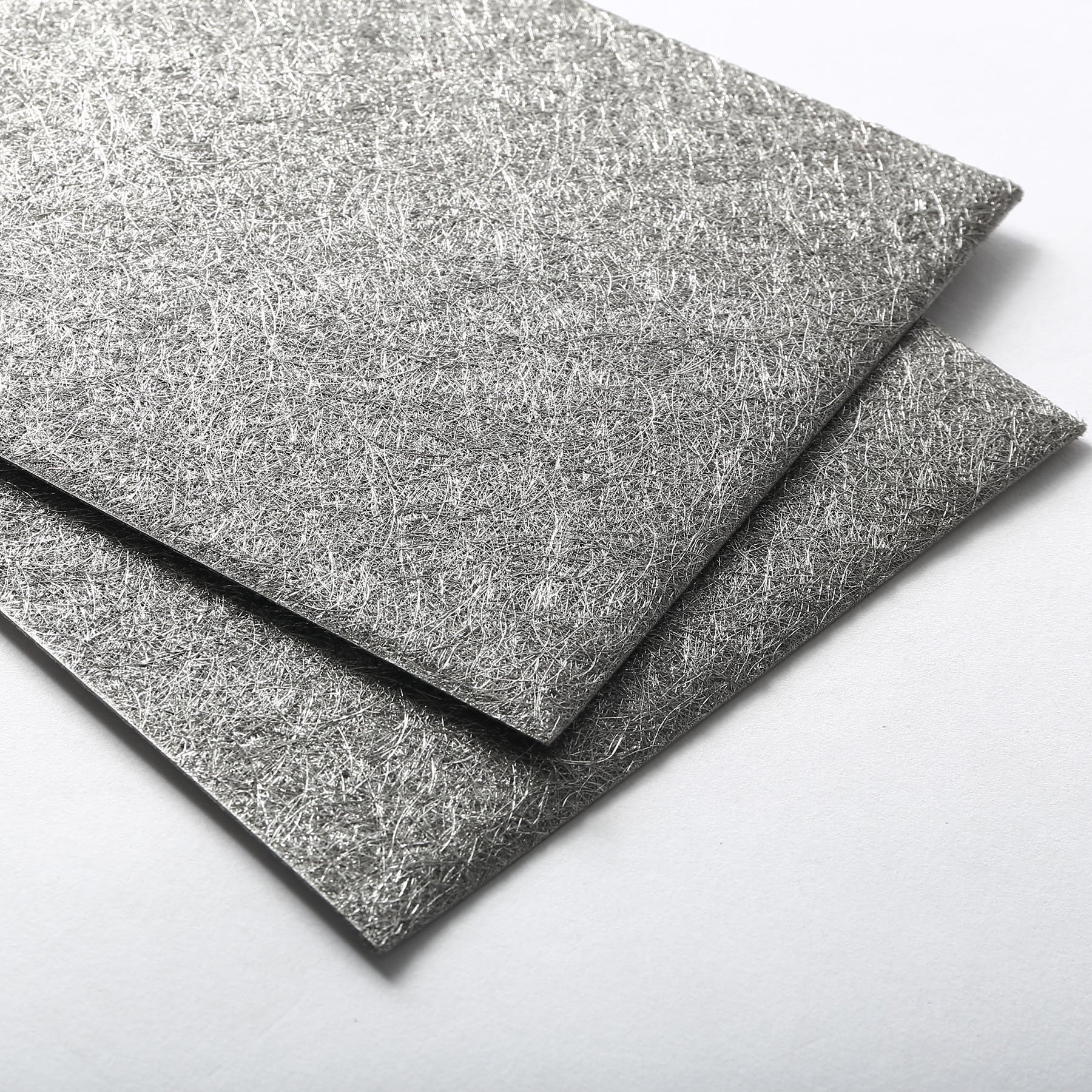

Sintered fiber felt

What is the function of a Sintered Metal Fiber Felt?

A sintered metal fiber felt is a porous material that offers superior filtration capabilities over other types of filtration media.

It has excellent filtration properties, which makes it a good choice for constructing a filtration element.

Consequently, you can add the material as a single layer on a sintered filter element or sintered mesh.

You can also sinter together multiple layers of the materials to construct a complete filter media.

Sintered metal fiber felt

How does a Sintered Metal Fiber Felt work?

Filter elements constructed using sintered metal fiber felt follow similar principles to other types of media.

However, the characteristics of the media, such as high porosity, increase permeability up to 20 times compared to other types of media.

Typically, you can use this type of media for filtering either gases or liquids.

A sintered metal fiber provides a porous and torturous path which blocks and retains the particles as the process fluid passes through the depth filters.

With time, the captured particles create cake deposition on the surface of the media though more particles stick on the previously retained particles.

Where the incoming gas is heavily contaminated, then cake filtration plays a unique role in dust removal.

Here, particles quickly create a filtration cake on the surface of the medium that further results in more pressure drop.

As more particles lodge on the surface, the pressure drop increase until the filter reaches the terminal pressure drop.

In self-cleaning filters, cleaning is initiated, and a clean gas/liquid is released in reverse flow to dislodge the cake.

As the particles move through the porous material, they hit and stick on the fibers through four main mechanisms. These mechanisms include:

- Inertial impaction

- Interception

- Diffusion and,

- Electrostatic forces

Cleaning could restore the pressure drop to initial levels if the pore sizes were appropriately chosen.

However, complete regeneration will not be possible if the dirt load is progressively lodged inside the porous media during the forward flow.

How is Sintered Metal Fiber Felt Manufactured?

You can prepare a sintered metal fiber felt by simulating the following procedures below.

Remember, this is the procedure you can use for the preparation of sintered stainless steel fiber felt.

- Place the sintered metal fiber felt in a vacuum sintering furnace and heat up to between 300-600°C. Maintain these temperatures for 30 to 120 minutes.

- Conduct low-temperature sintering. You will obtain a low temperature sintered metal fiber felt after natural cooling

- Compress the low-temperature sintered felt through the hydraulic press to achieve between 60-90% porosity.

- Return the compressed sintered metal fiber felt into a vacuum furnace and heat between 900°C to 1000°C. Maintain the temperatures for between 1 to 30 minutes.

- Conduct high-temperature sintering. Allow it to cool naturally to achieve quality sintered metal fiber felt.

What Applications use Sintered Metal Fiber Felt?

You can use sintered metal fiber felt in numerous applications requiring fine, deep, and sub-micron filtration such as:

- Purification of polymers and polyester melt

- Pre-filtration of ultrafilter

- Filtration of refining processes

- Electronic dust collection for gases with high temperature

- Purification of liquids in petroleum, food, and beverage, biological and pharmaceutical industries

- Protection filters for vacuum pumps

- Support for filter membranes

- Cars airbags, gasbag aerators

- Chemical and catalysts recycling

- Filtering fuels for aircraft and ships

- Chemical fiber filtration

- Purification of wastewater

- HEPA and ULPA filters

- Radiation of materials for manufacturing burners

- Ventilations in nuclear applications

- Filtration of viscose rayon

What are the features and benefits of a Sintered Metal Fiber Felt?

Sintered metal fiber felt of superior quality should possess the following features:

· Good Resistance to Heat and Corrosion

Depending on the type of construction metal, the sintered metal fiber felt can withstand temperatures of up to 1000°C.

Similarly, you can also use the fibers on corrosive applications, which would otherwise corrode ceramics, polymers, and non-metallic textiles.

· Very High Porosity

Sintered metal fiber felt has up to 85% high porosity. The high porosity enables the fiber to support up to 20 times more flow rates than other media types.

It also makes the material last longer on-stream and allows downscaling, where you will use a lesser filter surface to purify equivalent fluid volume.

· Lower Pressure Drop

The low-pressure drop is a result of the high fiber porosity.

It will help you save energy costs, particularly under high filtration velocities.

· Dynamic Filtration Applications

You can use sintered metal fiber felt in constructing both surface and depth filters.

When applied for surface filtration, you will achieve efficient filtration results as a consequence of cake accumulation.

Similarly, its high dirt holding capacity also makes it highly suitable for depth particle capture when it is used to construct depth filters.

· Long Service Life

Media constructed from sintered metal fiber felt have longer service life by a factor of 2 to 3 times compared to conventional media such as wire mesh.

· Ease of Cleaning

The material has an open structure which enables easy cleaning through backflushing or back pulsing in situ.

The in situ cleaning reduces downtime costs and enhances profit margins because you don’t have to halt production.

· Superior Mechanical Strength

Constructing the metal fiber involves sintering, which generates strong fiber bonding, which guarantees high-strength filtration media production.

Filter elements constructed using the material can withstand very high pressure, thermal shock, and frequent backflushing when supported with an excellent inner core.

· Thin Membrane

It has a thin membrane that enables quick and easy cleaning, pleating, shaping, and welding.

The thin membrane also enhances the capability of responding to backwashing and back pulsing.

· Assorted Materials of Construction

You can choose the most suitable sintered metal fiber felt from a material of your liking.

These metals are break-proof, weldable, have a low thermal expansion, and others can be cleaned using chemicals.

· Filtration Efficiency

You can use these fiber felts for HEPA and ULPA filters because they can remove particles down to 0.1 microns.

You can also use them for making screens that can retain particles as large as 100 microns.

What Types of Material can you use to make a Sintered Metal Fiber Felt?

You can use diverse types of metals and various alloys to construct a high-quality, sintered metal fiber.

Stainless steel 316L is the most widely used material.

You can also choose any of the materials below:

- Monel

- Hartz

- Nickel

- Stainless steel 304, 304L, 316

- Chromium

- Inconel

- Hastelloy

- Chromium-nickel-iron alloy

- Chromium-aluminum-iron alloy

- Double–phase alloys

- Sintered wire mesh support where applicable

How does a Sintered Metal Fiber Felt compare to a Woven Wire Cloth?

You need to understand the construction, advantages, and drawbacks of each product.

That will make it easier to compare the two products.

· Construction/Constitution

The main difference between the two products is in manufacturing because you can use similar metal alloys to manufacture each.

For metal sintered fiber felt, you first break the desired alloy into fiber-like, cut them into small pieces then thread them together by penetrating a needle.

Subject the knitted fiber through a sintering process to develop a permeate bond among the individual fibers.

In the case of woven wire, you can use a specialized weaving loom to interlock a series of wires together meticulously.

Advantages

Metal fiber felts:

- Have fine pore sizes compared to woven wire mesh

- It is easy to work with and transform into various shapes

- Have low electrical heat resistance making it perfect for filtration of hot materials and electrical applications.

- The pore opening is very stable and difficult to compromise

- It has a higher dirt holding capacity

- Easy to customize the wire diameter, pore size opening, weave pattern, micron rating, length width, etc.

- It has a lower pressure drop

- Provides precision for sharp-cut point; hence the end product contains uniform particles that adhere to the specifications of a given industry

- It is the only option for manufacturing elements with materials like copper and brass which cannot withstand the sintering process

Drawbacks

Metal fiber felt:

- Irregular pore openings are leading to the presence of particles with inconsistent particle sizes in the final product.

- Cleaning is not as easy as woven wire mesh because the particles entangle and trap in random pore spaces.

Woven wire mesh:

- More laborious to create and hence longer lead time

- The opening is very delicate and fragile

How can you Test the Quality of a Sintered Metal Fiber Felt?

You can conduct two main types of tests for sintered metal fiber felts.

They include:

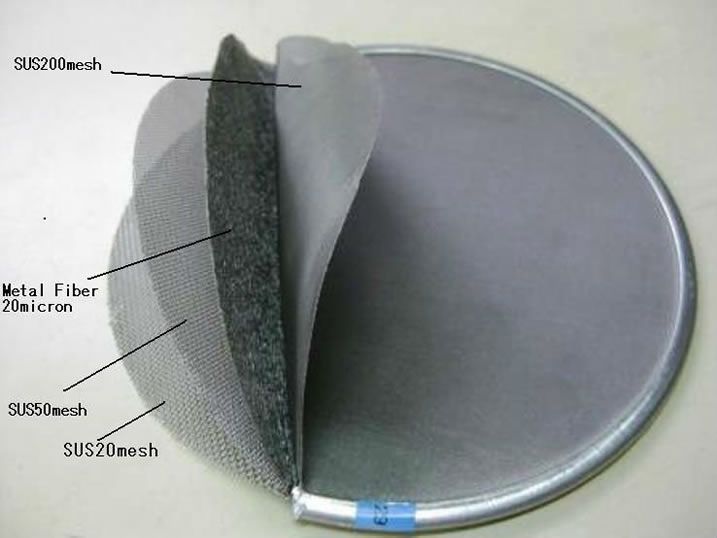

Sintered metal fiber felt

Bubble Point Test

You should carry out the test as specified under ISO 4003 guidelines.

The test lays down methods of determining the pore size of the porous structures such as bearings, electrodes, and filters.

Note that you can only use the test for quality control but not for grading filters.

Accordingly, you can consider the following for the test:

- Impregnate the sintered metal fiber felt piece to be tested with the test liquid.

- Immerse the test piece in the test liquid and introduce a gas (air) while gradually increasing the pressure

- Using a manometer, determine the pressure at which the first bubble stream is released from the test piece surface under standardized conditions.

- Using the appropriate mathematical formula, determine the equivalent bubble test pore size.

Air Permeability Test

You should conduct the test according to the guidelines of ISO 4022.

You can follow these steps to perform the test.

- Ensure that you remove all the liquid from the pores of the test piece before you begin the test. You can also remove grease and oil by extracting with an appropriate solvent as specified under ISO 2738.

- You should select a clean and dry inert gas as a testing fluid. However, you can also use liquids as test fluids to determine fiber permeability when considering a specific liquid.

- When testing a flat piece, you can use the guard ring test head. The apparatus conducts nondestructive tests on partial sections of the sintered metal fiber felt.

- You can use a jig for testing hollow cylindrical metal sintered fiber felts. Here, you clamp the cylinder between two flat surfaces axially, then directing the test fluid to permeate through its walls outwards.

Use a flexible seal to reduce the effects of surface irregularities that would otherwise cause leakage.

What Rating System is used to Grade a Sintered Metal Fiber Felt?

The sintered metal fiber filter grades depend on the pore size rating.

Consequently, the fibers are rated using an absolute rating scale based on the size of pore openings in the media.

The final rating of the sintered metal fiber felt filter element depends on the layer’s used layer weight and composition.

Several layers have been bonded together, then cumulative weight and the fiber content of the layers determine the final rating.

What Factors Influence the Performance of Sintered Metal Fiber Felt?

The effectiveness of a sintered metal fiber felt significantly depends on the following factors:

- The level of contamination of the incoming fluid

- The micron rating of the filter element

- The fluid flow rate of the system

- The dirt-holding capacity of the filter element

- The level of porosity of the fiber

- The fiber permeability

- The nature and characteristics of particulate contaminants

How can you Select the most Appropriate Sintered Metal Fiber Felt?

When you choose an appropriate sintered metal fiber felt to construct filter elements, you will get a quality product that meets industry requirements.

There are many things you need to know when selecting sintered metal fiber felt.

Ensure that you suit the following vital materials and properties to match your system requirements.

- The construction material

- The micron rating

- Porosity

- Permeability

- Effective filtration areas

- System flow rate, pressure, and temperature

- Compatibility to process fluids and contaminants

- Sealing configuration

- Size of filter

- The system working temperature

- Resistance to fire, heat, temperature, acids, and bases

- The aperture opening

- Filtration accuracy

- The filter specification

How long can Sintered Metal Fiber Felt Filter last?

The high porosity characteristic of a sintered metal filter gives the filter long service life, usually 2 to 3 times the lifespan of other common filter elements.

Can you Clean and Reuse a Sintered Metal Fiber Felt?

Yes, you can clean and reuse a sintered metal fiber felt. Cleaning helps you save on energy and helps protect the environment.

Consequently, you can use the following methods to clean a sintered metal fiber felt:

§ Chemical Cleaning

It is the most preferred and effective method for cleaning solvents involving acids and bases. It is also best suited for collecting polyester condensation.

§ Ultrasonic Cleaning

It involves ultrasonic sound, which produces cavitation and continuous burst responsible for removing particles trapped inside the fibers.

§ Backwashing

This type of cleaning removes contaminants embedded in the fiber material by pumping a clean liquid, usually water, in the reverse direction to normal flow.

§ Backflushing

Backflushing method is the most suitable for cleaning the fiber when the operation is on. It involves a periodic reversal of the system fluid to clean the filters.

§ Back pulsing

It is a promising alternative to cleaning that removes non-adhesive, external contaminants.

Using this method, you don’t have to stop production for cleaning because the fluid flow is reversed for only a fraction of a second.

The main difference between this method and the others is the force and duration.

Back pulsing employs a strong force and lasts less than a second, whereas backwashing can take a minute or more and uses lesser force.

How much can a Sintered Metal Fiber Felt cost?

The cost will vary depending on the type of metal used and the fiber size felt, among other factors.

For instance, stainless steel sintered metal felt can cost between $5 to $50 apiece, while sintered metal fiber felt constructed using nickel will cost between $20 to $80.

What are Quality Standards there for Sintered Metal Fiber Felt?

Sintered metal fiber felt disc

The standards are not legally binding and only acts as guidelines from which other countries or trade unions can forge their standards.

The standards include:

- ISO 4003: Contains standards that specify guidelines on how to conduct bubble point test

- ISO 4022: Contains specifications on how to carry out average air permeability

- ISO 4572: These standards give detailed guidelines on how to determine the dirt holding capacity of a sintered metal fiber felt

How can you Determine the Dirt Holding Capacity of a Sintered Metal Fiber Felt Filter?

The dirt holding capacity is the quantity of dirt that the filter element can retain before it reaches the terminal pressure drop.

You can use different methods to determine the dirt-holding capacities, such as multi-pass test, continuous or batch injection test, and single-pass test.

However, the multi-pass test under the guidelines of ISO 16889 (formerly ISO 4572) is the most commonly used.

Using the multi-pass test, you will need to continuously inject ISO medium test dust in the form of slurry in the reservoir upstream.

The setup simulates the actual lubricating or hydraulic system and allows the dirt not captured in the first round to recirculate the system.

Why should you Conduct a Bubble Point Pressure Test on a Sintered Metal Fiber Felt?

You will use the bubble point test to determine the pore size of the metal fiber felt.

In principle, under constant wetting for a given fluid and pore size, the size of the hole is inversely proportional to the pressure required to push air bubbles out of the pore.

The initial test results for a bubble point procedure give the size and location of the largest pore.

The open bubble point pressure reading determines the mean pore size of the fiber.

What makes Sintered Metal Fiber Felt Resistant to High Temperature and Corrosion?

The process of making fiber involves sintering and compression.

The process creates strong bonds between individual fibers, exponentially increasing the fiber’s mechanical strength and resistance to corrosion.

It also prevents coarsening of the crystal grains found inside the fibers.

FilSon offers a perfect solution in the sintered metal fiber felt industry, depending on your unique application requirements.

For questions or inquiries, contact the FilSon team now.