Your Sintered Bronze Filter Expert In China

Compare to other metal sintered filters, Filson sintered bronze filter has a more reasonable price, given its more economical raw material. Sintered brass filters from Filson are durable and simple to maintain and clean, with a long span of life to avoid replacing frequently.

Filson always offers a series of customized services from drawing design to the whole production process, choose us, you will receive preferred sintered bronze filters.

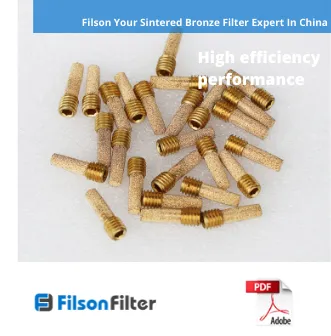

Sintered Bronze Filter

Why Choose Filson Sintered Bronze Filter?

As a reliable and professional sintered bronze filter supplier with over 18 years, Filson can engineer high-performance sintered bronze filters and keep on innovating to support your various complex applications, such as pneumatic muffler, flame arrester, pressure snubber, fluidizing pad.

With our advanced sintering technology, scaled processing factory, and skilled production team, Filson can manufacture quality sintered bronze filters within 10 days no matter for small lots, large quantities, or urgent orders.

FILSON: Sintered Bronze Filter Manufacturer

Filson Sintered Bronze Filter, also named sintered brass filter, sintered copper filter, bronze sintered filter, is a kind of filtration device with high temperature and pressure resistance and stable permeability features. It is made of numerous spherical bronze particles which experienced a sintering process in powder metallurgy.

A strictly controlled sintering process enables Filson sintered brass filters to produce uniform pore sizes and distributions, ranging from 0.1 to 100μm. Therefore, Filson sintered copper filters can offer excellent air permeability and high porosity.

After a period of time of use, the sintered copper filters may become color fading. Don’t worry about this problem as it is a normal phenomenon that will not influence the final filtration effect. Also, a Ni plating treatment is available to help you effectively avoid the problem.

- Choose standard Filson sintered bronze filters you need

Filson has kinds of standard sintered copper filters for you to choose from according to your specific applications. As for shapes, our sintered bronze filters are available in disc, square sheet, cylinder, cylinder with bottom, cone with flange, with a standard thickness of 4mm-120mm. Filson will assist you in making a correct decision with a free consultation.

- OEM /Custom your bronze sintered filter

Do you find your ideal filtration solution in our standard Filson sintered bronze filters? If not, Filson specializes in custom sintered brass filter engineering. Please contact us with your specifications including the viscosity of the fluid, working temperature, minimum&maximum flow rate, pressure drop, fineness, desired shapes, and sizes.

Note: minimum order quantity for Filson sintered bronze filter with Dia.<100 is 10 pieces.

No matter for product quality or shipping, Filson pays great attention to every process. All Filson sintered brass filters are fabricated in a dust-free room to avoid bringing new contaminants to enter into your system. For packages, we choose reinforced outer packaging to help you reduce the vibrations or shock during the delivery.

FILSON is your quality-driven manufacturing partner for bronze sintered filters. If you have any immediate questions, call +86-157 3695 8886 today! Or please contact Filson with sales@filsonfilters.com for a quick quote.

Filson is always here to provide you the most reliable solution of sintered bronze filters!

Filson Sintered Bronze Filter Cleaning Method:

1.Conventional cleaning: use pressurized water flush Filson bronze sintered filter from inside, then use compressed air flush it in the same way. Repeat this cycle 3-4 times.

2.Ultrasonic cleaning: simple and effective, please put Filson sintered bronze filter in an ultrasonic cleaner, then take it out after around half an hour.

3.Solution cleaning: dip the Filson sintered brass filter in the cleaning liquid which will react chemically with inside contaminants, thus will help you efficiently remove particles.

Filson Sintered Bronze Filter Advantages:

- High filtration efficiency: micron rating of 1-250μmwith 99.9% filtration efficiency

- Minimum thickness of5 mm: for higher mechanical strength and lower pressure drop

- High-temperature resistance: no deforming or degrading even under 200℃ condition

- High chemical resistance: can filter in corrosive fluids, a variety of gases, and fuels

- Easy welding: can be welded by resistance welding, tin welding, and arch welding

- Easy machining: are ready for any machining process like turning, milling, drilling

Filson Sintered Bronze Filter Specifications:

- Nominal chemical composition: Cu-89% Sn-11%

- Sintering density: 4.5-6.5 g/cm3

- Void ratio: 25%-43%

- Filtration rating: 1-250μm

- Temperature suitability: oxidizing atmosphere: -250℃ to200℃ reducing atmosphere: -250℃ to 450℃

- Tensile strength: 9.8 to 83.4MPa

Filson Sintered Bronze Filter Applications:

- Sieving of fluids: lubrication of fuels, fluidization of fine powder-like cement

- Sound dampening: pneumatic exhaust mufflers, breather vents, speed control mufflers

- Chemical use: water purifying, chemical products manufacturing

- Industrial use: pneumatic cylinder producing, geared motors&gear boxes fabricating

- Transportation industry: used in railway, automotive and marine sectors

Filson pneumatic mufflers are fabricated with sintered brass material to increase the surface area of the exhaust port which it covers. Therefore, its lager surface will further diffuse the released air to reduce turbulence and thus decreases noise levels.

Different shapes of Filson pneumatic muffler silencers can be designed depending on various applications, with two common designs are cone and flat.

Standard Filson pneumatic air muffler filter is available in 40 micron filtration, and 20 to 90 micron filtration can also be obtained by customizing.

Some specifications will directly influence the final design of Filson pneumatic silencer, such as housing materials, working temperature ranges, working pressure range.

Air exhaust silencer from Filson is usually produced by brass, withstand maximum operating pressure of 300 PSI and working temperature ranging from 35℉ to 300℉(1.7℃-148.9℃).

Filson air exhaust mufflers are suitable for non-corrosive and neutral environments with competitive cost option and longer service life. In addition, Filson compressed air exhaust silencer can also contain a filter as a cleaner to remove oil mist and dust during the exhaust air process.

People Also Ask

This is a filter that undergoes compression to form a solid mass of bronze.

It has openings that allow the removal of certain substances.

Production is from a spherical powder bronze with controlled proportions of particles.

This gives it a rigid structure with uniform pore sizes.

Sintered bronze filter

The process starts with the conversion of bronze into powdered form.

This is by various processes such as chemical decomposition, atomization, and grinding.

The powder is poured into a die and it is compacted under enough coercion to enhance adherence to contact points.

All these take place at room temperature.

Place the bronze part inside a furnace where extreme heat will combine the molecules of the metal.

This creates a rigid, durable, and porous component.

Manufacturing of this type of filter can be in specific shapes based on the clients’ requirements and specifications.

Making bronze sieves encompasses, filling a mild molecule of a spherical pattern.

Sintering activity allows bronze to keep its visible characteristics without alteration.

For this reason, this is the most preferred process of making filters with metallic materials.

An attribute which goes hand in hand with this strainer are outlined below:

- It is durable.

- Its cost is relatively cheap.

- Resistant to temperature.

- It is available in customized sizes.

- Simple to maintain and clean.

- Produces precise filtration.

- Quality materials.

- It resists high pressure.

- The filter has a stable pore size.

- It is made with a fine finish.

- These filters have a low-pressure drop.

Yes, it is possible. An effective way is by ultrasonic.

This entails, placing your desired sieve in the machine and heat for a period of half an hour.

Ensure inspection of its differential force for your filter enhances preciseness.

Tidy up the bronze porous parts to avoid contamination from surfaces.

This will help in increasing the continuous running of fluid to remove them.

Back-washing might also take place when you have solid impurities on your sieve.

Refers to a union or merger of many layer filter discs such as; woven and perforated filter discs.

Classification of this sieve puts the basis on the materials used.

It comprises five layers which include the filtration control layer, protecting layer, scattered skeleton layer, and skeleton supporting layer.

Metal sintered filter

Other than bronze, some include;

- Copper.

- Nickel.

- Stainless steel.

- Titanium.

- Aluminum

For one to make the right selection of this type of filter, certain factors may be helpful.

These include:

- Considering the removal capacity of various elements which might end up leading to its contamination resulting in frequent cleaning.

- Its porosity ability helps one select the correct element.

- Retention ability of molecule you want it to have.

There are many merits and these include the following;

· It Maintains Force Exerted and Temperature.

It has a lockout feature that prevents higher differential pressure generated by frigid temperatures.

This filter also comes with applicable maintenance instructions.

· Simple Processes

Sintered bronze filter processes are well simplified, hence easy understanding such as welding, Machining, and cleaning.

· Durability

Has a certain strength that enhances its long-lasting features.

This promotes its usability many times without replacing it.

· Efficiency in Filtering

It exhibits a higher degree to stop particles of certain sizes by filtering out abrasives and acid-forming moisture.

Useful for high-pressure filtration in both directions of flow.

Its process of control gives the greatest and reliable performance.

· Quality Service

This filter works well since it offers protection from various chemical and physical reactions because of its corrosion resistance.

· Reasonable Pressure Drop

Obstruction to its pressure between two points is under control to a certain degree.

In case it occurs, the effects are well mitigated from extreme damaging occurring on your filtrate.

· Fine Tolerance

It picks up finer details when cast.

Bronze filter entails the ability to remove unwanted particles.

Other advantages include:

- Using automated equipment and processes enhances productivity. As it takes place from a prime melting point with less difficulty.

- Dimensional tolerance on its components ensures no further machine process occurs. Hence scar becomes almost negligible.

- Easy to get parts of desired mechanical properties among others, i.e. electrical.

Efficiency in sieving describes the percentage of molecules of a certain size that is detainable.

Hence stopped by this filter medium.

Fabrication ensures unique performance characteristics for filtrates thus easy separation.

It sets particulate capture efficiency at 99.9% making it better using either surface or depth media.

Areas where the sieve has usage vary with purpose, function, and incorporation aspects.

Some of its use is in the environment like:

Sintered bronze metal filter

· Sieving of Fluids

Because of its ability to withstand the intense force applied.

The lubrication of fuels is a useful aspect of its application.

· Domestic Appliances

It is used to produce home appliances such as gas burners, boilers, and printers.

· Sound Dampening

Its usefulness in enhancing excellent distinct pitches in audio devices.

· Transportation

Used in railways automotive and in the marine sector.

· Chemical Use

Helps in purifying water, making chemical products, and in pharmaceuticals operations.

· Industrial Uses

Industries use these filters to make pneumatic cylinders, geared motors, and welding.

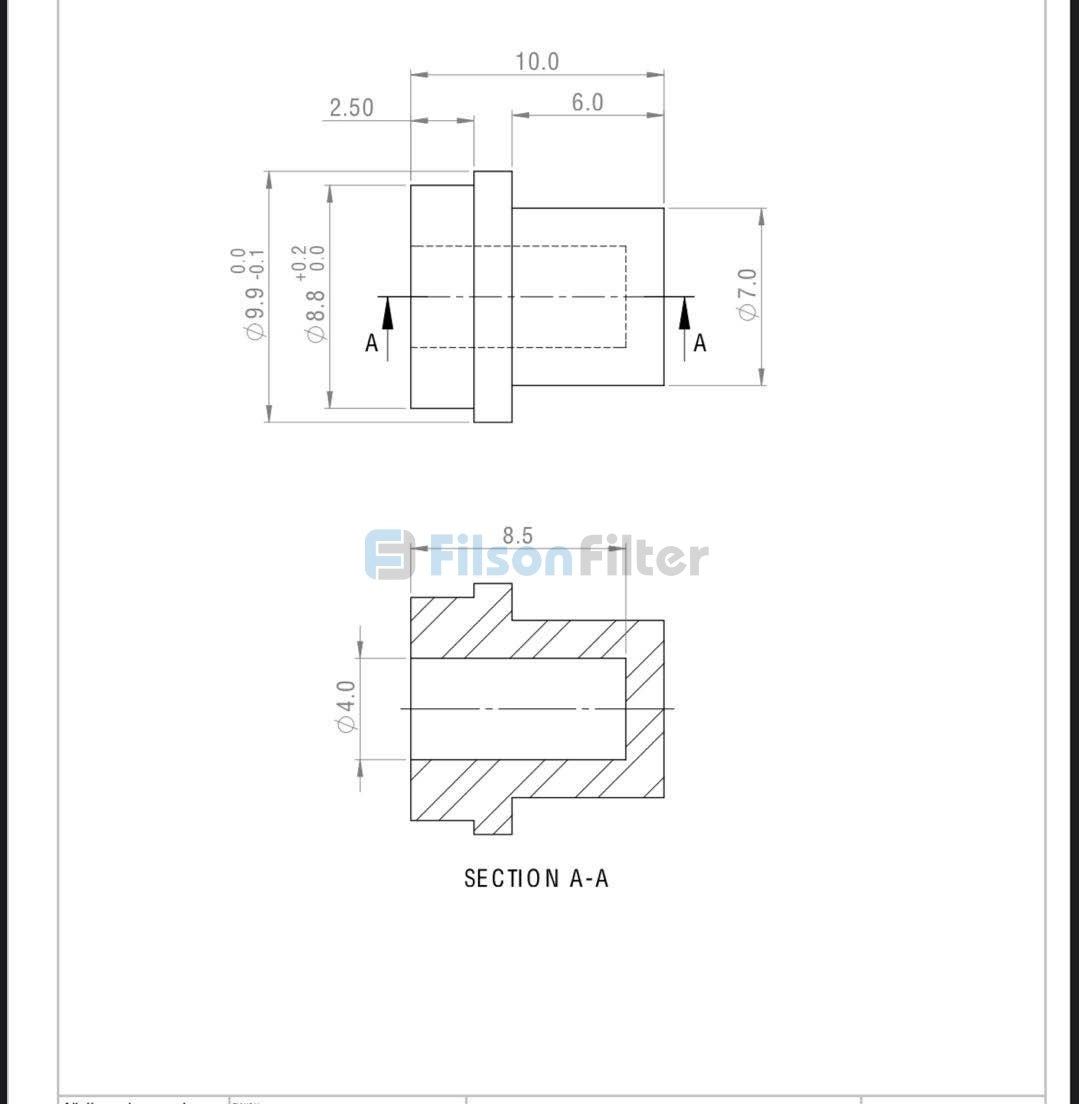

Dimension is very useful as it helps describe the length of your sintered metal filter and the application it can fit into.

The various sizes of sintered bronze filter are.

Em 12, 25, 37-90, 150, and 50.

The thickness of the filter which is available varies examples include;

4mm – 120mm

2000mm – 1000mm

0.10 – 0,30mm

Yes, disadvantages associated with usage of this sieve are there although they always vary.

Some of these demerits include:

· Costly

More expensive when used compared to brass and steel based on its copper component.

The price of copper is increasing because of its wide use.

Tooling and equipment can be costly when the production volume is small.

· Delicate Nature

Its softness and the fact that it cannot hold an edge well.

Makes it disadvantageous in certain conditions that do not favor its use.

· Core Migration

A manifestation of the non-bronze core can cause tiny white spots that enlarge over time, and removal by experts adds to cost.

· Deterioration

Poor resistance to ammonia and a compound of cyanides nature and dust and dirt can get to the surface.

· Contaminants

The appearance of rough spots and light green shows contaminants which is rust in iron-based metals.

If uncontrolled this might end up destroying the bronze.

· Complexity

The large and complex shaped part is difficult to produce because of the processes required.

Considerations that need priority when making this type of strainer include:

- Features of contaminants that cause defects associated with this model of filter should be a priority. It will help cut the effects attributed to factors that are not containable.

- Consider the environment this porous will operate in. It must be one tolerant of the conditions, hence no damages.

- Pore size. This helps to define micron rating which is the opening size of molecules it can contain. Such as the smallest microns. Be careful to make the right size.

- The strength you need your filter to have. This will help you provide the required level of strength needed for forward and reverse flow.

- Quantity of force, you will allow your filter to lose when substances pass through it. Making this very clear is of utmost benefit. This is because it gives you an edge to avoid future problems associated with distinguishing factors that exist between them.

Yes, they are different. For instance,

Bronze sieve has unique appliances to those of the bronzing powder.

Hence is not the same when applied in various areas.

A sintered bronze filter is used in applications such as domestic appliances, and sieving of fluids among others.

On the other hand, bronzing powder use is limited to cosmetic products.

They emulate sun glow to enhance a tan.

Its functionality bases on the removal of unwanted things found inside internal combustion engines such as dust and rust.

Features it possesses include;

- High volume.

- A variety of fuels sieved.

- Precise diameter for its flange.

- Warranty.

Of high importance is noting that its salient factors are the products of its components, which it uses to perform its function.

The regulations that assure consistency of this filter to meet requirements hence fit for use are:

Sintered bonze metal filter

- Physical durability. The filter possesses the ability to remain functional, hence will not need frequent maintenances besides repairs.

An assurance of its life duration is a key factor in its standards and quality.

- Filtration levels, ability, and efficiency in enhancing the passage of substances through the pores. This reflects filtrate quality performance and functionality.

- Resistance to temperature. This is the ability to withstand high temperature and this increases its resistivity.

It will help determine its level of adherence to standards.

- Materials used complement bronze and its components such as chemical composition, density, filtering degree.

The range of stretch must correspond to the quality needed for making a final output thus enhancing customer satisfaction.

- Use of varied grades infiltration by setting standard porosity grade for particle removal as this will state the caliber of your filter.

- Resistance to corrosion. This is how well it can withstand damage caused by oxidization or any chemical reactions.

This ensures it suits the specifications of damage given to the clients.

- Handling and maintenance procedures.

The written instruction followed, and the personnel ensuring the continuous functionality of the filtrate.

It should operate as designed within the safety parameters in place that should range from process risk to reliability management.

- The authenticity of a filter. The filter should be an original bronze made and not a replica thus avoids counterfeit purchasing. If made like this, it does not give negative reviews from your customers.

It refers to a sieve that has been through a process known as sintering.

It is done under high temperatures beneath the boiling point.

These filters have increased efficiency and work at a high climate and force without deformations.

Some factors to note when choosing the right filter of this type are:

- Chemical resistance capability.

- Flow rates and pressure drop

- The strength it possesses.

- Porosity rate.

- Electrical and thermal conductivity.

- Cleaning capability.

Usage of sintered filters are wide, but some of its applications where it is useful are in the following

- Aeration of liquids.

- Ventilation of injection molds in plastic industries.

- Sieving liquids and gases.

- Silencing and flame barriers.

- Humidification of gases powders and granulates.

The distinct features and their applications come in handy.

As each helps you decide which type you will select to fulfill the desired needs and performance.

There are many features that are unique to these types of filters.

The distinct factors that make them different from others include:

· Components Used

A material used is different as it uses metals in which infusion is with alloys of choice that suits the need.

The matter comes in various categories and features.

· Its Design Process

Manufacturing is by sintering and having a set of cleaning procedures if the need arises to wash them.

This enhances the avoidance of clogging on the sieves.

· Purpose

They deliver specific aims such as resistance to certain factors and conditions like heat and corrosion.

Which makes them different from other components in use.

· Appliances Used

Each metal has unique and wide usage in its specific areas of an application when designing them.

There are many differences between these two filter which include the following:

Sintered bronze metal filter

Sintered stainless steel metal filter

- Sintered stainless steel metal filter is stronger than bronze. This is because of stainless steel being an iron alloy mixed while the latter is a copper alloy.

- Pricing differs, as bronze is more expensive than steel. A situation based on its components, liability, and ease of acquisition, among other pricing factors.

- The oxidizing temperature of the stainless steel filter is 530 0C while that of the bronze filter is 480 0C.

- The maximum operating temperature differs with that of stainless steel being 800 0C while that of sintered bronze 480 0C.

- The density of sintered bronze can range from 4.5 to 5.6 g/cc while that of stainless steel ranges can be 5.2 to 5.8g/cc

- Stainless Steel has a better chemical change than resistance compared to a bronze filter as it maintains its properties after exposure to the chemical reagent.

- Stainless steel keeps its shape, thus little signs of distortion. While bronze is softer, thus elongation ability as its limits reaches.

This is modular sieves put inside a housing, used to remove particles or sometimes chemicals present.

Its composition comprises of a wide range of materials from distinct elements.

The advantages of using these types of filters are:

· Excellent Functionality

It is good at delivering its mandated functions in the filter as a high performing component.

· Durable Aspects

It assures one of long-lasting use and this saves on repairs and maintenances.

This gives the clients the ability to enjoy its extensive use, hence money worth felt for the product.

· Conforms to the Latest Qualification and Demand

It adheres to the existing current pace set in the industry.

Making it suitable since not recalled with the mandated authorities who inspect compliance.

· Diversifies Customer’s Demands

It does this by making sure non-identical demands incorporation fits the wants and use for its customers.

The success of any product in the market is tied to making sure that you incorporate the customer’s requirements.

· Broad Array

The category of a filter selected varies because of the high number of sieves available.

Each comes differing from the other to fit the taste and preferences of the various market segments.

This is a characteristic that attributes to its performance.

Some other Benefits it provides are;

- Its filter collection efficiency is much higher with reduced emissions of harmful substances thus helpful for use.

- Its size and weight are lighter and have a specification that saves on space

- Resistance to air compression.

- Does not need a maintenance workload.

The pressure drop across this type of filter can be established in various aspects of its performance and functionality such as:

- When the pressure maintenances are impossible in your fluid within your application.

- A time when the operation is not at its greatest.

- When there is no relevant force to filter.

- You can also determine this when there is an incomplete filtration because of contaminants.

- Yielding of better purging characteristics is also an indication of a low- pressure drop in your filter.

- When the application is not achieving the fluid rule needed.

It is a depth filtration that uses a set of processes in the filter media to trap particles.

Suitable for applications requiring high temperature and differential pressure requirements.

Less permeable and used in demanding environments.

Its uses include:

- Food and beverage industry.

- Chemical and pharmaceutical industry.

- water treatment system

- Petrochemical industry.

Sintered bronze metal filter

The life or duration of this filter usage depends on its holding capacity and pressure drop.

Bronze being one of the most durable metals lasts thousands of years.

However, it calls for change when there is the presence of water and chemical such as chlorides.

Apart from this, when bronze deteriorates, you have to change it.

At FilSon Filters, we offer high-quality and reliable sintered bronze filters.

For inquiries or orders, contact FilSon technical team.