Filson: Your Premier Sanitary Filter Choice in China

As a professional sanitary filter manufacturer, Filson has full capacities on sanitary filter fabrication. We can produce stainless steel sanitary filter housing, inline sanitary filter, sanitary tank vent filter, sanitary steam filter and so on.

Filson sanitary filters are typically used in applications that require cleanliness. And they are widely applied in food, beverage, dairy, cosmetics, pharmaceutical, biotechnology and electronics processing industries.

Filson sanitary filter is designed and built to manage contamination of liquids and inhibit the growth of bacteria in the process. It can also prolong the service life of pumps, valves and other process equipment through purifying the liquids and air.

If you are interested in Filson sanitary filter, feel free to contact with us. Leave your name, phone number, size, application site and drawing, we will provide you a suitable sanitary filter.

Filson Sanitary Filter

Why choose Filson Sanitary Filter

Filson has dived into sanitary filter research and development for over 15 years, we have made great progress in sanitary filter manufacturing. Till now our products have been exported to over 35 countries and regions, and we gain reputation for our high quality sanitary filter and after sales service.

Since the fluids that sanitary filter comes into contact with are used for food, drink, pharmaceutical and other demanding extremely cleanliness, it has strict requirements on the environment. Here, Filson sanitary filter has passed 3-A sanitary standard certification, so you can totally feel ease to use our products.

Filson is committed to offer one stop solution for sanitary filter manufacturing, we can customize your sanitary filter according to your final application. Send us your drawing and specifications, you will get an awesome one.

Filson: Your Leading Sanitary Filter Manufacturer

Filson is one of the best sanitary filter manufacturers in China, we have a plenty of professional engineering specialists. Since we have full capabilities on sanitary filter fabrication, we can tell you how to choose appropriate filter which is compatible with your equipment.

Sanitary is a broad term that relates to health or the protection of health. A sanitary filter is both designed and built in a manner were it inhibits the growth of bacteria. Filson sanitary filter has a broad application range with such numerous advantages and excellent filtration performance.

There is a big difference between sanitary filter and sterile filter. Filson sanitary filter can not only remove impurities from the fluid, but also prevent the growth of bacteria. While sterile filter cleans fluids that are already contaminated with bacteria.

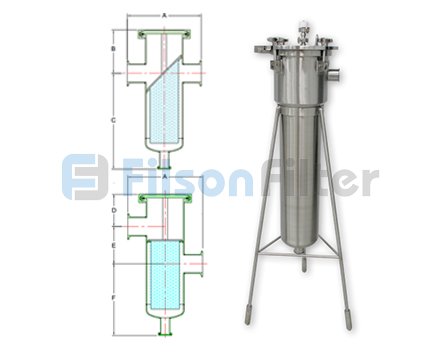

Filson supplies sanitary filter to prevent contaminated fluids or air entering into the main process. When untreated fluid enters into the filter housing and distributes around the filter housing cartridge, the filtration process takes place and collects solid or dirty particles of the fluid, then cleaned and purified fluid enter into the main process.

Filson sanitary filter are used in environments and processes with strict hygiene requirements. Food, drinks and pharmaceutical manufacturing often demand filters that are designed, built and certified to sanitary standards.

To deliver the highest hygienic requirement for your process, Filson adopts high-quality stainless steel material and advanced technology to construct sanitary filter.

With the support of advanced technology and equipment, Filson sanitary filter exhibits premium property. For example, it has super filtration accuracy down to 40 micron and less chance of blockage than other normal sanitary filter on the market.

Filson sanitary filter has rigid structure and good mechanical strength by using high quality 304/316/316L stainless steel material. Even in harsh environment, it still remains stable structure integrity and high filtration efficiency.

When it comes to corrosive resistance, Filson sanitary filter shows good performance. By the way, Filson sanitary filter can withstand temperature ranging from -10℃ to 225 ℃. It can fully meets the set standards in many applications where requires filtration.

Many fluids such as steam, compressed air, technical gas and water that direct come into contact with food, drinks, dairy or other demanding super clean applications, for safe and healthy purpose, a standard filter should be food grade. Filson sanitary filter has passed 3-A design standard certification, so you can use it with confidence.

Filson sanitary filter housing surface has undergone polished treatment to Ra 0.4 µin(we can polish it to the grade you want). It has gently curved corners, free from imperfections such as pits and crevice.

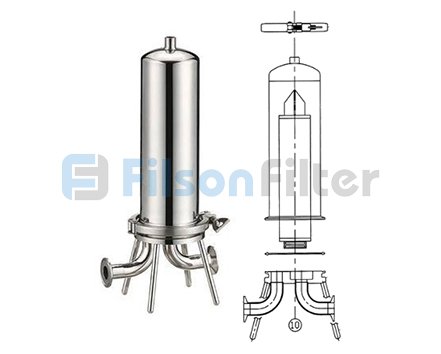

With dedicated design, Filson sanitary filter contains a filter housing and a changeable element. Users can easily disassemble the sanitary filter for inspection and cleaning. Then you can extend its life time and save a big expense instead of buying a new one.

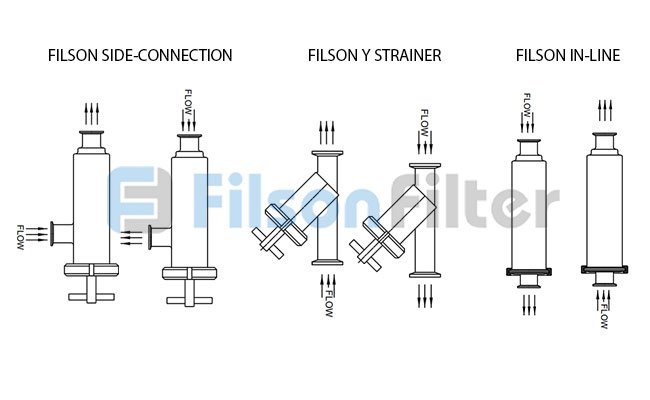

To meet varying needs of specific application, Filson sanitary filters use sanitary connections type rather than threaded connections that could trap contaminant. It mainly includes triple clamp, ANSI flange and welded end connection. And various connection sizes are also available.

Filson sanitary filter will be delivered within 15 days if the order is confirmed. At the same time, we can offer return and exchange service for the sake of manufacturing defects. To build a deep cooperation, you can give us feedback and we will continue improving our product.

If you have any need for Filson sanitary filter, we are always here to support you satisfied service and awesome product. Send us your inquiry for the Filson sanitary filter now!

More details to be known by the following ways:

Phone: +86-157 3695 8886

Email: sales@filsonfilters.com

Filson Steam Filter Function

- Eliminate impurities and inhibit the growth of bacteria from steam, compressed air, technical gas, water and other liquid

- Prolong the life time of other filters and protect pumps, valves, heat exchangers and other process equipment

- Provide purified liquids to the main process and keep clean environment

- Minimize costly downtime and reduce maintenance costs

- Keep products safe and healthy

Filson Steam Filter Features:

- High flow rate at a low differential pressure

- Both contaminants removal and bacteria growth inhibition

- High mechanical strength and rigid structure

- Easy to install and remove for cleaning

- High quality 304/316/316L stainless steel material assurance

- Available in different material, dimensions, connection mode and connection size

- Good corrosion resistance and high temperature resistance

- Save a big expense at low maintenance cost

- Mirror polished surface finish and sanitary connection mode without pits and crevices for clean environment

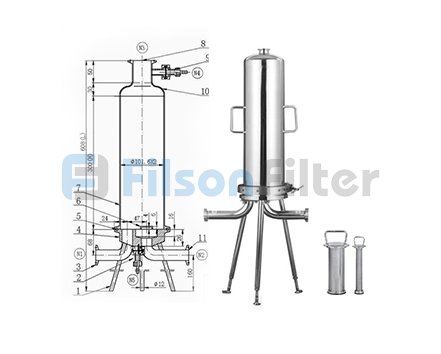

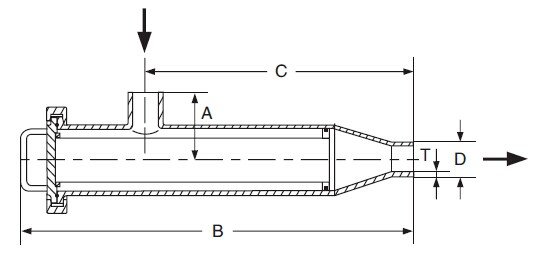

Filson Steam Filter Specification:

- Raw material: 304, 316, 316L stainless steel based on your requirement

- Absolute retention rates: ranging from 765 micron to 40 micron

- Flow rate: 15 T/H

- The sanitary filter housing size: 10-30 inch

- Element size: 1 inch to 4 inch

- Working temperature range: -10℃ to 225 ℃

- Max differential pressure: 10 bar, 200psi

- Filtration efficiency: 0.03-40 micron

- Cartridge type: pleated, wedge wire

- Connection mode: Tri-Clamp, ANSI flange and welded end connection upon your request

- Connection size: available in different sizes

- Seal: silicone gasket(standard), EPDM, PTFE or NBR (optional)

- Inside Ra: 04 micron

- Outside Ra: 0.8 micron

Filson Steam Filter Application:

- Food and beverage processing industry

- Pharmaceutical industry

- Dairy industry

- Cosmetics industry

- Pharmaceutical industry

- Biotechnology industry

- electronics processing industry.

Sanitary Filters: The Ultimate FAQ Guide

In this guide, you are going to learn everything about sanitary filters.

It covers, the working principle, components, applications, quality testing, and filter rating among other critical aspects.

So, if you want to be an expert in sanitary filters, read this guide.

Sanitary filter

Sanitary filters are devices used to remove contaminants from liquids and gases hygienically.

They are primarily used to maintain high levels of cleanliness or hygiene in cosmetics, chemicals, food processing, and chemical industries.

They are also essential devices in other systems that employ pneumatic control.

Sanitary filters ensure contaminants and impurities do not compromise the quality and integrity of products.

The housing of a sanitary filter should be easy to disassemble for cleaning or inspection.

You should also be able to clean all the product contact surfaces of the screen.

The filter material must be easy to clean, and the housing has to be perfectly polished to remove all crevices and cracks that will retain dirt.

They also remove any contaminants that can clog and damage the pumps and other sensitive components of the filtration system.

Strainers remove large particles, while filters clean smaller particles.

You will use a strainer if you want to filter particles that have a diameter of 40 microns and above.

On the other hand, you will use a filter when you are cleaning particles whose diameters are less than 40 microns.

Some filters can even remove particles as small as 0.3 microns.

Industry sanitary filter

This device is a filter that removes impurities from fluids in different industries that require high levels of cleanliness or purity.

The filters offer the highest level of filtration to meet the demand of industries with enhanced filtration requirements.

You should choose industrial sanitary filters that will enable you to modify the application to fit your specific filtration needs.

When selecting material for the construction of your sanitary filters, ensure you choose a material that is easy to clean.

It will make it easier to maintain high hygiene standards.

Make sure you remove all possible crevices and pits that can retain contaminants by polishing components surface to a Ra 32 µin.

The housing should smooth curved corners to allow proper cleaning.

You can choose the following materials for the construction of your sanitary filters.

· Steel

You can consider this material because it is easy to clean and resistant to corrosion.

You can choose between SS 304 and SS 316L.

These two grades of steel have different properties.

They should be selected based on the characteristics of the fluid you want to filter.

For example, SS 316L has about 2-3% molybdenum, which is lacking in SS 304.

The addition of this element makes SS 316L more resistant to corrosion by chloride and other corrosive substances.

· Carbon Steel

This material is perfect when you want reliable and durable filters.

You can choose from different classes of carbon steel such as low, medium, high, and ultra-high carbon steel.

You can use this material when your application operates at high pressure and temperature.

It is best suited for applications where fire hazard is common.

· Cast Iron

You can choose this material when your application does operate under high temperature and pressure.

Cast iron is suitable where the system’s mechanical shock and thermal conditions are low.

This material will also cost you less compared to steel and carbon steel.

· Glass

You can use glass when you want to see through the filters during operation.

However, many manufacturers don’t use glass because of the potential risk of breaking.

· Aluminium

You can use aluminium when you want lightweight filters.

However, you will need to do frequent replacements because the material can crack easily under high pressure and temperature.

Aluminium is also susceptible to corrosion.

Other materials that you can choose for your filters include plastic, bronze, titanium, and chrome.

Parts of sanitary filter

The main components of a sanitary filter include:

- The clamp: Help you perform quick element replacement.

- Inlet/Outlet ports: Inlets port bring in the contaminated fluid and outlet port release the filtered fluids.

- Gasket: They prevent leakage

- Filter Elements: They perform the filtration by retaining the impurities

- Housing: Hosts the components of the filter.

- Differential pressure gauge: Indicates when the filter element is due for replacement

- Air valves: They are installed in CIP housings to keep out foreign materials.

Yes, sanitary filters have standards.

These standards vary from one industry to the other and from one agency/country to the other.

The 3-A sanitary standards specify guideline that manufactures of processing equipment in beverage, food, and pharmaceutical industries should follow.

Pressure Equipment Directive 2014/68/EUis a set of standards that must be followed by fabricators of pressure equipment in the European Union.

ISO 13408 provides standards for the aseptic processing of health care products, including testing of sterilization filters.

Other relevant ISO certification standards include ISO 9001 for quality management services and ISO 22000 for food safety management systems.

These are standards and accepted practices set by 3-A Sanitary Standard, Inc., an independent, nonprofit, voluntary organization.

The goal is to ensure that all equipment used in industries is easy to dismantle for the mechanical cleaning of the product contact surfaces.

Similarly, they also protect food products from contamination.

The standards specify guidelines that should be adhered to when manufacturing equipment for use in beverage, food, and pharmaceutical industries.

In total, there are 70 standards and nine accepted practices.

Currently, more than 360 companies spread across 23 countries conform to 3-A standards worldwide.

These companies display the 3-A symbol in there processing products to show that the equipment meets the set sanitary standards.

All industries whose application demands highly intense impurity filtration will use industrial sanitary filters.

They include;

- Food processing and beverage

- Dairy products

- Aseptic packaging

- Pharmaceutical

- Medical

- Aseptic laboratories

- Electronics and Semiconductors

- Biochemical and chemical processing

- Pneumatic control systems

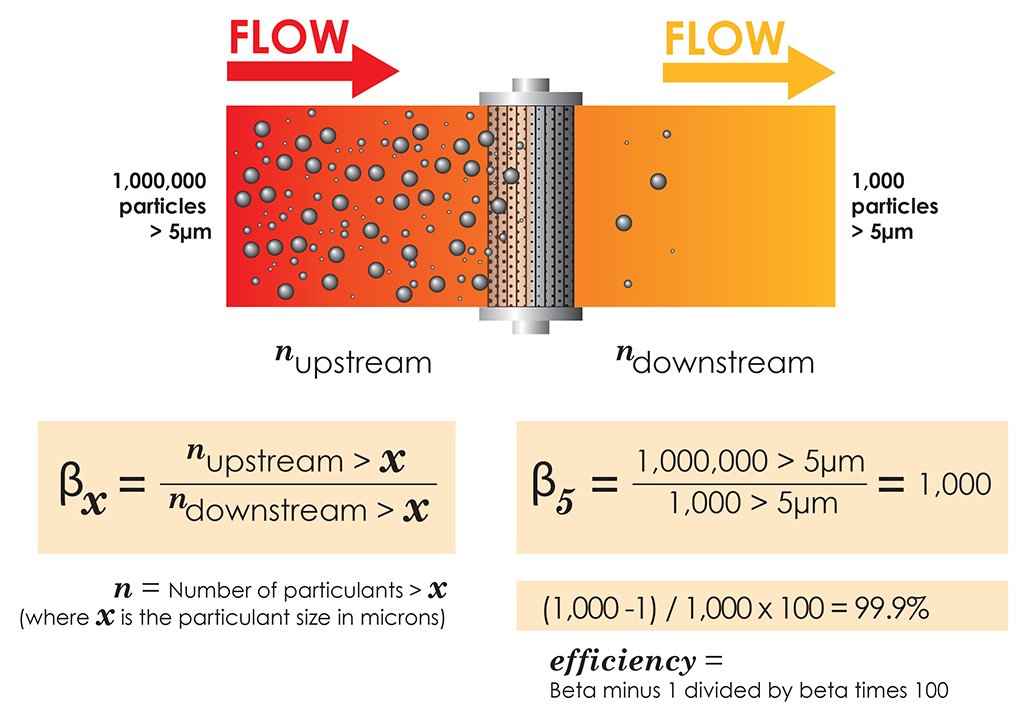

You can use the multi-pass test to check the quality of your filters.

ISO 16889:2008 specify the requirements and procedures for conducting the analysis.

Inline sanitary filter

Follow these steps to carry out the test:

- Measure and add a volume of clean fluid into the reservoir. Similarly, weigh a known volume of dust and mix it into the liquid/air/gas.

- Using a pump, pass the fluid through the filter slowly at a constant speed.

- Count the dust particles from fluid on both upstream and downstream using an automated particle counter/online particle sensor.

- Work out a beta ratio through dividing the number of particles of a given size detected upstream by the number counted downstream

- The higher the beta ratio, the better the filtration efficiency.

There are different types of sanitary filter elements.

They include;

Sanitary filter element and housing

· Pre-filter

You can use these elements to remove large solids and liquid particles.

They will help you extend the service life of the higher grades of filters installed downstream.

· Particulate Filters

This filter element removes large, medium, and small particles through impaction, interception, and diffusion.

They filter the fluid from outside to inside.

Coarse mesh on the outside removes larger particles while finer mesh intercepts the smaller particles on the inside.

· Coalescing Filters

You can use these filters for sanitary filtration of air and gas.

They remove water, oil, and dirt from the fluid.

They perform filtration from the inside-out flow.

Coalescence filters can clean particles down to 0.1 microns at 99.99% filtration efficiency.

· Activated Carbon Filters

These filters mainly remove odour from the air or gas through adsorption.

The large surface area of the activated carbon filter is capable of producing air/gas.

This is 400,000 times cleaner than the contaminated one.

· Sterile Filters

The sterile filters are located just before the outlet downstream.

They remove microorganisms such as bacteria, fungal spores, and viruses from the fluid.

These filters must have a rating of 0.2 microns and below with a filtration efficiency of 99.98%.

Sanitary filters use filter medium to separate the impurities from liquids and gases.

The fluids flow into the filter due to differences in pressure, that is, from high-pressure regions to low-pressure regions.

When the fluid passes through the filter element.

It produces a positive trans-membrane pressure which pushes particles that are smaller than the size of medium perforations.

All bigger particles remain in the filter element.

On the other hand, adsorption filters remove odour from the fluids through binding with activated charcoal.

The filters must be constructed in such a way to enable quick disassemble for cleaning all contact surfaces regularly.

Also, the filter housing should have gentle curves.

The construction materials should be non-corrosive and easy to clean.

You will achieve the highest levels of cleanliness when you use sanitary filters.

Specifically, these filters have:

- Simple structures that allow you to carry out a fast substitution of elements and servicing

- High-quality stainless steel housing that is resistant to corrosion and rusting.

- Very high filtration efficiencies of up to 99.99% at 0.1 microns for coalescence and sterile filters

- Made of quality materials that are very easy to clean.

- Sterile filters allow you to remove harmful microorganisms from the product, which would otherwise cause diseases.

Sanitary filter housing and element

You should consider the following factors before you place an order for a sanitary filter:

· Construction Material

Ensure that you choose a material that will not be eroded by the fluid you are filtering.

When handling materials that require you to observe high levels of hygiene, then you can use stainless steel filters.

This material is easy to maintain besides being durable.

· Nature of Application

Application is one of the most critical factors to consider before placing a purchase order.

Ensure that you gather enough information on the requirement of your industry to enable you to select the most appropriate filters.

Some industries, like food and beverage or pharmaceutical, have standards, regulations, and requirements that have to be satisfied with processing equipment.

Ensure that the filters you import meet the standards set by regulatory agencies in your country.

· Contaminants to be Filtered

You need to know the type, nature, and characteristics of the impurities that you will be filtering.

That is, if you have to produce high-quality products.

Though the process may seem simple, choosing the wrong size of a filter will highly compromise the integrity of your products.

It will have dire financial consequences starting from product rejection to court cases related to the production of substandard goods.

· Level of Contamination and the Percentage of Impurities to Retain

You may also shut down several times for cleaning up or replacing the elements.

That is if the fluid you are filtering is highly contaminated.

Similar drawbacks will persist when the filters you are using have to retain very high percentages of impurities.

You can choose a filter medium which has a high retention capacity to extend on the service intervals.

Similarly, a larger filter also has a longer service life compared to smaller once.

In case your operation is time-sensitive and cannot be stopped, then you can consider using a duplex filter.

The duplex filters will enable you to continue with the process between interchange of elements and servicing.

· The Flow Rate of the Process

The flow rate affects the operation of the whole application system.

The flow rate is determined by the amount of fluid that is passing through the filter per unit time.

For efficient filtration, you will need to know the flow rate of your system before placing an order.

If you install filters with lower flow rate, your system process will suffer constant holdups and blockage.

It will slow down your operation, resulting in time wastage and underproduction.

· Working Pressure

You should consult a specialist before purchasing any filter for your process.

The level of operating pressure and temperature varies within and between applications.

Similarly, a particular model of the sanitary filter can only withstand a given amount of pressure and temperature.

You should pay more attention to optimal and maximum pressure.

Installing a sanitary filter with low working pressure will lead to the destruction and collapse of the screen.

A collapsed filter allows bypass fluid that will result in product contamination or process breakdown.

· Cost of Operation

You should always match the price of the filter you need and the budget.

The aim is to increase profits while ensuring the filters you are getting effectively restrain the process contaminants.

Here, you need to consider the initial cost of buying the filters and the operational cost of maintenance or replacement.

You should select a high-quality screen that will effectively meet the requirements of your system at the least cost possible.

Stainless steel is prime and flawless material for constructing your filters because of the following reasons:

· Reliability and Durability

Stainless steel is inert and non-corrosive, which makes it one of the most suitable materials for sanitary applications.

Other materials are affected by rust, which leads to the accumulation of bacteria that end up in the product.

Rust also reduces the effectiveness of filter housing, especially by compromising the integrity of welds and joints.

Generally, products manufactured from quality stainless steel can last up to 100 years under regular operation!

This level of durability will allow you to save a considerable amount of money.

· Ease of Cleaning

You can consider using steel if you want filters that support hygienic production.

Cleaning stainless steel is very easy and fast.

It also allows for the production of quality goods at minimum production cost.

Using a material that is easy to clean is very important if you are using the same application to process different types of products.

It will enable you to reduce contamination levels to the minimum.

· Temperature Tolerance

Stainless steel filters can withstand wide variations in temperature without compromising integrity.

You can use this material if you have to filter hot, cold, or both fluids simultaneously or consecutively.

This property makes the material flawless for use in beverage and food production.

Sanitary filter housing

Sanitary filters must be kept clean at all times to achieve the highest levels of hygiene.

You should have sanitary filter housings that are easy to dismantle for cleaning and replacing the elements.

Ensure that you doa regular and thorough cleaning of contact surfaces to avoid any food contamination.

Conduct regular checks and replacement of the filter elements as soon as the service life is out.

Replace any filter housing with visible cracks, dents, or leakages.

Replace the threads and flanges that can retain dirt with sanitary connections and stainless welds.

If you are using a sterile filter, ensure that you have installed other sanitary filters upstream to remove the other contaminants.

You should change the filters every time you shut down process because bacteria will multiply rapidly when the system is not operating.

Sterile filters also need frequent sterilization.

You can do this through autoclaving or by using steam or hydrogen peroxide.

Sterilize the filters and the piping at the service end every time you dismantle them and line for cleaning or replace the elements.

Yes, sanitary filters which have a filtration value of 0.2 microns and below can filter out bacteria.

No, sanitary filter and sterile filter are not the same.

A sterile filter is a type of sanitary filter, but not all sanitary filters are sterile filters.

The primary purpose of a sanitary filter is to protect human health.

When you are using sanitary filters, your main aim is to meet the highest levels of cleanliness and hygiene standards expected of your application.

On the other hand, sterile filters have to remove all the microorganisms from the fluid.

Scientifically, a sterile filter has to retain all the cells when the bacterium Brevundimonasdiminuta passes through it at a concentration of 107 /cm2.

A sterile filter must have filtration ability of 0.2 microns since most cells of bacteria range from 0.3 microns to 9 microns.

You can choose to use a depth filter or a membrane filter depending on the requirements of your application

You will have to sterilize these filters after installation by either using steam or hydrogen peroxide

Sanitary filters are rated based on the size of particles they can filter out.

For example, a 0.5-micron filter can clean particles that have a diameter of 0.5 microns and above.

There are three main methods used for sanitary filter rating.

They include:

Filtration efficiency

· Absolute Rating

This rating is also known as the cut-off point.

It refers to the largest particle size that will pass through the filter under a low-pressure differential in the laboratory.

It gives the size of the pore opening of the filter medium in micrometres.

In an ideal situation, the medium should retain all particles that exceed the absolute value.

However, it is impossible to achieve 100% retention.

Therefore, most manufacturers will define absolute efficiency for filters that can retain 98.98% of the particles or higher.

- Nominal Rating

This rating shows the potential of a filter to retain a minimum percentage of particles that exceed than the nominal micron size.

This rating grades the filters based on the micron size together with percentage filtration efficiency.

However, this method of rating greatly varies to other factors, such as the level of contamination and operating pressure.

· Beta Ratio Rating

You will use the multi-pass test to determine the beta ratio of a filter.

When using this method, you count the particle size upstream and divide by the particle counts downstream.

You can also determine the filtration efficiency of the filter from the beta ratio using the formulae; ((beta-1)/beta) x 100.

The cost of sanitary filter will significantly vary depending on the application, type of element, flow rate, working pressure, construction material, and rating.

For example, a sanitary stainless steel water filter will cost you between $5 to $10.

On the other hand, a sanitary activated carbon filter for food processing will cost you between $600 to $5000.

Ensure that you contact the manufacturer before placing an order to get the most appropriate filter for your application.

Sanitary filter

Yes, sanitary filters have a warrant.

However, the period and conditions of the warranty vary from one manufacturer to the other.

While most manufactures will offer a one-year warranty for sanitary filter assemblies, others can have warranty cover that extends up to five years.

You should note that most warrants only cover manufacturing defects.

You will get high-quality sanitary filters that will work correctly in staged applications.

Chinese manufactures adhere to the highest industry standards, with the majority being ISO certified.

Better still, the products from China will cost you less compared to similar products from other countries.

Also, there range of options to choose from.

Additionally, Chinese filter manufacturers support OEM businesses.

In short, you will have a high chance of growing your business when you import sanitary filter from China.

Yes, you can clean and reuse sanitary filter elements in your process application.

However, this is only possible with some types of filter medium like stainless steel.

The elements always come with instructions on how to clean the filters.

Some sanitary filters have self-cleaning models which are capable of removing excess contaminants as small as 10 microns.

You can clean your elements using forward and back flashing ultrasonic bath or compressed air.

Clearly, there are so many things you should consider before buying sanitary filters.

We hope our sanitary filter guide has explored everything you need to know.

However, in case you have any questions, or you’d like to learn more about sanitary filtration systems, you can contact FilSon team.