High Quality Stainless Steel Filter & Strainer

Filson adopts high quality 304 or 316L stainless steel materials to construct stainless steel filters and strainers.

- High quality stainless steel materials

- Anti-corrosion and anti-abrasion

- High filtration efficiency, long service life

- Wide industry filtration applications

- Customized service and competitive prices

What is Stainless Steel Filter & Strainer?

Stainless steel filter & strainer, as the name implies, is made of stainless steel.

Stainless steel filters strainers are specially designed and manufactured to get rid of unwanted particles for your process line. It helps protect downstream critical equipment from tear and wear. This also ensures safe operation and meets sanitary requirements.

The difference between strainers and filters is that strainers are generally used to remove large particles in filtering media, while filters are used to eliminate small and fine particles from media. Most of them are washable and reusable.

Stainless steel filters strainers are primarily founded in the food and beverage industry, dairy, cosmetic, pharmaceutical industry, chemical industry, petroleum industry and so on.

Stainless Steel Filter & Strainer Base Category

Stainless steel filter housings come in various types and styles, for use with single or multiple filter bags or cartridges. At a given micron rating, they exhibit splendid filtration performance which is rated at efficiency up to 99.98%.

Stainless steel filter cartridges are available in multiple shapes such as cylindrical, candle, pleated, basket to adapt different installation spaces. In addition, upon your accuracy requirement, you can pick the most filter cartridges.

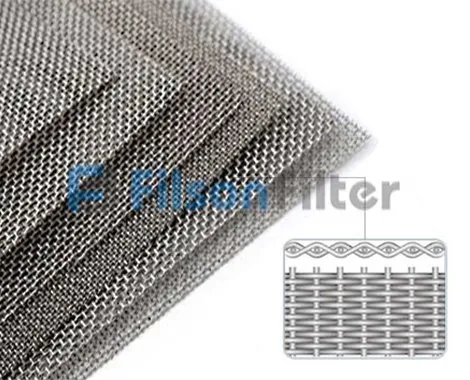

Stainless steel filter mesh is available in standard and custom types. The size and distribution of the holes are decided by selecting different wire diameters, aperture sizes, mesh layers and weaving methods of the wire mesh.

Stainless Steel Filter & Strainer Media Type (6)

Stainless Steel Filter & Strainer Features

Filson adopts advanced technology and equipment to construct stainless steel filter & strainer. It is rigid and durable with high mechanical strength.

Due to the chromium, nickel in stainless steel, Filson stainless steel filter & strainer has good corrosion resistance and high temperature resistance.

The filtration efficiency of stainless steel filter&strainer depends on micro rating, etc. It can remove 99.99% contaminants of 0.2 micron particles in media.

Stainless steel has a high hygienic property, and some of stainless steel filter & strainer is polished finished. It is easy to clean and reuse for a long term.

What is the Function of Stainless Steel Filter & Strainer?

The primary function of stainless steel filter & strainer is to capture contaminants from fluid through mechanical filtration.

- Remove unwanted particle such as dirt, scale, microorganisms from filtering medium

- Protect downstream sensitive components from damage and extend their lifespan

- Increase fluid performance and improve the reliability of the process and products

- Ensure food and drink safety, improve taste, appearance and prolong their shelf life

- Meet sanitary requirements, protect environment and increase revenue of project

If you are running industry project, you may need reliable stainless steel filters and strainers to achieve filtration requirements. Filson filter is your best choice.

The Advantages of Stainless Steel Filter & Strainer

304 or 316L stainless steel is one of the most frequently used material to build industry filters. If necessary, Hastelloy, Monel and other special alloy is available. There are numerous advantages of stainless steel filter & strainer.

- High porosity up to 90%, excellent permeability

- High filtration efficiency up to 99.99% of 5 micron particles

- High temperature and pressure resistance, anti-wear

- Accurate filtration precision: 1 micron, 5 micron, 10 micron

- Firm structure and high mechanical strength

- Easy forming, painting, polishing, welding and cleaning

- Reliable and durable, long service life

Send us your drawing and specifications, we will quote for you immediately.

Main Applications of Stainless Steel Filter & Strainer

Stainless steel filter & strainer are widely in industrial applications for their excellent properties.

- Filtration of air and gas: compressed air filtration, nitrogen filtration, natural gas filtration, fuel gas filtration, high pressure gas filtration, CNG filtration, vacuum filter, filtration of corrosive gas, etc

- Filtration of liquid: seawater filtration, desalination, disposal of sewage water, filtration of corrosive liquids, beer filtration, etc

- Filtration of solid: glass, coal, food processing, cosmetics, fluid beds, etc

- Filtration of oil: oil refining, hydraulic oil filtration, oilfield pipelines

- Filtration of other fields: textile industry, insulation industry, automotive industry, chemical industry, metallurgy industry, pharmacy, electronic field, etc

Why Choose Filson Stainless Steel Filter & Strainer?

Filson has been producing stainless steel filter & strainer over two decades. we can customize your stainless steel filters strainers based on your requirements. Filson swears to bring you satisfactory stainless steel filter & strainer with competitive prices.

Filson stainless steel filter & strainer have passed the U.S. listed for food contact use as well as in accordance with ISO standard and CE standard. So you can trust Filson as your reliable stainless steel filter & strainer supplier.

We have sufficient stock, order now and ship now. We use carton or wooden case to package your items at your request. The lead time is very short, samples could be offered within 3-7 working days, batch production (custom type) time is 7-30 working days.

If you have any requirements or questions of Filson stainless steel filter & strainer, please feel free to contact us. We will reply to you immediately.

You may find a suitable stainless steel filter strainer solution by following ways:

Call: 86 – 157 3695 8886

Email: sales@filsonfilters.com

Filson is looking forward to being your stainless steel filter & strainer partner in the future!

- Construction material: 304 or 316L stainless steel, titanium, nickel, Hastelloy, Monel and other specially alloy

- DN: 25-300 mm or tailor-made

- Micro rating: 1 micron to 250 micron

- Working temperature: ≤200℃

- Max working pressure: up to 400 bar

- Connection size: thread or flange connection

- Sealing material: NBR, Viton or at your request

- Finish: polished (inside and outside Ra on request)

- Food and beverage industry

- Fermentation industry

- Metallurgy industry

- Electronic industry

- Chemical industry

- Pharmaceutical industry

- Petroleum industry

- Water treatment

- Pulp making industry

Stainless Steel Filter & Strainer Related Products

Stainless Steel Filters Strainers: The Complete FAQ Guide

In this guide, you’re going to learn everything about stainless steel filter strainers.

Whether you want to know the material type, classification, efficiency, beta rating, ISO standards or applications – they are all here.

The goal – to answer all questions you may have in about stainless steel filter strainers.

By the end of this guide, you will be an expert in stainless steel filters and strainers industry.

Let’s get started.

The main difference between a stainless-steel filter and a stainless-steel strainer in their filtration particles.

A strainer removes particles that are visible and usually are larger than 40 microns.

A stainless-steel filter removes particles that you cannot see using your eyes.

These particles are less than 40 microns in size.

Stainless steel filter

Stainless steel basket strainer

The primary function of a stainless-steel filter and strainer is to remove unwanted particles from fluids through filtration.

The main types of stainless-steel strainers available are:

- Cylindrical stainless-steel strainers

- Pleated stainless-steel strainers

- Plain stainless-steel strainers

- Woven stainless-steel strainers.

Filter mesh size

Filter mesh size

The primary way of determining stainless-steel strainer mesh size is by carrying out a mesh count test.

This test determines the number of stainless-steel threads per inch of your filter and strainer.

It is an essential factor when determining the quality of filtration for your fluid.

A high mesh count implies that you have a high-quality filtration for your fluid.

Modes of filtration

Modes of filtration

The working principle of a stainless-steel filter and strainer is relatively simple if you understand the various functions of its components.

It is vital to note that stainless-steel filters and strainers combine the function of a filter and a strainer.

That is, fluid enters the stainless-steel filter strainer through the inlet of your application.

The first point of filtration is the strainer where it removes particles of a given size from your fluid.

From there, the liquid flows through the filter, where further filtration takes place.

After that, the filtered fluid flows out of the filter through the outlet and into your application.

The difference in the two-filtration process is the particles removed.

Stainless-steel strainers remove particles whose size is higher than 40 microns.

Such particles are visible, while Stainless-steel filter removes particles that are not visible and have a size of less than 40 microns.

The filtration process continues until there is clogging of the strainer and filter.

At this point, you need to unclog these two for the filtration process to continue.

There are several ways of unclogging your filter and strainer.

A cost-efficient way is the backwash process, where you use the filtered fluid.

There are different types of stainless-steel filters in the market, depending on the design and area of application.

The advantage here is – you are sure of getting the right stainless-steel filter for your use.

The main types of stainless-steel filters include:

i. Stainless steel perforated filter

ii. Stainless steel wedge wire filter

Stainless-steel strainers have a wide range of applications in different industries. These industries include:

· Water Treatment Plants

Clean water is an essential part of our lives.

Filtration plays a key in ensuring we have clean water for use.

This is through the use of a stainless-steel strainer.

Also, in waste treatment plants, the use of stainless-steel strainer helps in removing unwanted particles from the waste.

You can, after that, use the resulting product for various functions such as making fertilizers or biogas digester.

· Oilfield Plants

Filtration of oil is vital in ensuring we have different oil products.

The use of a stainless-steel strainer here is because of its properties, such as high heat resistance and non-reaction.

· Mining Industry

In the mining of precious metals, you have to filter the metal core to remove unwanted particles.

The use of stainless-steel strainer is critical in achieving this.

· Food Industry

Another sector of our lives that require a clean filtration process.

Here, stainless-steel strainer function is common in the juice making industry.

This offers a clean filtration process and safe products for our consumption.

· Chemical Industry

In the chemical industry, the function of a stainless-steel strainer is to filter unwanted particles from different chemical solvents.

Its effectiveness depends on the pore sizes of your stainless-steel filter basket.

· Pharmaceutical Industry

Hygiene is critical in the pharmaceutical industry due to the prevention of contamination of drugs.

The use of a stainless-steel strainer in the filtration of various medicine is because of its high level of hygiene.

It also does not react with various chemicals that are in drugs, ensuring you have the right drugs for your use.

· Paper Making Industry

Stainless-steel strainer helps in removing unwanted substances in the pulp for paper making.

This ensures a smooth paper making process and enhances the quality of the paper products.

When selecting a stainless-steel filter for your application, you need to consider the following factors:

Stainless steel filters

Stainless steel filters

· Design

The design of a given stainless-steel filter and strainer should be compatible with that of your application.

Such design should consider the inlet and outlet point of your application.

Other design consideration includes the size of your application, which should accommodate the filter and strainer housing.

You also need to consider the weaving type of your stainless-filter and strainer

· Filtration Accuracy

Filtration accuracy depends on the micron rating of your filter and strainer.

You will have to check on the quality of filtration that you want for your fluid when selecting the micron rating of your filter.

· Mesh Size

Mesh size determines the size of contaminants that you are filtering.

You need to check on the micron rating when considering the mesh size for your stainless-steel filter and strainer.

The increasing usage of stainless-steel filters and strainer in different industries is due to the numerous benefits it offers.

Some of the primary reasons why you need to use stainless-steel filter and strainer are:

· Efficiency

Stainless-steel provides efficiency in its operation.

Efficiency ensures that you have the desired filtration of your fluid.

· Ease of Cleaning

A stainless-steel is easier to clean and therefore has a high hygienic property.

This ensures that you can use these filters in sensitive applications such as in the food industry.

The ease of cleaning ensures that the stainless-steel filter basket is always clean.

· Durability

Stainless-steel provides longevity to your application.

This is because it does not react with different fluids.

Durability ensures that you have a maximum operation for your filtration process.

You also spend less on purchasing a stainless-steel filter and strainer.

· Aesthetic Appeal

A stainless-steel filter offers an aesthetic appeal for your application.

This increases the appearance of your stainless-steel filters and strainers as well as overall hygiene.

· Versatility

You have a wide range of applications that you can use a stainless-steel filter.

This is because of the unique features that stainless-steel offers.

These features include their operating temperature and pressure, corrosion resistance, and compatibility with different fluids.

Furthermore, there are different sizes of the stainless-steel and that you can use for your application.

Stainless-steel filter strainer is a vital component in the filtration of your fluid.

You, therefore, have to clean it frequently, especially in sensitive industries such as the pharmaceutical industry.

Since there is various cleaning method, the ideal one depends on the type of stainless-steel filter strainer you have.

A perfect cleaning procedure entails:

- You need to wear the necessary protective gear for protection purposes. This reduces accidents that may harm you while cleaning your stainless-steel filter strainer.

- Switch of your application. This prevents the occurrence of faults while cleaning your stainless-steel filter strainer.

It also protects you from electric shock during the process as the fluid cannot flow through the stainless-steel filter strainer.

- Remove the stainless-steel filter strainer from its position. While doing this, you need to be careful not to destroy the other parts of your application.

Removing the stainless-steel filter strainer helps in ensuring you clean it properly.

- Select a cleaning agent that does not react with your stainless-steel filter strainer. This needs to be a mild detergent that does not have a reaction even to the fluid within your filter strainer

- You also require a cotton cloth that you will use to clean the stainless-steel filter strainer.

- Using your cotton cloth and detergent, properly clean every part of the stainless-steel filter strainer. This removes all the contaminants from your filter strainer.

The main cleaning methods for your stainless-steel filter strainer are:

Stainless steel strainer basket

Stainless steel strainer basket

- High-temperature burnout involves placing the stainless-steel filter strainer in a high-temperature environment. The temperature removes contaminants from the stainless-steel filter strainer.

It is a common technique in the food and pharmaceutical industry.

- Backwash cleaning involves the use of the filtration fluid to remove dirt in your stainless-steel filter strainer.

The fluid flows under pressure in a reverse flow, which forces all the contaminants out of the filter strainer.

It is an ideal option for cleaning a stainless-filter strainer that is in water treatment plants.

- Chemical cleaning of your stainless-steel filter strainer entails the use of chemicals.

The chemicals, however, should not react with the filter strainer or the filtration fluid.

The contaminants either dissolve or react with the chemical to produce less harmful residue from the filter strainer.

Water forces the residue out of the stainless-steel filter strainer.

- Ultrasonic cleaning uses ultrasound to clean your stainless-steel filter strainer. It works alongside water and a cleaning agent.

However, it is less common due to its relatively high cost.

After cleaning, you need to rinse your stainless-steel filter strainer using plenty of water.

This removes all the detergent that you have used. It helps in preventing any reaction of the detergent with your fluid.

You need to consider the following factors selecting your stainless-steel filter and strainer housing:

Stainless steel filter housing

Stainless steel filter housing

· Design

The design of a given stainless-steel filter and strainer housing should be compatible with that of your application.

Such design should consider the inlet and outlet point of your application.

Other design consideration includes the size of your application, which should accommodate the filter and strainer housing.

You also need to consider the weaving type of your stainless-filter and strainer.

· Clogging Indicator

The clogging indicator is a button that either sounds an alarm or changes its color when there is clogging of your filter housing.

It allows you to know when to clean your stainless-steel filter and strainer housing.

This occurs when clogging takes place within your filter housing.

Clogging has the effect of reducing the efficiency of your filtration process hence the need for cleaning.

· Sealing Configuration

The sealing configuration that you select for your stainless-steel filter and strainer housing should be airtight.

It should also be able to cope with the high pressure of the fluid flowing through the filter housing.

In high-temperature applications, the sealing configuration should be able to withstand this temperature range.

· Material

There are two types of materials, that is,316 and 304 stainless-steel filter and strainer.

Each type has features that make it ideal for different applications.

When choosing material, consider the working environment.

· Size of your Stainless-steel Filter and Strainer

The size of your stainless-steel filter and strainer should be compatible with that of your application.

It should perfectly fit your application and ensure optimum operational efficiency.

You need to consider the length and weight of your filter housing before purchasing to minimize the inefficiency of your application.

· Dirt Holding Capacity

A larger dirt holding capacity implies that you can continue with the filtration process without worrying about cleaning for a while.

It increases productivity while reducing costs related to cleaning.

However, the dirt holding capacity should correspond to the design of your application.

That is, the overall weight should not hinder the effective operation of your stainless-steel filter and strainer.

A stainless-steel sintered filter is one that undergoes the process of metallurgy with other metals.

The essence of this is to improve on the qualities of the stainless-steel filters and to increase their functionality.

Such improved qualities include high corrosion resistance, high thermal shock, and better filtration.

Sintered stainless steel filter

Sintered stainless steel filter

Proper selection of a stainless-steel filter element helps in facilitating the filtration process.

You, therefore, have to consider several factors before picking the best for your use.

Among these key considerations you need to check for include:

· Contaminants Type

The size of the individual contaminants is vital in determining which filter element to select for your application.

The ideal filter element should remove all the contaminants from the fluid as per your expectations.

The mesh size and micron rating are essential when looking at the contaminant aspect.

· Type of fluid

Different fluids have different characteristics that affect the filtration process. For instance, the operating temperature and pressure and viscosity.

Such affect the type of filer element you are selecting for your stainless-steel filter.

Other should be working pressure and temperature. When you exceed any of these limits, there is a possibility that the stainless steel filter will fail prematurely.

This the standard unit of measurement of the size of the pore openings on your filter media.

The higher the micron value, the large the size of the openings.

For instance, a stainless-steel filter with a micron value of 10 implies it has large openings than one with a 5-micron value.

You need to consider a couple of factors when selecting the right micron value for your stainless-steel filter filters.

For instance, the level of filtration you want for your fluid.

Remember, the smaller the filter micron value, the more efficient it is at filtering your fluid.

However, such a rating removes all the contaminants from the fluid, which might not be the intention.

Your micron value can either be nominal or absolute.

A nominal value defines the ability of a particular filter to remove between 50-98.6% of contaminants of a given size from your fluid.

Absolute value refers to a stainless-steel filter ability to remove 98.7% or more of the contaminants of a given size in a fluid.

Absolute value is vital when selecting the type of stainless-steel filter for your application.

Adequate maintenance of your stainless-steel strainers enhances their durability.

It also ensures the proper filtration process for your application.

Consider the following when maintaining your stainless-steel strainers.

Stainless steel strainer

Stainless steel strainer

· Cleaning

The essence of frequent cleaning your stainless-steel strainer is to remove dirt and contaminants.

The effect of dirt and contaminants is that it lowers the filtration quality of your fluid.

· Replacement

Your stainless-steel filters and strainers tend to wear out over time hence reducing their effectiveness.

They also tend to accumulate contaminants, which is hard to remove through cleaning.

When this occurs, you have to replace the filters and strainers.

· Tightening Loose Screws

There is a possibility of loosening up of the screws during operation.

This reduces operational efficiency while increasing the probability of personal accidents.

After every operation, you must tighten every screw on your stainless-steel filter and strainer.

Frequent replacement of your stainless-steel filters and strainers maximizes the filtration process of your fluid.

Among the factors that cause you to replace your stainless-steel filters and strainers include:

· Low Fluid Pressure

Low fluid pressure within the stainless-steel filter and strainer reduces the filtration efficiency of your fluid.

The reason for this is an insufficient flow of fluid through the filter and strainer for filtration to occur.

Low pressure is due to the clogging of your stainless-steel filter and strainer.

When this occurs, you need to replace your stainless-steel filter and strainer for efficient filtration.

· Poor Quality Filtration

Poor quality filtration causes a breakdown in your application.

You have to replace your stainless-steel filter and strainer when the filtrate does not match the expectation of your application.

· Tattered Filters and Strainers

Tattered filters and strainers have the effect of reducing the quality of filtration.

This is because particles flow through the filter and strainer.

You have to replace filters and strainers to ensure maximum filtration.

Determining the efficiency of your stainless-steel filers and strainers is critical when it comes to filtration.

The primary determinant of the efficiency of the stainless-steel filter and strainer is in the quality of filtration.

Quality filtration implies there are no contaminants present in your fluid.

The net effect of this there is an efficient operation of your application.

Beta Rating refers to an efficiency level assigned to a given filter element based on its ability to remove contaminants of a given size.

To calculate beta ration, you use an ISO multi-pass test standard 16889:1999.

It involves the addition of particles of a given size to a test fluid until it is saturated.

Then, you use a filter to remove the particles in one flow via the filter element.

The importance of a beta ratio is it helps you in selecting the best filter for your application based on the pore size.

A beta ration is also a vital element in ensuring there is proper functioning of your fluid system since it reduces mechanical breakdown.

Beta Rating

Beta Rating

ISO 4406:99 Fluid Cleanliness is crucial in ensuring there are minimal emissions, which is a result of poor filtration.

It defines the parameters of an efficient filtration system.

The standard helps in facilitating your engine operation and removal of contaminants from the fluid.

Quality is essential in the filtration of your stainless-steel filters and strainers.

The following quality tests are critical on your stainless-steel filters and strainers:

· Stainless-steel Filters and Strainers Thickness

The filter thickness affects the filtration process since it determines the size of contaminants that you are filtering.

Effective stainless-steel filters and strainers should have the right thickness for the proper filtration process.

· Elongation Test

Elongation test helps in determining how stainless-steel filters and strainers will perform when you subject it to a given amount of force.

It is an important test when you are evaluating the pressure level that you can insert on your stainless-steel filters and strainers

· Mesh Count Test

It is an essential factor when determining the quality of filtration for your fluid.

A high mesh count implies that you have a high-quality filtration for your fluid.

· Thread and Hole Diameter

Thread and hole diameter determines the size of contaminants you want to filter from your fluid.

A smaller diameter implies that you will filter small size particles from your fluid.

Woven stainless-steel filters remove finer contaminants from your fluid when you compare to perforated stainless-steel filters.

This is due to their physical structure where woven stainless-steel filter has smaller mesh sizes than perforated stainless-steel filter.

Perforated filter element

Perforated filter element

Woven stainless steel filter element

The main weaving patterns that you will find in a given stainless-steel strainer are:

· Dutch Plain Weave

The use of course filter wire strands and fine filter wires that has relatively small wires within the fill.

It features an excellent strength stainless-steel filter and strainer, which has fine openings.

Its primary application is as a filter cloth.

· Reverse Weave

This type of weaving utilizes coarse filter wire strands in wrapping and a fine filter wire strands for filling the spaces.

It features excellent strength and fine openings.

Its primary use as a filter cloth with the positioning and shape of the openings facilitating particle retention while enhancing the filtration process.

· Dutch Twilled Weave

This weaving a stainless-steel filter and strainer combines both the Dutch plain weave and the twilled weaving methods.

It uses different latitude and longitude thread and also has a different number of wires meshes.

The filter strands alternately pass over and under two warp strands.

This forms a coarse filter in one direction and a fine filter in the other direction.

It can support heavier loads than a Dutch plain weave and offers finer openings when you compare to twilled weave.

· Plain Weave

This type of weaving involves passing wrap wires alternately over and underwires that run traversed through at a right angle to the cloth.

It is a standard method of weaving stainless-steel filter and strainer as you can use it in a wide range of applications.

· Twilled Weave

Twilled weaving involves passing of the wire strands under and over two warp wires.

This method offers the heavier wire strand count over the plain weave.

It is ideal for higher loads and also if you want a finer filtration solution for your application.

Filter weaving type

Filter weaving type

Among the key factors affecting the efficiency of your stainless-steel filters and strainers include:

· Temperature

High temperature has the effect of damaging your stainless-steel filter and strainer. This affects its effectiveness in filtering your fluid.

The operating temperature of your fluid needs to be equal or less to that of your stainless-steel filter and strainer for efficient operation.

· Contaminants

For effective filtration, you need to select a stainless-steel filer strainer that effectively removes contaminants from the fluid.

This includes one that has the appropriate mesh size for filtering given contaminant sizes.

· Pressure

For effective filtration, the pressure of your fluid needs to be at an optimum level within the stainless-steel filters and strainers.

High-pressure results in a faster flow of your fluid, which minimizes the filtration process in the filters and strainers.

Low pressure causes an insufficient flow of the fluid through the filters and strainers, which results in poor filtration.

The pressure, therefore, needs to be sufficient for the filtration to be effective.

· Viscosity

Viscosity refers to the thickness of the fluid.

This affects its flow.

A fluid with a higher viscosity has a slow flow when compared to one with a lower viscosity. The effect is the higher the viscosity, the slower it is to filter it, which affects its efficiency.

· Micron Rating

Micron rating is the size of the individual opening of your stainless-steel filter and strainer.

This facilitates the efficiency of your stainless-steel filter and strainer by removing particular contaminants.

Having an incorrect micron rating affects the efficiency of your stainless-steel filter and strainer.

A lower pressure rating for your stainless-steel filter and strainer reduces the efficiency of the filtration process.

This is because the fluid does not flow smoothly through the stainless-steel filter and strainer for filtration to take place.

A higher-pressure rating has the effect of a high flow rate of your fluid through the stainless-steel filter and strainer.

While this may result in effective filtration, a continuous high flow rate results in the rapture of your stainless-steel filter and strainer.

An effective pressure rating should consider the fluid flow and the nature of the stainless-steel strainer filter.

There are two main differences between a cylindrical design and a pleated design stainless-steel filter cartridge.

That is, area of application and their composition.

The filtration process of a pleated design is through the use of a pleated media.

The cylindrical design uses a sleeve as its filtration media.

The fabrication process of a cylindrical design uses sintered wire mesh. That is five layers of sintered wire mesh within a vacuum.

Pleated design offers maximum filtration efficiency when you compare to a cylindrical stainless-steel filter cartridge.

Different types of stainless-steel filters and strainers can handle various fluids.

This is dependent on the design of your filter and strainer and also the characteristics of your liquid.

Such characteristics include viscosity, temperature, pressure, and chemical reactivity.

The common liquids that you can use stainless-steel filter and strainer on include water, paints, and oil.

The main limitations to the use of stainless-steel filters and strainers are:

· Cost

Stainless-steel filters and strainers are costly when you compare to other types of filtration systems.

This is due to the combination of both a strainer and a filter.

Maintenance

Stainless-steel filters and strainers require regular maintenance, which is tedious.

The maintenance procedure also requires qualified personnel, which is costly.

Yes.

There are self-cleaning stainless-steel filters and strainers.

These stainless-steel filters and strainers have unique features that allow for self-cleaning during the filtration process.

An example includes backwash stainless-steel filters and strainers.

They offer continuous filtration for your fluid, which maximizes your application’s operation.

Yes.

You can order a customize stainless-steel strainer and filter from your manufacturer.

However, you need to submit the customized dimensions early enough to your manufacturer.

A reliable manufacturer will streamline these specifications to ensure they adhere to the quality standards available before manufacturing.

The key components that you will find in a stainless-steel filter and strainer are the filter element and the filter and housing.

The filter and strainer elements are the main components where the filtration takes place.

You can have a different strainer and filter elements depending on contaminants you want to remove from your fluid.

The filter and strainer housing is the outer case that holds and protects the filter and strainer element.

It helps in ensuring the element stays in place during the filtration process.

FilSon has been in the industry for 15 years, which is long enough to understand the different filtration requirements of our customers.

This includes customized stainless-steel filters and strainers, depending on your specifications.

We offer quality stainless-steel filters and strainers that guarantee quality functionality.

Our stainless-steel filter and strainer adhere to the internationally recognized standards.

You can relax while using our products as we warranty for all our stainless-steel filters and strainers.

With the information in this guide, we hope you can choose suitable stainless steel filters and strainers.

However, if you have any question about filters and strainers, the FilSon Filters team will be happy to help.