Your Specialist Well Casing Pipe Manufacturer With Fast Delivery

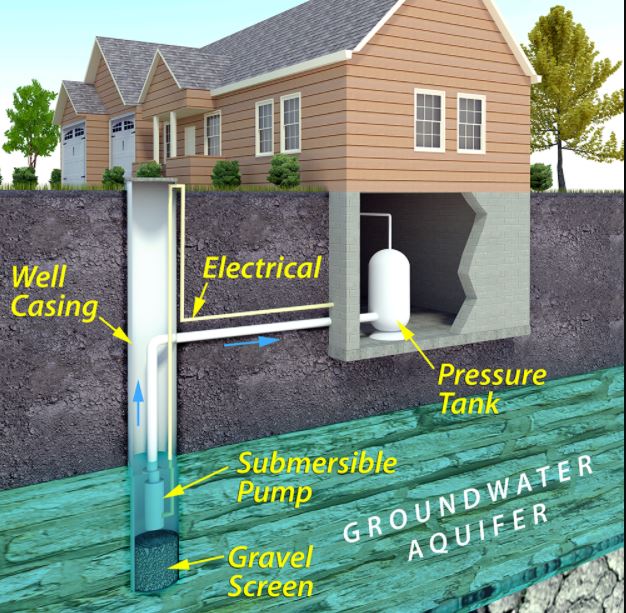

Filson well casing pipe is mainly used for water, gas, and oil wells as a structural retainer. By inserting it into the well bore, it can always stabilize the subsurface formation, while allowing the circulation and extraction of drilling fluid.

In addition, Filson well casing pipe is usually manufactured by sturdy materials like steel or PVC, making it a durable well component for a longer time using. Plus, we have a sufficient inventory of well casing to enable your urgent or large quantity order.

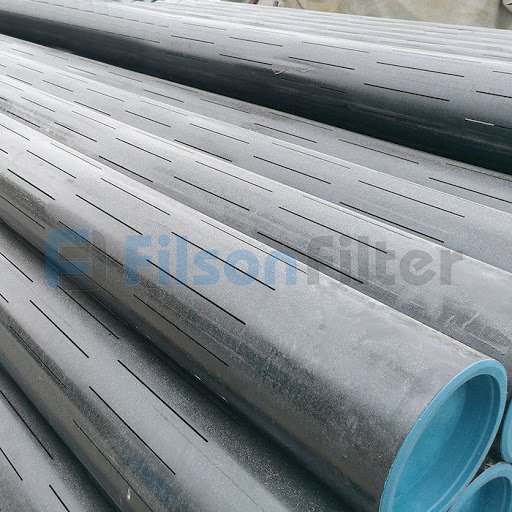

Well Casing Pipe

Why Select Filson Well Casing Pipe?

Filson has its own production factory with professional engineers and a skilled workers team, we are passionately working to serve you better. By cooperating well with our worldwide customers in more than 40 countries, our reputation for high-performance well casing pipe runs deep.

Each Filson well casing pipe experiences a series of strict inspections and quality tests and is ISO 9001 certified. If you want to check our product quality, you may consult our sales or technicians to obtain a free sample within 7 days.

Filson: One-stop Solution Of Well Casing Pipe For Worldwide Customer

Filson well casing pipe is a tube-shaped assembly specifically designed for the well construction. It can support the wall of the well to ensure the stable production and keep well inside from collapse.

Filson well casing pipe can be designed with a variety of structures, including wedge wire structure, slotted structure and perforated structure. Therefore, it can efficiently prevent unwanted solids&particles from contaminating water during drilling and production operations.

The most common materials for Filson well casing pipe are carbon steel, stainless steel and PVC. When you choose a suitable well casing, you should pay more attention to your present equipment type, local geology, project budget, practical installation criteria and perhaps local code requirements.

Over a long period of time, Filson steel well casing pipe is the most popular choice in the well construction filed. Because it provides an excellent corrosion resistance as well as can withstand high temperatures generated by curing cement grout.

However, with the improvements in strength and durability, Filson PVC well casing are very common as a casing material at present. Besides, Filson PVC well casing is made of a thermoplastic material with high PH corrosion resistance and non-conductive properties. Thus you can totally trust it in your underground well construction process.

Your application is another important consideration before you make a choice. Filson steel well casing is more suited in industrial&mineral wells, while Filson PVC well casing is a preferred option for domestic and municipal wells.

Filson well casing pipe is easy to install due to its various end types, such as plain end, threaded both ends, threaded and coupled, insert joint. Meanwhile, our engineer will give you some specialized installation guidance to avoid the deformation or cracking of your well casing.

Filson supplies well casing pipe with the diameter from 4 inch to 48 inch, both welded and seamless. Standard diameter size of Filson well casing pipe is 4”, 6” or less-often 8” for residential using with the length of 10’-20’.

Moreover, Filson standard well casing pipe has the wall thickness of 0.188-0.219 inch, and we can also custom well casing pipe dimensions upon your request. Just please tell us your application needs or give us your drawing, then you will receive a perfect solution.

When you use it for a while, your well casing pipe may have leakage issues, causing the well fail to work. You can repair Filson well casing pipe easily by placing a new liner inside the casing, or find a replacement after evaluating the pressure and corrosion situation of surrounding soil.

Any other specification questions about Filson well casing pipe? We can offer you our standard well casing size chart, or several case studies for you as a reference.

Or are you searching other types filters? We can also fabricate wire mesh filters, sintered metal filters, wedge wire filters, high flow filter cartridge, stainless steel filters …

Do not hesitate to contact us! Call at +86 157 3695 8886 or email to sales@filsonfilters.com right now!

Filson well Casing Pipe Features:

- Steel well casing can withstand high temperature and pressure

- PVC well casing can resistant most of acid and alkali

- Traditional service life is 20-25years, PVC pipe can up to even 50 years

- It can be manufactured with several end types for easy installation

- It can efficiently keep particles or solids from entering water

- Its unique design supports smooth flow without loosing load capacity

Filson Well Casing Pipe Specifications:

- Raw material: steel, PVC, stainless steel

- Diameter range: 4” – 48”

- Length: up to 40 ft. or on request

- Thickness: 0.1”

Filson Well Casing Pipe Applications:

- Residential wells

- Industrial wells

- Mining wells

- Oil & Gas production wells

- Municipal wells

- Drinking water wells

People Also Ask

A well casing pipe is a large diameter pipe fabricated, fitted, and attached into a part of a freshly drilled borehole.

It is widely used in the oil drilling industry.

The design of a well casing pipe ensures that it can withstand collapse, tensile failure, chemically excessive compounds, and excessive forces such as burst.

The main importance of a well casing pipe include;

- Protection of freshwater formation.

- Isolation of zones of lost returns having a dissimilar pressure gradient.

- Strengthening the well hole.

- Allows a safe passage for hydrocarbon extraction minus contact with other formations or fluids found underground.

- Important in ensuring there are no blowouts, which provides top-sealing should pressure levels become critical.

Notably, the entire casing procedure is done during an operation referred to as running pipe.

A Well Casing Pipe

The material used for a well casing pipe dictates where the well casing is suited for.

Various groundwater quality and geologic formations will determine the ideal well casing pipe material needed.

Commonly, three materials are rampantly used for well casing pipes;

- Stainless steel

- Carbon steel

- Plastic – PVC is the typical plastic material, but not the only one.

Earlier on, we highlighted that different well casing pipe materials are ideal for specific places. For example, steel is a perfect material for well casing pipes intended for use in areas bearing hard rocks underground.

Nonetheless, some areas may be ideal for casings made from either material.

In such a scenario, you will need to factor in the cost. Consequently, you will install an economically friendly well casing pipe.

Carbon Steel Well Casing Pipes

Notably, steel has taken the top seat as the preferred material for well casing pipe.

However, with the advent of a more robust, durable, and corrosion-resistant PVC, steel faces competition from plastic material.

There are two common types of well casing pipes, steel well casing pipes, and PVC well casing pipes.

Steel Well Casing Pipes

Most old wells have metal well pipe casing, specifically steel well casing pipes.

Nowadays, these types of well casing pipes are primarily used for heavy-duty applications.

Stainless Screen water Well Casing Pipes

PVC Well Casing Pipes

Since PVC was introduced in the market about 40 years ago, PVC well casing pipes have given the steel ones a fair share of competition.

Currently, most wells use PVC well casing pipes due to their durability and high corrosion resistance.

PVC Well Casing Pipes

The types of well casing pipes strings available in the market are specified by the American Petroleum Institute (API).

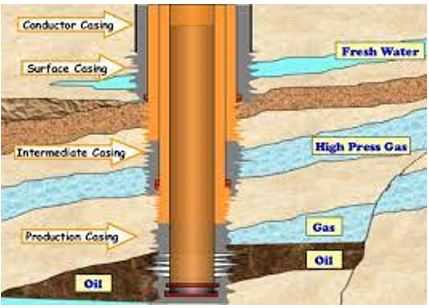

There are five types of well casing pipes strings or segments;

- Conductor casing

- Surface casing

- Intermediate casing

- Casing Liner

- Production casing

Various Casing Specifications

Principally, these types of casing strings do not function alone. They are installed together in layers and decreasing diameter, resulting in the whole well casing pipe.

To better understand the entire concept of well casing pipe strings, let us consider each type.

Conductor Casing

Before the drilling rig arrives, the conductor casing is first installed. Meaning, the conductor casing is cemented into place prior to drilling.

Commonly, the hole in which the conductor casing is to be fixed is drilled using a small auger drill attached to the back of a truck.

In terms of length, the conductor casing should not exceed 20 to 50 feet.

The diameter of the conductor casing ranges from 16 to 20 inches for onshore applications, while the offshore diameter ranges from 30 to 42 inches.

The critical roles of the conductor casing include;

- Prevention of the wall from caving in

- Aid in the circulation of the drilling fluid from the well’s bottom.

Surface Casing

The surface casing is installed immediately after the conductor casing. Similar to conductor casing, it is cemented into place.

Notably, the thickness of the cement is vital to minimize the possibility of freshwater contamination.

Compared to the conductor casing, it has a smaller diameter. However, its length can range anywhere from 100 feet to 2,000 feet.

During the installation, the surface casing ought to fit inside the conductor casing’s top.

The prominent roles of the surface casing are to:

- Protect freshwater deposits close to the well’s surface from being contaminated by leaking salt-water or hydrocarbons from underground.

- Acts as a passage for drilling mud coming back to the surface.

- Prevent the damage of the drill hole during the drilling process.

Intermediate Casing

Significantly, the intermediate casing is the longest part of the well casing.

Commonly, you can also cement them into place for increased protection, but cementing isn’t a must.

Primarily, the intermediate casing minimizes the potential hazards that accompany sub-surface formation.

These hazards may damage the well. They include;

- Underground silt rock

- Below ground pressure zones

- Formations that may lead to well contamination such as underground salt-water deposits

Although sub-surface formation and its accompanying hazards rarely occur, the intermediate casing ensures the well remains in contact regardless.

Liner Strings

Liner strings can be used as an alternative to intermediate casings.

Notably, they are not cemented but instead attached to the previous casing using ‘hangers.’ Consequently, they are less permanent than the intermediate casings.

Location-wise, these casings run from another casing’s bottom up to the open well zone.

Production Casing

Last but not least is the production casing, also referred to as long string or oil string. It is the deepest part of the well casing and is installed last.

Notably, the production casing provides the passage from the well’s surface to the petroleum-producing bed/zone.

The size of this type of casing is dependent on;

- The lifting equipment to be employed

- Possibility of deepening the well in the future

- Completions number needed

Let’s consider one of the above factors as an example. If you plan on deepening the well in the near future, the production casing should be wide enough to allow a drill to pass through.

PVC well casing pipe has gain popularity since its advent about 40 years ago.

The superb mechanical and physical properties of PVC make it the go-to material for water wells.

Here are some reasons why you should consider using a PVC well casing pipe in your next project.

- High chemical resistance – PVC features an outstanding chemical resistance, making it unsusceptible to most chemicals found in wells.

Such chemicals include the extremely corrosive acids applied in well rehabilitation and the widely used chlorine-based disinfectants.

- PVC has no extreme effect on the color or taste of water – This is a conclusion reached after thorough tests carried out by NSF international. As such, most people prefer water pumped through PVC as opposed to metal pipes.

- Long-life – PVC’s complete immunity to galvanic and electrolytic corrosion prevents it from rusting or rotting away like its metal counterpart. Also, PVC is a non-conductor, meaning it has low chances of lightning damage.

- Lightweight and easy handling – PVC is generally plastic, which we all know has quite lightweight.

- Ease of installation – It is quick and easy to install a PVC well casing pipe due to its lightweight and simplicity.

- Worldwide approval – Most State Regulatory Agencies have a green light for the use of PVC well casing pipes.

Well casing pipes come in two standard lengths, 10 inches, and 20 inches. What differs is the connection type of the well casing pipes.

As such, mostly the well casing pipes have either of the above lengths, but the connection type can be:

- Insert joint

- Plain end

- Threaded and Coupled

- Threaded on the two ends.

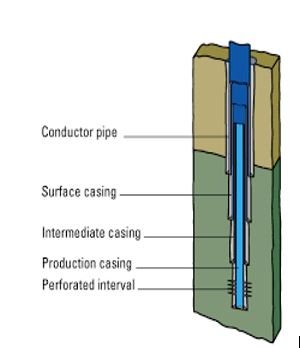

Well casing pipes comprise casing strings or segments, usually five, that are inter-joined. These segments are arranged in a specific order, and they include:

- Conductor pipe

- Surface Casing

- Intermediate casing

- Liner

- Production casing

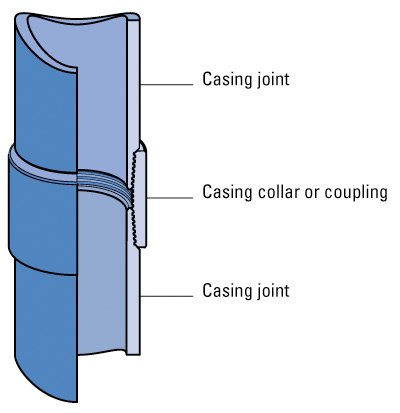

A Diagram Showing Segments of A Well Casing Pipe

Commonly, each of these segments has a male–threaded end. A short female threaded pipe known as coupling or collar is fitted in between the strings to connect the segments.

However, some manufacturers produce segments with female-threaded ends to ease the joining process.

Notably, each string has a smaller diameter than the preceding string.

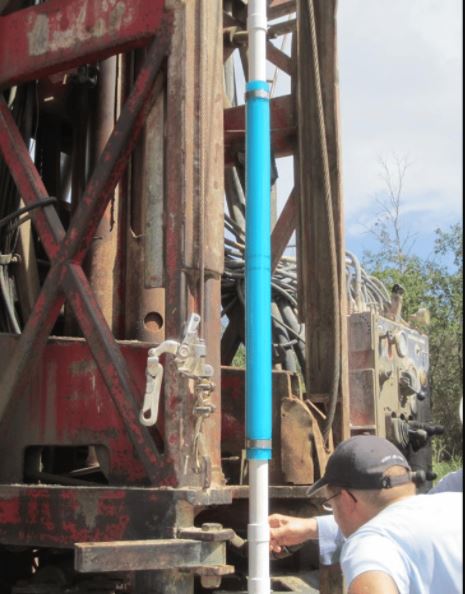

The well casing pipe is installed in a wellbore. During the installation, the well-casing pipes alternate with the drill strings.

A summary of well casing pipe installation is as below;

- The drilling string forms a new section of drilling

- The drilling string is pulled out of the hole (wellbore)

- A section of the casing string is inserted and cemented.

- The drill string is once again inserted with a smaller bit, bearing in mind that the next pipe to be installed is narrower than the previous one.

- The above procedure is repeated until all the well pipe segments are inserted in the wellbore

In the above steps, we mentioned cementing, but we did not dive deep into it. Below is a detailed explanation of how cementing of the well casing segments is done;

- Note that the cementing is done around the pipes outside diameter

- To carry out cementing, you pump drilling mud and cement slurry mix down the casing string. The mixture then flows down through the casing, filling the space between the casing and the well wall.

- When cementing two segments of the well casing pipe, the mixture will fill the space between the segments,

- After efficient cementing, you can proceed with drilling since the well casing pipe segment is now firmly held in place.

Image Showing Installation Of A PVC Well Casing Pipe

During the installation of well casing pipes, you may need some additional fittings.

Also, you may need fittings after installation to ensure the efficient functioning of the well casing pipes.

Some standard fittings used with well casing pipes include;

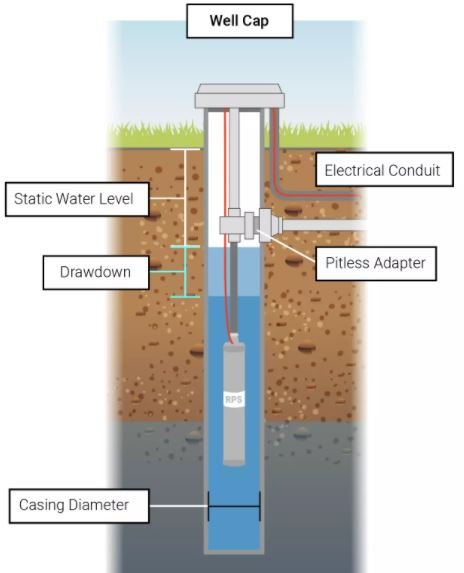

Caps

The well casing cap is the cover at the top of the well casing pipe that protrudes out of the ground. Most caps are usually thermoplastic or aluminum.

Majorly, the cap functions to keep contaminants out of the well casing pipe. Contaminants may include runoff water, airborne debris, or even insects that build nests in wells.

Additionally, the cap can feature a vented screen that equalizes the water pressure on the inside and outside of the well during pumping.

Couplings

These are useful in joining the segments of well casing pipes that both have male-threaded ends.

Couplings are small pipes with both female-threaded ends that fit into the male threaded ends.

Reducers

As the name suggests, the reducer mainly helps reduce the diameter of a specific segment of the well casing pipe so that it can fit on the next segment.

Usually, a reducer has one opening similar to the pipe’s diameter and the other opening with a smaller diameter.

Also, if the well casing pipe is connected to a pipe, a reducer is essential at the joint to avoid any pump failure due to different velocities in the pump inlet.

Pitless Adapters

Pitless adapters are attached to offer a frost-proof and sanitary seal between the well pipe casing and the waterline.

Simply put, this adapter prevents freezing of the water. At the same time, it allows for quick access of the well together with the well components without necessarily digging around the well.

Usually, the adapter is connected to the well casing pipe at the depth where the ground does not freeze, known as the frost line.

The pitless adapter prevents water from freezing by diverting it horizontally.

Coupling and Casing Joint Of A Well Casing Pipe

Essentially, a square cut is made to guarantee proper assembly or beveling.

You can use any of the following for cutting the well casing pipes:

- Hand saw

- Power type saw with an abrasive disc or a steel blade

- Fine-toothed hack saw.

Some don’ts when cutting the well casing pipe include;

- Not using a standard pipe cutter since the cutting wheel may damage or crush the pipe.

- Avoid burning the pipe while cutting

Well Cap

Usually, well cap extends outside the pipe. Commonly, they are used with pitless adapters in areas prone to freezing.

Additionally, the well cap features a side opening for electrical cables connecting the pump to the breaker box or controller.

A Well Cap Used With A Pitless Adapter

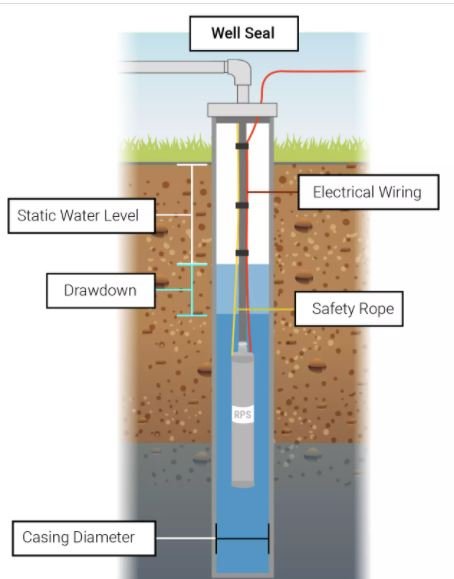

Well Seal

On the other hand, a well seal is inserted down into the well casing, with a rubber ring. Importantly, it ensures even weight distribution of the hanging pump.

It also holds the pipe in place.

Unlike the well cap, the usage of the well seals is mostly in warmer environments where there is minimal probability of hard freezes.

Anatomy Of A Well Showing A Well Seal

Before installing the well seal or well cap to the well casing pipe, you need to get the correct dimensions. Let’s look at how you can do this.

Sizing For Well Seal

Here, you will need a measuring tape to measure the internal diameter of the pipe.

You will place the end of the measuring tape on the pipe’s interior and measure it to the inside of the opposite end.

Notably, the figure you obtain from the measurement is the correct dimension of the well seal.

To judge if your measurement is correct, use the below estimates;

- Residential wells usually have 4, 5, or 6-inch casings.

- Agricultural or older wells use larger casings of around 8, 10, 12 or more inches depending on the capacity of water being pumped.

Sizing For Well Cap

Unlike the sizing for the well seal, with the well cap, you measure the external diameter. However, you can still use a tape measure to do the measurement.

You will place the tape measure to the outside lip of the pipe and measure to the opposite outside lip.

Sizing For The Well Seal And Well Cap Without A Tape Measure

Alternatively, if you do not have a tape measure, you can wrap a string around the well casing’s outside.

You will then cut the string to length and then carry it with you for later measurement.

Principally, the length of the string is the circumference of the well. To get the outside diameter in inches, you divide the measured length by 3.14.

For the internal diameter, you will subtract ½ inches from the outside diameter.

Well casing pipes have a number of uses. Some typical applications of these pipes include:

- Water well casing and water pipelines for potable water hand pumps

- Sewerage, rainwater, drain, and wastewater pipeline system

- Conduit pipes for electrification work

- Water treatment plants

- Industrial effluent disposal

- Various plumbing works

- Submersible pumps

- Irrigation schemes

- Pressure systems

- Well liners

As a well owner, you may want to extend your well casing pipe to avoid contamination or maybe for easy maintenance.

In such a scenario, you can opt to install a new well casing pipe altogether or add a new section of pipe.

Out rightly, the former is expensive; thus, adding a new pipe section is the go-to option for economic purposes.

Let’s look at how you can add a new pipe section for both PVC and Stainless Steel well casing pipes.

Stainless Steel Well Casing Pipe

Selecting The Joint Option

You can join the two pieces of pipe with either a welded join or a screw coupling.

If the pipes are have threaded ends and similar diameters, then a screw coupling is the best joint option. However, you should select an air-tight coupling by ensuring that it is of the correct diameter.

On the other hand, if the pipes have different diameters and have no threaded ends, you can weld them together.

Joining

Now that you have settled on the joining option, the next step is to join the two pieces of pipe together.

Importantly, ensure that the coupling is water-tight. If it isn’t, you can resort to the welding option as it guarantees a water-tight joint.

For the non-threaded pipes, directly weld the extension to the main pipe.

PVC Well Casing Pipe

Selecting The Joint Option

As opposed to the stainless steel pipe, PVC well casing pipes have no welding option for the joints. You can either choose a slip coupling or a screw coupling to join the two pieces together.

If both pipes have threaded ends, then the screw coupling is the ideal joint option. However, if they have no threads, definitely a slip coupling will do.

Notably, ensure that the coupling you intend to use is of the suitable diameter for both pipe pieces.

Joining

Join the two pipes with the type of coupling you have chosen. Check that the pipes sit correctly on the coupling and that the two, casing and coupling, form a tight seal.

It is advisable not to use tape or adhesive to join the two PVC well casing pipes.

Impact Classification (IC) involves rigorous testing of the well casing pipes to ensure that they conform to the required quality standards.

For example IC-2 standard for PVC well casing pipes requires that;

- 9 out of 10 ten pipes to be tested

- The pipes should be pre-conditioned to a temperature of 320F

- They should also withstand the impact of a 30-pound tup dropped from 7.1 feet for 4 ½ inch casing

- However, 6 ¼ inch casing pipe should withstand a 30-pound tup drop from 8.9 feet

Judging from the above information, a PVC well casing pipe with an IC-2 rating marking ought to have a good performance.

Conclusively, IC rating ensures that the well casing pipe you purchase will perform efficiently.

Usually, well casings used in agricultural or old wells have a larger diameter than those used in residential well casings.

The amount of water being pumped determines the size of the well casing pipe needed. Typically, residential well casing pipes usually have a diameter of either 4, 5, or 6 inches.

There are primary joint connections for well casing pipes are couplings, weld, or flanges.

Couplings

It is the most used joint connection for both metal and PVC well casing pipes. There are two main types of couplings;

- Screw coupling – Used when both the well casing pipes to be joined have threaded ends. They are screwed into place

- Slip coupling – Commonly, they are used for PVC well casing pipes that lack threaded ends. As the name suggests, you slip them over the two pipes.

Weld

The weld joint option is applicable for only metal well casing pipes since PVC cannot be welded.

Usually, two pipes are welded together is they have different diameters and lack threaded ends.

Also, if both pipes have threaded ends, yet the coupling is not water-tight, you can still weld the pipes together.

Flanges

Though rare, some well casing pipes might have flanges. Depending on the type of flange, you can quickly join the two well casing pipes without the need for coupling or weld.

Commonly, the prices of well casing pipes are measured per ton.

The price is dependent on the type of pipe material and the length.

Typically, the price range is between $600 per ton to $1000 per ton.

Usually, the strength of a PVC well casing pipe is determined through IC testing.

For a PVC well casing pipe to have the required strength, the following should hold during the IC testing;

- A 4 ½ inch casing should withstand the impact of a 30-pound tup dropped from 7.1 feet.

- A 6 ¼ inch casing pipe should also withstand the impact of a 30-pound tup drop from 8.9 feet

Conclusively, if the PVC well casing pipe has the IC rating marking, it is a surety that it has met the required strength standards.

Generally, steel casing pipes have a service life of between 20 to 25 years.

However, this time frame can be shorter depending on the steel quality and the media passing through the well casing pipes.

PVC well casings do have a longer life span since they have high corrosion resistance. However, they are rarely used in deep wells due to strength factors.

Quality control is a key issue in the efficient functioning of a well casing pipe throughout its service life.

Below are some ways to ensure quality control;

First, ANSI/AWS D1.1 requires that qualified welding professionals conduct all welding procedures.

Also, the tensile strength of the well casing pipe should meet the set threshold of not less than 95% of the material’s minimum strength.

A meticulous examination should also be done on the connections to ensure they are free of any defects that might otherwise be injurious.

Additionally, quality control experts should examine each well casing pipe manufacturing step to ensure they are up to standard.

Lastly, the manufacturing company should have a quality control certification from ISO, specifically ISO 9001:2000

There are several industry standards that well casing pipes, regardless of the type, should comply with.

Specifically, PVC compounds used in the production of well casing pipes should meet the requirements of ASTM D1784, cell classification 12454.

Other standards PVC well casing pipes should comply with include;

- ASTM D-1785

- ASTM D-2665

- ASTM F-480

- ANSI/NSF Standard 14, for all the materials.

Some common standards for the stainless steel well casing pipes are;

- ASTM A132

- ASTM A312

- ASTM A409

- AISI standards

- API standards, for connection types

Selecting the correct well casing pipe is economically sound and ensures that you have an efficient well casing pipe.

As such, the below considerations will help you make the right decision when you set out to purchase a well casing pipe.

Strength

An IC rating mark will help you ascertain that the well casing pipe has the industrial recommended strength.

Strength is essential since it influences the ability of the pipe to resist collapse under stress.

Durability

Concerning durability, consider the corrosion resistance of the well casing pipe. High-grade stainless steel has high corrosion resistance.

Thus ensure that the pipe is made from the correct stainless steel.

Generally, PVC has good corrosion resistance. Thus, PVC well casing pipe also carries with them this characteristic, making them durable.

Application

The type of well casing pipe you select is dependent on the intended application.

Stainless steel well casing pipes are ideal for deep wells since they are stronger.

For shallower wells, you can opt for PVC well casing pipes, depending on the medium being passed through the pipes

Handling

Regarding handling, consider the transport cost of the well casing pipes and the ease of installation.

The handling cost should not overstretch your budget.

Maintenance

Ideally, a well casing pipe should be designed to enable efficient maintenance such as cleaning, repair, redevelopment, and incrustation removal.

Also, the well casing pipe design should provide room for future well deepening.

Rarely do people know how to detect a leak in their well casing pipes.

Nonetheless, we won’t completely ignore the fact that catching a leak is an uphill task, especially if it is below the surface.

However, to free you from this headache, you can watch out for these signs to know if your well casing pipe is leaking;

- A gradual decrease in the water flow

- Contaminants such as dirt, sand, sediments, etc. in your water supply

- Discovery of a new contamination problem

- Frequent replacement of water filters

A leak’s prompt discovery and repair is essential to ensure a longer lifespan for your well casing pipes.

Also, leaks will directly contribute to the contamination of your water line, posing a risk to your health.

Watch out for the above signs and call in a professional for immediate repairs if any of them manifests.

Commonly, you will need to repair a well casing pipe once you notice a leak.

Upon noticing the leak, you should promptly call your contractor or a professional.

Usually, the professional lowers a camera into your well to establish the root cause of the leak. Your well casing can have a single leak or multiple leaks.

If they are minor leaks, they can be repaired using well liners or sleeves.

Fixing sleeves is easy due to the compact design of the sleeves and does not cause any disruption to the well.

However, if there are multiple major leaks, it is clear that your well casing pipe has corroded.

Placing a sleeve over such leaks is close to impossible, which leaves you with the option of replacing the entire well casing pipe or a segment.

Essentially, a well casing pipe supports the well’s wall.

That is, it prevent the collapse of the loose rocks or unconsolidated gravel and sand (through which the well has penetrated) from collapsing into the well shaft.

Also, a well casing helps prevent surface water and/or potential contaminants such as fertilizers and pesticides from descending down the well.

The well casing pipe accomplishes this role by forming a cylindrical surface. Between the cylindrical surface and the wall of the well there is a gap.

The gap is filled with an impermeable grout seal which prevents the aforementioned substances from descending the well.

How A Water Well Casing Pipe Works

The depth of installation of the well casing pipes differs with regard to the type of soil.

For softer soils, the well casing is drilled down to the bottom of the well.

After which, slotted screens are installed to keep the debris/sand out but permit water flow through the surrounding gravel pack.

In areas having bedrock, the well casing is drilled down to the bedrock.

However, it is not cased at the bottom as the bedrock functions as a casing to prevent debris accumulation.

There are key specifications that will be of help when selecting a well casing pipe. These specifications include;

- Size in inches

- Outer Diameter

- Internal Diameter

- Minimum Wall

- Weight

- Material

- Socket depth in inches

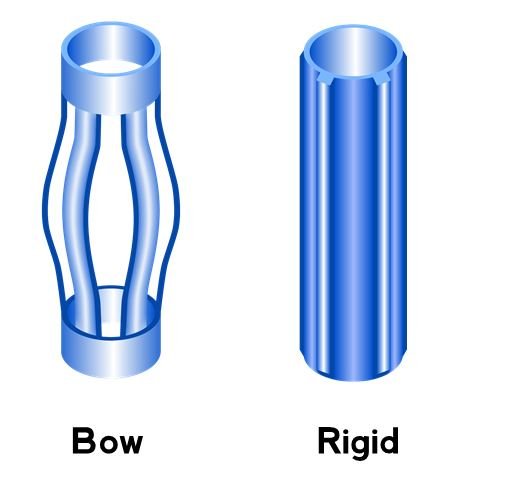

By definition, a centralizer is a piece of mechanical equipment that prevents the well casing from coming into contact with the sides of the wellbore.

Consequently, leaving a 360-degree space around the well casing pipe for cementing or applying other completion materials.

The two common types of centralizers used are;

- Bow spring centralizer – It is slightly larger than the borehole. It features a spring mechanism that holds the pipe in place by applying pressure against the wellbore sides.

- Rigid blade centralizer – Typically, rigid blades are arranged around the casing, preventing it from touching the wellbore walls.

Notably, rigid blade centralizers offer more significant support. On the other hand, the bow spring centralizer keeps the casing well centered.

Bow String And Rigid Blade Centralizers

I know you may also be interested in:

If you have any inquiry or question on well casing pipe, contact FilSon Filters now.