Filson: Your Premier Duplex Basket Strainer Manufacturer

- Can be manufactured to any size for a variety of applications

- Competitive price and faster delivery than other suppliers

- Strict pressure test to ensure no valve leakage and safe operation

- Balance valve for pressure relief and smooth changeover

Send Your Inquiry Today

Why Filson Can Be Your Reliable Duplex Basket Strainer Manufacturer

- Over 20 Years Manufacturing Experience in Duplex Basket Strainers

- Housings Are Functionally And Dimensionally Interchangeable To Any Brand.

- Full Range Of Filter Material Available With Standard Or Special Dimensions

- Our Duplex Basket Strainers Are With 18 Months Warranty On Quality

Filson duplex basket strainers are manufactured and designed totally based on your detailed requirement and we provide full support on duplex basket strainer training, duplex basket strainer installation, duplex basket strainer cleaning, duplex strainer basket replacement, duplex basket strainer troubleshooting and more. Not only a duplex basket strainer manufacturer, Filson is a reliable partner that can fully support your business.

Filson duplex basket strainer also name dual basket strainer, double basket strainer. It is ideally used for systems that must run continuously without any downtime, even during duplex strainer basket changing or cleaning.

Filson duplex basket strainers are available with a full range of material, including carbon duplex basket strainers, stainless steel 304 duplex basket strainers, stainless steel 316L duplex basket strainers and even with dual-phase stainless steel material.

As a professional duplex basket strainer manufacturer, Filson duplex basket strainer has been using to totally replace over 50 foreign brands, such as Eaton duplex basket strainer, Hayward duplex basket strainer, Mueller duplex basket strainer, Titan duplex basket strainer, Keckley duplex basket strainer, Pall duplex basket strainer…

Filson duplex basket strainer has both replacement standard dimensions and customized service for you. The Filson Ball Valve Type Duplex Basket Strainer is a patent design with several important features and advantages for large size but no valve leakage.

Send Your Inquiry Today

- Recent Projects

- Contact Us

Helpful Resource to Help You Know More About Duplex Filter

Duplex Basket Strainer:The Ultimate Guide

We cannot underestimate the importance of a duplex basket strainer in piping systems.

Remember, contaminated fluid systems can be a disaster – from total system failure, frequent shutdowns to expensive maintenance procedures.

So, what exactly do you need?

Well, today, you’re going to learn everything about a duplex basket strainer – from technical designs, specifications, construction material to working principle, just to mention a few.

But first, I want you to watch this video:

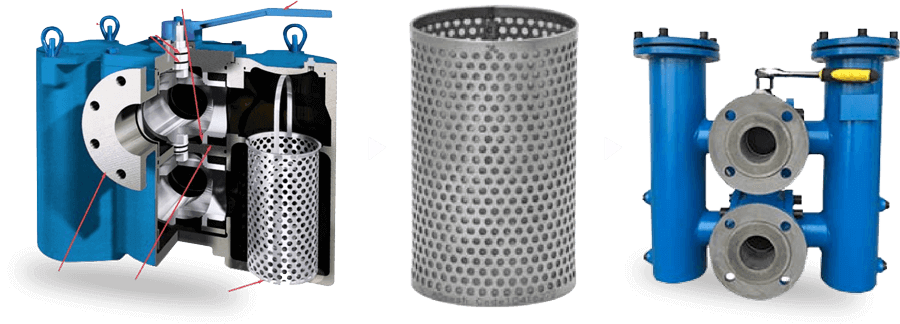

What is a Duplex Basket Strainer?

Before we proceed, let’s start by defining what a duplex basket strainer is.

A duplex basket strainer refers to a device that you can install in a pipeline when you want to filter dirt and unwanted particles from fluids.

They achieve this by utilizing either a wedge wire or a mesh straining element. What sets the duplex basket strainer apart from the other basket strainers is the number of strainers.

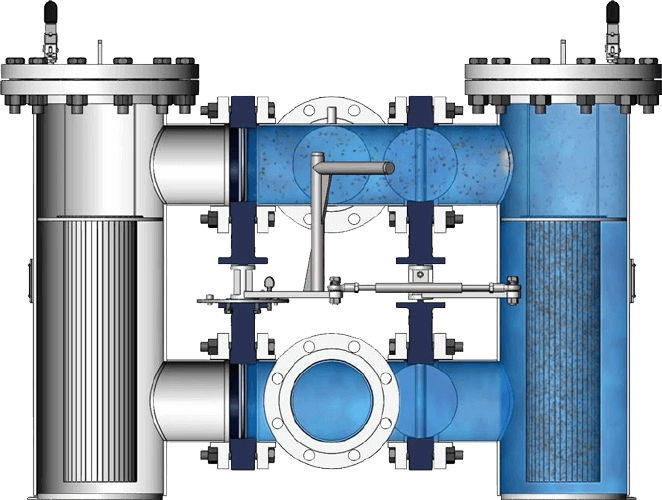

A duplex basket strainer consists of two basket strainers that help in continuous filtration of your fluid.

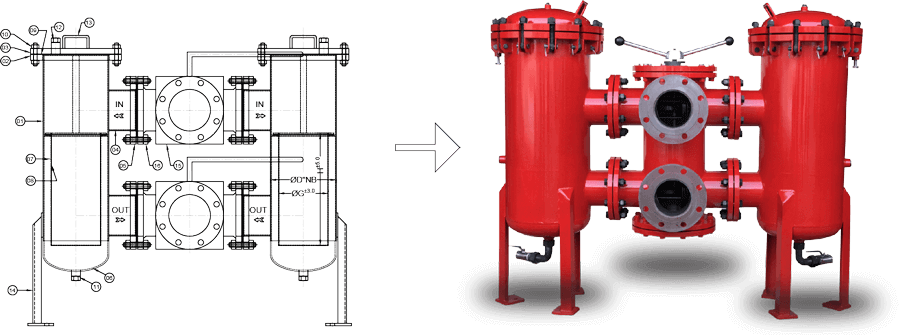

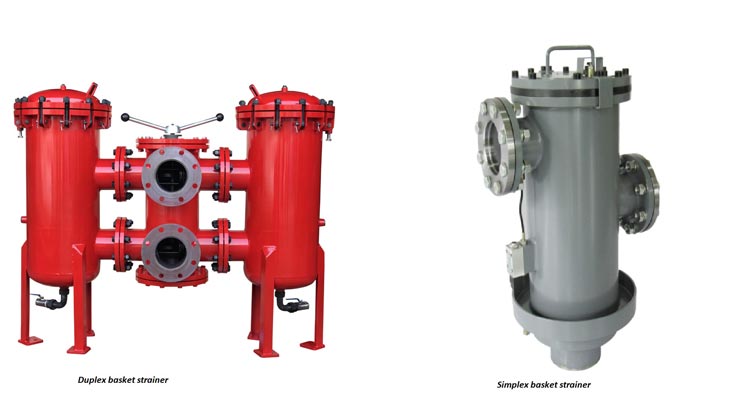

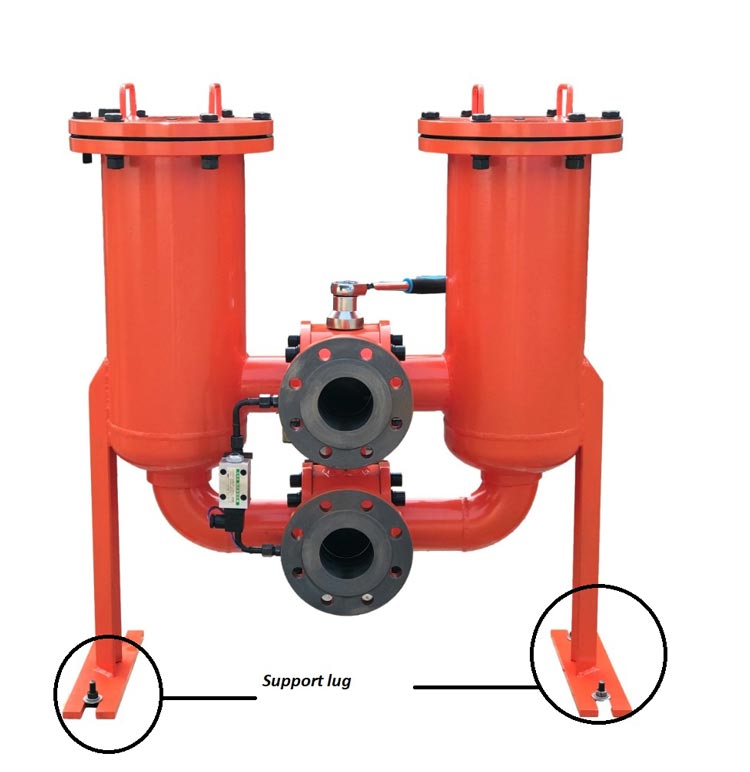

Duplex basket strainer

By using a duplex basket strainer, you can continuously filter contaminants from your fluid thus ensuring continuous functionality of your application.

This does not imply that both strainers function at the same time. No, in fact, as one strainer functions, the other one is on standby.

It will only operate once the functioning one is clogged with contaminants.

How does this happen? By having a ball valve which completely shuts down the functioning strainer. The airtight valve ensures that there is a diversion of the fluid to the other.

Once the fluid starts flowing through the other strainer, you can remove the clogged strainer and clean it before replacing it.

Benefits of Duplex Basket Strainer

As from the definition, you can see that duplex basket strainer plays an important role in the filtration of fluids.

As such, you need to understand the benefits of using a duplex basket strainer.

Duplex in piping system

There are several benefits that you can get from using a duplex basket strainer. They include:

You have a wide range of filter materials to choose

By having a duplex basket strainer, you can virtually remove any size of the contaminant from your fluid.

This is because you have different sizes of filter materials that you can choose from for your strainer.

The advantage of this is that you can filter your fluid to the level that you want.

Large volume for holding contaminant

For the efficient running of your system, you need a strainer that can hold a high volume of contaminants for efficiency purposes.

A duplex basket strainer can hold a large volume of contaminants before you remove for cleaning.

The volume of contaminants your basket strainer can hold depends on several factors such as pore size, pore density, and filter material.

Provides a large filtration area

To be able to filter as many contaminants as possible, you will need to have a large filtration area. This is what a duplex basket strainer offers thereby allowing you to filter contaminants from your fluid.

The continuous flow of the system

One of the benefits that you will realize by using a duplex basket strainer is that you don’t have to shut down the system. The availability of two basket strainers enables you to use one of strainer at a time.

Once one of the strainers is clogged, you can change and use the other strainer. This is made possible by the ball valve system which you can use to switch to the other strainer.

Maintenance cost

The use of duplex basket strainer requires less maintenance cost. Actually, you can reuse most of the components of the duplex basket strainer which are otherwise long-lasting.

Components such as the filter elements only require cleaning and are good to be used again.

Easy to operate

There is nothing technical about handling a duplex basket strainer. Once you have installed it, the system runs on itself.

The clogging indicator will show you when the basket strainer is clogged. By using the valve handle, you can switch between the basket strainers which ensures a continuous flow of the fluid.

They come in different sizes

You can never miss a perfect size with the specifications that you need when it comes to a duplex basket strainer.

They come in multiple sizes which ensures that you have the right duplex basket strainer for your application.

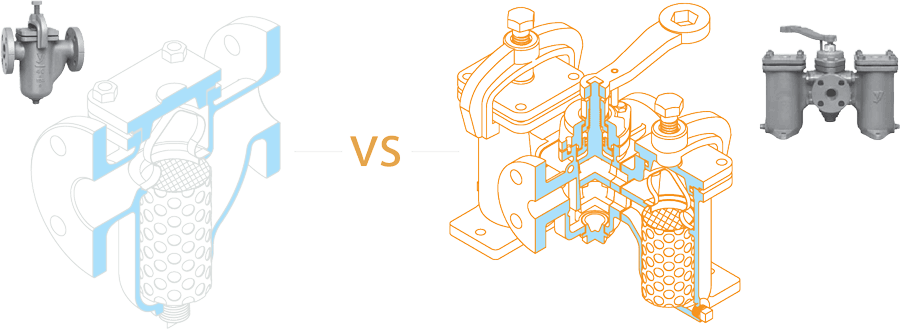

Simplex Basket Strainer vs. Duplex Basket Strainer – An Ultimate Comparison

Comparing the simplex basket strainer and duplex basket strainer can help you to understand which strainer you can use for your application.

Here is a look at the similarities and the difference between the two types of strainers.

To start off, a simplex basket strainer basically means that it has a single basket strainer while a duplex basket strainer means that it has two basket strainers.

Duplex basket strainer vs simplex basket strainer

The obvious difference that you will note between the two types of strainers is in their designs. When using a simplex strainer, you will have to shut down the system when they are clogged to clean them.

You need to ensure that the basket is empty before fixing it back to allow the system to resume operation.

On the other hand, the use of a duplex strainer does not necessarily mean that you shut the system when you want to clean the basket.

They have two strainer basket housing and a valve handle which can divert fluid into one strainer.

The valve handle which is in between the two baskets can divert fluids to one basket when you want to clean the other basket.

With this, the system continues to operate maximumly with no interruptions.

The design is not the only aspect that you can compare the two types of strainers. You can also compare the areas of comparison of the two baskets strainers.

Basket strainers – Photo courtesy: Sure Flow

The fact that with a simplex strainer you can shut down the system to allow for the maintenance of the system means that you can use it in a system that requires shirt interval shutdowns.

On the other hand, you can use a duplex strainer for systems that require a continuous flow of the fluid.

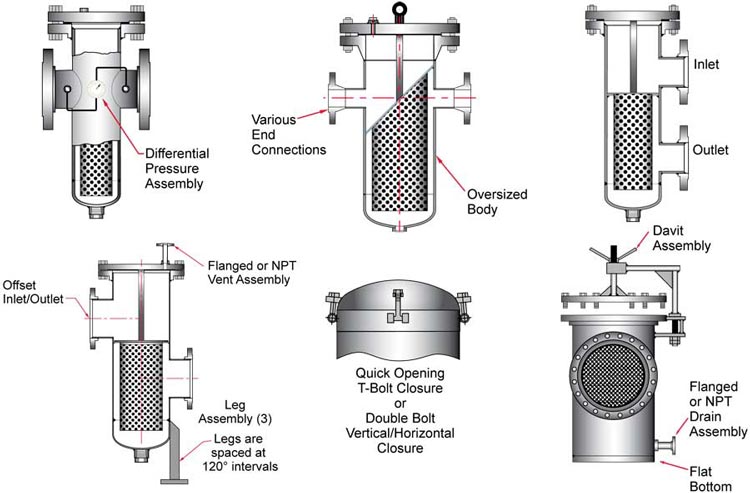

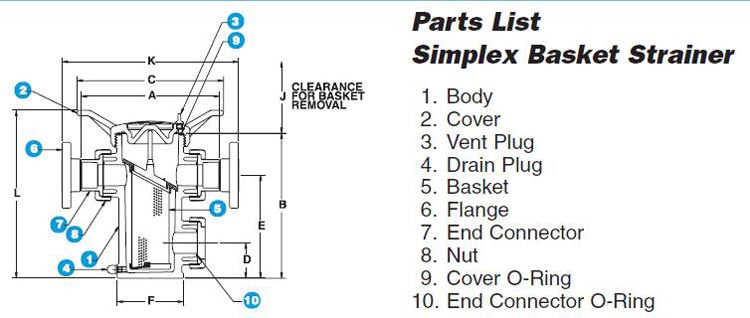

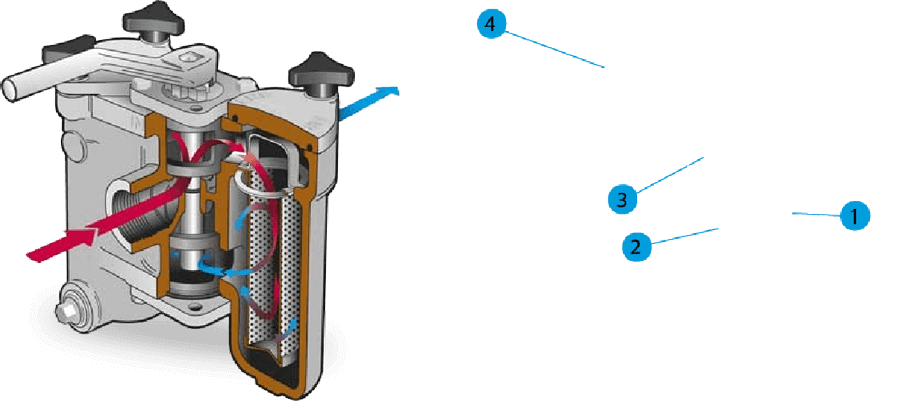

Parts of Duplex Basket Strainer

If you are considering installing a duplex basket strainer, you need to understand its parts. The advantage of this is that you will be in a position to identify the function of each part.

You will also be in a position fix any part in case of a breakdown. To do this, here is a look at these parts.

Basket strainer parts

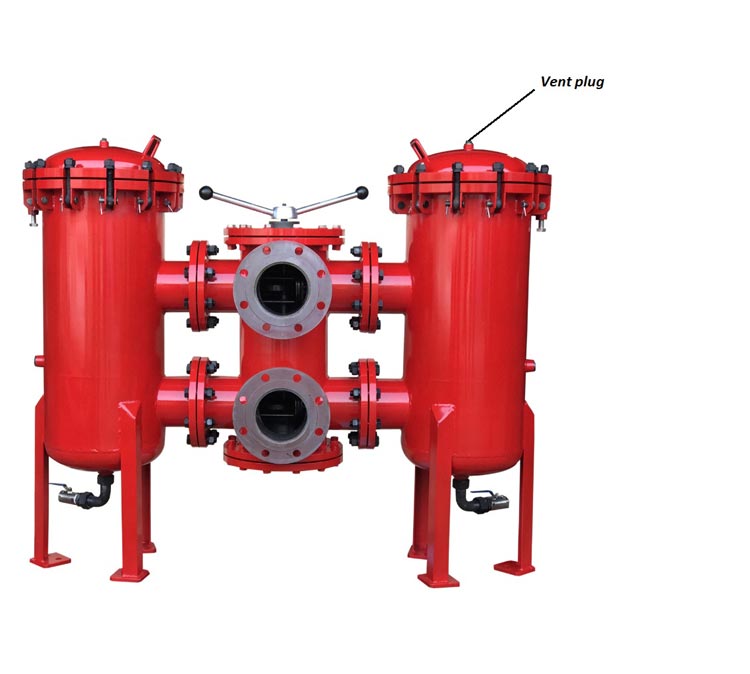

1. Vent Plug

The function of the vent plug is to assist in relieving the pressure from the duplex basket strainer. This is important in helping the fluid flow smoothly.

Too much pressure may cause the strainer and the application to bust which can be a serious loss. The vent plug helps in preventing this from occurring.

Vent plug

There are different vent plugs that you can use for your duplex basket strainer. They include vent plugs with filters, vent plug with filters and check valves and vent plugs with deflectors.

Other types of vent plugs are vent plugs with filters and deflectors and special vent plugs.

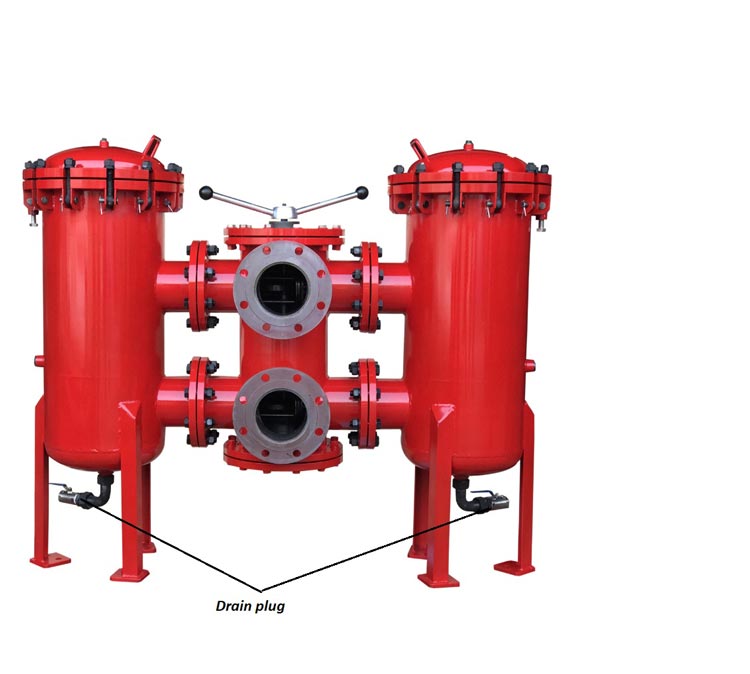

2. Drain plug

A drain plug is a plug that you will use when you want to drain the fluid present in the duplex basket strainer. This is important especially when you want to clean and maintain the basket strain.

Drain plug

3. Handle

The function of the handle is to cover the basket when you are using it and to prevent the opening of the filter cover by accident.

Handle

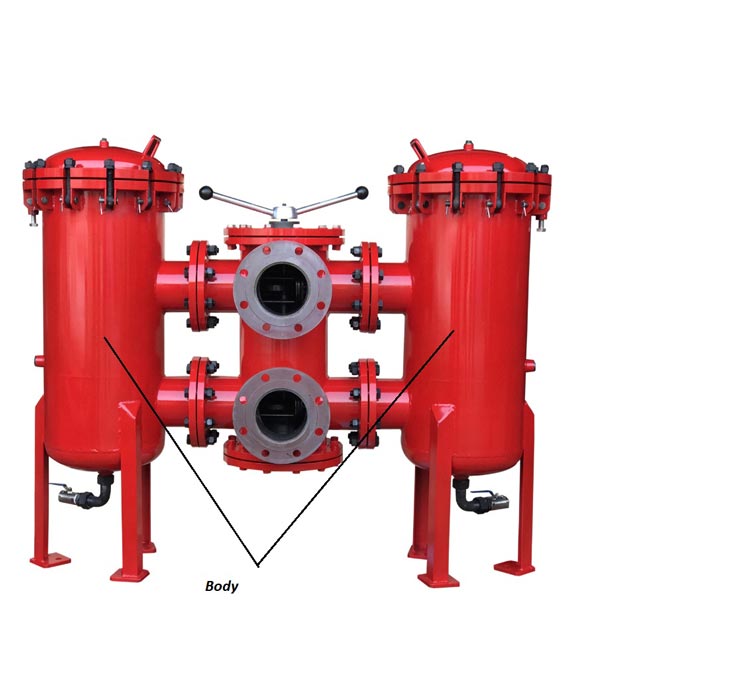

4. Strainer body

The strainer body is the one that holds all the components of the duplex basket strainer. You can have several materials making up the strainer body.

Body

The choice of which strainer body to use will depend on the application that you want to use the duplex basket strainer on.

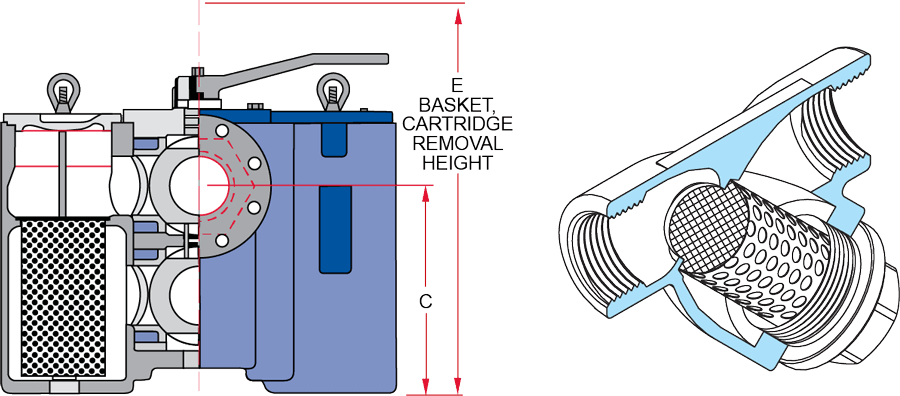

5. Cover

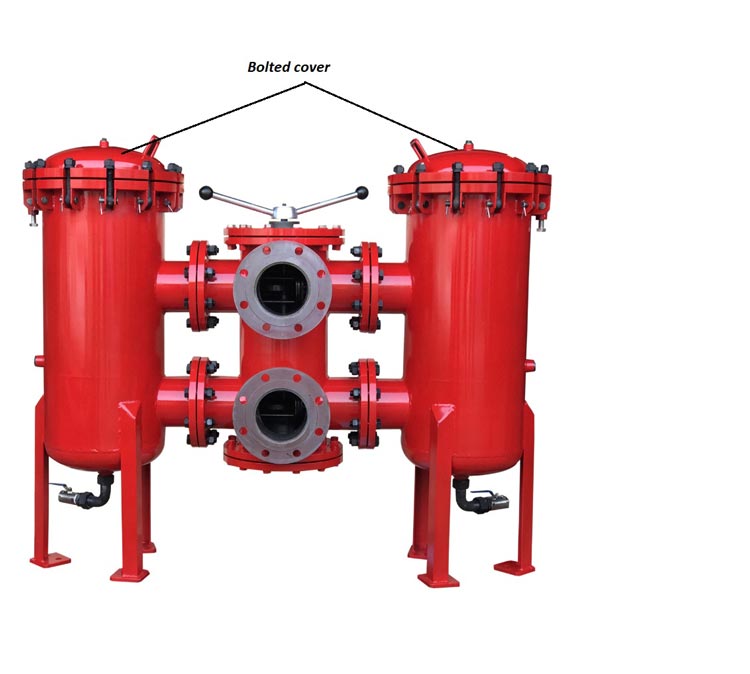

The cover is an important part of the duplex basket strainer since it encloses the components of the strainer. You can easily open the cover for maintenance and cleaning of the inner parts of the strainer.

Bolted cover

There are different types of covers that you can have for your duplex basket strainer. Some of the common ones include:

Bolted cover

These are perhaps the common ones, and most recommended types of covers that you can find for your duplex basket strainer. When you want to clean or do maintenance on your strainer, you can easily loosen the bolts.

Clamping yoke cover

This kind of cover entails a tee shaped handles which have threads that you use to hold the cover onto the body. You can easily remove the cover since it is attached to the body via a hinge mechanism.

This kind of cover is expensive when you compare it to the other kinds of covers.

Automatic covers

For larger circulation systems, you can have an automatic cover for your duplex basket cover. Having these covers implies that you won’t have to open them manually for maintenance or cleaning purposes.

It constitutes of a circular screen which rotates allowing for water inflow which is attached to the basket.

6. Pressure equalizer valves

The purpose of the pressure equalizer valve is to prevent the pressure difference from rising which will deform the filter element.

Pressure equalizer valve – Photo courtesy: CMC Technologies

It achieves this by feeling the pressure difference in the filter elements and automatically opening up.

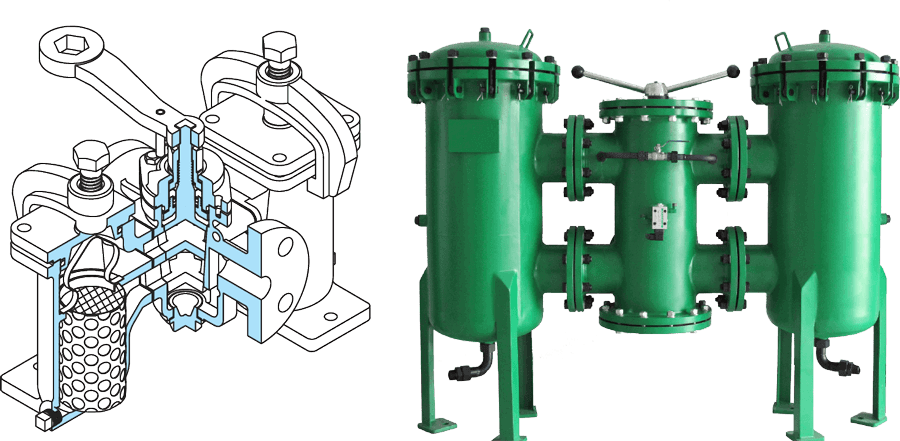

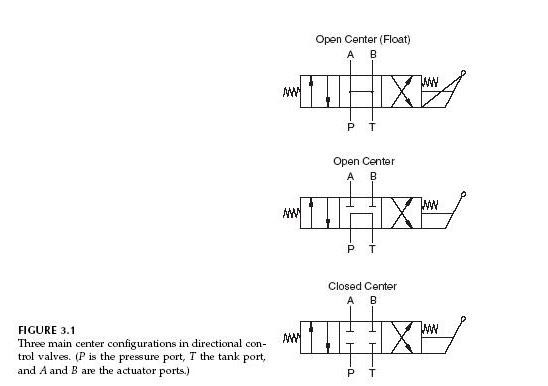

7. Changeover valve

The importance of the changeover valve also known as the switch valve is to help in switching from one basket strainer to the other. This is important especially when one basket strainer is clogged hence need for maintenance.

Directional control valve – Photo courtesy: Valve Hydraulic

The changeover valve consists of two outputs and one input which allows for the connection between the two basket strainers and the pressure device.

By doing this, it ensures that there is always one basket strainer on standby as well as the other operating.

This ensures that there is no excessive pressure on the application. The size of the changeover valve will depend on the size of the basket strainer.

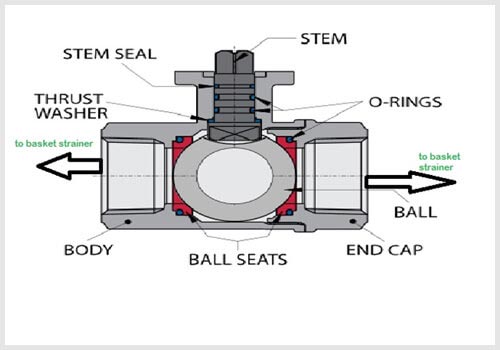

8. Ball valve

The function of the ball valve is to completely shut down the clogged strainer which ensures that the fluid does not keep flow into it.

Ball valve

The ball valve is airtight hence no fluid will flow once it closes the strainer.

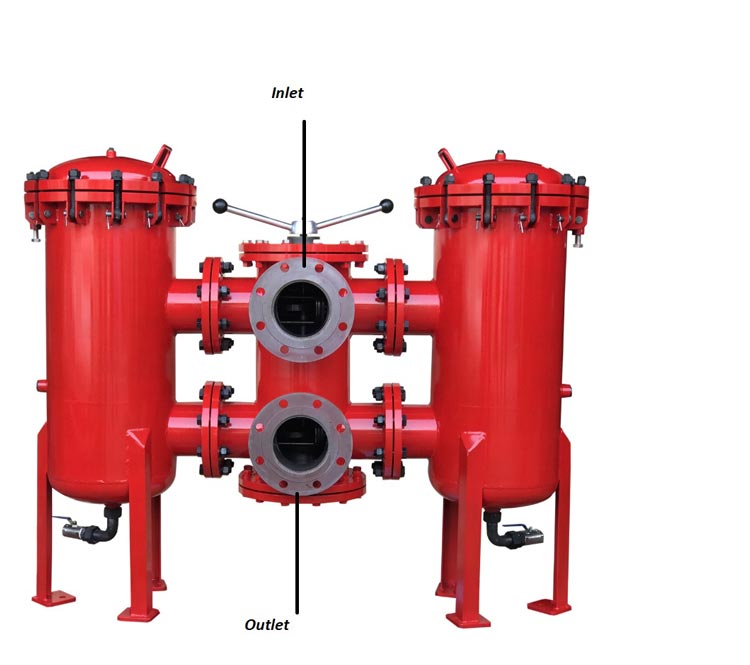

9. Inlet and outlet

The design of the duplex basket strainer is such that there is an inlet part of the strainer is on the upper part. The outlet port is on the lower section of the strainer.

Inlet and outlet

The purpose of the inlet is to allow for the inflow of the fluids into the strainer. The outlet, on the other hand, lets out the fluid from the basket strainer after filtration.

10. Strainer basket

Strainer baskets help in protecting the application from potential contaminants which may be carried along as the fluid flows.

You can have either an automatic or a manual basket strainer.

Strainer basket

11. Filter indicator

The purpose of this indicator is to monitor the contamination levels of the duplex basket strainer.

It will alert you if the levels are high and thus you need to change the strainer to clean it.

Clogging indicator

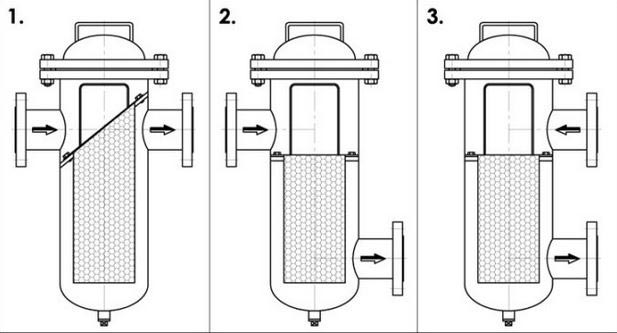

12. Basket strainer element

The most important component of a duplex basket strainer whose function is to filter the fluid that passes through.

When the fluid is passing through the basket, the strainer element traps any contaminant that is present in the fluid.

The strainer element consists of a perforated plate which can either be straight or staggering. The material of the strainer element can either be iron, carbon steel, bronze or stainless steel depending on its application.

Basket strainer options

The design of a basket strainer is that water flows from the inside to the outside which ensures that there is continuous fluid filtration. The structure of the strainer element consists of a support body and the filter mesh that is around the body.

You can have different designs of the strainer element such as the filter cartridges or the start sieves. The aims of such are to provide a large surface area for filtration which ensures that your fluid attains the needed cleanness.

On top of this, you can have strainer element accessories. They include air eliminator, mounting feet, welded heating jacket and equalizing lines.

The welded heating jacket is available for strainers whose applications utilize a lot of heat.

You can have different types of strainers for your duplex basket strainer. For instance, you can have a ball type duplex strainer which is effective in removing contaminants in the fluid of medium flow.

The presence of the ball enables the strainer to shut off completely thereby diverting the fluid to the other strainer. This is important especially during the clogging period when you want to switch the strainer.

The advantage you have with this kind of strainer is that it is easy to operate. In fact, you can use your little force with your hands to divert the flow of the system.

You also have a plug type duplex strainer whose design allows for minimal interference during operation. This is due to the availability of a special plug port on the diverter mechanism plug.

The other type of a strainer is the large duplex strainer. This kind of strainer is ideal for large duplex basket strainers and features a sliding gate valve and disc.

The valves and disc are in such a way that they can work inversely during operations. This implies that as one basket housing opens, the other basket remains closed

13. Support lug

Since the duplex basket strainer won’t be moving around, it is important that you fix it firmly on the ground. A support lug is a projection that you find at the bottom of your duplex basket strainer.

Support

Its importance is that you can screw or drill your duplex basket strainer on your working environment.

14. Gasket

This is a ring-shaped rubber that you will use to seal the junction between two junctions of the duplex basket strainer.

It completely joins the two junctions thereby preventing any leakages from occurring.

Gasket

Apart from rubber, you can have several materials for your gasket such as asbestos in instances of high-temperature applications.

15. Nylon washer

To be able to tighten nuts properly on the duplex basket strainer, you will need to have a nylon washer.

Nylon washer

Nylon washer works by spreading the pressure of the nut or bolt over the surface of the duplex basket washer.

16. O-rings

The function of the O- rings is to make it easy for the rotation of the backwash arm. The material for the O- the ring is rubber.

O ring

However, there are different rubber materials that you can have for the O-rings. The choice of which O- ring to use will depend on several factors.

Such factors include chemical compatibility, the temperature of the application, lubrication requirement and the sealing pressure.

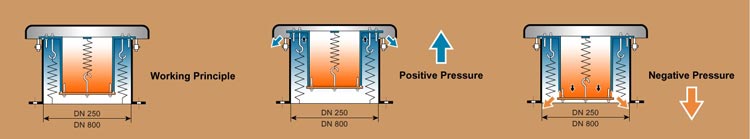

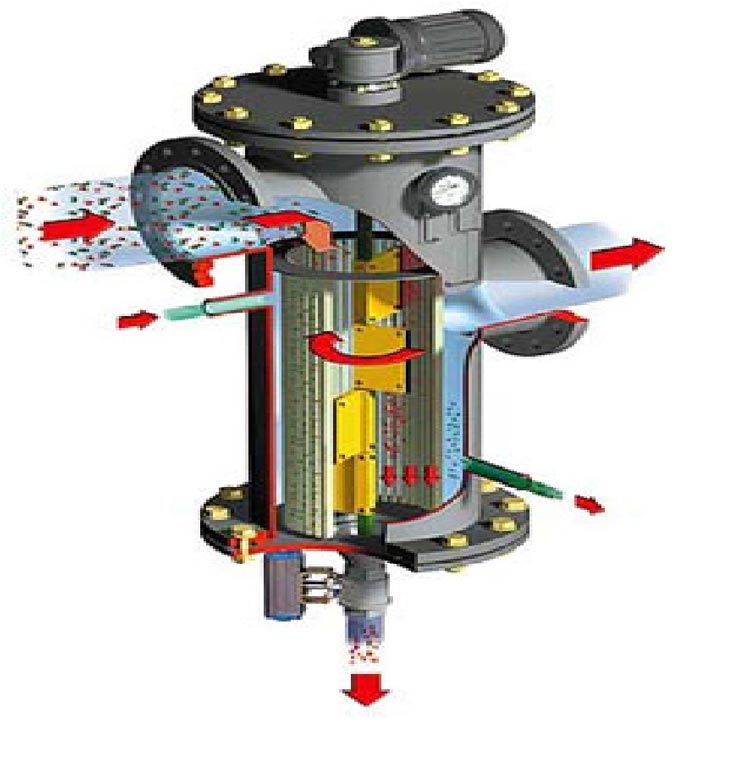

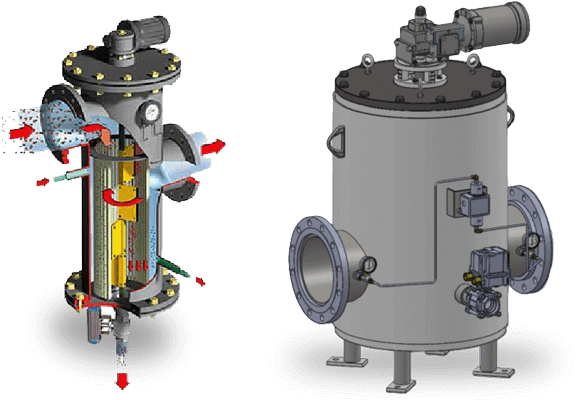

Duplex Basket Strainer Working Principle

But how does a duplex basket strainer work?

This is an important question if you are considering to install a duplex basket strainer.

To be able to break down how a duplex basket strainer works, let me take to you through the duplex basket strainer working principle.

Have a look.

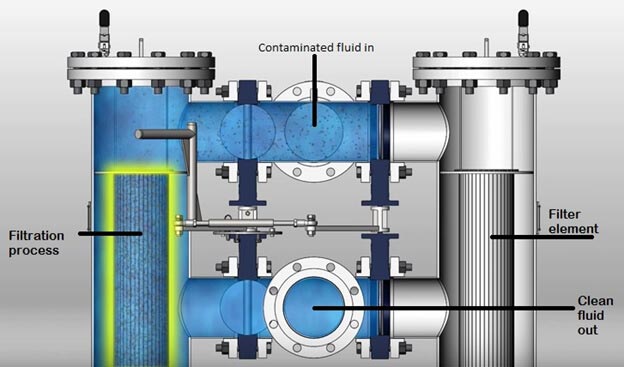

The work of a duplex basket strainer is basically to remove contaminants such as debris and other dirt from fluids. It also guarantees a smooth flow of the fluid in the system.

To achieve this, here is what happens.

First, always ensure that you purchase a duplex basket strainer that meets all the specification as your application. By doing so, it will ensure that the pressure of the system is at a constant level as you are using the duplex basket strainer.

Once you install the duplex basket strainer, you can allow the fluid to flow. The fluid which can either be oil, water or any fluid that you want to remove contaminants will enter through the inlet of the duplex basket strainer.

The fluid passes through one of the inlets with the valve obstructing the direction through which the fluid flows. You can control this valve by using the valve handle that is on one side of the duplex basket strainer.

From the inlet, the fluid flows to one of the strainer baskets. It is here that the filter element nets all contaminants available in the fluid.

The filter element will continue netting contaminants from the fluid until it is clogged. All this time, the flow of the fluid is at a constant pressure.

You can monitor the clogging level of the element using the cogging indicator that is on the side of the duplex strainer. When the basket strainer is clogged, you will observe a pressure drop of the fluid as well as the clogging indicator indicating that the strainer is clogged.

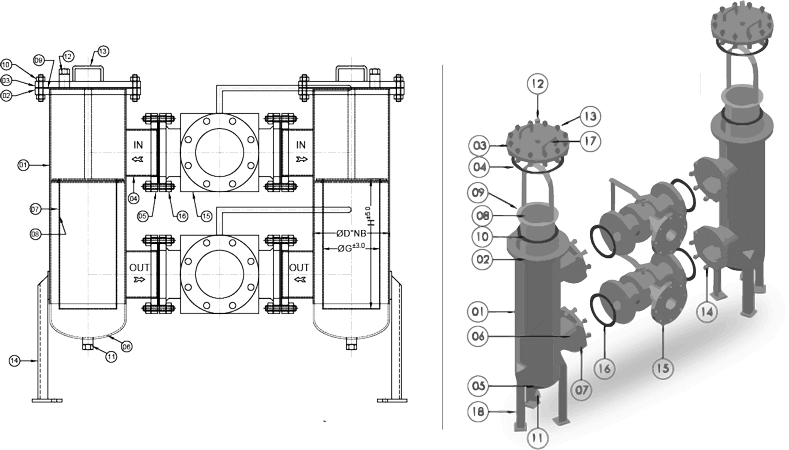

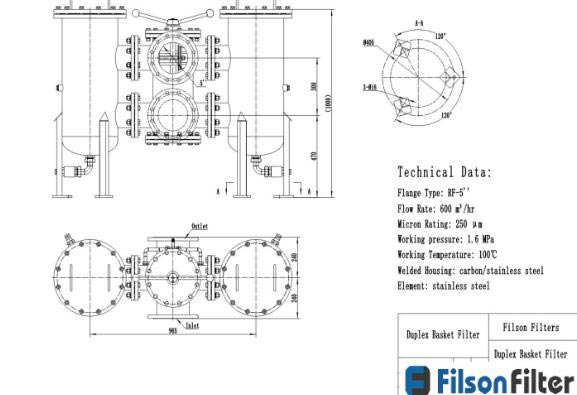

Technical drawing of duplex basket strainer

You can use the valve handle to switch to the other basket strainer.

By doing this, your system will continue to run without any interruption since the other basket strainer will be in use as you clean the clogged one.

The availability of the ball valve system ensures that there are a complete shutdown and an airtight sealing at the diversion point.

The importance of this is that there are no leakages which can be costly regarding maintenance.

Also, by using a ball valve, you can prevent suction of air into the application. Allowing air into the application increases the pressure of the system which may cause malfunctioning of the system.

That is how simple a duplex basket strainer works. As you can see, there is nothing technical about it.

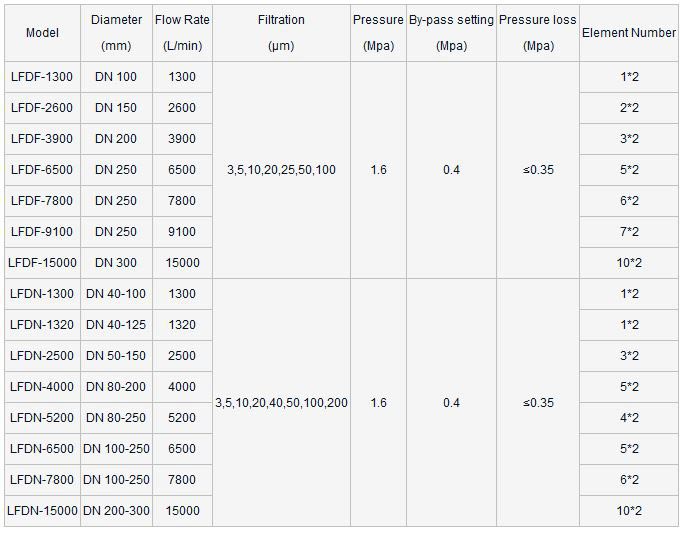

Duplex Basket Strainer Specification

For efficiency, you need to understand some specifications about the duplex basket strainer.

These specifications will play an important part especially when you are installing your duplex basket strainer.

Let’s go through these specifications in this section.

Technical specifications

Duplex basket strainer material

There are different materials for your duplex basket strainer. The choice of which one to use will depend on the application that you intend to use.

You can have carbon steel if you intend to use it on high-temperature applications. The carbon steel can withstand a higher temperature.

Stainless steel filter housing

The other option you can have is stainless steel. The use of this kind of duplex basket strainer is common in applications that don’t require corrosion.

Most commonly you can use this kind of duplex basket strainer in food industries.

Iron duplex basket strainer is the other kind of strainer that you can use in your applications. This is common especially if you want to cut cost.

However, there is a limitation to the use of this type of a duplex due to its corrosion properties. Corrosion will with time affect the quality of your filtration and the lifespan of your application.

Also, by using an iron duplex basket strainer, the maintenance cost is relatively high since you will be in constant replacement of the components.

Lastly, you can use a bronze duplex basket strainer in applications that require high temperature while at the same time corrosion-free results.

Flow rate

You need to consider the flow rate of your duplex basket strainer such that it is in line with that of your application.

For this to happen, you need to consider the size of your inlet as well as that of your outlet.

Basket strainer

Having incorrect sizes may result in pressure either building upon the duplex basket strainer or along your application.

The effect of this is that there may be rapture along the way which may result in extra costs.

Filtration accuracy

The filtration accuracy depends on the size of the strainer element pores. Having strainer element that has small pores will result in a complete filtration of your fluid.

Filtration process

However, there are some instances that you will have to adjust your strainer element pores. This will depend on the aim of the filtration of your fluid.

Working pressure

Understanding the working pressure for your duplex basket strainer is very important. It will enable you to regulate the flow of the fluid.

Not regulating the pressure may result in damage to the components of your duplex basket strainer. The best working pressure for most duplex basket strainers is between 100- 120 PSI.

Working temperature

The working temperature will depend on the kind of material of your duplex basket strainer. However, for most duplex basket strainers, the working temperature is at 60 degrees Celsius.

In case your application is for a higher temperature, then you can use a duplex basket strainer that is of carbon steel.

Pressure loss

At times you need to reduce the pressure within the duplex basket strainer. You can achieve this by using the vent plug and the pressure equalizing valve.

Connection type

When it comes to connecting your duplex basket strainer with your application, you have three ways that you can use. First, you have the threaded connection method which is secure and durable.

Threaded connection type

What happens with this kind of connection is that the duplex basket strainer has threaded ends which you can use.

You can make threads on your application through which you can join with your duplex basket strainer.

This kind of connection is common in cases where your application consists of plastics. You can also have a duplex basket strainer that comes with weld ends.

Welded connection

With such a connection, all that you need to do is welding your duplex basket strainer application onto your application. This kind of connection is durable since it will last for a long time once you have made the connection.

You can ideally use this kind of connection in metallic applications. Lastly, some duplex basket strainers come with special ends.

Flange connection

What happens in such a connection is that you will fit the ends onto your application, and you are ready to go.

These ends are in such a way that they ensure that your application does not leak and can withstand the pressure.

Whichever connection method that you choose, you need to ensure that it does not leak during the application process. Also, you need to ensure that it can withstand the pressure of the fluid during application.

Type of screen material – stainless steel perforated basket strainer

There are several types of screen materials that you can use for your basket duplex basket strainer. The type of strainer to use will depend on the nature and type of application that you are going to use.

Generally, there are four types of screen materials that you can have. They include bronze, carbon steel, Iron and stainless steel.

Screen type

The choice of which screen material to use will depend on a couple of factors.

This includes the flow rate of your fluid, the temperature, the operating pressure of your application and the kind of contaminant.

Most strainer elements are of iron since it is the most affordable.

You can use carbon steel if the application involves high temperature for example in the oil and petrochemical industries.

The use of bronze is common in corrosion free applications and in some applications that need have a high thermal requirement. However, there is a thermal range that you can use a bronze strainer element.

Stainless steel is common in corrosion free applications. This is, particularly in the food and beverage industries, chemical and pharmaceutical industries.

Basket strainer mesh sizing chart

You can have different strainer mesh sizes depending on which application you are using. To be able to choose which strainer mesh size you can use, here is a simple chart for you.

| Mesh Size | Particle Diameter (meter x 10-6) |

| 4 | 5,205 |

| 8 | 2,487 |

| 10 | 1,923 |

| 14 | 1,307 |

| 18 | 1,000 |

| 20 | 840 |

| 25 | 710 |

| 30 | 590 |

| 35 | 500 |

| 40 | 420 |

| 45 | 350 |

| 50 | 297 |

| 60 | 250 |

| 70 | 210 |

| 80 | 177 |

| 100 | 149 |

| 120 | 125 |

| 140 | 105 |

| 170 | 88 |

| 200 | 74 |

| 230 | 62 |

| 270 | 53 |

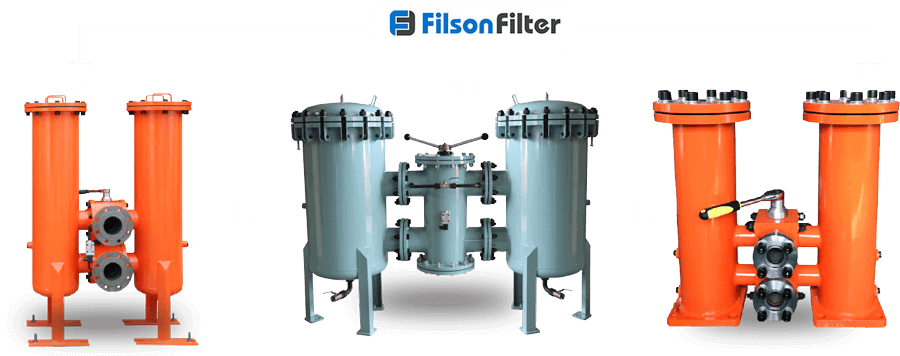

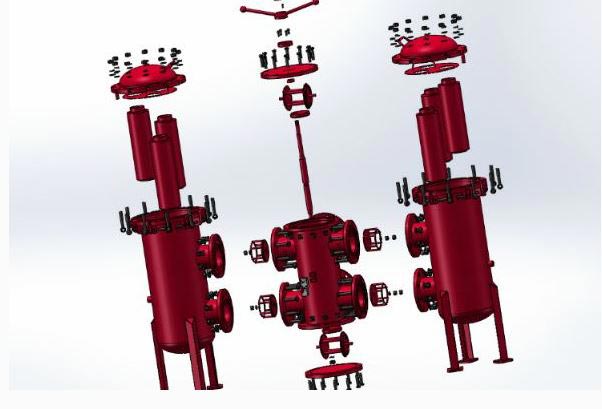

FilSon Fabricated Duplex Basket Strainer

We all understand how hard it can be when you are going into the market to search for a duplex basket strainer that can fit your application. At times getting the one you need can be a near impossible task.

To minimize such chances and to ensure that you continue with your production, we have a solution for you.

By choosing a FilSon Fabricated Duplex Basket Strainer, you can continue with your production efficiency.

FilSon Fabricated Duplex Basket Strainer offers you the opportunity of customizing your duplex basket strainer according to your specification.

There are two variants of this basket strainers. That is the carbon steel fabricated duplex basket strainer and the stainless-steel fabricated basket strainer.

FilSon basket strainer

The advantage of this kind of duplex basket strainers is that they are economical when you compare them to the standard unicasting duplex strainers.

Also, the fact that you are fabricating a duplex basket strainer does not imply that you cannot find replaceable components.

This kind of duplex basket strainers fit with nearly all other spare parts available hence you can comfortably fix when maintenance is required.

Lastly, you can customize these duplex basket strainers the way you want. That is, you can modify the pressure ratings, the basket size, flange size and the coating color to those that you want.

Also, you can modify the size of the inlet as well as that of the outlet and even their positioning to match your application.

You can virtually modify any component of your fabricated duplex basket strainer to fit your specification.

Get in touch with FilSon today, and we will be able to advise you on how to go about our FilSon fabricated duplex basket strainer.

Duplex Basket Strainer Installation Process

It is imperative that you know how to install a duplex basket strainer for it to work efficiently. The process of installation may seem hard, but the truth is it is an easy process.

Here is how to go about installing a duplex basket strainer.

Before we proceed, you need to make sure that you have all the safety equipment with you. Such equipment includes boots, overall, helmet and other equipment that will keep you safe.

Safety gear

The other thing is that it is important that you confirm the specification of the duplex basket strainer to ensure that they fit your system.

The specification of your basket strainer will depend on various factors such as the application you are using, the design and type of the application.

By doing this, you will minimize the chances of the basket strainer not working properly once you have installed it on your application. After confirming all the details and specification, you are now ready to install your duplex basket strainer.

Also, when you are unpacking the duplex basket strainer, you need to ensure that it is in proper condition. Check if there are any damages including cracks.

In case they exist, check with your supplier for replacement.

Now that you have this in mind, we can go ahead and install the duplex basket strainer on your preferred location.

Actually, you don’t need to have experience or call a technician to install a duplex basket strainer.

This is how you will install your duplex basket strainer.

Safety gear

Step 1

Start by preparing the space where you will install the duplex basket strainer. Remember that you will need enough space that will accommodate the changeover and maintenance procedure.

The purpose for this is that a duplex basket strainer offers a continuous flow of fluid.

As such, during maintenance, all the work will be done at the site so as not to interrupt the flow.

Step 2

You also need to prepare the platform that you will install the duplex basket strainer.

Here, I am talking about the area along the piping system where you will join the duplex basket strainer.

You need to ensure that the measurements match to avoid any form of leakages as well as air inlet which can compromise the pressure. One of the ways you can ensure that the piping system is secure from thermal expansion is by using expansion joints.

When the piping system is in place, you can use a concrete platform or a steel pad to offer a base to the duplex basket strainer. It is here that you will fix your duplex basket strainer firmly using bolts and flanges.

Ensure that the diplex basket strainer is stationary including it not vibrating. Always avoid using the duplex basket strainer as a support base to your piping system as it may lead to misalignments.

Step 3

Once you place the duplex basket strainer, you can now connect the inlet port and the outlet port onto the piping system. A normal duplex basket strainer will indicate which port is the inlet and which one is the outlet.

It is important to observe the flow of the fluid before joining the inlet and outlet to place them correctly. There are three ways that you can use to install the inlet and the outlet as well as the pipework of your duplex basket strainer.

These ways include Threaded connections, welding connections, and flanged connection. The choice of which way to use will depend on the design of your duplex basket strainer.

However, the most common way is the flanged connection while the least way is the welding connection.

Step 4

Now that you have finished, you can go ahead and carry out tests on your duplex basket strainer. The purpose of this is to check if there are any leakages that you need to fix.

The main causes of leakages include loosening bolts or incorrect size of the pipes. So you can check if you have any of these in your connection and make the necessary amendments.

Step 5

After you have tried the application and it is operating at a normal pace, you can now switch on the application and let it filter your fluid.

However, there are a few things that you need to adjust if your duplex basket strainer does not have them. First, if your duplex basket strainer lacks a clogging indicator, you will have to improvise one.

That is, you will have to use a differential pressure gauge which you can install between the outlet and the inlet port. Remember, the function of this is to give you an indication of the clogging level of your strainers.

Also, to maintain the air pressure difference, you will need a vent valve which you can place on top of your duplex basket strainer.

Duplex Basket Strainer Changeover Procedure

At several instances, you need to change the basket strainer to ensure the efficiency of its workings. Such times include when the strainer is clogged.

Disassemble duplex basket strainer

The indicator will always alert you when the strainer is clogged, and thus you need to change it.

To assist you, here is the changing procedure that you need to follow.

The best time to carry out a basket strainer changeover is when there is a clogging indicator alarm. You can do this at least once per year.

However, if your duplex basket strainer lacks a clogging indicator, the appropriate time to do a changeover is at least twice a year.

There might be times that the clogging indicator doesn’t indicate it’s time for a changeover. This doesn’t imply that your basket strainer is functioning properly.

The reason for this might be that the pass valves are not functioning and hence you need to check and replace if possible.

When it is time to replace your basket strainer, you need to ensure that you have reduced the pressure within the strainer. You also need to ensure that you have cooled off the particular strainer.

You can reduce the pressure through the use of the isolation valve. This valve shuts off the supply of pressure to the strainer from the source.

The advantage of reducing the pressure and cooling off the temperature is to reduce body injuries while you are operating the strainer.

The reducing of the pressure on the straining value that you want to do maintenance helps in the flow of the fluid into the other strainer.

This is by the use of the equalizing valve which ensures maintenance of the pressure of the application. Before opening the strainer, you need to ensure that there are no leakages.

Leakages can be harmful to the application. As such, in case there are any leakages, shut down the equalizing valve together with the vent.

Once you do this, you can drain the fluid through the drain plug. To completely drain the fluid, you can open the basket chamber and dry it up.

If there are no leakages, you can remove the old basket strainer from the basket housing. Hold the basket strainer element upright on the chamber to drip it out.

The next step is for you to replace the basket strainer with a new one. Be careful to ensure you have placed it correctly.

If the strainer element is of steel, you need to replace it with a new one since the old one wears off quite often. Another component that you need to check on is the cover seal. In case it is damaged or worn out, you can replace it.

After you have finished replacing all the components, you can now go ahead and reassemble the unit.

Make sure you have secured it properly on the basket strainer using the bolt.

You will have to test if the strainer is airtight to prevent chances of leaking. To do this, you will slowly open the equalizing valve to allow for a medium flow of the fluid from the vent valve.

Leakages might occur due to loosen bolts or if the cover seal, vent plug or the drain plug is damaged or dirty. As such, you need to ensure that these components are clean as well as replacing them when they break up.

Also, ensure that you screw the bolts tightly.

Basket Removal and Cleaning Procedure

You need to be careful when removing the basket during cleaning. If you are not careful, you might end up destroying other components of the basket strainer.

To assist you to do this, here is the procedure that you need to follow.

Removing strainer from the housing

The first step that you need to follow is to maintain your safety. You can achieve this by making sure that you properly wear all the necessary protective gears properly.

This includes goggles, overalls, and gloves. You need to observe extra precaution if the fluid in your application is harmful to the human body.

After that, have a look at the pressure of the duplex basket strainer system as well as its temperature. You can now check on which strainer that needs cleaning.

Doing this gives you the opportunity to note where the lever handle is. You can then use the plug handle to switch the filtration to the other strainer.

Remember, at no point will your system shut down. To minimize any form of leakage, always ensure that you have turned the plug handle up to the correct position.

Using the drain valve, you can release the pressure off the strainer to give you easy access to the system. Once this is over, you can remove the cover by unscrewing the nuts or bolts of your duplex basket strainer.

You can now remove the strainer that you want to remove the contaminants. Most dirt will always be on the perforations of the strainer.

The easiest way to clean the clogged strainer is by using pressurized water. This water will flush out all the contaminants thereby ensuring that you have a clean strainer.

However, you need to take extra care when handling the basket chamber screen. This is to prevent it from possible contamination.

After cleaning, you can go ahead and replace any component that needs replacement. This will include the washer, the O- ring as well as the drain valve.

You can now return the strainer into the strainer chamber. Ensure that the there is a protrusion of the handles above the strainer body.

Before tightening the bolts, you need to ensure that you have placed the strainer properly. You also need to ensure that everything is in its correct position.

Your strainer is now clean and ready to use. Remember, the only time that you can switch to another strainer is when the one in use is clogged and therefore needs cleaning.

The indicator will notify you when it is time to switch off. Another way to know it is time to switch off is when there is a pressure difference in your application.

However, this is not always a guarantee that you need to change your strainer. The reason for this is that there are other factors which can cause a pressure difference in your application.

You, therefore, need to take note not to turn the valve handle which will switch the filtration to the strainer that you have just cleaned.

Self Cleaning Duplex Basket Strainer

As we have seen, there will be times during the running of the system that your basket strainer will clog.

As such time, you will have to switch to the other basket strainer as you clean the clogged one.

So how do you go about cleaning your duplex basket strainer? Let me take you through the process.

When you are self-cleaning the duplex basket strainer, you need to open the cover of the strainer. This will give you quick access for cleaning.

Carefully stir the fluid on the strainer you are cleaning which allows for the movement of the contamination. This minimizes the chances f a buildup within the strainer.

While stirring, you need to direct the contaminants towards the discharging valve. Once you have finished this, your duplex basket strainer will self- drain which minimizes the loss of the fluid.

Numerous advantages come with self-cleaning a duplex basket strainer. First, it is an efficient way of filtering your fluid especially with those that have a thick viscosity.

You are also in a position to clean the duplex basket strainer without necessarily having to stop the application’s process. The area of operation remains clean thus keeps up the hygiene to the recommended standards.

You can have two kinds of Self-cleaning duplex basket strainers. That is automatic duplex basket strainer and manual duplex basket strainer.

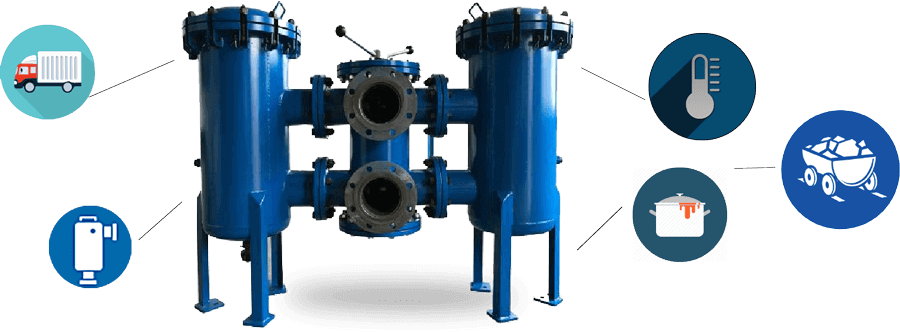

Applications of Duplex Basket Strainers

There are several areas you can apply your duplex basket strainer. Identifying these areas is crucial in getting the right duplex basket strainer.

Duplex basket strainer

This section takes you through areas that you can use your duplex basket strainer. Keep reading.

Transportation

This is the common application of a duplex basket strainer that you can find around you. Placing a duplex basket strainer on your engine ensures that your engine works efficiently and without interruption.

This is possible since the duplex basket strainer will filter your oil thereby ensuring that no contaminant goes through your engine.

Refrigeration

You need a duplex basket strainer in refrigeration to help in keeping the brine in the refrigeration clean. Brine occasionally collect dirt or from corrosion with salt.

Food processing industry

To ensure the safety of the food that we eat, you can apply a duplex basket strainer in several food industries.

For instance, you can use a duplex basket strainer in the wine industry.

Here, its functions include filtering grape skins or pulp skins from the wine. In the chocolate industry, you can use the duplex basket strainer to filter out lumps thus ensuring a smooth chocolate production.

Another area of application is in the baking industry. Here, you can use it to remove dough particles and seeds from the water before discharging it to the environment.

Water recycling

Water recycling is one of the important applications of a duplex basket strainer. By filtering the wastewater, you can reuse the water for other purposes.

Filtration of the water depends on the perforation size of your filter element.

Mining industry

Another area of application that requires a continuous flow of fluid is in the mining industry. Mining of minerals such oil and gold require a constant flow of fluid.

In mining chemicals and drilling boreholes, you also need an uninterrupted flow of fluid. For instance, you will need a continuous flow of fluid in drilling equipment.

To achieve this, you can use a duplex basket strainer to filter any contamination in your fluid.

Paper coating industry

Duplex basket strainers are used in the paper coating industry to help in filtering lumps that are common in the pulps. You can also use the duplex basket strainer to filter pulps from industrial water before releasing it to the environment.

Construction machinery

You can have a wide application of duplex basket strainers in the construction industry. Be it in machines such as excavators, graders, and loaders; you can use a duplex basket strainer.

The importance here is to ensure hydraulic fluid flows continuously thereby enabling the machine to work efficiently. The result of this is that there is filtration of the machinery oil which ensure that the machine works properly.

Electricity generation

In electricity generation, there is some equipment which cannot function without proper oil flowing in them. As such, you require a device which will ensure that oil flows uninterrupted.

A duplex basket strainer offers this as it also helps in the filtration of the oil from contaminants.

Sea water filtration

Industries that harvest sea water need this device to keep the flow of seawater constant while at the same time filtering it. A duplex basket strainer does this by maintaining the pressure of the water while at the same time removing dirt from the water.

Ceramic industry

You will need a duplex basket strainer to ensure that there is a smooth production of ceramics. The duplex basket strainer achieves this by filtering contaminants such as glazes thereby ensuring smooth ceramics.

What you need to do is to install the ceramics just in front of the glazer spray equipment.

Painting industry

In painting, nothing is annoying as having “fish eyes” which makes paints unattractive. To prevent this, you can use a duplex basket strainer.

Conclusion

I hope this guide has explained all that you need to know about a duplex basket strainer. You cannot underestimate its importance in our daily application.

It is therefore important that you get to select the perfect duplex strainer for your application. Be careful to note the specifications before picking one.

Selecting the best duplex basket strainer is of paramount importance. Contact us today for the best of your duplex basket strainer.