Your Premier Industry Basket Strainer Manufacturer

Your Best Industrial Basket Strainers Supplier

If you are looking for industry basket strainer manufacturer for your pipeline, then you are in the right place.

Filson manufacture all kinds of industry basket strainers include simplex basket strainer, duplex basket strainer, inline basket strainer, fabricated basket strainer.

All Filson basket strainers are made of stainless steel( 316 and 304), and carbon steel.

The basket strainers will protect your equipment effectively via filtering the unwanted solids from process liquids.

The basket strainer elements in every Filson industry basket strainers are also made of stainless steel and can be reusable, so you will save a lot on the filter element replacement.

As a professional industry basket strainer manufacturer, Filson aims to solve all filtration problem for you with our high-quality basket strainers and other filtration product like filter cart, vacuum dehydrator etc.

Your Premier Industry Basket Strainer Manufacturer

Filson industry basket strainers , also named industry basket filters, our standard basket strainer materials are carbon steel, 304 stainless steel or 316 stainless steel.

Filson manufactures standard designed industrial basket strainer, but also can fabricate custom designed basket strainers to meet your detailed micron filter requirements.

As a 10 years basket strainer manufacturer, Filson will meet any of your requirement.

Industry Basket Strainer: The Definitive Guide

Are you struggling to remove solid particles and debris from your pipe systems?

If yes!

Then you should install an industry basket strainer.

It will protect other equipment downstream from damage.

And today, I am going to show you how to choose a suitable industrial basket strainer.

I will discuss different types, applications, basket filter element and technical specifications of industrial basket strainers, just to mention a few.

Check these out:

Chapter 1: What is the Industrial Basket Strainer?

An industrial basket strainer is a closed vessel with wire mesh screens for removing solid debris or particles from the flowing fluids.

I know this sounds complicated – don’t worry, I will break it down for you.

But first, I want you to watch this video:

Now, this is exactly what I am talking about.

You can also look at this:

Internal section of duplex basket strainer

I hope we are together up to this point.

But, this alone is not enough.

Normally, industrial basket strainers can remove particles that are either 100 microns or larger.

By removing these particles from fluids flowing in the piping systems, you will protect:

- Compressors

- Pumps

- Meters

- Valves, or any other delicate equipment.

And by the way:

As a standard engineering practice, you should install industrial basket strainers ahead of these components.

This way, they will be safe.

Again, let me quickly mention a few things about industrial basket strainers:

- Design configuration mainly focuses on pressure drop, flow rate and particle size. In fact, they can withstand full line pressure

- Loading capacity is not the main design aspect here.

- They come in different alloys that can resist harsh chemicals from industrial processes

Are we getting somewhere? I hope so.

As an engineer in a sugar plant, most people ask me this question everyday:

Which industrial basket strainer should I use after the milling train?

From experience, you may find it really difficult to choose the right industrial basket strainer.

That’s why I want you to read chapter 2 – I am going to discuss everything you need to know about classification and type of industrial basket strainers.

Chapter 2: Types of Industrial Basket Strainer

If you want to buy an industrial basket strainer, know the different types available in the market.

Yes, because it will help you to choose one for your unique specifications.

It’s no secret that industrial basket strainers come in many designs and options.

Here, I will quickly show you some of the most common basket type strainers:

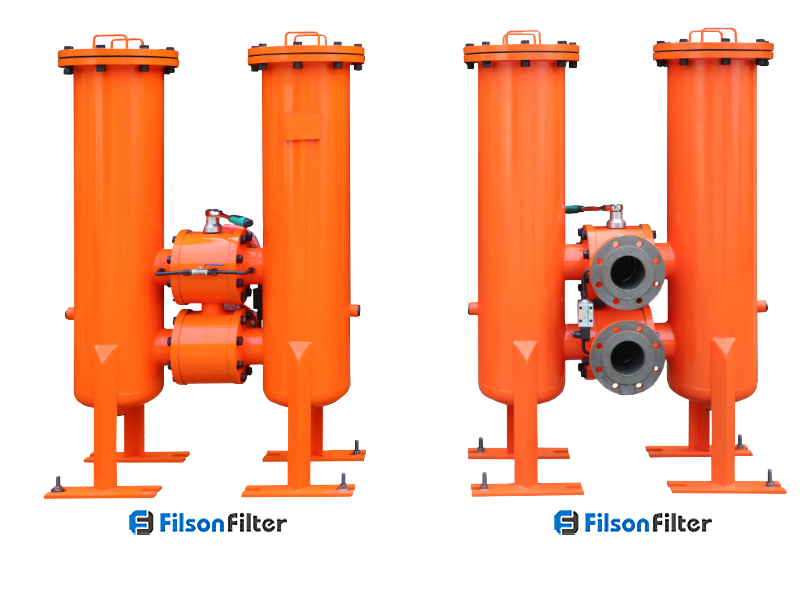

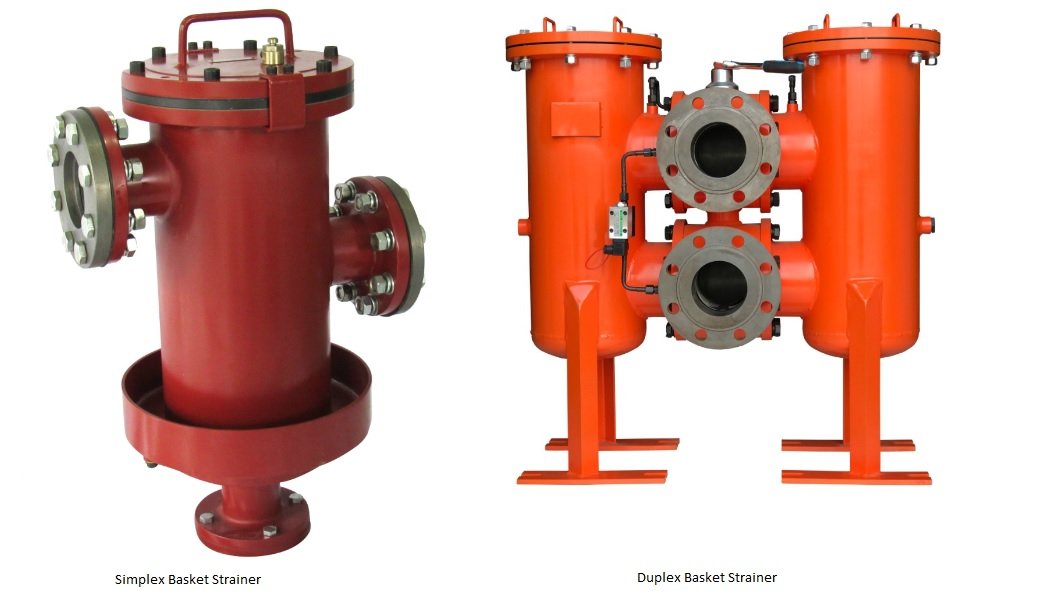

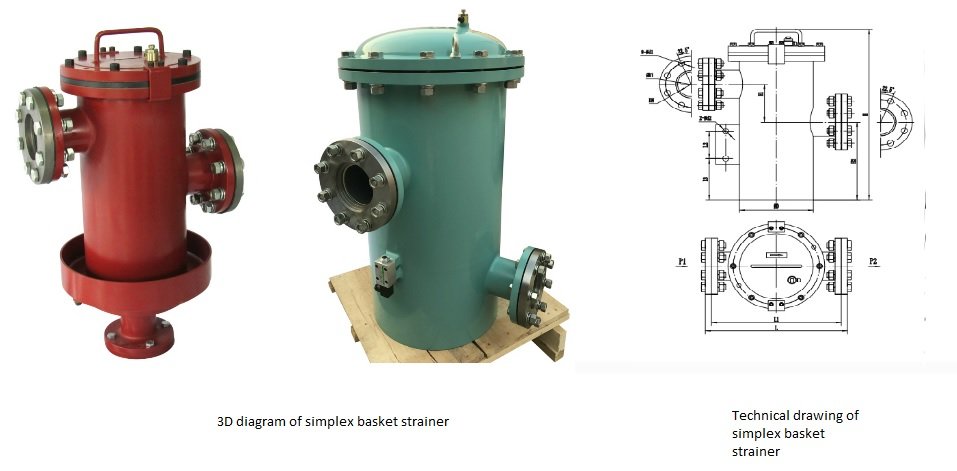

· Simplex Basket Strainer

Simplex industrial basket strainers have a single chamber where the contaminated fluid flows through.

Here, the strainer basket rests in this chamber.

It removes particles and debris from the flowing fluid in the pipeline.

Depending on your specific needs, you can choose from many shapes and designs available on the market.

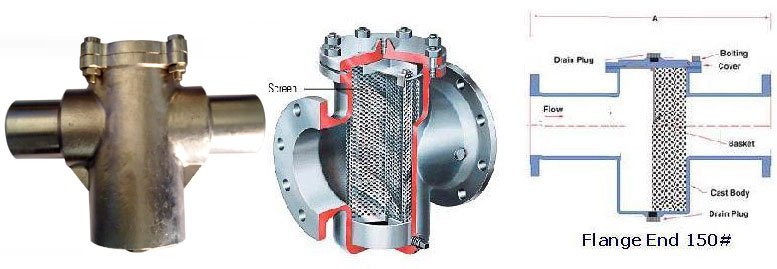

This how a simplex basket strainer looks like:

Simplex basket strainer

As you can see, these industrial strainers are an assembly of different components and parts.

The industrial strainer manufacturers use either bolts or welding to join various components.

But still, fully welded simplex basket strainers are better than the casted ones.

But, why so?

This is because they ensure “zero leakage”.

And, I am sure this what you’d wish to have.

Now, the working principle of simplex basket strainers is quite simple:

- Water or any other fluid enters the simplex basket strainer from the inlet

- It flows into the chamber with the strainer

- Strainer captures dirt and particles in the fluid

- Fluid flows through the strainer

- Clean fluid leaves the simplex basket strainer via the outlet

- By comparing the inlet and outlet pressure of the pipe system, you can tell when the strainer is clogged. Go ahead to replace or clean the basket strainer

Now, he is what you must know:

To clean or replace the basket strainer, you must shut down the system for a period of time.

Here, you don’t have any other alternative.

Therefore, you can only install these industrial basket strainers in pipelines that can be shut down for some time during maintenance.

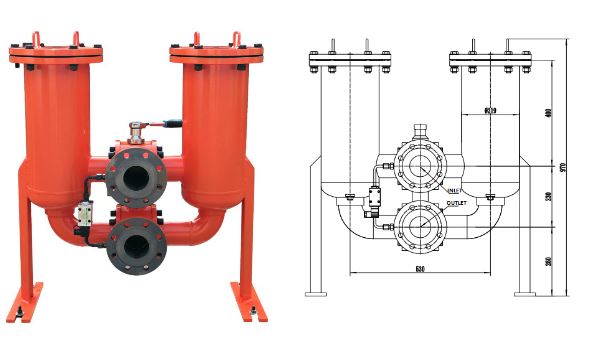

· Duplex Basket Strainer

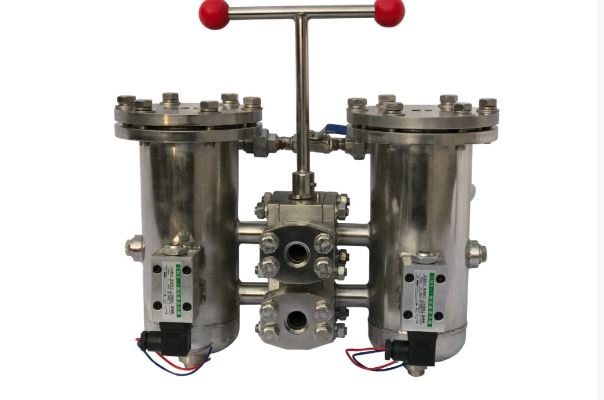

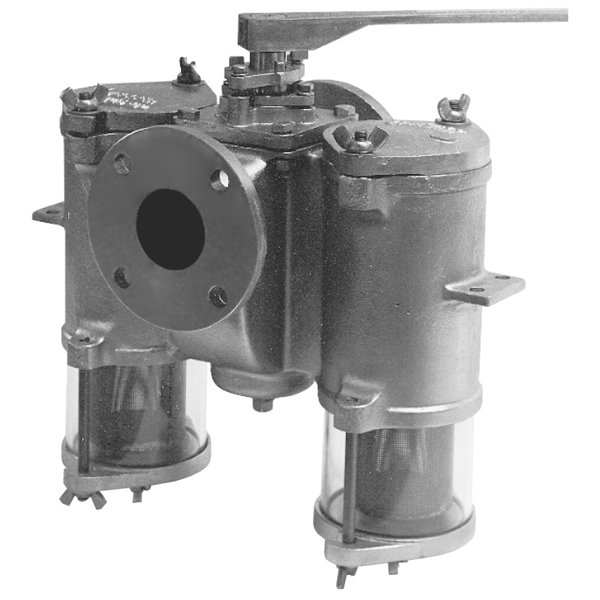

Looking at this accessory, you will see two simplex basket strainers connect via pipes and valves.

As you can see, this is quite evident from the 3D and technical drawing of duplex basket strainer in the image below.

Duplex basket strainer

Well, I am not going to take you back why you need to install duplex basket strainer.

I am sure, from section 1, you know that contaminants in fluids can be a disaster in the pipe systems.

And, this type of industry basket strainer can save you from unnecessary expenses.

Now, what’s unique about this pipe line basket strainer?

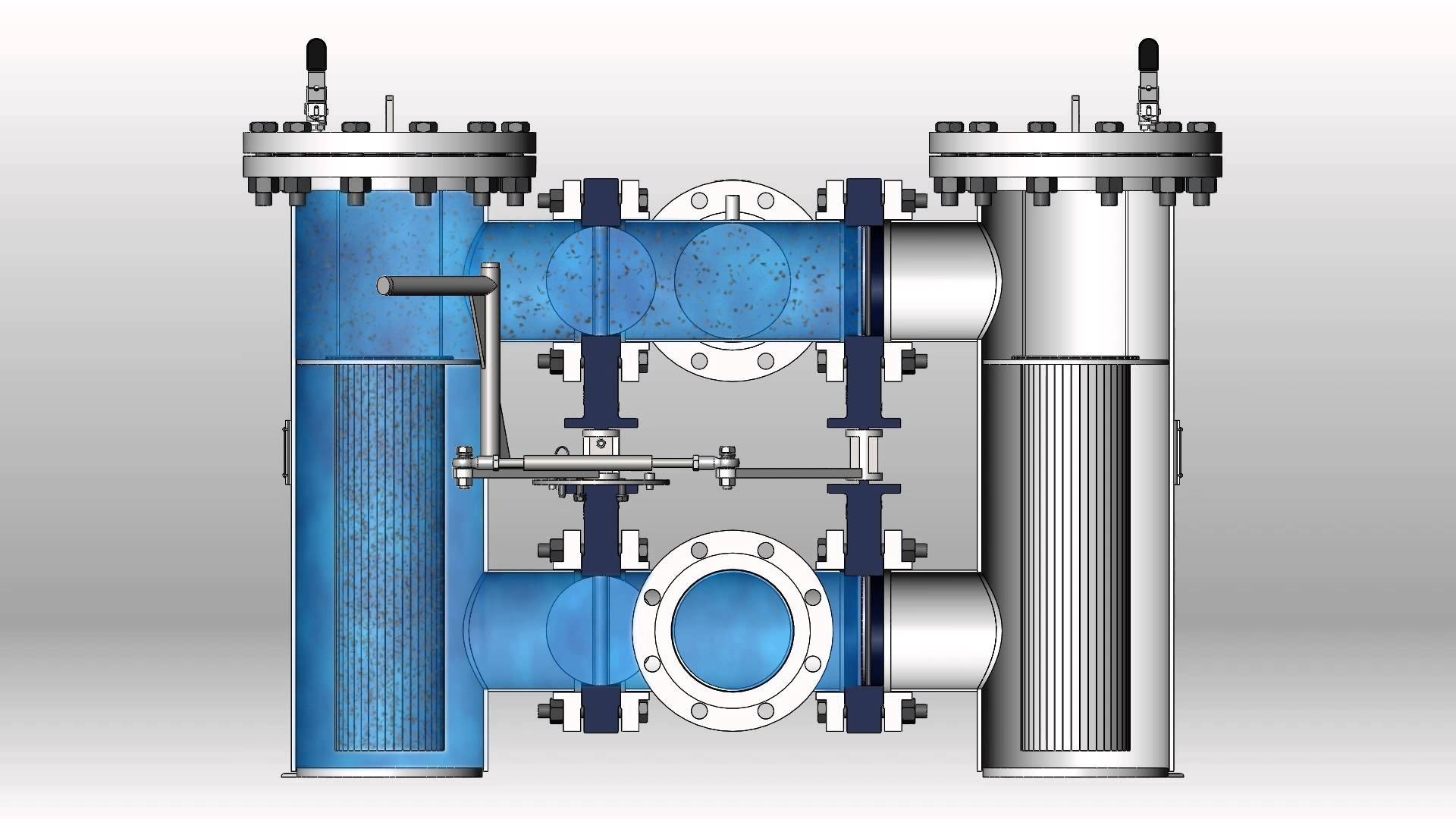

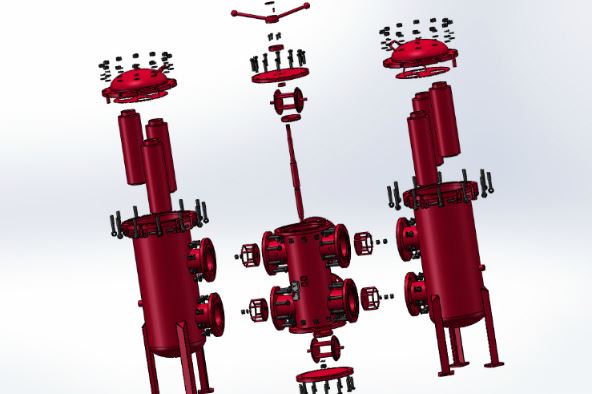

· Design and Structure of Duplex Basket Strainer

Just as I mentioned earlier, this basket type strainer has two identical simplex filters, separated by a valve.

Let me disassemble it so that you may see this clearly:

Fully disassembled duplex basket strainer

I hope, you can understand what I am talking about.

Now, this takes us to yet another fundamental question:

What makes this design of industrial basket strainers important?

Well, let me take you through the working principle of duplex basket strainers.

Certainly, with this knowledge, you will begin to appreciate why you may need it.

Let’s get straight to that:

· Working Principle of Duplex Basket Strainer

As you have seen, this double basket strainer has two independent basket strainer chambers.

Of course, it has one input and output.

So, this is what happens:

i. Once you install the duplex basket strainer, the contaminated fluid flows into the system through the inlet pipe.

ii. Depending on the position of the valve, the fluid will flow into one of the basket strainer chambers (say it flows to chamber A). It is this valve that blocks fluid from flowing into two basket chambers at the same time.

iii. As the fluid flows through chamber A, all large particles or debris will remain here. Therefore, only the clean fluid will flow through to the outlet of the twin basket filters.

iv. Once the strainer gets clogged, a clogging indicator will send or show some signal. Of course, the signal is due to the pressure drop between the inlet and outlet of the duplex filter.

v. Now push the valve lever, diverting fluid flow to the next basket strainer chamber that was on standby (say chamber B). By doing so, you will close the clogged basket strainer chamber A, hence you can clean it. I will show you how to do that in chapter 5.

vi. After cleaning the basket strainer chamber A, let be on standby. You will let the fluid flow until chamber B gets clogged then switch to chamber A.

Are we on the same script? Good, let’s move on.

Now, let’s get to yet another important aspect of these types of industrial basket strainers.

Duplex industrial basket strainers are suitable for piping systems where operation should be continuous.

That is, you don’t have to stop the system to clean the basket strainer – simply switch from one basket to another.

With that, let me take you step further to discuss other types of industrial basket strainers.

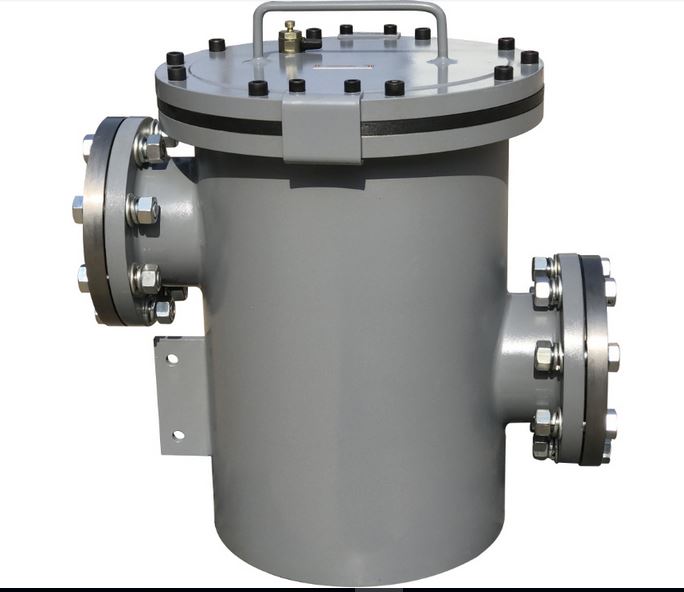

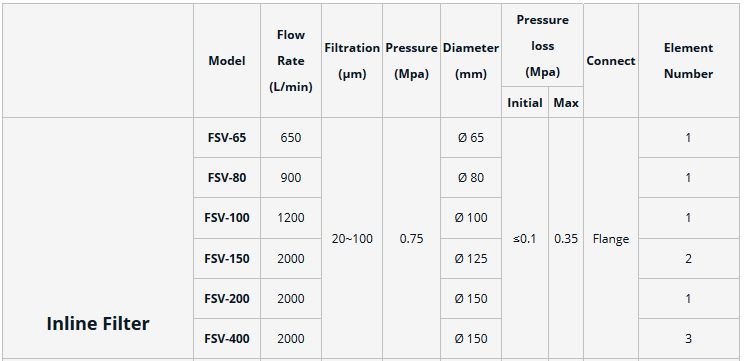

· Inline Basket Strainer

From experience, industrial pipelines are not complete without these basket strainers.

Normally, inline basket strainers protect other systems, equipment such as flow meters, heat exchangers, valves, cooling towers, spray nozzles, etc.

They remove all contaminants such as dirt and large particles.

By protecting your sensitive components, they will save your hydraulic systems from possible downtime, thereby reducing expensive maintenance costs.

Inline basket strainer

As you can see, this pipeline basket strainer is not very different from the industrial simplex strainers I had discussed earlier.

It is for this reason that you may also refer to these industrial basket strainers as inline simplex filters.

However, the inline industrial strainers have both the bypass valve and electrical indicators.

Also, whenever you’re installing inline duplex filters, you don’t have to worry about flow rate in pipe systems.

You can easily match them with the intended flow rates in the pipe systems.

Apart from simplex inline filters, another critical industrial filter is the:

· Fabricated Industry Strainer

Maybe this may sound a little complicated – anyway, I will make it simple for to understand.

Fabrication is the process of making industry basket strainers by manipulating materials.

It may involve cutting, bending or assembling various components.

By doing so, you can have:

i. Simplex industrial basket strainers

ii. T type basket strainer

iii. Industrial duplex basket strainers

iv. Y type basket strainers, etc.

The good thing about fabricated basket strainers is that they come with a range of flexibilities.

That is, you can easily customize it to your unique application requirements.

Fabricated basket strainers

Basically, you can choose from:

i. Different features such as welded construction, compact designs and configurations

ii. Materials such as stainless steel, carbon steel or carbon iron

iii. Numerous end connection such as butt weld or flanged (flat faced, raised faced or ring joint)

iv. Ratings and sizes

Does that sound even more complicated?

No, it shouldn’t.

Basically, what I mean here is that fabrication is a process of making different types of industrial basket strainers.

Always feel free to discuss all fabrication needs with the industrial basket strainer manufacturer.

· Y Industrial Strainer

Like the name suggests, these industrial strainers come in the shape of latter “Y”.

Maybe you should look at this:

Y industrial strainer

Clearly, it has a different design.

Even with their unique design and shape, their main purpose still remains the same – remove contaminants in pipe systems.

You can see this clearly in the video below:

Now, let me take you a step further here:

· Design and Structure of Y Industrial Strainer

As I mentioned earlier, Y strainers are quite different from the other industrial strainers.

Of course, this due to their unique “Y” design, as I had mentioned.

In these industrial strainers, the filtering element intersects the main pipe system.

That is, it connects to the main piping system at a diagonal angle.

You see this:

Position of the strainer element

To clean the strainer element, you will simply remove the cap (that slants downwards).

This makes the cleaning process less labor intensive.

Normally, we use Y strainers in applications that do not require frequent cleaning.

Therefore, you should use it in pipe systems with only a small amount of contaminants.

In fact, Y strainers are common in gaseous applications such as steam, air or natural gas systems.

Their design can withstand an enormous amount of pressure in the pipe system.

Also, depending on the application at hand, you can choose Y industrial strainer which you can install either in a vertical or horizontal position.

But even in these two options, the leg with the strainer element should face downwards.

In that position, it is easier to collect and remove all contaminants in the pipe system.

· T type Strainer

Apart from the Y type strainer, we have the T types strainer too.

As I had mentioned earlier, this name is due to the physical appearance and design of the industry strainer.

You can have a quick overview of what I am talking about in the diagrams below:

T type strainer Photo Credits: CASCO INTERNATIONAL

As you can see these bath tub strainers, have a different design compared to the available options.

And, depending on the specific applications at hand, you can get from 2″ (DN50) to 48″ (DN1200).

Unlike most industry strainers, the T type strainers are suitable in piping systems with limited installation space.

Besides, you can install it either horizontally or vertically.

Also, you can clean this trainer without necessarily draining the housing.

This makes cleaning easy and simple.

What’s more?

From the design, it is a perfect choice in applications that require a low pressure drop in the system.

It is for this reason that it is ideal for boiler feed pump and condensate feed pumps.

· Self-cleaning Strainer

Are you tired of cleaning industrial basket strainer every time?

If yes, then you should try a self-cleaning strainer, also called automatic self-cleaning strainer.

I know this may sound strange – I will explain.

But even before I proceed, you can watch this video to have a rough idea of how automatic self-cleaning strainers work:

As you can see, the working principle of self-cleaning strainers is more advanced.

That is, it incorporates the self-cleaning aspect – other ordinary industrial strainers do not have this feature.

Of course, this comes with two main advantages:

- A worry free filtration process

- Low maintenance costs

Also, I know there are many automatic self-cleaning strainers out there with different working principles.

However, for the scope of this guide, I will give a general working principle.

Here we go:

i. Fluid will flow into the self-cleaning trainer through the inlet, then to strainer element and to the outlet

ii. Strainer element will strap the contaminants to a point where it is clogged

iii. Once the differential pressure between the outlet and inlet exceeds a specific threshold, clog removal begins.

iv. The system will then backwash the strainer element. During this time, it will block the inlet pipe while opening another valve through which the dirt particles leaves the filter system. Please note, the process of removing contaminants may vary from one self-cleaning strainer to another.

I believe up to this point, you can confidently classify the various types of industrial basket strainers.

Still, there is one more thing you need to know about industrial basket strainers.

How Can You Fabricate Industrial Basket Strainer Housing?

People ask me this question every day.

Most definitely, I do give a general answer – it will depend on the main application of industrial basket strainer.

Having said that, let me go ahead to what I consider the best industry basket strainers.

You should go for fully welded strainer housing.

And, why fully welded strainer housing?

Unlike the casted basket strainer housing, the fully welded basket strainer guarantees “zero” leakage.

Furthermore, the fully welded industry basket strainers have a lightweight than the cast types.

This reduces the installation and transportation costs.

And lastly, the welding process produces flexible industrial basket strainers, which you can adapt to any piping system.

In short, you can always count on fully welded basket strainers.

But, knowing these alone is never enough.

You should know the appropriate material you want to weld or fabricate to make industry basket.

Let’s get to that:

Chapter 3: Material for Industry Basket Strainers

As I mentioned earlier, you can make industry basket strainers from a range of materials.

It will all depends on the nature of applications, more so, the type of fluid in the pipe system.

The truth is:

Although the market offers a range of industrial basket strainers, the choice of a suitable material is even more important.

Below are the most reliable materials for industrial applications and specifications:

· Stainless Steel (316 and 304 stainless steel) Industrial Basket Strainer

Stainless steel (304 and 316) industrial basket strainer are made using an alloy of iron and chromium.

The shiny appeal is attributed to the chromium composition in the alloy.

Stainless steel material is also made from other elements such as nickel and titanium for different applications.

It is a perfect choice when you want to deal with sediments in the pipe systems.

Why?

Because it provides a robust filtering as well as debris collection in industrial fluid systems.

In addition, stainless steel industrial basket strainers work perfectly for gross contaminants pre-filters.

Stainless steel duplex strainer housing

· Advantages of SS Basket Strainer

Some of the main advantages of stainless steel industry basket strainers include:

i. All stainless steel designs, that is, 304 and 316 materials are corrosion resistant.

ii. It is attractive and durable, thus can last for quite a long time with no wear and tear signs.

iii. Stainless steel mesh basket strainers effectively remove larger particles that range between 840µm-149µm (20 to 100 according to U.S. mesh) from liquids with as high viscosity as 15,000 SSU.

iv. Its most designs are lightweight and come with a permanent handle for easy removal, cleaning and installation.

v. It is reusable as the strainer element media can be cleaned over and over again.

vi. Stainless steel industrial basket strainers are resistant to rust and water damage.

vii. The material structural integrity and properties surpass the set ISO requirements and S. FDA standards.

viii. Stainless steel is non-porous, making it appropriate for many applications in food and beverage industries.

But again, this does not imply that stainless steel is a perfect material when it comes fabricating industrial basket strainers.

There are certain issues you’ll have to deal with – let’s look at them.

· Disadvantages of Stainless Steel Basket Strainer

Any time you opt for a stainless steel industrial basket strainer, you will deal with the following main challenges:

i) Stainless steel type of industrial basket strainer is very expensive.

ii) Heat dissipation is rapidly fast in stainless steel makes such basket strainers undesirable for modification on the site; difficulty in welding.

In most cases, you can use stainless steel industrial basket strainers in water filtration process, ink filtration, coolant filtration, cutting-oil filtration, etc.

I will discuss more on that later in this guide.

· Carbon Steel Industrial Basket Strainers

If you mind about affordability, durability and strength in an industrial basket strainer, carbon steel may be what you are looking for.

Carbon steel is made by doping iron with carbon, thereby impacting its unique physical and chemical properties.

The familiar dark color is due to carbon elements.

Carbon Industrial Basket Strainer

· Advantages of Carbon Steel Industry Basket Strainers

Some of the main benefits of carbon steel industry basket strainers are:

i. Carbon steel base materials: iron and carbon, are abundantly available and much cheaper. Therefore, carbon steel industrial strainers are more affordable than stainless steel

ii. Carbon steel is recyclable. And in fact steel is easily recyclable as compared to aluminium, glass, paper and plastic materials.

iii. Carbon steel has high durability.

iv. It is resistant to harsh weather, shock and pressure variation.

v. Carbon steel is non-combustible.

vi. Carbon steel has naturally excellent tensile strength, thus basket strainers can withstand high pressures.

Now, what are some of the main challenges that you’ll face by choosing carbon steel as the primary material for your industrial basket strainers?

Here we go.

· Disadvantages of Carbon Steel Industrial Basket Strainers

There are three main challenges that you’ll face by industry basket strainers made from carbon steel.

They include:

i) The high carbon content in carbon steel makes such industrial basket strainers hard but brittle. Therefore, they can collapse under extreme pressure conditions.

ii) Carbon steel industrial basket strainers are unattractive when compared to stainless steel—a highly-aesthetic metal.

iii) Basket strainers made of carbon steel are heavy as the carbon component makes the metal dense.

In most cases, I can recommend carbon steel basket strainers for bulk chemical filtration, discharge water filtering and paint filtration.

· Copper Basket Strainers

Copper-based alloy is also another useful industrial basket strainer fabrication material.

Copper is doped with nickel to form an alloy with desirable properties.

Industrial basket strainers made from copper are common in specialized applications.

Take for instance, the corrosion resistance copper is suitable for marine applications.

Bronze duplex basket strainer

Remember, bronze is a copper alloy.

Normally, the industrial duplex filter made from copper allows have the following main advantages:

i. Just like carbon steel and stainless steel, copper industrial basket strainer is also resistant to corrosion.

ii. It can handle welding modifications, unlike stainless steel.

On the other hand, they also have these main disadvantages:

iii. Extremely expensive due to the base material that forms the alloy

Depending on the copper alloy, you can use these industry basket strainers in many applications such as resin filtration, solvent filtration, etc.

Honestly, these are the main materials you’ll find in most industry basket strainers.

However, at times you may also go for:

- PP Basket Strainer; they are made from Polypropylene material. Normally, we use molding technique to make Polypropylene basket strainers.

- PVC Basket Strainer; PVC basket strainers are molded from a polyvinyl chloride material.

The bottom line:

Depending on the type of fluid in the piping systems and the environmental conditions, you should choose an appropriate material.

That is – one that will serve you for a long period of time without much downtime.

More importantly, it must not react with the fluid.

Chapter 4: Technical Specification of Industrial Basket Strainer

I know this is what you have been waiting for.

And, for a fact, technical specification of industrial basket strainer is one of the most critical aspects of any industrial basket strainer.

However, for the scope of this section, I want to make everything simple for you.

So, I will go straight to what you need to look for in the basket type strainer datasheet.

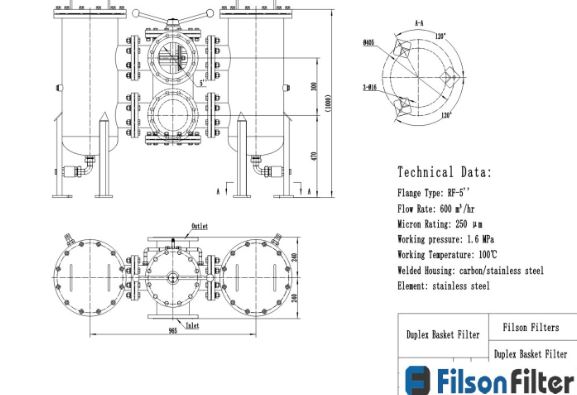

Take a look at this duplex strainer technical drawing:

Industrial basket strainer specification

Can you see the writings on the bottom right of the diagram?

I am talking about the section – “Technical data”.

Of course, from that, you will know all the essential parameters of an industrial basket strainer.

Let’s have a quick overview of the key things you should consider:

- Technical and 3D drawing; it shows you how the industrial basket strainer looks like. For instance, here we have an industrial duplex basket strainer.

- Flange type

- Working pressure

- Flow rate

- Working temperature

- Type of material

- Fabrication types; in this case we have welded construction

- Type of element

- Basket type strainer dimensions

Whenever you’re buying an industrial basket strainer to install in a piping system, the system parameters (fluid flowing in a pipe) must match these strainer standard specifications.

Also, you can get more details about the strainer standard specifications from the datasheet.

Here is an example:

Technical information about industrial basket strainer

Buying an industrial duplex strainer using this information is simple and straight forward.

Let the engineers and technicians specify the performance requirements in the piping system.

With that information, contact an industrial duplex strainer manufacturer.

In case they have a standard design that meet your performance specifications, you can go for it.

Alternatively, you may request for custom industrial basket strainers.

With that, I want us to look at a critical aspect of industrial basket strainer.

Chapter 5: Basket Filter Element for Industry Basket Strainer

A basket filter element is a cleanable screen, built-in industrial basket strainer to allow filtering of larger particles or dirt in the pipe system.

This is exactly what I am talking about:

Basket Filter Element

Generally, some of the main features of an industrial basket filter element include the following:

- Have a superior filtration surface area as compared to wye strainer

- Basket filter element is easier to clean and service

- Most basket strainers are installed horizontally

- Major design features come in simplex or duplex configurations

- It can provide an uninterrupted flow process with great ease of operation

- Given the same screen specification, Cv factor ratings is the most critical feature in basket strainer.

Now, having said, that, what is the main purpose of a basket filter element?

Basket filter element functions as a “sieve”.

It removes all large particles from fluid flowing in the hydraulic system.

I have mentioned this several times throughout this guide.

So, there is no need to go into those details here again.

Still, I want you to note that, the best material for the basket filter element are stainless steel, copper nickel alloy or carbon steel.

Stainless steel basket filter element

Now, depending on your unique applications, you can choose one that meets your specific needs.

However, the truth is:

The best basket filter element should accommodate high fluid flow and hold colossal amount of dirt.

Still, you can choose from:

a) Perforated Basket Filter Element

Basically, the screening material is punched an array of holes in either staggering or straight patterns.

The holes may vary in sizes depending on the filter media application.

b) Mesh Basket Filter Element

This type of design option superimposes both mesh layer and perforated screens.

This design produces fine filtering because of its fine openings, unlike perforated basket filter element.

c) Customized basket filter element

This design option is custom made to suit one’s specific filtering applications

Now, let’s come to what I promised you earlier.

At some point, your basket filter element will be clogged.

And, here, you have only two options:

- Clean, then replace the basket filter element

- Buy a new basket filter element and replace the old one

Let me show you how to do it:

· How to Replace Basket Filter Element

Replacing a basket filter element is a simple and straightforward process.

Just follow these 11 steps and you’ll have your pipeline up and running.

Let’s do this:

i. Carefully handle, unpack and inspect the new basket filter element before replacing it. This will allow you to confirm whether it is the right replacement.

ii. Wipe out any preservatives using a solvent-dampened cloth rag.

iii. Always remember to adhere to all safety measures to avoid unnecessary injury or damage on the system.

iv. Reduce the system pressure to atmospheric pressure.

v. Cut off the supply to both the inlet and outlet valves.

vi. Depending on the type of basket strainer in the system, you can open up the strainer cover top or shut down the system to unscrew the basket gasket.

vii. Drain out the basket chamber to access the dirt-lodged basket filter element.

viii. Pull out the basket filter element using its handle to avoid coming into contact with the dirt that can be hazardous.

ix. Place it safely aside and replace it with the new spare which is clean at its spot.

x. Make sure the new basket filter element squarely fit into the original position.

xi. You can as well replace the cover gasket before properly tightening it.

Voila! You have successfully replaced the basket filter element – I hope you can see how simple this is.

Just get the right tools and equipment and everything will alright.

So, where exactly do we use the industrial basket strainers?

Let’s find out.

Chapter 6: Applications of Industrial Basket Strainers

Let me be brief and straightforward:

You can install industrial basket strainers in any pipeline to remove large particles or debris from the system.

This way, you will protect other components within the piping network, just as I had mentioned in chapter 1.

Let’s look at some of the most common and practical applications of industrial basket strainers.

It will give you more insights on what I am talking about here:

· Industrial Basket Strainers in Marine Applications

All fresh water systems on board ship such as boiler feed water system, drinking water system, and others are installed with basket filter element strainers.

This helps remove solid particles out of the system.

Marine

In fact, the sea water side has more basket filter strainers cascaded in line than the fresh water system.

This is because the latter is a specially closed system.

Some of the main applications include:

- Sea chest strainers—It is the first line of solid impurities filter at the inlet of the sea water system into the ship water chambers. The basket strainer is intentionally fitted with marine growth-preventive system. Another purpose for the sea chest strainer is to keep up a constant water flow into the system.

- Fire line Suction System—Basket strainers are designed in the fire system suction to trap solid particles from getting through the fire line. The basket mesh screen holes allow for the continuous water flow.

- In the bilge line filter—The bilge well has the highest concentration of solid contamination as compared to other systems. Hence, all the suction at the bilge is provided with basket strainers to remove impurities for instance, rag

· Industrial Basket Strainers in Pharmaceutical Industry

Many processes in pharmaceutical industry depend industrial basket strainer.

The basket strainers help control debris and particles that can contaminate the manufacturing process.

SaintyCo Oral Syrup Filling Line

And therefore, you should use a sanitary 3A certified industrial basket strainer in the production process.

It will make sure the products not only clean, but also safe for human use.

· Industrial Basket Strainer in Chemical and Food Industry

Just like in pharmaceutical production processes, 3A certified industrial basket strainers are a must.

They help make food safe for consumption.

Coca Cola

On the other hand, the chemical industry is characterized by pipe and system damages caused by specific harsh chemicals flowing through.

That is why they deploy basket strainers to remove any solid particles that may result to further chemical reactions.

If not prevented, uncontrolled chain reaction can be catastrophic.

· Basket Strainers in Medical Industry

Medical field is a very sensitive industry that must have the highest standards of sanitation.

This is to prevent catastrophe and reduce risk of further patient infection.

Medical industry

Thus, it is important to adhere to set standards – choose approved industrial basket strainers in the medical industry.

This is to provide better protection to patients.

· Industrial Basket Strainer in Power and Utility Industry

Industrial basket strainers are used as trap strainers to remove resin from ion exchange reaction.

Power Generation Plant

Furthermore, downstream processes are provided with protection from the sand or carbon filtration set up.

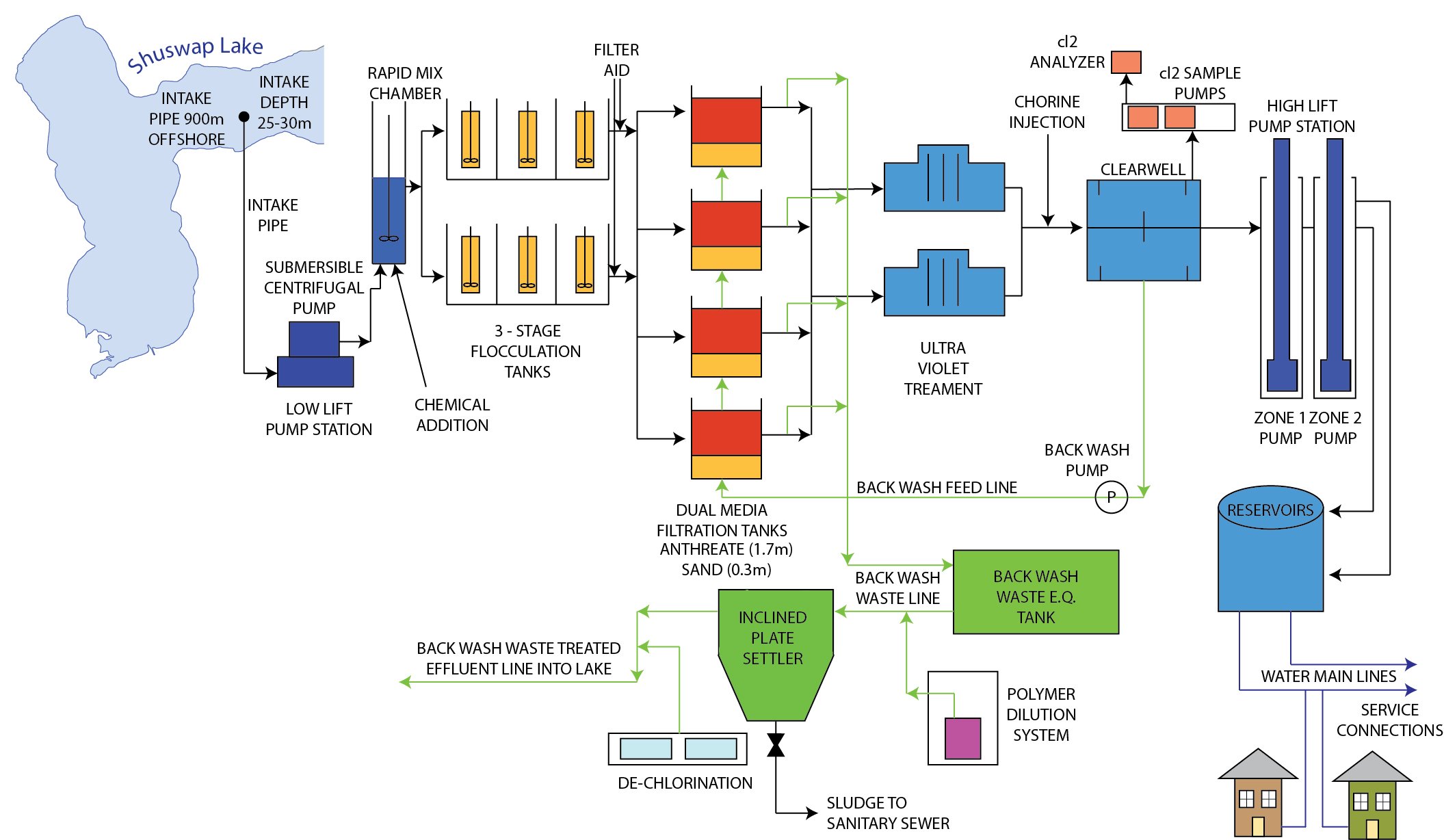

· Industrial Basket Strainer in Water Treatment & Supply Systems

Water processing systems are prone to large deposits of solid impurities like gravel, sand, pebbles, etc.

This is because water is collected from various sources such as rain water, river, dams.

The presence of debris in the water can cause more damage to the system equipment and instrumentation parts.

Hence, industrial basket strainers give the solution to remove the unwanted solid wastes from the processed water flow.

Water treatment plant – Photo Credits SALMONARM

Also, industrial park sewage systems use basket strainers to remove large solid waste components to prevent system blockage.

· Industrial Basket Strainers in Off-Shore Application

Industrial basket strainers are also capable to give equipment and system protection for offshore rigs as well as Floating Production Storage & Offload (FPSO) vessels.

They also deploy in fire water-deluge systems on all offshore rigs around the world.

And, please, don’t get me wrong.

I am not saying that these are the only applications of industrial basket strainers.

There are quite a number.

So just do the assessment and choose an industrial basket strainer that meet your application requirements.

Now, to my last section of this guide – Let’s take a quick look at the various solutions FilSon Filters offers when it comes to industry basket strainers.

Chapter 7: FilSon Filter Industry Basket Strainer

FilSon industry basket strainers are fabricated from either stainless steel (304 or 316) or carbon material.

However, for specialized applications, you can request for specific materials.

The industry basket strainers are designed to meet high quality standards.

They guarantee and contamination free fluid in pipe systems.

What’s more?

To ensure “zero” leakage and lightweight, FilSon industry basket strainers have a fully welded strainer housing.

And, they come in a range of shapes and designs such as:

- FilSon simplex basket strainer

- FilSon inline basket strainer

- FilSon duplex basket strainer

- FilSon fabricated industry strainer

Whether you need standard or custom designs, FilSon Filters provides exactly that.

From unique color for the housing, flow rate to pressure rating, FilSon Filters provides just that.

With over 10 years in industry basket strainer manufacturing, FilSon Filters understands exactly what you need.

All FilSon industry baskets strainers are designed to meet the exact specifications of different applications.

Even when they are clogged, they have a clogging indicator that will alert you.

You can then clean or replace the strainer element – it is a simple process that does not require any special training.

For a fact, FilSon industrial basket strainers are accessories you can always count on.

Conclusion

With the information I have shared with you in this guide, I am sure you can easily choose the right industrial duplex strainer for your application.

Just take your time to evaluate every aspect I have highlighted here.

From different types, working principle, design to technical specifications of industrial basket strainers.

And in case you have any questions on industrial basket strainers, feel free to contact us.

At FilSon Filters, we offer free consultation on industrial duplex strainers.