Filson Oil Coalescing Filter

- Optimized design to minimize space requirements

- Robust construction structure even in harsh environment

- High temperature resistance and high pressure resistance

- Good performance of oil-water and oil-gas filtration

- High quality stainless steel and carbon steel material

- Good protection of downstream equipment and components

- Specifications

- Send Us Inquiry

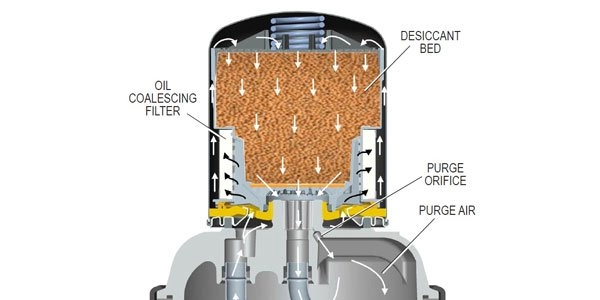

Filson oil coalescing filter concludes oil water coalescing filter and oil gas coalescing filter. The working principle of Filson oil coalescing filter is when fluid pass through the fiber, small oil drops in fluid will be aggregate into large droplets and discharged by gravity.

- Construction material: carbon steel, stainless steel

- Medium material: fiberglass, stainless steel mesh, borosilicate

- Filtration type: oil-water separation, oil-gas separation.

- Cartridge number: 1,3, 5, 7, 15, etc

- Cartridge Length: 10-40 inch

- Filtration grade: from 0.1 micron to 100 micron

- Capacity: 20-100L

- Filtration efficiency: up to 99.99%

- Effective filter areas: 2. inch ≥14m2

- Working temperature range: from -70℃ to 150℃

- Maximum working pressure: 10-15bar

- Maximum oil and liquid aerosol residual: less than 0.003 ppm

- Quality certification: in accordance with CE certification, ISO 12500

- Accessories: pressure gauge, automatic or manual drainage mechanism

Send Your Inquiry Today

Filson Oil Coalescing Filter

Your Best Oil Coalescing Filter Supplier in China

As a dependable oil coalescing filter manufacturer in China, Filson can produce high quality oil coalescing filter as well as competitive price. Compared with conventional filters in the market, Filson oil coalescing filter is used for a higher grade filtration.

Some oil content, aerosol are difficult to remove completely in the first stage, Filson oil coalescing filter is specially designed to reduce the concentration of oil, aerosols in the fluid medium which is down to 0.003ppm level.

Filson utilizes unique filter material cartridges and special design that allows you to work with the increased load and minimized pressure differential. The pleated cartridge provides surface area 4.5 times than ordinary filter media.

If you are interested in Filson oil coalescing filter or have any doubts about them, feel free to contact with us, leave your name, e-mail and requirement specifications, our professional engineering specialists are ready to help you!

Any other questions? Click Here for more information.

Oil Coalescing Filters: The Ultimate FAQ Guide

In this guide, you’re going to learn everything you need to know about oil coalescing filters.

Whether you want to learn more about classification, working principle, material types or parts, you will find everything here.

Keep reading.

What is an Oil Coalescing Filter?

The compressed air present in the oil processing stations and industries often contains several kinds of contaminants, some solid particulate while other fluids such as oil.

To recover the oil, you will need an oil coalescing filter element.

The case above is a typical case for the separation of the gas-liquid phase.

Oil coalescing filter element

Elsewhere, the oil coalescing filter is also useful when purifying waste-water stream or water-oil interphase (A typical scenario of a liquid-liquid phase).

For efficient filtration, you may singularly use an oil coalescing filter or use it as a sub-unit of a bigger separation unit.

However, please note that your selection between the two would entirely depend on the nature or degree of filtration.

What is the Function of an Oil Coalescing Filter?

An oil coalescing filter extracts contaminants from contaminated air or effluent by the coalescence process.

Coalescence is the procedure of the liquid aerosols combining to form greater droplets.

The droplets would, in turn, become big enough to get drained away by gravity—the process known as agglomeration.

With that process, the coalescing filter thus operates contrary to the emulsifier, which does so by emulsification.

Furthermore, the filter removes the oil particles even up to those of micron-sized.

The filter does the whole filtration process by holding the contaminated air.

Then it proceeds to combining the contaminate particles through coalescence, decanting and dropping them by gravity into the extraction chamber.

In addition to the extraction of contaminants, the filter also guarantees the mechanical integrity of the downline oil processing systems.

Several contaminants (liquid oil, oil vapor, dust, etc.) that may be present in the mix processes may potentially cause blockage to the valves and tubes.

The contaminants may as well cause swellings to the seals, and corrode pipes.

All those adverse effects would likely cause mechanical failure to the pneumatic equipment and other systems.

Moreover, the coalescing filter reduces the level of pollution by effectively eliminating potential pollutants present in the oil process.

Similarly, the filter minimizes the possibilities of downstream corrosion.

Please note that some of the contaminants may be corrosive in nature, which would, in turn, corrode the surfaces of the following systems.

Ultimately, while considering the various roles of the coalescing filter, it is an indisputable fact that the filter would thus reduce operational and maintenance costs.

Eventually, it promotes the health and safety of the workers or operational personnel.

What are the Features of an Oil Coalescing Filter?

The oil coalescing filters are outstanding in their performance (filtration).

However, you have to take note of some adorable characteristics of the filter before purchasing any.

Besides, you can pre-customize the features of the coalescing filter or perhaps customize them after purchase.

Again, remember that you only need to customize the features in cases whereby you need the filter to uniquely perform contrary to the standard operations.

Nevertheless, the following are certain features of the oil coalescing filters:

- Construction material is of an appropriate kind usually A-36 carbon, stainless steel 304 or 316 with a dye penetration tested welding joints.

- The filters are of compact design, thus saves much of the floor space.

- The oil coalescing filters are easy to clean.

- The oil coalescing filter attracts only minimal maintenance procedures during usage.

- Besides, it has an integral oil reservoir.

- The filter also ultimately has no moving parts/ sections.

What are the Applications of the Oil Coalescing Filter?

Well, an oil coalescing filter is applicable in a series of industries.

A typical application is in the oil and gas operations, together with petrochemical industries.

In such cases, the filters undertake a liquid-liquid or liquid-gas separation throughout the entire process of refining.

Precisely, the fuel coalescers in the downstream sector separate liquid hydrocarbons and mist from streams of natural gas to guarantee a high level of product purity.

Additionally, in petrochemical industries, oil coalescer is integrated into the filtration systems to expel oil and water vapor from products before storage.

That aside, oil coalescing filters are useful across several industries for a wide range of applications, including but not limited to:

- Oil production and spill recovery

- Petroleum plants/ refineries

- Pulp and paper mills

- Tramp oil

- Airports

- Chemical processing

- Processing plants

- Water treatment plants

Which Kinds of Contaminants do the Oil Coalescing Filters Extracts?

The oil coalescing filters eliminates submicron-sized liquid oils –water and solid-particulate contamination.

They include the following impurities:

- Non-emulsified oils

- Gasoline

- Fuels

- Diesel

- Pipe dope

- Condensed moisture

- Carbonized oils

- Dust

- Dirt

- rust

How do we Classify Oil Coalescing Filters?

We can classify oil coalescing filters in regards to two parameters, namely:

- Mode of operation

- Design of the filters

Oil coalescing filter

· Mode of Operation

Mode of operation, in this case, refers to the consideration of the mechanisms or techniques of filtration.

By so doing, we, therefore, have two types of filters that are mechanical coalescers and electrostatic coalescers.

i. Mechanical Coalescers

As their name suggests, mechanical coalescers often use mechanical or physical means to form droplets of the contaminants.

In particular, they use filters or baffles to form droplets by coalescence.

These types of coalescers are commonly applicable in oil and gas industries for the extraction of water or hydrocarbon condensate.

In such applications, the liquid-gas coalescing filters are appropriate.

The removal is such efficient that they extract up to particles of a minimum size of 0.011 ppm.

For compressed air purification, the filters separate oil and moisture from compressed air by coalescence besides separating other impurities.

ii. Electrostatic Coalescers

Unlike mechanical coalescers, the electrostatic types majorly use electric fields to form droplets.

Specifically, the electrical charges induced by the currents (i.e., DC or AC or both ) prompt coalescence of liquid molecules onto the collection tank surface.

In this case, the electrostatic charges formed increases the molecular sizes of the droplets by destabilizing the emulsion.

Thereby, making them drop beneath the tank.

· Design of the Filters

In terms of design, the oil coalescing filters are available in Simplex and Duplex designs.

a) Simplex Oil Coalescing Filters

The simplex type consists of only one principal primary unit chamber for the purification of the raw influent or compressed air.

The general structure of the filter is simple and not sophisticated at all.

Normally, the compressed air flows in via the single unit chamber while the impurities get trapped and after that eliminated.

Also, the simplex design is easy to install, maintain, and clean.

Furthermore, the simplex configurations are available in basket type filters and Y-type filters.

b) Duplex Oil Coalescing Filters

The duplex design consists of two – solitary filter chambers interlocked with switching valves together with a plug system.

The dual design structure, therefore, increases the surface area of the filter, which in turn widens the filtration scope.

Importantly, each of the dual chambers functions independently to facilitate seamless operation even when one compartment breakdown.

Ultimately, the duplex design guarantees a continuous type of activity with no downtime during maintenance or cleaning.

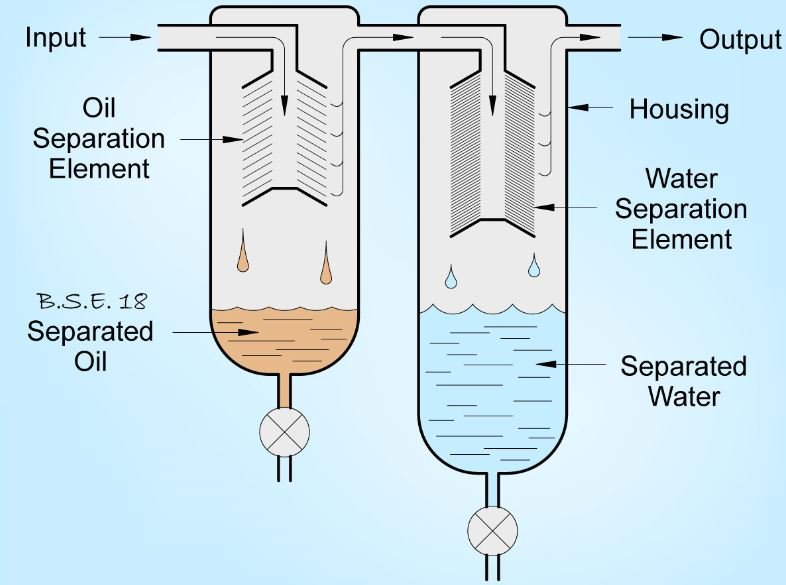

How does the Oil Coalescing Filter Work?

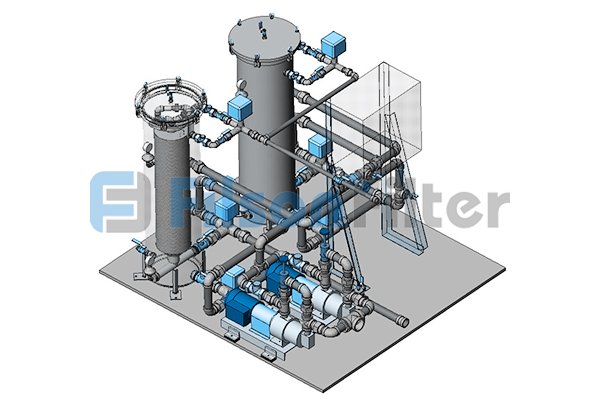

Oil coalescer filter system

The filtration process of a coalescing filter involves the following procedures:

The compressed air gain entry into the oil coalescing filter via the housing then flows through the filter media.

Besides, the flow of the air in the filter element is from the inside to the outside.

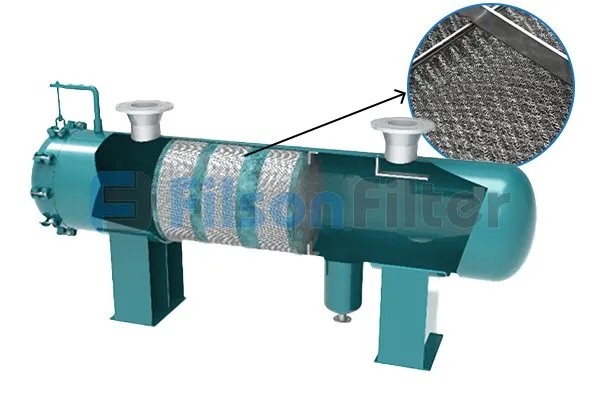

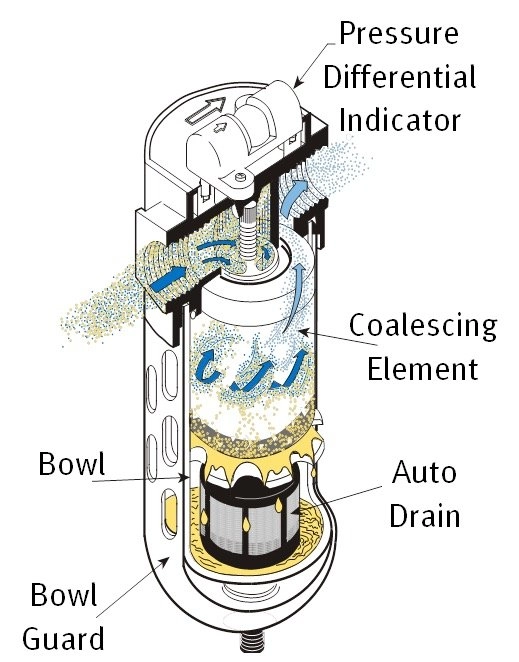

First, the product flows through a series of filter elements present in the coalescer.

These filter elements have got very fine fiber meshes that intercept and trap aerosol particles.

Secondly, the coalescing filters then separate the constituents of the product into phases.

They trap the impurity while allowing the pure form of the product to flow through to the collection points.

Thirdly, after that, the tiny particles of the impurities (oil and water droplets) amalgamate into larger sized ones on the filter fibers.

As the product flows through the filter fiber elements matrix, all the tiny droplets of liquids form into more significant sized ones.

These are more substantial and thus get mechanically drained away usually by gravity.

Finally, the pure air exits the coalescer filter housing via the outlet port.

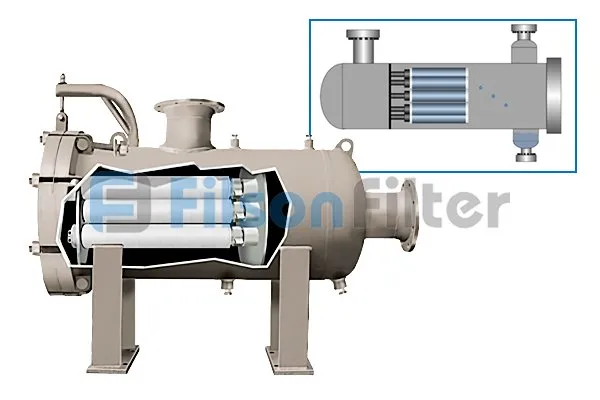

What is an Oil Coalescing Filter Element?

The oil coalescing filter element is the solely responsible equipment for trapping the impurities in the gas stream either by diffusion, direct impact, or interception.

The equipment is also the critical point for the coalescence of the droplets.

Typically, the series of filter elements are the ones responsible for the actual filtration of your product.

What are the Design Considerations of an Oil Coalescing Filter Element?

The coalescing filter elements have got fine fiber meshes, which are the fundamental principle in the design.

It is the fiber meshes that intercept and capture the aerosol particles.

Most importantly, the size of the element is also a contributing factor in the design.

More prominent filter elements increase the separation mechanism.

What are the Primary Parts of an Oil Coalescing Filter?

The following are the certain segments of an oil coalescing filter system:

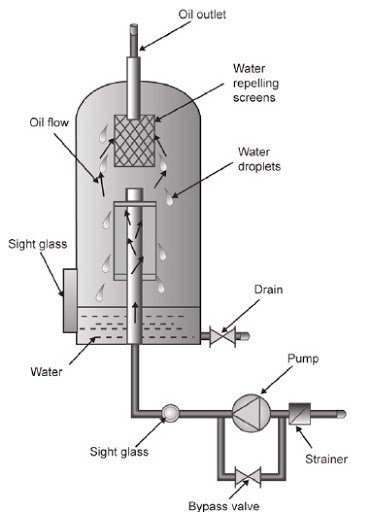

· Inlet Chamber

The impure compressed air enters the filter via a clog-resistant baffle.

The flow then uniformly disperses across the entire chamber.

Heavier solids would drop straight into the sludge compartment before the air enters the filter elements.

· Separation Chamber

The filter elements are the major components of the separation chamber.

Here, the oil drops get trapped, collect, and coalesce.

The filter elements guarantee effective filtration of the media by often averting the flow direction, thus ensures efficient coalescence of the oil droplets.

· Sludge Chamber

Located beneath the separation chamber, the sludge chamber guarantees the retention of more massive solid particles.

To enhance the complete extraction of the sludge from the chamber, it has sloppy structured walls.

· Oil Reservoir

The isolated oil reservoir provides storage of the decanting oil drops.

You can as well often expand the storage allowance of the oil reservoir depending on your needs.

· Effluent Chamber

The effluent chamber provides temporary storage or channel for the passage of purified compressed air.

Similarly, you can always adjust the capacity of the effluent chamber depending on your storage needs.

· Tank Seals

The filter has got several seals that cover the various compartments and chambers of the equipment.

On request, you may also have inspection hatches included.

How does Coalescing Filtration Differ from Particulate Filtration?

Particulate filtration entails the complete separation of solid particles (dust, dirt, rust, pipe scales, etc.) from a liquid phase or gas phase.

To undertake particulate filtration, you may pick any kind of filter you wish; no strict restrictions.

Such types of filters include dry gas filters, demister filters, compressor air filters, etc.

Whereas coalescing filtration involves the removal of aerosols and liquid droplets from gas interphase.

The technique in play, in that case, is coalescence.

However, coalescing filtration also eliminates all the particulate contaminants such as dirt, dust, rust, etc.

For coalescing filtration, you will strictly need an oil coalescing filter and not any other.

In summary, please note; particulate filtration only eliminates particle kind of contaminants while coalescing filtration eliminates aerosols, liquid droplets, plus particulate pollutants.

How do you Select a Coalescing Filter?

Picking a perfect oil coalescing filter for your application is the ultimate decision you will have to undertake.

To assist you to do precisely that, here are a few parameters you should consider before making a purchase.

Type of substance to be filtered; always ensure that the material for the filter is compatible with the substance that you need to filter.

Temperature and pressure; suitable oil coalescing filters should have a higher pressure drop and a tolerate operational temperature variation.

Always verify the pressure drop and temperature from the technical manual of your filter.

Manual or automatic drain; the typical oil coalescing filters are available with either a manual or automatic drain option.

While automatic drains require a minimum pressure drop to close, manual drains require only a one-time fit.

However, manual drains require frequent supervision to ensure if they are still properly sealed.

Consequently, most users prefer automatic drains for their systems.

Degree of air purification; according to ISO 8573-1 Standards, coalescing filters should extract oil droplets of up to 0.01 mg/m³ with a corresponding particle extraction down to 0.01micron.

Size and weight; you should pick an oil coalescing filter that has got a considerable weight and size.

Of course, the weight would depend on the material of the filters; an example of lighter material is polycarbonate.

Visual service indicator; though optional, most oil coalescing filters come already fitted with signs which display when replacing is essential.

Usually, the indicator shifts color from green to red whenever there is a need for replacing filter elements.

What is the Recommended Material for the Coalescing Filter Element?

Oil coalescer filter system

The oil coalescing filter elements comprises three layers of fine mesh substance.

The inner layer is within the two outer layers.

The inner layers are the coalescing layers that capture the solid contaminants, while the outer layer comprises of coarser fibers.

Note that the outer layers are predominantly reserved for draining the pollutants.

Nevertheless, coalescing filter elements are made of fibrous materials, which, when combined, form a complex matrix.

Examples of such fibrous materials include borosilicate micro-glass, closed-cell foam, fiberglass, and chemical resistant lattice materials.

Why Install Oil Coalescing Filters in Pairs?

Installing oil coalescer filters in pairs of series has a significant benefit: it protects the fine filter by reducing the pressure loss and ultimately saving costs.

Every filter eliminates the contaminants though to varying degrees of purity.

The first filter, which serves a general-purpose, protects the second, a highly efficient filter from bulk contamination.

With that, there would be a significant improvement in the performance of filtration, reduction in pressure loss, and finally, cutting down of operational expenditure.

At long last, the arrangement also lengthens the service life of the element usually from a range of 3-6 months to about 12 months.

Is there an Option for Pairing Oil Coalescing Filters?

Yes, you may opt for a single type of filter alternative.

Nevertheless, several users report an underachievement with this type of filter, as portrayed theoretically.

The two in 1 kind of filter cut the pressure losses, which results from having two filter housings of compressed air filters.

Better still, the filters still maintain an equal level of performance in terms of purification.

How do you Clean Oil Coalescing Filter?

After several usages and duration, there would be an excessive accumulation of contaminants on the elements, thereby reducing the volume of the filter left for filtration.

Therefore, to avert any potential sipping of the solids and mineral oils into the discharged effluent, you need to often remove the accumulated pollutants.

You may need to remove the sponge support of the element and wash it thoroughly.

Again, you need to clean the filter at an interval of 1-2 months.

When you need to clean, remove the steel housing of the filter.

Then wash it with a jet of water.

However, you will need services of an authorized waste disposal personnel to remove the loose material, bottom sediments, and also to clean the inlet and outlet tunnels.

Please Note: First, the frequency of cleaning would depend on the quantity of oil and grease.

Secondly, never use toxic or poisonous chemicals (insecticides, bleach, aggressive detergents, disinfectants, solvents) for cleaning.

What Factors should you Consider when Installing Oil Coalescing Filter?

Coalescing filter element

· Pressure and Temperature

It is always advisable that you install the filter at a point of the highest pressure within the compressed air system.

Similarly, the position of installation should be of the lowest temperature.

· Point of Use

Always install the filter closest to the location of use to prevent any possibility of condensation of the liquid.

What other Auxiliary Devices should you Install Alongside Oil Coalescing Filter?

In cases whereby you need an incredibly pure air or product, then you might consider installing a general-purpose filter upstream of the processing system.

Such kind of filter would initially trap large contaminants from the gas stream.

Besides that, a typical oil coalescing filter may be accompanied by:

- Control panel

- Effluent pump package

- Influent pump package

- Level switches and alarms

- Sight glass

- Walkways/ ladders/ platforms

When should you Replace Oil Coalescing Filter?

You should automatically do a replacement of the filter.

That is, whenever it indicates a pressure drop rise from 8 psi to 10 psi. of course, the clogging of the contaminants is a great contributor to the rise in pressure drop.

What are the Typical Maintenance Procedures of Oil Coalescing Filter?

The usual and most apparent maintenance procedures are inspection, cleaning of the filter, and entire replacement of the filter.

You should inspect the filter after every 1-2 months, similar to cleaning.

However, replacing is not time-bound but would mostly depend on the pressure drop.

With this information, am sure you can choose high quality and reliable oil coalescing filter.

At FilSon Filters, we design and manufacture high-quality oil coalescing filters.

Whether you want a custom or replacement oil coalescer filter element, Filson offers perfect solutions.