Filson Lube Oil Filters

Filson lube oil filters also name lube oil filter cartridges are used to eliminate the impurities and other contaminants from the lube system. It has superior filtration efficiency and higher contaminant holding capacity.

Filson lube oil filters are available in multiple media options, include high-quality microglass, stainless fiber, glass fiber, cellulose and metal mesh filter materials… All Filson lube oil filter elements are tested according to ISO Standards to perform under the most challenging industrial and mobile applications

Filson lube oil filters deliver the optimal balance of separation, capacity and restriction for lube systems and components. The updated mesh structure allows lubrication oil filters to capture dirt particles with maximized available area and minimized resistance to fluid flow. Enhanced pleat stability can extend lube oil filter element service life and reduce change-out costs.

Compared to other lube oil filter manufacturers, Filson lube oil filter replacements can reach efficiencies as high as 99+% much greater than most lube oil filters and ensure better oil cleanliness by more completely removing all size contaminants.

Filson can offer a broad range of lubrication oil filter replacement elements coverage to fit systems built by other manufacturers. Using Filson lube oil filter cross reference can direct replace other standard filters – no system modifications or special disposal requirements. Filson is also glad to custom the lube oil filters with your own design and parameters.

- Features

- FAQ Guide

Features of Filson Lube Oil Filters

- Large contaminant carrying capacity – for much longer life

- Delivers lower restriction to provide maximum lubrication oil flow

- Heavy-duty, long life seals to support extended service life,

- Element fits a full range of lube oil applications

- Using polyester outer wraps to improve fatigue resistance

- Optimized Beta efficiency, contamination retention, ∆P/Q characteristics

- Wide range of micron rating: from 1μm to 500μm

- Exclusive fan-shaped end pan to avoid fluid spillage during the change out

Lube Oil Filter: The Ultimate FAQ Guide

In this guide, you will find all information you’re looking for about lube oil filter.

Whether you want to learn about components, benefits, features, or working principle – you will find all information right here.

Keep reading to learn more.

- What is a Lube Oil Filter?

- What are the Advantages of Lube Oil Filters?

- What are Some Disadvantages of Lube Oil Filters?

- What Components Make up a Lube Oil Filter?

- How Does a Lube Oil Filter Work?

- What is the Purpose of an Oil Lube Filter?

- What are Some Features of Lube Oil Filters?

- Is it Advisable to Drive an Automotive with no Lube Oil Filter?

- Can You Customize a Lube Oil Filter?

- Can You Reuse a Lube Oil Filter?

- What are the Risks of not Replacing a Lube Oil Filter?

- How Will You Determine if Your Lube Oil Filter is Not Operational?

- What are the Different Types of Lube Oil Filters?

- What are the Benefits of having a Clean Lube Oil in the System?

- Where do Lube oil Contaminants Come From?

- How Can You Maintain a Lube Oil Filter?

- What Features Make up a Good Lube Oil Filter?

- What are Some Lube Oil Filtration Techniques?

- What is Beta Rating and Beta Stability?

- What ISO Standards Should a Lube Oil Filter Conform To?

- What is the Function of Pressure Relief Valves in Lube Oil Filters?

- Do You Require a Special Lube Oil Filter for Synthetic Oil?

- What are the Advantages of Using a Synthetic Lube Oil System?

- How Do You Compare Inline and Off Line Systems?

- How do You Compare Synthetic and Conventional Lube Oil Filters?

- When Should You Apply a Premium High-Capture Efficiency Lube Oil Filter?

- Is it Necessary to Pre-Fill a Lube Oil Filter Prior to Installation?

- Are there Trends that Influence Lube Oil Filter Technology?

- What Types of Filtration Systems Exist in the Market?

What is a Lube Oil Filter?

This is a piece of equipment that eliminates impurities and other wear and tear-causing contaminants from the lube system.

Lube oil filter

What are the Advantages of Lube Oil Filters?

Here are the benefits of using an oil filtration system:

Prevents the Engine Heat from Spiking

When you use low-quality lube oil, it will ultimately heat the engine.

If the pollutants build up in the lube oil, the engine may wear out and inhibit thermal conductivity.

Lube oil filters will help to preserve the engine components by maintaining their lubrication.

Also, the pure lube oil-free pollutants protect the engines from excessive heat.

Prevents Wear and Tear

Lube oil filters will minimize moving parts of the engine from wearing and tearing out.

This would improve their longevity.

It protects the Engine Against Oil Oxidation

Lube oil in cars can oxidize no matter how appropriate or undesirable the road conditions you are moving.

Oxidation contributes more toxins to the lube oil, diminishing its performance.

The lube oil filters will inhibit contaminants from entering the engine.

This helps avoid damage to the engine.

Extend the Durability of An Engine

Engines need the circulation of clean lube oil to help them work in the best way possible.

Also, the best lube oil filters can prevent pollutants and dirt from accessing the inner parts of the engine.

The outcome of this would enhance the performance of the engine and its life span.

What are Some Disadvantages of Lube Oil Filters?

These disadvantages should not deter you from purchasing and installing one.

They include:

Cost

The more specialized a lube oil filter is, the costlier it will be to purchase.

Performance

Also, high-performance lube oil filters will cost more I.e. sports cars’ lube oil filters.

What Components Make up a Lube Oil Filter?

Several components make up a lube oil filter.

All these work together to improve the quality of lube oil.

The parts include:

These are the parts that make up an oil filtration system:

Filtration Unit

This section has many microscopic celluloses and synthetic fibers such as glass and polyester.

It works by improving the reliability and longevity of the lube oil filter.

Also, it contains resins in it that provide more strength and rigidity to the medium.

Many synthetic fibers are present in high-performance lube oil filters.

Pleats

This is the component of the lube oil filter that has many folding to maximize the contact area.

A wide surface area means that the lube oil makes contact with this component thereby enhancing the efficient filtration operation.

The density of the material shall determine by the number of pleats necessary.

End Discs

The purpose of this component is to prevent oil that has not undergone filtration from flowing back to the middle steel tube.

The substance that makes up this component may be either fiber or metal.

Besides, the end disk links to both ends of the filter medium.

Anti-drain-back Unit

This is a flap that has a rubber valve.

It works by stopping lube oil from entering the filter while the engine is not operating.

This portion is critical since the filter is normally between the middle and the bottom sections of the engine.

Tapping Plate

This is the entrance and exit section of the lube oil filter.

It also has many tiny holes along its edge that allow the oil to flow freely through the lube oil filter.

The threaded hole in its middle causes the lube oil to stream out of the filter when it approaches the engine.

Middle Steel Tube

This section will provide the lube oil filter with robust support.

It also allows oil that has undergone filtration to leave the filter and access the engine.

The configuration, size, and position of the holes of the entrance increase the efficiency of the oil flow.

It also prevents the restriction of lube oil.

Relief Valve

Dense lube oil may prevent the filter from filtering, particularly at a cold start.

This implies you need to eliminate the possibility of an engine lacking lube oil.

The relief valves will unlock when there is enough friction to make the spring travel downwards.

This allows dirty lube oil to penetrate the filter through the top part of the filter.

It also means that there is oil in the filter on all occasions.

Retainer

This is a metallic component that acts as a leaf spring.

It is responsible for keeping the filter medium together with the end disc tight on the tapping plate.

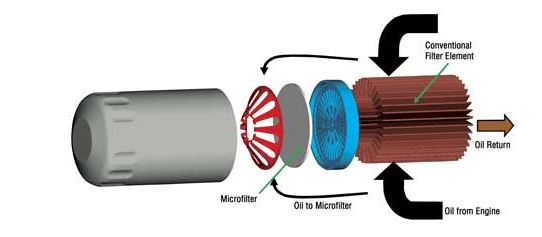

How Does a Lube Oil Filter Work?

The functioning of a lube oil filter is straightforward.

All the components work together to achieve this feat.

Here is how a lube oil filter works:

Step One: Lube Oil Entering the Filter

The engine pump will enable the lube oil to enter the lube oil filter through the surrounding pores at the bottom of the plate.

At the same time, the anti-drain back system unlocks as oil begins to enter the lube oil filter under pressure.

This membrane will not open when the engine is not functioning thus closing all the pores of the filter.

It operates by ensuring that lube oil remains in the filter hence preventing dry starts where an engine powers on with no lube oil.

Step Two: Lube Oil Undergoing Filtration

The dirty lube oil passes through the filter media while under pressure.

This makes impurities stick on the filter and clean lube oil to pass through via the middle hole.

Step Three: Lube Oil Exiting the Filter

The clean lube oil will now exit the filter and into the engine.

What is the Purpose of an Oil Lube Filter?

Lube oil is a vital requirement for the smooth operation of engines and other of its components.

The purpose of lube oil includes:

Lubrication

That is the key feature of the lube oil.

It works by lubricating the moving components of the engine that are always under friction.

A lot of friction will reduce the durability of the engine.

Lubrication assists by minimizing the wear and tear action of these components thus enhancing their longevity.

Cooling

Energy is lost due to combustion and friction between the mechanical parts.

This causes the temperature of the engine to rise.

The lubrication component of the lube oil helps to reduce heat through the lubrication system.

It, therefore, increases the coolant, which only cools certain parts of the engine.

Gap Filler

The area between the piston and cylinder is not as smooth.

Lube oil will assist in enhancing its efficiency and performance as a gap filler in these components.

Sealing

Lube oil also enhances the sealing of the engine and, more accurately, the sealing of pistons and cylinders.

A protective film will deposit between the different parts, and seal the clearances that may develop.

Cleaning

While less well known, the cleaning power of the lube oil is very significant.

Microscopic deposits build up into the engine and are also within the suspension.

They can have fragments or remnants of combustion.

If you end up not using lube oil, it causes the engine to clog thereby lowering its output.

The engine oil flow continuously carries these pollutants to the oil collector, whereby they filter out.

Prevents Corrosion

When oil undergoes combustion, it will emit corrosive acid that can damage the metallic parts of the engine.

By adding additives to new lube oils, the rate of corrosion will go down.

However, over time and in the presence of oxygen, the lube oil oxidizes and thus no longer prevents corrosion.

This is why one needs to replace lube oil regularly.

What are Some Features of Lube Oil Filters?

The features may vary from one lube oil filter to another.

For instance, high-performance lube oil filters will have more features than standard lube oil filters.

Some of these features include:

- It has a large capacity to contain contaminants, thus lasts for a long duration.

- The filter can operate on several lube oil applications.

- Also, it has a wide spectrum of micron rating that ranges from 1 micrometer to 500 micrometers.

- Besides, it incorporates heavy-duty, durable seals that will promote a long service life.

- It conveys a low restriction that provides a maximum flow of the lube oil.

- The filter has an optimized beta efficiency, retention of contaminants, and delta [Δ] P/Q traits.

- It comprises an end pan that has an exclusive shape that minimizes the spillage of lube oil during changeovers.

- Also, it applies the use of polyester to enhance fatigue resistance.

Is it Advisable to Drive an Automotive with no Lube Oil Filter?

No, it is not advisable to drive an automotive without installing a lube oil filter.

A good system allows your engine to function optimally and increases its durability.

It also minimizes damages due to wear and tear.

Can You Customize a Lube Oil Filter?

Yes, one can liaise with the manufacturer to customize a lube oil filter.

Customization will depend on:

- Type of oil

- Filtration accuracy

- Rate of flow

- Dewater efficiency

customized oil lube

Can You Reuse a Lube Oil Filter?

Considering that it is cheap to buy a lube oil filter than it is to buy a new engine, it is advisable to purchase a new one.

Once the lube oil filter reaches its capacity, always buy a new one as it will enhance and improve your entire system.

What are the Risks of not Replacing a Lube Oil Filter?

These include:

Clogging

When a lube oil filter has clogs, lube oil will not penetrate through.

The engine can quit working without warning as this may be due to overheating and no lubrication in the parts.

When this happens, you will have to overhaul the engine and this will increase your expenses and downtime.

Inefficient Lube Oil Filtration Process

The lube oil will contain more micro contaminants as some of them leak back into the oil.

This will provide low-performance lube oil.

The machine will encounter high levels of wear and tear as it operates with dirty lube oil.

Increase in Consumption

When lube oil filters age, they consume more lubricants due to the partial clogs or small filtration capability.

This means you will spend a lot on lubricants as the engine uses them quickly.

Also, the rapid consumption will increase organic residue that comes from incomplete combustion.

Faster Wear and Tear of Engine Parts

Engine parts will not have enough lubrication to minimize friction.

This makes them rub against each other thus increasing friction and ultimately wearing and tearing the engine parts.

Pollution of the Environment

This means the engines are not operating smoothly thus releasing a lot of fumes due to overheating and friction.

The oil will also not burn completely thus increasing the amount of air pollution.

This will impact the environment negatively.

Mechanical Breakdowns

These breakdowns may happen time and time again in small capacities.

However, it will cost you a lot of time and money to fix.

Thereby, always replace a lube oil filter to minimize such drawbacks.

How Will You Determine if Your Lube Oil Filter is Not Operational?

Here are some tips that will indicate when a lube oil filter is faulty:

Metallic Sounds

Metallic components will rub against each other since there is a clog in the lube oil filter.

This is evident as you will start hearing metallic sounds coming from the engine as you operate it.

In such an instance, immediately stop operating the machine.

This will minimize further damages to the engine.

Thereafter, replace the lube oil filter and replenish the system with fresh oil.

Less than Average Performance

The obvious sign happens when the engine is not accelerating normally making you think the acceleration pedal is faulty.

Also, the engine may operate at a lower rate and light sputtering may occur causing huge problems.

Essential components of the engine will wear and tear, eventually breaking down if you continue to operate the engine.

A Decrease in Oil Pressure Gauge

One can see the oil gauge pressure displaying on the dashboard of automotive.

A pressure drop indicates an error with the flow of lube oil.

Take caution when you notice a pressure drop, as it may lead to irreversible damages to the engine.

Sputtering

Sputtering occurs when the lube oil filter does not efficiently release lube oil.

This means the engine cannot maintain the speed, and the sputtering may start gently then worsen later.

It is advisable to replace a lube oil filter when you notice such an issue.

Also, it will assist you in avoiding sputtering altogether.

What are the Different Types of Lube Oil Filters?

There are several kinds of lube oil filters on the market.

They include:

Here are some major oil filters you will find:

Sedimentation Lube Oil Filters

These filters use gravitational force to force heavy contaminants than oil to settle at the bottom.

seriation lube oil filter

Mechanical Lube Oil Filters

This filter has a lot of material medium or pleated paper filters.

It operates by trapping contaminants that suspend on lube oil.

mechanical lube oil filters

Cartridge Lube Oil Filters

This is an easy-to-use full flow lube oil filter that mounts in an upright position.

Cartridge oil filters are available as metal and fiber.

The common type is fiber since it is easy to recycle.

cartridge lube oil filter

Full-flow Lube Oil Filters

Also known as primary lube oil filters, they are some of the most common oil filters.

They are suitable for colder temperatures because cold temperatures will make the oil dense.

Besides, full-flow lube oil filters will make oil move freely within the engine than other types of filters.

If a filter causes restriction, the engine will not get adequate lubrication thus cause tear and wear.

This filter will provide adequate lube oil to the moving parts to ensure it performs optimally.

full flow lube oil filter

Magnetic Lube Oil Filters

It is a kind of secondary lube oil filter that provides extra support to full-flow lube oil filters.

Also, it is suitable for removing metallic dirt from the oil.

However, they cannot eliminate dust or grime.

magnetic lube oil filter

Spin-on Lube Oil Filters

As a type of full-flow lube oil filter, it comes with a steel canister having paper elements.

Also, it offers ease of use, and it simple to repair.

spin on lube oil filter

Secondary Lube Oil Filters

Also known as by-pass oil filters, some cars need these filters to provide support with full-flow filters.

The design of these filters makes them purify less than 10% of lube oil thus remove contaminants that a full-flow filter did not.

Besides, they lengthen the life of lube oil and also provide extra protection to the engine.

Centrifugal Lube Oil Filters

As a rotary sedimentation filter, it uses centrifugal force and not gravity to remove dirt from the lube oil.

A centrifugal lube oil filter does not block as easily as does conventional lube oil filters.

They also separate water from oil as oil weighs less than water.

Thermal Chamber Lube Oil Filters

The first function by filtering all contaminants from the oil then heat lube oil to increase its temperature.

The high temperature means some particles will combust.

High Efficiency [HE] Lube Oil Filters

It is a type of by-pass lube oil filter

Also, they indicate to extend the drainage of lube oil.

They come with a pore size of around 3 micrometers which studies indicate to minimize damage to the engines.

Spinner Lube Oil Filters

This filter employs centrifugal force to eliminate dirt from the lube oil.

They have the capacity of producing over 2000 newton force, that is greater than gravity.

Also, they can remove the tiniest contaminants from the lube oil.

What are the Benefits of having a Clean Lube Oil in the System?

The benefits include:

- A reduction in tear and wear of moving parts.

- Increase in the durability of the engine.

- Low maintenance costs.

- Clean environment.

- Improvement in the performance of engines.

Where do Lube oil Contaminants Come From?

These sources include:

Internal Sources

Condensation in engines can introduce moisture in the lube oil.

External Sources

Water blasting at high pressures, washing, etc. May introduce moisture in the engine system.

Leaking Coolers

When this part leaks, it may introduce water in lube oil.

Air Vent

This component may allow the entry of particles, dirt, and water to enter the engine and contaminate the lube oil.

Rust and Corrosion

Metals will start to rust and corrode when it gets into contact with water.

As it corrodes, the dirt may enter and contaminate the lube oil.

Oxidation

Oxidation may cause water to form.

Also, high temperatures and dirty oil cause the formation of acids, water, and resins.

How Can You Maintain a Lube Oil Filter?

Maintaining this filter ensures that it operates optimally and lasts for a long duration.

Conduct regular inspections to ensure there are no clogs.

Make sure the engine is in good working condition and does not introduce contaminants in the lube oil during operation.

Backwashing can assist in cleaning out any contaminants that may clog the system.

Ensure the valves are working properly to minimize dirty oil from mixing with clean oil.

Install the lube oil filter properly to ensure it filters oil efficiently.

Ensure the filter housing has no damages that will negatively impact the filtration process.

Always use clean and not dirty lube oil in the system when replenishing.

Use a suitable and recommendable filter for your engine to enhance the filtration process.

What Features Make up a Good Lube Oil Filter?

These include:

Holding Capacity

This is the ability of the filter to hold contaminants with no replacement.

The media type and the design of the filter will influence its capacity.

A large capacity means the filter will last for a long time while under operation.

When the filter reaches its capacity, it begins to release unfiltered lube oil into the system via the dump valve.

Ease of Use

Lube oil filters come in varying shapes and sizes.

Make sure you select a filter that will fit your engine.

Filtration Media

Lube oil filters have a material that assists in filtering lube oil and it can be synthetic, cellulose, or a combination of both.

Synthetic material originates from polyester, nylon, or glass, and offers the best filtration rate as it has tight-knit fibers.

This means it can remove even the tiniest dirt.

Cellulose has a low quality to it and it also cheap than synthetic media.

When you combine these media materials, you achieve the best deal in terms of cost and efficiency.

Housing Design

Different lube oil filters come with their specifications as per the manufacturer.

The weight and configuration of the housing will determine if you can install it.

Make sure the specifications of the lube oil filter match the requirements of your engine.

What are Some Lube Oil Filtration Techniques?

A lube oil filtration process is necessary to maintain the oil at its optimum level.

An excellent lube oil filter guarantees that the oil stays free from impurity and executes its tasks effectively.

Thus, there are at least 3 approaches that you can filter lube oil with:

Full Flow Filtration

In this technique, you will filter out all the lube oil before it enters the engine.

Bypass Filtration

This is where you will filter a specific amount of lube oil better than that of a full flow lube oil filtration technique.

After that, you will move it back inside the oil sump.

Combination Filtration

Here, you will utilize both full flow and bypass techniques in the filter.

What is Beta Rating and Beta Stability?

Beta rating is the ratio of the number of particles before filtration to those after filtration.

This means that a higher beta ratio means the lube oil filter has high efficiency of capturing particles.

Besides, this information is vital when it comes to selecting a lube oil filter.

It will indicate the filter’s efficiency to capture contaminants of varying sizes.

Beta rating originates from a Multipass Method for Evaluating Filtration Performance on Fin Filter Element [ISO 16889:1999].

Beta stability will measure how you can repeat the beta ratio of a lube oil filter under extreme conditions at pressure drops.

What ISO Standards Should a Lube Oil Filter Conform To?

Manufacturers should conduct proprietary and ISO 16889:1999 tests.

Also, other ISO standards it should conform to include:

ISO 2941

This will verify the burst and collapse pressure ratings.

ISO 2942

This is for verifying the fabrication integrity.

ISO 2943

It determines the compatibility of the fluid material.

ISO 3723

This will test the end load technique.

ISO 3724

It determines the resistance to flow fatigue when you using contaminants from solid oil.

ISO 3968

This will assess the differential pressure on all lube oil filter elements versus their flow characteristics.

What is the Function of Pressure Relief Valves in Lube Oil Filters?

This is a device that encourages the oil to circumvent the filter when dealing with a restricting flow.

It would also help to supply the engine with lube oil.

Filter bypass occurs when the filter clogs or the oil hardens due to cold temperatures.

A pressure relief valve is a standard part of oil filters.

Excess oil that drains from filters has an anti-drain-back valve that contains oil within the filter when the engine shuts down.

This occurs to minimize delays in the oil pressure from building up once you restart the engine.

If you lack an anti-drain-back, pressurized oil has to pre-fill the filter then goes towards the engine.

This scenario can cause moving components to wear and tear rapidly due to friction.

Do You Require a Special Lube Oil Filter for Synthetic Oil?

Confirm with your engine first as modern lube oil filters can clean all types of oil.

Major manufacturers do not necessitate the use of special lube oil filters for synthetic oil.

This is because good lube oil filters are better at eliminating contaminants.

What are the Advantages of Using a Synthetic Lube Oil System?

These include:

- Increase in durability.

- A high engine efficiency

- Better capacity

How Do You Compare Inline and Off Line Systems?

inline oil filter

One will install an in line system after the system pump to protect the sensitive parts from contamination.

Off line systems are suitable for external filtration.

They were usually applicable when you need filtration or before using fresh oil in the system.

How do You Compare Synthetic and Conventional Lube Oil Filters?

Synthetic lube oil is better than conventional lube oil filters.

It offers high performance and protection than conventional oil filters.

Besides, conventional oil uses less-refined base oils than synthetic oil.

Thus conventional oil has less chemical stability, oxidizes easily, and loses the protective qualities rapidly.

When Should You Apply a Premium High-Capture Efficiency Lube Oil Filter?

The applications include:

- Luxury car engines

- Suitable for low viscosity oil.

- Towing services.

- High-performance driving I.e. motorsports.

- High-performance engines.

- Extreme cold starts.

- Long engine life.

Is it Necessary to Pre-Fill a Lube Oil Filter Prior to Installation?

When you pre-fill, the engine will not start dry.

This will provide the engine with adequate lubrication as it builds up the oil pressure.

Are there Trends that Influence Lube Oil Filter Technology?

One trend is internal combustion engines that provide suitable consumption and emission standards as others are still in development.

What Types of Filtration Systems Exist in the Market?

They include:

Magnets

Here, the magnets attract and eliminate ferrous contaminants.

Centrifugal Systems

They use spinning bowls to separate water and dirt from oil.

Media-based Filtration

It applies either a full flow or depth filter to filter oil.

Coalescing Systems

It uses a system that attracts water together so that gravity eliminates it.

Vacuum Dehydrators

They are suitable for eliminating emulsified water, or dissolved water.

In short, there are many factors you should consider when choosing lube oil filter systems.

The best part – this guide has outlined all the critical aspects you need to know.

At FilSon Filters, we offer a range of oil filter systems including oil coalescing filter, oil water separator filter and hydraulic oil filters, just to mention a few.

However, if you have any questions or inquiry, feel free to contact us.