Your Hydraulic Oil Filter Supplier

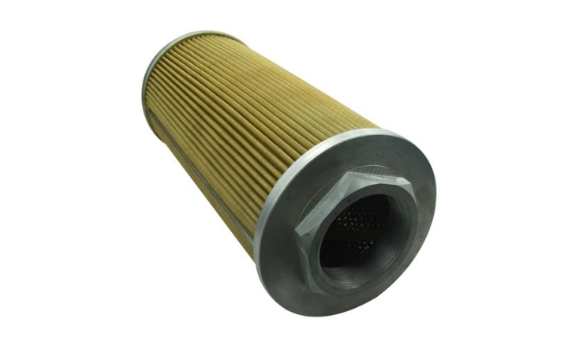

Filson hydraulic oil filter also called hydraulic filter element are ideal for use in hydraulic oil filter housing to protect system components such as valves and hydraulic motors and reduce oil contamination.

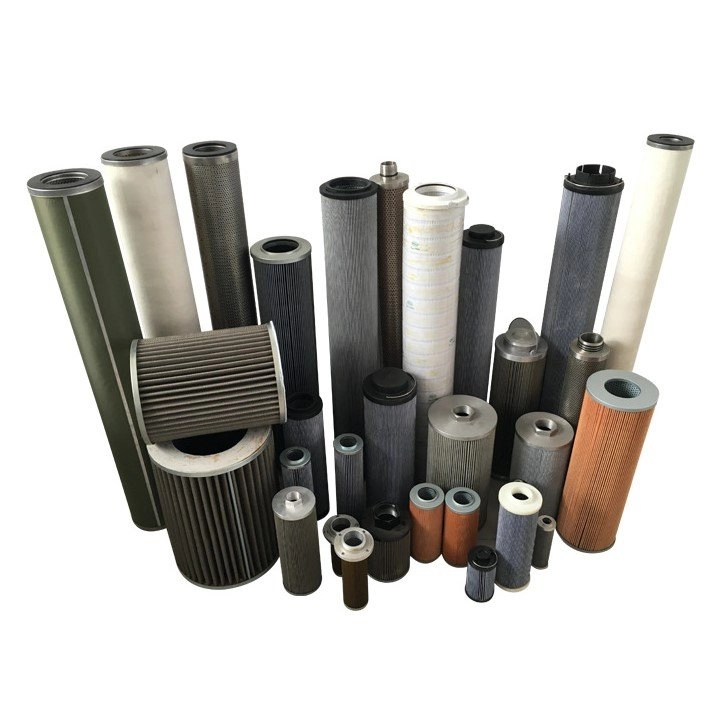

Filson hydraulic oil filter is made with three kinds of filter element material layers, include microglass hydraulic filter elements, paper oil filters, stainless steel hydraulic filter elements. These hydraulic oil filters are available for various construction types.

Filson hydraulic oil filters could achieve removing solid contamination and water in one operation by using a microglass and a water absorption layer. Also, Filson hydraulic oil filter offers consistent filter efficiency, multiple hydraulic filter micron ratings and different flow rate sizes.

- More Details

- Applications

- Test Standards

Filson Hydraulic Filter Elements

Compared to other hydraulic filter element suppliers, Filson hydraulic filter elements contain more pleats and surface area and can reduce overall costs by requiring fewer element changes. When you need to change the original hydraulic oil filter, using a Filson hydraulic filter replacement elements will ensure the same quality and filtration efficiency and protect your strainers.

All Filson hydraulic oil filters can be tested according to ISO Standards in our lab to deliver the best cartridge oil filters for your hydraulic and lubrication systems. For easy hydraulic oil filter elements size selection, you can use our Filter hydraulic oil filters cross reference.

With the Filson’s know-how in hydraulic oil filter industry, we can keep your system contamination-free by being your OEM partner for hydraulic oil filter elements. Whether for standard, custom or special filter design, Filson hydraulic oil filter offers a perfect solution for all markets.

Features of Filson Hydraulic Oil Filter

- High resistance to variable operating pressures and flow rates

- Wide range of micron rating: from 1μm to 500μm

- Improved system reliability and lower maintenance costs

- Customized hydraulic oil filters for specific filtration requests

- More pleats and surface area for a higher dirt-holding capacity

- Consistent filter efficiency to remove particles and water, even at a high differential pressure

- Compatible with a wide range of fluid types, such as mineral oils, emulsions and most synthetic hydraulic oils

Hydraulic Oil Filter Material Layers

Microglass on Hydraulic Oil Filter

- Multi-layer pleated structure made of synthetic microglass fiber

- All microglass hydraulic filter elements are sealed with epoxy adhesives

- Machining end caps for greater elements integrity

- High collapse resistance, even at high Δp

- Deep filtration with wide range of micron rating

- Combines particles and water removal by using microglass and water absorption layers

Paper on Hydraulic Oil Filter

- Single-layer pleated structure made of paper and polyester fiber

- High material stability and strength for flushing operations

- 5, 10, 20 and 40μm micron ratings

- Media packaging fully encapsulated in sealant to eliminate fluid bypass

- Extended surface area for extended life and high flow performance

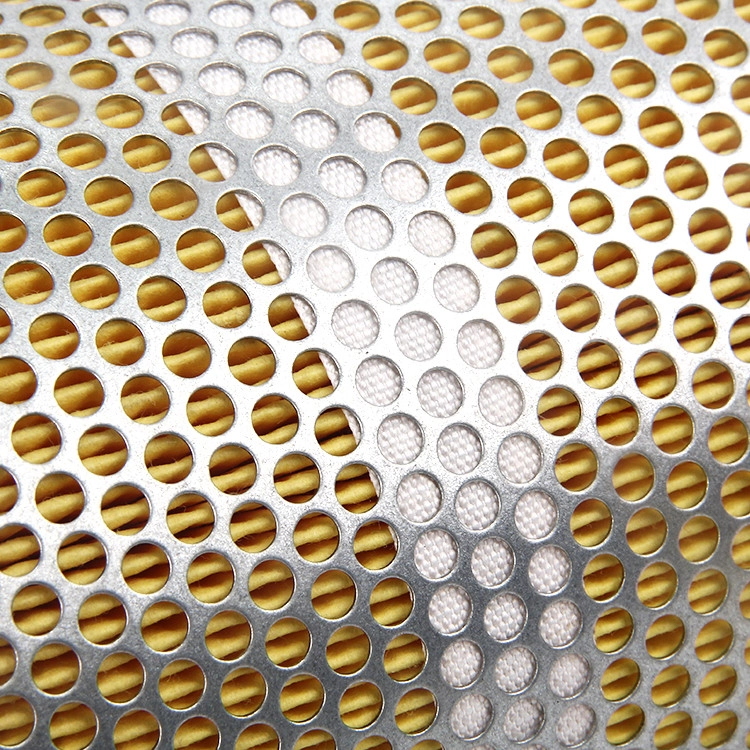

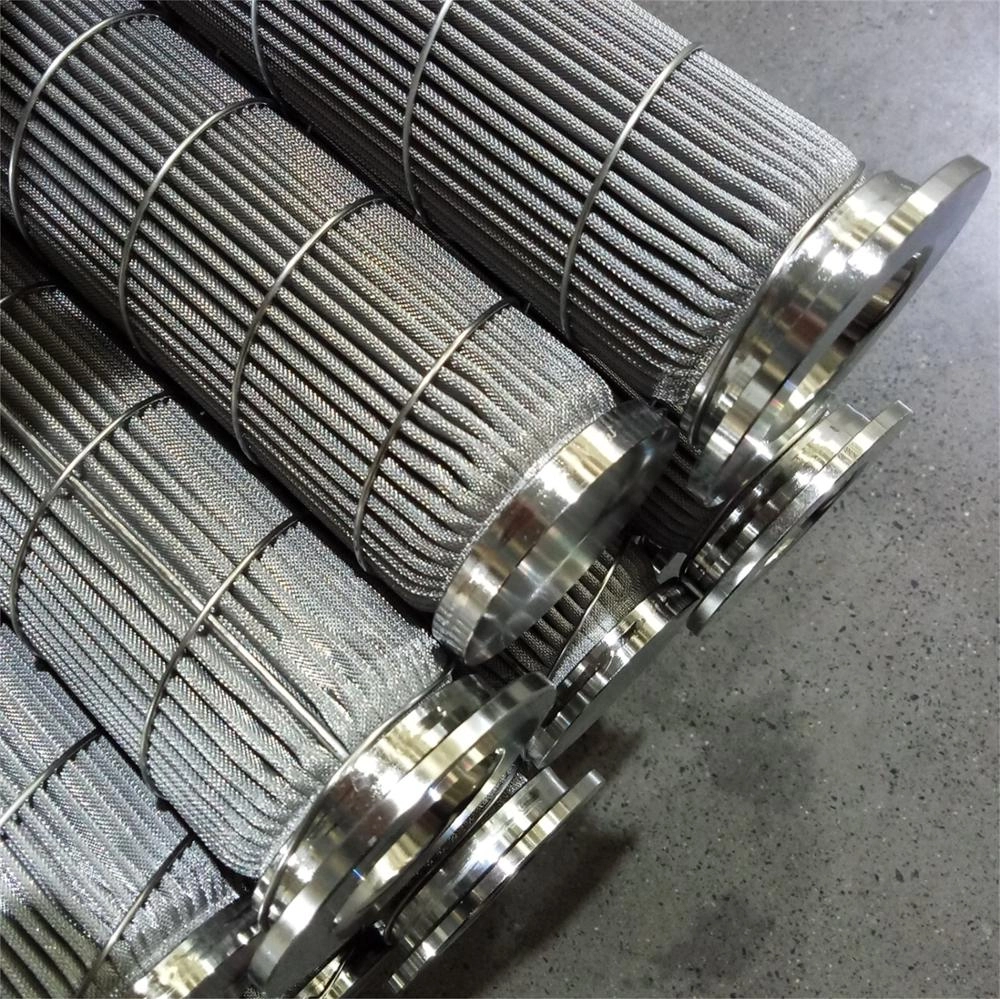

Stainless Steel Wire Mesh

- Single/multilayer pleated structure made of stainless steel wire mesh

- Surface filtration to remove particles and protect pumps

- Available in 25 μm, 40 μm and 80 μm, other micron ratings on request

- High resistance and re-used

- Compatible with heavily contaminated oils

Hydraulic Oil Filter: Definitive Guide for Importers

In today’s guide, I want to walk you through vital aspects about hydraulic oil filters.

And, why should you learn about them?

Because, nearly 77% of hydraulic systems fail due to contamination issues, leave alone the high cost of maintenance.

Therefore, importing high quality and reliable hydraulic filter is the best solution.

To evaluate a hydraulic oil filter, you need to know what it is, working principle, specification and cross reference chart, just to mention a few.

The good news?

I am going to share all that information here with you.

So, let’s dive right in.

Chapter 1: What is a Hydraulic Oil filter?

Basically, hydraulic oil filter is a device containing three types of filter media layers, namely: metal, paper and micro glass elements.

As hydraulic oil passes through the filter, it traps and removes particulate matter.

As a result, it prevents ingress of foreign particles that may cause damage to hydraulic system.

Mesh hydraulic oil filter

According to a study by Damen Technical Agencies, about one million particulates (> 1 µm or 0.001 mm) ingress hydraulic systems.

Also, the cause of fluid power systems failures is by greater extend contributed by excess medium contamination.

Such contamination issues give rise of consistent hydraulic system failures.

Since hydraulic oil is susceptible to contaminate ingression then these particles pose a great danger to pneumatic or hydraulic system components and parts.

So, what should you do?

It’s simple.

Adopt an advanced and effective hydraulic filtration device guarantees long life service for hydraulic components and parts.

You should note that the contamination levels in hydraulic medium determine the adversity of the abrasion on the hydraulic system components.

Further, the presence of metal components (copper and iron) in the system can drastically accelerate its wear down.

With such knowledge, you should plan meticulously to use an appropriate hydraulic oil filter, which remove these harmful debris.

In the process, the oil is kept clean as it circulates in the hydraulic system.

And by the way, even before I continue, here is something some people still don’t get right – the difference between the hydraulic oil and gear oil.

Watch this short video:

https://youtu.be/kIKlHoFMtCk

Now, how would you determine the performance of your hydraulic oil filter?

This is best defined by its contamination removal-efficiency.

For example, different parts of a hydraulic system need an oil filter with specified ratings.

Therefore, components subjected to high contamination section is advisable to use hydraulic oil filter with high dirt-holding capacity and vice versa.

Now, how about we look into the multiple causes of hydraulic fluid contamination.

Below are some of the main causes of hydraulic oil contamination:

- Poor plumbing

- Ingress of contamination from new components or fluid

- Wear of moving components and parts

Let me tell you the truth, most of these causes are inevitable.

And the solution is to find an effective hydraulic filter.

More importantly, you must install the filter where it will protect hydraulic components.

Take for example:

You should install hydraulic filters between actuator and pump.

Here, you need high pressure filters.

Also, the section between tanks and actuators will have return line filters or low pressure filters.

Do not worry about types of hydraulic oil filter as we shall deal with in chapter 4.

It is clear that hydraulic oil filters can enable the system to meet desirable oil cleanliness for the system to run at optimum performance specification.

In this modern era, fluid power systems require better hydraulic control and filtration to extend components life as well as deliver exceptional machine performance.

Therefore, hydraulic components like hydraulic oil filters are designed and built with reliable tolerance which improve their contamination sensitivity.

I can attest without fear of contradiction, that FilSon hydraulic oil filters meet such system demands.

You can put your hydraulic systems under protection of FilSon hydraulic oil filters.

Because they are specially built to absorb a range of contaminants.

Therefore, these hydraulic filters guarantee sturdy system performance and much more.

Chapter 2: Working Principle of Hydraulic Oil Filter

Hydraulic fluid serves a number of purposes in hydraulic systems.

Undoubtedly, its core role is to transfer force to the actuators from the hydraulic power unit.

However, it also does the following:

- To keep the system surface lubricated to avoid friction on metal surface on each other.

- Maintain a conducive temperature by transferring from one end to the other.

- Seals the hydraulic system through adhesion and surface tension.

The truth is:

There is no hydraulic system that can run without a hydraulic oil filter.

Therefore, it will be of greatest importance we understand the working principle of the hydraulic oil filter.

Hydraulic oil filters

Let’s begin the working principle discussion:

First, the hydraulic medium enters via the cartridge’s tube at the bottom where the inlet is situated.

It then passes from the inside to the outside.

In process, it goes through the hydraulic oil filter element and makes an exit at the outlet side.

As the filter element continues to eliminate debris, dirt, etc., there is an equal dirt deposits on the hydraulic filter element.

Consequently, the pressure differential rises across the inlet and outlet of the hydraulic filter media.

The pressure differential is detected by the by-pass piston that is held in place by a spring.

When the hydraulic oil filter requires cleaning, this implies that the pressure differential is much higher that compresses the spring, pushing the spring off its ‘seat’.

The piston movement brings about the sign that the hydraulic oil filter needs cleaning.

Even if you ignore the calls to clean the hydraulic oil filter, still the ‘cleaning’ signal comes on, and pressure differential continues to build-up.

Eventually, this will cause the piston to re-route the medium through a bypass passage.

This deliberate action helps to limit the uptick of the pressure differential to a value same as the spring tension.

The working mechanism of hydraulic oil filter makes an entire hydraulic system function more appropriately.

As you can see, the biggest threat to any hydraulic system is contamination.

And, you must choose an efficient hydraulic filter element that will remove all contaminants.

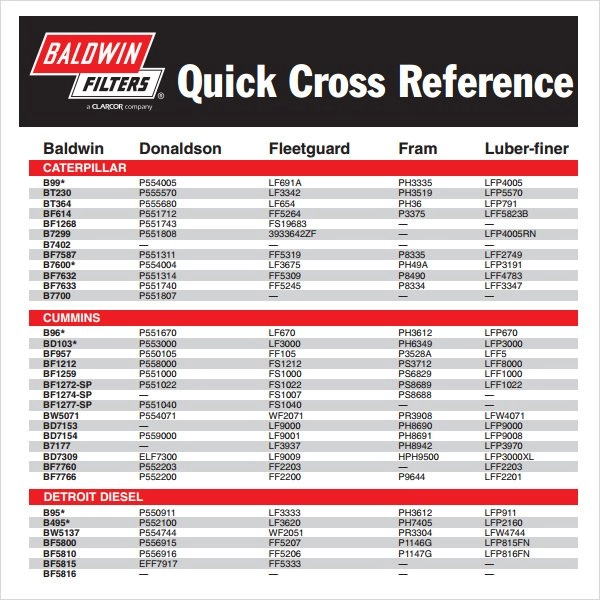

Chapter 3: Hydraulic Oil Filter Cross Reference

Here, you are going to understand why you need hydraulic oil filter cross-reference and how to use this resource to your benefit.

As an owner of hydraulic systems and industrial machineries, it is very important to have access available hydraulic oil filter cross-reference chart.

Section of hydraulic oil filter

Furthermore, this forms a critical and essential resource for your technical staff.

And what kind of information can you find in a hydraulic oil filter cross reference chart?

You should come across the following information about the filter:

- Beta rating

- Type of the filter media

- The filter’s model number

- Filtration efficiency

However, most cross-reference charts come with an elaborate guide to help the user to satisfactorily use it.

For instance, you will get one from FilSon Filters when purchasing hydraulic oil filters.

Today, the leading oil filter manufacturers have tailored a comprehensive information about oil filters to publish a single cross reference chart.

This has given customers unlimited choices of top-notch hydraulic oil filter brands to choose from.

In such hydraulic oil filter cross reference charts, oil filter elements with same specification are clustered under the group.

The best part:

In case of a breakdown, you can use them interchangeably.

Creation of an online oil filter reference has made it possible for anyone with internet access to confirm or search for any hydraulic system parts including hydraulic oil filter.

Cross reference chart – Photo courtesy Baldwin Filters

The hydraulic oil filter cross reference, for a fact, has reduced the bustle and hustle in reading through various manufacturers’ charts.

By a click of the button, you will get a suitable hydraulic oil filter.

Why do You Need Hydraulic Oil Filter Cross Reference?

Here are some of the main reasons why you need this resource:

1. Useful Budgeting Resource

If you happen to have an access to a number of hydraulic oil filter cross-reference charts, it implies that you can compare both prices and brand models at once.

By running parallel comparison between prices and models, you should get an approximation of the market price for various hydraulic oil filter models.

Once satisfied with what the market offers, you can generate your budget estimate for repair and service.

It is also recommended to rely on newer and updated hydraulic oil filter cross-reference charts to match spares for your modern filtration systems.

This is because technologically advanced hydraulic oil filters have far-reaching intrinsic properties as compared to the yesteryear.

2. Helps Technical Team Make Accurate Acquisition Decision

When involved with one or more hydraulic systems, it becomes pretty much necessary to have hydraulic oil filter reference chart.

To make that decisive action, there is need to confirm the model and type of hydraulic oil filter.

It will help you to place an order for a new hydraulic oil filter much faster.

In fact, through this cross-reference chart you can check and choose among readily available brands of unparalleled qualities.

In a nutshell, hydraulic oil filter cross-reference chart has an array of premium choices with other customization offers on request.

3. Access to Hydraulic Oil Filter Information

Hydraulic oil filter cross-reference chart harbors innumerable information that needs you to invest ample time to understand.

This classified information can bring immense difference for your hydraulic filtration needs.

Such useful data are:

- Dirt-holding capacity

- Beta ratings

- Product efficiency

For example, when you settle for a hydraulic filter element with lower dirt-holding capacity, you’ll have to replace or clean it quicker than the previous one.

Also, such hydraulic oil filters can collapse given that they are designed to hold less dirt content within a given period of time.

Different types of hydraulic oil filters

And since you now know about hydraulic oil filter cross-reference, it becomes easier to prioritize important information about the hydraulic filter element.

The hydraulic oil filter cross-reference chart gives alternative information about other brand’s oil filter element that can certainly fit your hydraulic system.

Despite the varying beta rating, a hydraulic oil filter can have an exemplary dirt-holding capacity that may suitably serve your purpose.

Chapter 4: Hydraulic Oil Filter Types

It is vitally essential to protect expensive internal hydraulic and machinery system components from preventable abrasion.

A right choice of hydraulic oil filter can eliminate contaminates, improve system reliability and long part service life.

Typically, hydraulic fluid, filters and the system at large work conveniently to protect these fragile components.

However, with an array of hydraulic oil filter types, it becomes a daunting task to select the right one.

Hydraulic oil filters made from different material

In this chapter, I will walk you through various types of hydraulic oil filters and how they are mostly applied to help you meet system filtration needs.

It is also important to understand that not all hydraulic oil filters would typically same one purpose.

· Suction Filter

Normally, a suction filter precedes a hydraulic pump at the suction port or otherwise submerged in the reservoir mostly attached along the suction line before the pump.

Suction filters are never placed on the suction end as they can damage or fail the pump because of the high pressure differential.

In this case, a rather large filter is preferable to handle huge flow rate and miniaturize larger pressure differential.

This type of filter is designed with a higher micron rating that buffers the pump from harmful hydraulic fluid contaminants that circulates within the medium.

· Pressure Filter

This hydraulic oil filter is located downstream between the exit of the pump and the other hydraulic system components.

It is strategically positioned at the pump’s outlet to protect the fragile and sensitive components such as actuators, valves and instrumentation from contamination emanating from the pump.

The filter media element deployed in such a filter can remove a higher percentage of minute fluid contaminants.

· Return Filter

Return filter may be located either inside the fluid reservoir or in-line (at the control valve).

It is available in different assembly styles.

The location of this filter allows all the system medium to flow through it before directing it to the fluid reservoir.

This type of filter is designed with media material that can trap and remove debris generated from the hydraulic system.

· Pilot Line Pressure Filter

In an elaborate hydraulic system, some sections usually carry extremely sensitive components and only receives a fraction the medium flow.

Pilot line pressure filter is installed at critical system juncture to check properly system medium cleanliness level.

· Off-Line Filter

Other new hydraulic or lube systems are installed with off-line filter systems.

Off-line filter is predominantly self-contained filter system.

It consists of power source (pump-motor) and an array of filtration flexibility to clean hydraulic fluids before circulating in the hydraulic system.

It mainly gets connected to system reservoir.

· Duplex Low Pressure, High Flow Filter

There are hydraulic systems where shutting down for service does not stand a chance like high flow and low-pressure systems.

Hence, they need a duplex low pressure, high flow filter.

This type hydraulic oil filter can handle high viscosity and high flow media.

The duplex low pressure, high flow filter may constitute of up to 22 filter media materials in each vessel.

It extends life of system components.

· Duplex High-Pressure Filter

Use of a single filter assembly means that you are bound to experience downtime when there is a breakdown, service or cleaning the filter media element.

In other applications like in power generation, the condition is highly undesirable.

Therefore, it is prudent to use a duplex high-pressure filter.

Duplex has identical filter housing; one in operation while the other one on standby.

It also has an integral valve occasionally used to divert the medium flow when one needs servicing.

There is no system shutdown experience while using duplex high-pressure filter.

It is wise to note that correct hydraulic oil filter and installation can guarantee years of durable system components as.

Of course, it will also improve system performance.

And more importantly, this guarantees affordable system maintenance since contamination-related failures are contained.

Chapter 5: Hydraulic Oil Filter Specification

In this chapter, I am going to cover various hydraulic oil filter specifications design and materials.

Of course, I will also touch on the cutting-edge technologies in hydraulic oil filters.

A proper hydraulic oil filter choice will ensure efficient and effective hydraulic system.

Besides, it guarantees a sturdy system performance that exceeds optimal specifications.

This is because such specification gives the filter outstanding characteristics.

In particular, great particulate absorbent in fluid power, engine oil, lubrication oil as well as transmission oil systems.

What follows are the various hydraulic oil filter specifications that can help you meet acceptable cleanliness levels for different applications:

1. Stainless Steel Hydraulic Oil Filter

In order to keep up a robust and reliable filtration process, inevitably, you can bank on the efficacy of stainless hydraulic oil filters.

Also, it has been designed with a sound structural integrity that ensures a long service life.

For example, the refined stainless steel micronic material enables the hydraulic oil filter do ultra-filtration accuracy together with sustainable system protection.

Stainless Steel Pleated Filter Cartridge

Product customization put into consideration the following technical details: application environment, layer, mesh and wire-mesh counts.

This is to ultimately meet the filtration requirements for your hydraulic machineries.

· Features

Some of the main features include:

- They have stainless steel-wire cloth-strands woven in a variety of patterns to form nominal as well as absolute filtration ratings.

- It consists of single or multilayer well-pleated structure.

- The woven wire cloth elements make it suitable for hostile applications in severe environments.

- Stainless steel hydraulic oil filters are easily cleanable, therefore, reusable cutting down disposal cost and highly resistant.

- Compatible with an array of fluids.

- Majorly available in 25 µm, 40 µm and 80 µm other micron ratings can still be customized on request.

- Surpasses all ISO tests.

2. Fiber-glass Hydraulic Oil Filter

It is designed using synthetic fiber-glass material.

Fiber-glass hydraulic oil filter is an excellent choice for gases and liquid applications.

It offers essential protections for your hydraulic and machinery systems due to its increased particulate capture efficiency and dirt-holding capacity.

This is attributed by the typically minute and uniform fiber size made with varying qualities in dimensions.

Fiber glass hydraulic filter

Ability to enhance the structural permeability of filter media element makes it safeguard your systems from wear down, increased throughput and reliability.

There are a number of fiber-glass hydraulic oil filter for various specialty configurations: coalescing filter elements, Coreless filter elements, Industrial process filter elements and anti-static filter elements.

Features

The main features include the following:

- Fiber-glass hydraulic oil filter material is designed long to increase filtration surface area and cleaning cycles.

- It is highly versatile being capable to stand high humidity and temperature ranges.

- Fiber-glass hydraulic oil filter media element rigidity plays a great role to its structural integrity and sturdy system performance.

- It conforms with all ISO quality and beta tests.

- Also available in various custom sizes.

- Exceptional collapse resistance despite extreme pressure differential across the oil filter.

- It has a wide range of filter media micron ratings.

3. Cellulose (Paper) Hydraulic Oil Filter

Hydraulic oil filter with cellulose multilayer filter media experience rather low medium flow resistance and possesses relatively high dirt-holding capacity.

Unlike stainless steel and fiber glass oil filter, paper on hydraulic oil filter it is the best in absorbing from hydraulic fluid.

Such paper filter media materials are made from wood pulp and polyester.

Paper oil filter is suitable for applications where it is necessary to remove water from hydraulic oil.

Cellulose hydraulic filter

On the other hand, polyester filters are equally inexpensive as the paper counterpart, however, it has low hygroscopic properties.

This makes it an affordable filter where little or no water removal required.

Newer filters are designed and configured for heavy-duty use.

They are mainly forged from a combination of paper and synthetic media materials.

Whereas the fiber blend improves efficiency and increases dirt-holding capacity, the cellulose effectively draws out water from hydraulic systems.

· Features

Here are some of the main features of cellulose hydraulic filters.

- They are disposal as well as recyclable filter elements.

- The filter media is affordable as compared to other materials.

- Meets the threshold ISO multipass test for various industrial applications.

- Paper hydraulic oil filter is high in capacity and efficiency rated 98% at 40 µm.

- Useful in varied application environments such as air, oil, fuel even in hydraulic systems.

- It can retain oxidation compounds, varnish and oil sludge/resin (about 4 kg of degradation products).

- Excellent in water removal from oil reservoirs.

- Available in a range of micron ratings, i.e. 5, 10, 20 and 40.

- Media properly encapsulated by adhesive sealant to avert medium bypass.

- Appropriate for high flow applications.

- A blend of cellulose and synthetic media materials produces an effective medium for severe environment applications.

At this point, you should be able to determine the type of hydraulic oil filter that best suits your hydraulic filtration requirements.

Chapter 6: How to Change Hydraulic Oil Filter

Hydraulic oil filters are designed with dirt-holding capacity, which once are attained, there is an urgent need for the oil filter element overhaul.

But if changed early before using up the dirt-holding capacity, it becomes a waste of resources.

On the other hand, if you change it due past its capacity, you subject the hydraulic system to the harmful particles flowing within medium since the bypass shall have opened.

In the long run, it becomes a costly affair altogether.

The main point is to change the hydraulic oil filter when all the dirt-holding capacity is used up before the bypass valve goes on.

Continuous monitoring of hydraulic system filter element should keep you posted about the filter condition and performance of the system.

Hydraulic oil filters

Let’s start right away to elaborate on how to change hydraulic oil filter.

· Step 1

It is advisable to make sure the safety of the technician before anything.

Make sure the hydraulic system is off-line, i.e., there is nothing running to avoid oil losses around the filter assembly.

To avoid contamination ingression around the workstation, use a vacuum cleaner to dust out the filter, otherwise use a clean cloth rag to carefully wipe the area.

Never use a solvent because it can contaminate the hydraulic fluid system.

· Step 2

Proceed to vent and drain the hydraulic oil filter assembly before dismounting it.

You may either drain the medium into the system or drain it into a bucket and transfer it to a quarantine tank.

Also, remember to recycle the quarantine oil through an off-line filter cart to remove the fluid contaminants.

Afterwards, make sure you take a sample for testing to find out whether it meet the set cleanliness level and necessary application requirements like viscosity, additive packages.

If the hydraulic oil meets the specification still use the off-line filter cart to inject it back into the system.

· Step 3

If you take off the lid of the filter assembly, do not drop it on the floor.

Place it on a clean lint-free cloth rag and another one on top to avoid exposure to contaminants.

Remove the used up filter element and place it aside.

Perhaps, you should wear a new pair gloves when handling the new hydraulic oil filter element.

Unpack the hydraulic filter element from its carton, however, access it from the bottom and keep the element wrapped to avoid environmental contamination ingression.

Adhering to such details will greatly extend the life of the element.

This is because most severe contaminants cannot be seen through the “naked eyes”.

· Step 4

Now, may be the right moment to set the new element in place.

It should be an easy exercise if the assembly is accessible from the top.

Gently guide the filter to slide down to seat at the base of the assembly housing using the wrappings or clean gloves.

This should lower contamination cause during the overhaul.

Make sure you check out the bowl or lid for defect, otherwise opt to use a new one to avoid system contamination ingression.

Now return the filter assembly cover gasket to re-seal the hydraulic system.

· Step 5

Use compressor air to purge around the assembly before bringing it back on-line.

Voila!

You are through with oil filter element changeover procedure.

It’s that simple.

Chapter 7: Industrial Applications of Hydraulic Oil Filters

In chapter 2, you saw why hydraulic oil filters have proven beyond reasonable doubt that they effectively trap and remove hydraulic fluid contaminates.

This in turn oils filter improves optimal performance, tames down the cost of repair and maintenance.

In addition, they reduce system downtime and extend service life for system components.

In this second last chapter, you are going to cover industrial applications of hydraulic oil filters.

Since hydraulic oil filters are used in vast industrial applications, we shall look at an industry at a time.

Hydraulic oil filter

Let’s get right to the main subject of this section:

· Oil and Gas

Hydraulic oil filters have built a reputation for oil and gas industry, helping instrumentation technicians and engineers carry on robust filtration.

A profound research and development has resulted to specialization of in instrumentation filters that can as well as analyze the medium quality.

Furthermore, instrumentation filters are available in an array of specification for instance, sizes and pressure ratings.

Dynamism of industrial processes allow for hydraulic oil filter customization to meet varying filtration demands.

· Factory Equipment

Hydraulic oil filters are best for fluid sample analyzing in most filtration systems.

This is because they can coalesce, trap particulate etc.

Factory machines together with complete lines of production rely on hydraulic oil filters to stop oil contaminates from causing irreversible damage to factory equipment.

· Marine

Marine hydraulic and machinery systems are installed with hydraulic oil filter to improve the engine performance and reliability.

The huge fuel and oil reservoir of ships are built with advanced and efficient filtration mechanism that have been conveniently installed with hydraulic oil filters.

This is to make sure that engines and hydraulic systems are supplied with clean fuel and oil that has no sludge and system contamination ingestion.

These oil filters continuously and vigorously filter out oil and fuel impurities.

It thus, enables ferries and ships to reliable do their transportation schedule with no downtime.

· Off-Shore Drilling

Industrial hydraulic oil filters are used to protect offshore rigs during oil drilling.

Most drilling equipment utilizes hydraulic machines that must run at optimum performance specification.

To avoid debris, dirt and other fluid particulates from unnecessary hydraulic system breakdown, they fit hydraulic oil filters.

· Power Generation

Fossil power generation industry is one industry that uses hydraulic oil filter to remove particles ingested in the hydraulic circuit of operations.

Before entry into the reservoir, return line filters are installed to remove particles of medium flow.

This avoids reintroduction of impurities into the system reservoir.

· Petrochemical Industry

Hydraulic oil filters are also playing very important roles in the petrochemical processing industry as they are specially installed just after the pump.

Pressure oil filter designs are more robust to accommodate the immense full-system pressure.

The petrochemical processing plants have fragile and sensitive components, instrumentation and parts like proportional valves, meters, gauges, low pressure filters, etc.

Using hydraulic pressure oil filters provides adequate protection for such equipment.

Therefore, there is no situation where contamination will cause hydraulic system failure.

· Industrial Vehicles

Hydraulic oil filters serve as a ‘kidney loop ‘ in industrial vehicles like bulldozers, excavators, tractors and many more.

As the engine runs, lube and oil systems circulate medium from reservoirs of hydraulic oil filters.

The purpose of the filtration is to refine the medium and avoid contaminated fluid from reaching the engine and machine moving parts.

After using up the dirt-holding capacity the filter is changed.

Chapter 8: Hydraulic Oil Filter Housing Assembly

Having a right hydraulic oil filter housing assembly is also an important aspect to check on while making a purchase order.

You may have excellent filter media choices that excel in a number of applications, however the housing assembly must also be for the environment.

Now, whenever you want to buy a new hydraulic filter housing, first ask yourself these simple questions:

What important configuration should my hydraulic oil filter bear?

The housing assembly must meet integrity tests and regulatory compliance.

On the other hand, it should not hugely inflate the price of hydraulic oil filter or no hassle for customization.

Hydraulic filter

What is the right size of hydraulic oil filter housing?

There are various flexible hydraulic oil filter housing assembly options, such as drain locations, steam jackets and special vent.

However, biopharmaceutical, biotech, food & beverage and pharmaceutical industries, housing assembly should meet the set stringent requirements.

It is essential to understand your hydraulic system environment and special requirements.

Make sure you confirm that the hydraulic oil filter housing assembly is made to meet critical features and match premium product standards.

The following are three lines of the housing assembly:

A. ASME rated vessels;

B. Industrial; and

C. Sanitary.

Basically, these units are designed and made from 316L stainless steel.

For sanitary ones, both the exterior and interior surfaces are expertly electro-polished.

The hydraulic oil filter housing assembly must meet ASME and ISO 9001 standards.

All the housing assemblies are designed with ease of cleanability with little obstruction to medium flow.

And, let me tell you one thing:

There is an ever-increasing demand for exceptional filter cartridge, but most people fail to recognize the integrity and construction of filter housing assembly.

You should understand that without proper housing assemblies, the filter element is useless.

What material should my filter housing be made of?

The best filter element must have:

- An enclosure that does not allow the medium to bypass it

- No external leaks

- Chemically and mechanically compatible with the application environments

- Withstand maximum pressure and temperature.

Quality hydraulic filtration processes need a quality filter cartridge as well as quality housing assembly.

A housing assembly that is up to scratch make quality its primary goal.

As much as you will focus on quality, also pay attention to other housing assemblies that offer an economical alternative, particularly, for less critical filtration applications.

Conclusion

At this point, I know you’re now enlightened about the fundamental aspects of hydraulic oil filter you should look for.

From the working principle, best material, replacement to choosing the right housing for the hydraulic oil filter.

The truth is:

With this information, you can prevent possible contaminations that can lead to hydraulic system failure.

Now it’s your turn.

Do you have questions or inquires about hydraulic oil filters?

Well, you can leave a quick comment or contact us for free consultations.

Further Sources

Applications of Filson

- Mobile hydraulics

- Factory equipment

- Power generation

- Agriculture and construction

- Material handling

- Wind

- Oil and gas

- Mobile hydraulics

- Factory equipment

- Power generation

- Agriculture and construction

- Material handling

- Wind

- Oil and gas

Filson hydraulic oil filters are tested according to ISO Standards:

- ISO 2941 Verification of collapse/burst pressure rating

- ISO 2942 Verification of fabrication integrity

- ISO 2943 Verification of material compatibility with fluids

- ISO 3723 Method for end load test

- ISO 3724 Determination of resistance to flow fatigue using particulate contaminant

- ISO 3968 Evaluation of pressure drop versus flow characteristics

- ISO 16889 Multi-pass method for evaluating filtration performance