Your Extraordinary Stainless Steel Filter Cartridge Solution

Filson stainless steel filter cartridges are available in multiple shapes such as cylindrical, candle, pleated, basket to adapt to different installation spaces. In addition, upon your accuracy requirement, you can pick the most suitable filter cartridge from wedge wire(-, pleated sintered filter cartridges, which are all offered by Filson.

Filson engineer team is always here to help you choose the perfectly matched stainless steel filter cartridge based on your filtration accuracy/temperature/pressure/flow rate, etc. After you receive the filters, we will also keep providing technical support to ensure their better operation.

Stainless Steel Filter Cartridge

Why select Filson Stainless Steel Filter Cartridge?

Since 2003, Filson has been cooperating with chemical plants, water treatment plants, and food plants by providing CE, ISO 9001 qualified stainless steel filter cartridges.

Filson adopts high-grade stainless steel material to supply premium SS filter cartridges. Before leaving the factory, each cartridge must be experienced a series of rigorous quality tests like bubble point tests to ensure specified pore size and reliable filtration effect.

Meanwhile, with our mature production line and ample inventory, we can guarantee a quick delivery time within 2-3 weeks.

- Gallery

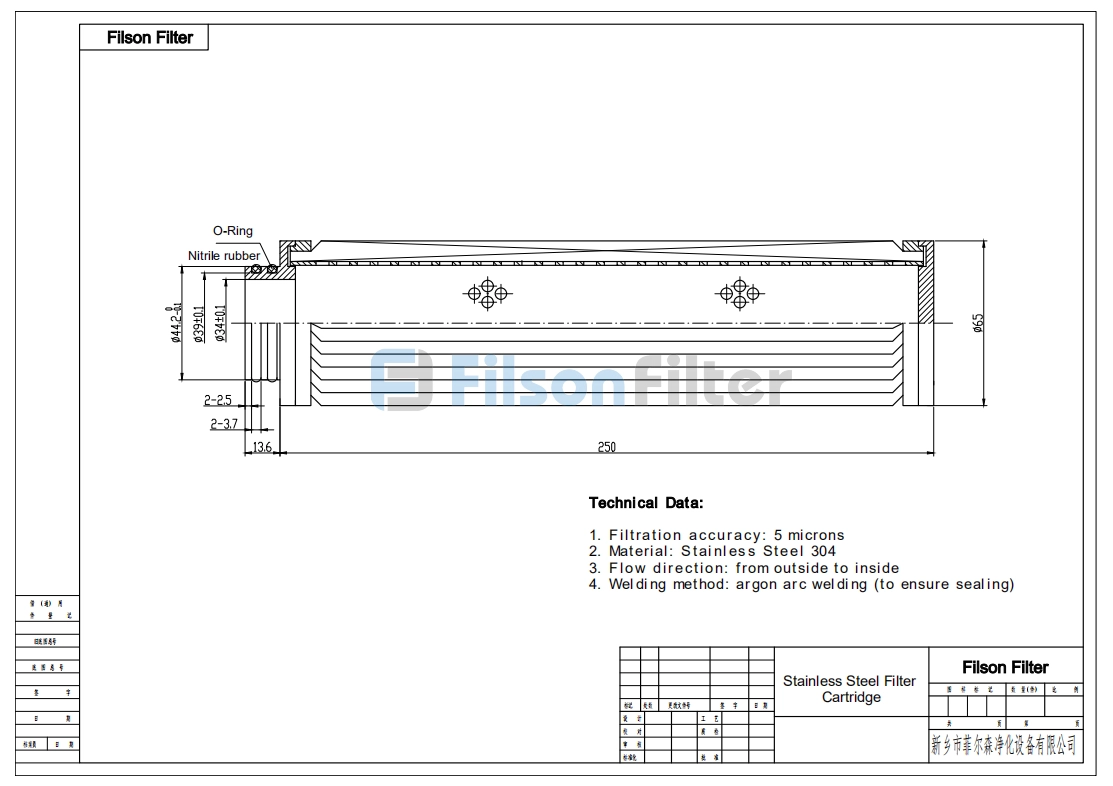

- Drawing

- Features

- Specifications

- Applications

- High differential pressure capacity up to 60 psid

- Customizable micron ratings range from 0.2 to 2000

- Washable and reusable for overall costs reduction

- Stable pore size for consistent filtration accuracy

- Large dirt holding capacity for less cleaning needs

- OEM service to meet your specific requirements

- Superior particle removal efficiency up to 99.9%

- Raw material: SS 304, SS 316L…

- Micron rate: 0.2-2000

- Operating temperature: Max. 500°F

- Differential pressure: Max. 60 psid

- Shape: disc, tube, cylinder, candle, basket, pleated…

- End cap model: flat gasket, fin, 222/flat, 226/flat, 1 in .NPTM, 1 in. NPTF

- Water Treatment

- Petrochemical&chemical Filtration

- Seawater Desalination

- Gas-liquid separation

- Fuel and hydraulic oil filtration

- Power generation

- Analytical equipment

- Polymer Filtration

- Cross-flow filtration

Filson: An Irreplaceable Stainless Steel Filter Cartridge Supplier Focused on Quality

Filson stainless steel filter cartridge, also called stainless steel micron filter, is generally made of SS 304 or SS 316L material, showing high temperature and rust resistance. It is your optimal solution for liquids and gases filtration with efficient particle removal capability.

Filson stainless steel filter cartridges contains numerous types: cylindrical stainless steel filter, stainless steel filter basket, stainless steel filter disc. Moreover, they could be made from stainless steel wire mesh, sintered stainless steel wire mesh, stainless steel sintered powder for different performance.

You can apply all Filson stainless steel micron filters for gas or liquid filtration with eminent rust resistance from SS304 or SS316L material. Even for purifying chemical fluids like acid and alkali, Filson stainless steel filter cartridge is competent since the extraordinary anti-corrosion ability.

Filson stainless steel mesh filter cartridge offers high particle removal rate up to 99% and high heat resistance within 260°C. Further, the updated sintered SS filter cartridge is selectable to fulfil your higher temperature and applications.

Filson stainless steel filter baskets are mainly used in pre-filtration process(5-2000μm), while stainless steel candle filter performs better in finer fluid filtration down to 0.2μm. Meanwhile, Filson stainless steel micron filter provides an effectively filtration whether in fine, medium or coarse filtration based on widely micron rating ranging from 2 to 840 microns.

Filson stainless steel mesh filter cartridge is more suitable for high flow filtration since higher filtration surface and larger dirt holding capacity with more pleats. It is widely used to replace traditional PP high flow water filter cartridge, helps you to save overall costs by reusable&cleanable property and more environment friendly.

For instance, each 10” of a 2.75” OD cylindrical Filson stainless steel mesh filter cartridge permits filtration area about 0.55ft2, however, Filson pleated stainless steel filter cartridge with same diameter allows 1.7ft2 per 10” cartridge.

After a period of using, you may need to clean your stainless steel filter cartridges for longer service time. There are 3 kinds of optional cleaning methods like ultrasonic cleaning, chemical solution immersion, or back flushing to assist you washing it easily. It may retain original filtration accuracy with 90% efficiency after cleaning.

To enable your quicker and easier installation, Filson provides SOE and DOE treatment with optional end caps: 222, 226, fin, flat, gasket, for your stainless steel filter cartridges. And for highly pressured working environment, Filson can fabricate frame protector, spiral wound outer ring or added perforated layer for your extra working pressure needs.

Filson certainly offers OEM service once you need, you can order different sizes, materials, fitting types… Besides, a free sample is also available for the convenience of your quality check, and we are always looking forward to a sincere cooperation with you.

Want to know more information about stainless steel filter cartridge? Please don’t hesitate to contact us at sales@filsonfilters.com or call +86 157 3695 8886!

Stainless Steel Filter Cartridge: The Complete Guide

Are you tired of using a filter cartridge that will require continuous maintenance every now and then?

Maybe, you are of the idea that there are very few filters that can help you work out your filtering issue.

Why don’t you take a tour into the world of stainless steel filter cartridges and see a huge difference?

- What is Stainless Steel Filter Cartridge?

- Stainless Steel Filter Cartridge Features

- Advantages of Stainless Steel Filter Cartridge

- Types of Stainless Steel Filter Cartridge

- How to Clean Stainless Steel Filter Cartridge

- Replacing Stainless Steel Filter Cartridge

- Applications of the Stainless Steel Filter Cartridge

- FilSon Filters Stainless Steel Filter Cartridge Solution

- Conclusion

https://youtu.be/Sty1Lo_ns6M

What is Stainless Steel Filter Cartridge?

A stainless steel filter cartridge in simple terms is a filter cartridge with stainless steel as the main material.

Stainless steel filter cartridge

The simple definition might be a little bit too short and might not drive the point home.

I will, therefore, break it down into simple parts and explain every component differently.

Physical filtration involves the removal of physical impurities that contaminate the purity of water and other fluids.

It involves the use of a filter which blocks further movement of the solid impurities as the fluid passes through.

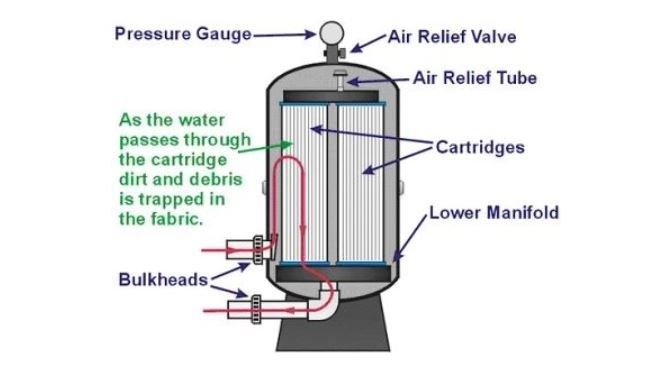

A filter cartridge is a type of a filter that has a housing to protect it from physical damage and other external factors.

Working of filter cartridge – Source: Clean Pool and Spa

A stainless steel filter cartridge is a filter with a stainless material as the main material for the filter.

You can use a stainless steel filter cartridge to remove impurities such as physical impurities and chemical impurities as well.

The filter cartridge may be from different types of materials but the main material is polypropylene and stainless steel.

The working principle of a stainless steel filter cartridge is similar to the other types of cartridges.

Generally, a cartridge will block or trap the impurities in the fluid as the fluid flows through.

The filter manufacturer produces different filters with different micron rating for different applications.

The stainless steel filter cartridge filters industrial fluids such as oil, syrup, liquor, sugary fluids, fruit juices, and alcoholic products.

The stainless steel filter cartridge has very small micron ratings that can filter sediments such as yeast sediments, and bacterial sediments.

There are different designs of the product that is able to filter fluids at high temperatures with a lot of efficiencies.

The stainless steel is available in different micron ratings which include:

i. 5 microns for fine filtrations

ii. 10 microns responsible for medium filtrations

iii. 50 microns which are responsible for pre-filtration as it traps larger particles of the sediments.

The design of the filter is supposed to target certain industries that deal with applications that would destroy the polypropylene.

Such applications include:

i. Applications that involve fluids at very high temperatures

ii. Applications that deal with chemicals that can react with polypropylene

iii. Applications with fluids flowing at very high pressure

Filter Cartridge

The stainless steel filter cartridge will offer resistance to the high pressure, temperature and corrosion of the chemicals.

The stainless steel material can either be SS 304, SS 316 L or SS 316.

To increase the area of filtration, the elements can either be cylindrical or plain.

The stainless steel filter cartridge possesses coarse filtration media that will ensure minimal damage to the main filtration media.

Manufacturers perform a bubble point test which ensures that all the pore openings are of similar size.

It does not allow migration off media and you can easily backwash and reuse the stainless steel filter cartridge.

Stainless Steel Filter Cartridge Features

The stainless steel filter cartridge is available in different features and sizes depending on the application.

The different features and designs of the stainless steel filter cartridge allow it to perform the different functions.

Some of the main features of the stainless steel filter cartridge are in the following paragraphs.

The features of the stainless steel filter cartridge assist in improving the quality of the device.

They are the components that make the device corrosion resistant, with very little maintenance for longer life.

Stainless steel filter

It, therefore, means that the features of the stainless steel increase the durability of the device.

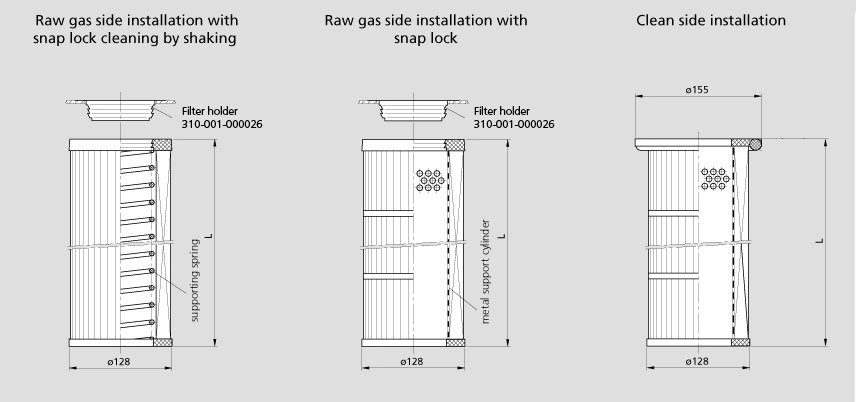

· Design – Plain or Pleated

Manufacturers have two main designs of the stainless steel filter cartridge which can either be pleated or plain.

The difference in the two is basically on the mode of application for different industries and composition.

The plain design provides a sleeve of filter media in support of a central core.

Apart from that, the plain design has a sintered wire mesh with five layers sintered in a vacuum.

The filter ratings range from 0.5 to 200 microns making it among the finest micron filters.

It has very good permeability, easy to clean, high strength, resistance to corrosion and a guarantee to last longer.

The pleated design of the stainless steel filter cartridge will use a pleated media in support of a central core.

Stainless steel filter cartridge

It is, therefore, able to provide twice the efficiency of the cylindrical stainless steel filter cartridge.

The method of construction in both designs rely on the ultra-clean, modern plasma and TiG welding systems.

The construction method will guarantee the integrity of the cartridge as it eliminates bypass risks.

It also eliminates the presence of the extractables that is available in any of the bonding agents.

· Material type

The main material that many manufacturers use in making the stainless steel filter cartridge is stainless steel.

It is the material of choice in many of the devices because it is durable and able to withstand high temperature.

It is also an important material of choice due to the strength as it can withstand very high pressure.

Stainless steel is a combination of many different types of metal making up a wide range of steel resistant to corrosion.

It basically consists of 11% chromium, which you can change to add nickel, titanium, molybdenum, and niobium.

The addition of these substances will change the physical and chemical properties of steel this the name stainless steel.

The results of combining different types of metal give stainless steel of different grades.

Manufacturers choose to use the stainless steel 304 or 316 grade in making the filter cartridge.

Different designs of stainless steel cartridge filter

The general grades of stainless steel are in five main groups which include:

i. Ferritic stainless steels

ii. Austenitic stainless steel

iii. Martensitic stainless steel

iv. Duplex stainless steel

v. Precipitation hardening grades.

Specifications such as mechanical properties, grade composition, and production specifications are under the government of different national and international standards.

These classifications are the reasons why you find certain grade with the three code digit such as 304 and 316.

The three-digit code is the AISI numbering system which is still in use even though it is old.

Super Duplex stainless steel is a mixture of the ferrite and austenite in equal measures.

The resulting steel is superior to the features of the ferrite and the austenite steel.

The most significant difference is in the composition where super duplex steel has more chromium and molybdenum.

The high concentration of chromium and molybdenum makes the super duplex steel more resistant to corrosion than other duplex grades.

It is a material of choice because it is cost effective and reliable in chloride environments.

The other properties of the steel are the same with the other types of steel except it has cheaper alloys.

· Length

The length of the stainless steel filter cartridge varies depending on the type of application that you intend to do.

The length of the stainless steel filter cartridge will also depend on the area with which you are measuring.

The length of the stainless steel filter cartridge is in millimeters.

Technical drawing of cartridge filter – Photo courtesy: RB Filter

Nominal length is the measure of the distance from the top of the cartridge to the bottom of the cartridge.

It is usually given in centimeters or inches and it will vary according to the application.

The longer the filter cartridge the more the area available for filtration of the fluid passing through the filter.

· Diameter (inner/outer)

The diameter of the stainless steel filter cartridge is the measure of the widest part of a circle.

It involves measuring the line that passes directly through the center of the circle from one end to another.

There are two main diameters in a stainless steel filter cartridge which include the inner and outer diameter.

Stainless steel cartridge filter with different diameters

Outside diameter is the diameter of the outer part of the stainless steel filter cartridge.

You will measure it in inches or centimeters by measuring the widest part of the stainless steel filter cartridge.

The outside diameter also varies in different types of stainless steel filter cartridges.

The longer the outside diameter of the cartridge, the bigger the cartridge.

Therefore, it means that the cartridge has more surface area for filtering the liquid.

The smaller the diameter the smaller the surface area and the lesser the surface area.

Inside diameter is the distance between the widest part of the hole in the stainless steel filter cartridge.

The inner diameter is the space that the manufacturer leaves after installing the filter cartridge in its place.

You can determine the inner diameter in inches or centimeters but the sizes will vary greatly.

The smaller the inner diameter the bigger the filter cartridge as it covers a wider surface area.

It implies that the wider the surface area the smaller the filter cartridge as it does not cover more space.

· Micron rating

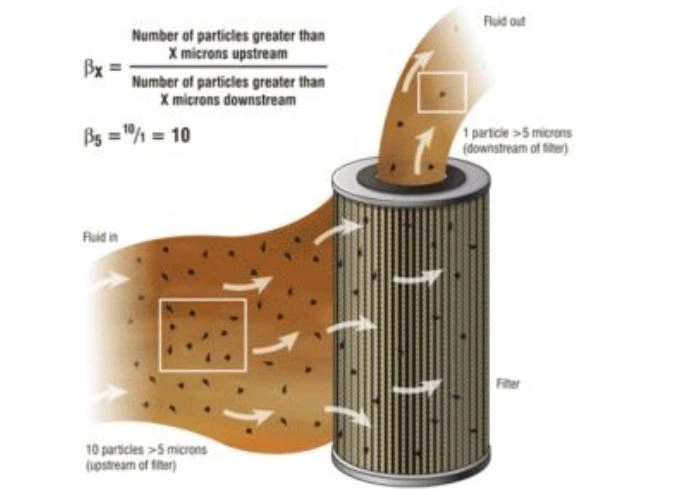

Micron ratings are the representation of the overall size of openings between the pieces of the filter media.

The larger the micron rating of a filter media, the wider the holes meaning 20 microns is wider than 5 microns.

On the same note, the wider the micron rating the more the impurities that will pass through the filter.

Stainless steel filter cartridges have very small micron ratings so that they can trap more impurities.

The smaller the micron rating, the higher the chances of trapping the small impurities that are available in a fluid.

Smaller micron rating of 0.2 to 2 microns is capable of trapping micro-organism such as bacteria.

Filter system

The stainless steel filter cartridge varies in terms of micron ratings and that depends on the application.

Industrial applications that require to filter the smallest of microorganisms will use the filter cartridges with the smallest micro ratings.

The stainless steel filter cartridge will ensure that the fluid that passes through it is pure.

· Sealing configuration

Before you decide on the final seal of the stainless steel filter cartridge, you should know the sealing configuration.

The sealing configuration will guide you in making the necessary measurements before complete sealing.

In many cases, the stainless steel filter cartridge goes through the heat or melting sealing system which is permanent.

In this case, the sealing configuration of the stainless steel filter cartridge should be very strong.

You should have a strong seal or high integrity that will not break under very high pressure and temperature.

It is a process that does not require compromise so it might be costly to achieve strength and beauty of the seal.

In this case, you will have to specify the width of the stainless steel filter cartridge before making the seal.

Stainless steel filter cartridge

It ensures the integrity of the seal and will help in avoiding any form of leakage of the filter.

Wider seals are more important and do not leak but require more force to make thus making it expensive.

· Working pressure and temperature

The stainless steel filter cartridges work under great pressure and very high temperatures.

These are the conditions that determine the type of material manufacturers use in making the fibre.

Filtration process – Source: Machinery and Lubrication

It is therefore important to know the industrial application where you will use the filter cartridge.

Manufacturers make different types of stainless steel filter cartridges using different materials.

They also make the filters that can operate within a given temperature and pressure.

To determine how strong, the material should be, you have to specify the working pressure and temperature.

In the manufacture of normal stainless steel filter cartridges, manufacturers will specify the working temperature and pressure.

They will indicate the maximum temperature where you can operate the filter cartridge comfortably without damages.

They will also indicate the maximum pressure where the filter cartridge can work well without any hitches.

The stainless steel filter cartridges usually undergo a test to determine the conditions which they can work best.

These test will help the manufacturer in rating a particular type of stainless steel filter cartridge.

· Construction Method

Broadly the most common construction methods for stainless steel filter cartridge are the adhesive or welded joint method.

Welded joint method

It involves joining two or more pieces of the stainless steel filter together to make a complete structure.

It involves welding the different parts of the cartridge according to the geometry and dimension.

There are five main types of welding joints which include Tee, butt, corner, lap, and edge.

Stainless steel sintered cartridge filter

Adhesive joint construction method

This construction involves joining the different parts of the stainless steel filter cartridge using an adhesive.

An adhesive can either be glue, mucilage, paste, among others for joining the parts strongly.

The strength of the adhesive bond will depend on the distribution and direction of the stress within the joints due to the load on it.

There are six main types of adhesive joints that you can choose.

They include butt joint, scarf joint, single lap joint, double lap joint, single strap joint and double strap joint.

The typical forces in adhesive joints are compression, tension, shear, bending involving compression plus tension and torsion.

The basic rules to consider when doing adhesive joints are:

i. Cleavage and peeling stress should be very small

ii. Shear stress should be more considerable than tension

iii. Make the area of bonding to be as large as possible

iv. The layer of adhesive thickness should be uniform and on the minimal

The two methods of construction should guarantee a strong bond between the elements put together.

It should be very strong as the stainless steel works under very high temperature and pressure.

To avoid any breakage or destruction, welding the joints is the best methods of constructing the stainless steel filter cartridge.

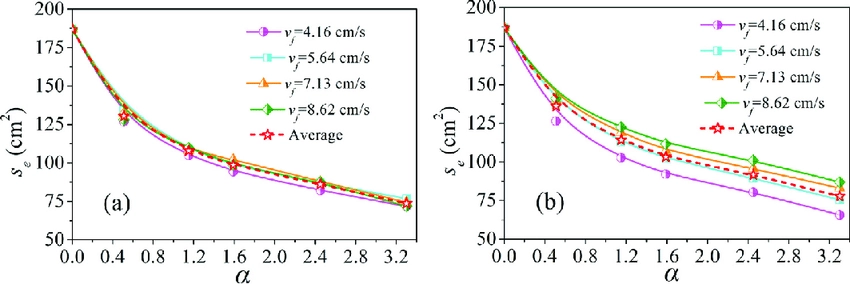

· Effective Filtration Area

Effective filtration area (EFA) is the area of the stainless steel filter cartridge that is available for the purpose of filtration.

A wider or larger filtration area provides a bigger surface area for the filtration of the fluids.

The small filtration areas provide very small effective filtration areas for the fluid that passes through the stainless steel filter cartridge.

Effective filtration area

The rate of flow at a given pressure is also higher when the effective filtration area is wide.

This is the reason why we have the pleated stainless steel filter cartridge that has a wide surface area for filtration.

It provides more room for the fluid to flow through making the filtration area more effective.

In case you want to order for a custom stainless steel filter cartridge, make sure the filtration area is wide.

The wide filtration area will increase the effective filtration area by making the device more reliable.

Stainless steel filter cartridges require a more effective filtration area that is why most of them are big in size.

· End type

Most of the stainless steel filter cartridges have double open ends (DOE) where both ends are open.

There are some that have only one open end which you will identify as the single open end filter cartridge.

There are five main end types of the stainless steel filter cartridge as you are about to discover.

The five main end types of the stainless steel filter cartridges include:

i. Double open end with the grommet type of seal

ii. Single open end with a female NPT connection

iii. Single open end with the grommet type seal

iv. Single open end with the 222 O-ring

v. Single open end with the male NPT connection

End connection types

The end types vary in sizes according to the type of machine that you intend to use it on.

You will make an order for the stainless steel filter cartridge with the right sizes that will fit your machine.

Advantages of Stainless Steel Filter Cartridge

The stainless steel filter cartridge is on high demand from different industries due to its advantages.

Many industries prefer using the stainless steel filter cartridge because it does not require a lot of maintenance.

Some of the major advantages of using the stainless steel filter cartridge include:

i. It is a device that has very high tensile strength thus boosting its resistance to high pressure. Industries that operate using fluid flowing in high pressure use the stainless steel filter cartridge for filtration purposes. Such industries are sure that the device will stay in operation for a long time despite the fluid pressure.

ii. The device remains stable even under very high temperatures that usually destroy other devices. The stainless steel material is able to withstand the high temperatures and remain in operation for a longer time. Other materials are susceptible to expansion under high temperatures but the stainless steel filter cartridge remains stable.

iii. Since the material is stainless steel, it becomes very easy to clean and use again. Cleaning the device will involve removing the impurities and reinstalling it for further operations. The stainless steel material often remains with no stains on it and does not require too much cleansing.

iv. The mechanical strength of the stainless steel filter cartridge is also very high to withstand the high pressure. Mechanical strength can withstand both high temperature and pressure and it will remain in shape throughout the operation.

v. The pleats on the pleated stainless steel filter cartridge increase the surface area of filtration for the gadget. It makes it more durable and you can use it for an extended period before replacing it.

vi. It is available in different sizes and you can use it for a wide range of industrial applications. The different sizes can easily fit in different sizes of the machine. It also provides for different O-ring or gasket options for different applications.

vii. It has a fixed pore structure that will resist the unloading of impurities back to the clean fluid. The absolute rating of the pores will provide consistent, reliable and repeatable filtration of the fluid. It also improves the efficiency of retention providing better filtration of the downstream filters.

viii. Since the material is stainless steel, the device is resistant to corrosion and can last longer. Resistance to corrosion also makes it a proper instrument that does not contaminate the fluids that pass through.

ix. It allows for backflushing of fluids to ensure that there is no fluid that remains in the filter. It also allows the fluid to go through the second face of filtration making it purer.

The advantages of using the stainless steel filter cartridge will save you a lot of money.

Stainless steel housing for filter cartridge

It will save you money that you could be used in continuous maintenance or purchase of replacements.

In simple terms, it is very economical and you can channel the money into other ventures.

Types of Stainless Steel Filter Cartridge

Stainless steel filter cartridges are available in different forms depending on the application and design.

The different types of stainless steel filter cartridges available give you a wide range to choose from.

Filter Cartridge

It also gives value for your money as you are able to get the most efficient device at a fair price.

The most significant types of stainless steel filter cartridges include:

1) Stainless steel mesh filter cartridge

The stainless steel mesh filter cartridge consists of a steel wire mesh of very high quality.

The wire mesh forms under very high-temperature conditions and pressure.

It then goes through a drawing machine that stretches the wire to provision.

The characteristics of the wire mesh include:

i. The structure of the wire is precision and the resulting mesh is uniform

ii. The wire mesh has a very high filtration accuracy and is very strong and resistant to wear

iii. It is also resistant to very high temperatures and can work in applications with high temperatures.

iv. Apart from temperature resistance, it is also resistant to chemicals and acids.

You can use it in the filtration of fluids that have very strong acidic and alkali conditions without damage.

Oil industries use it as the mud filter and sieve strainer in the chemical fibre industries.

In the electroplating industry, you can use the stainless steel mesh filter cartridge for acid pickling.

The main parameters of the stainless steel mesh filter cartridge include:

i. Material – you can find it in different materials such as stainless steel wire, brass wire, nickel wire. The stainless steel material is available in different sizes such as SUS 302, 304, 304L, 316 and 316 L among others.

ii. The mesh which shows the space and density of the wire mesh and has two main divisions. You will describe it as high mesh if it is more than 80 and coarse mesh if it is less than 80.

iii. The diameter of the wire has two main dimensions which are either weft or warp.

iv. It has the common types of weaving which are twill weave, plain weave, Dutch weave, and double wire Dutch weave. Apart from that, you can find more with the mat type twill weave and the five heddle weave.

2) Stainless Steel sintered filter cartridge

The main materials that you will find in a stainless tell filter cartridge are the stainless steel.

The elements of the stainless steel consist of five layers of the 316 mesh.

The layers sinter together and form an element that is fully integrated.

The mesh at the middle is very fine and will be the determinant of the rate of filtration.

Normally, the middle layer has five outer and inner layers of coarse mesh overlaying to give protection and support.

The stainless steel sintered filter cartridges or elements are very important in filtering fluids with heavy contaminations.

It can act as a pre-filter before the fluid finally goes through a disposable filter.

The filter has seals of PTFE, Viton or alloys of copper especially in applications of very high temperatures.

Apart from the five-layer sinter elements filter, you can find the single layer mesh filter element.

The single layer element consists of 316 woven wire mesh and is ideal for low-cost filter applications.

The other option is the sintered powder filter elements which consist of sintered powder 316L materials.

You can make an order to get the supply of this type of element in different lengths and diameters.

Examples of the stainless steel sintered filter cartridge are:

i. AlfaSinter F Sintered Metal Fibre which manufacturers make from metal fibres, with sinter bonds. It forms a uniform filter medium that has uniform porosity and high permeability. It also has low-pressure drops, minimal maintenance, longer life and is very easy to clean.

ii. AlfaSinter P Sintered Metal Powder which manufacturers make from sintered metal powder. It offers robust construction, low permeability, depth filtration, corrosion resistance, and self-supportive thus eliminating the need for more hardware. It is cost-effective, efficient, and you can find it in standard 316L.

iii. AlfaSinter M Metal Mesh which involves wire meshes woven to precision in different weave forms. The main weave forms that you can find are Dutch Twill and plain square mesh for defined absolute rating. It also has plain square weaves for sieving duties that are very simple through different weave patterns.

It has good permeability, high tensile strength, and is available in a simple to complex structures to maximize filtration area. Others are available with diffusion bonds to increase the performance of the pore size and shape. You can find it in 316L stainless steel and is standard with other types of alloys such as 304L stainless steel.

iv. AlfaSinter MC Sintered Metal Composite which manufacturers produce using the process of novel sintering. It comprises many layers, without joining strips, superior shapes, and designs, and is mechanically strong. Is very economical as you can use it more than once after cleaning it.

Apart from that, it comprises of non-shedding media that provides enough resistance in case of mechanical abrasion.

It provides an allowance for manufacturers to design and make custom filters with different dimensions as thickness and flow requirements.

It is resistant to many chemicals and you can use it in temperatures reaching 540 degrees centigrade.

Pleated filters

3) Stainless Steel pleated filter cartridge

The stainless steel pleated filter cartridge has a stainless steel fibre web as the main material.

Apart from that, the material can also be the stainless steel wire mesh.

Some of the designs have the stainless steel sintered fibre web which acts as the multi-pore filter media.

The advantages of using the stainless steel pleated filter cartridge include:

i. The pleats increase the surface area where the fluid flows thus increasing the chances of fluid filtration

ii. It has very high porosity levels due to the presence of the filter elements

iii. It has one of the largest areas for filtering and a huge capacity for holding dirt.

iv. You can clean it properly and reuse it through the process of ultra-cleaning and chemical cleansing

v. It filters the fluids through a range of 3 to 200 microns.

vi. It has a very low initial pressure drop

vii. The material many manufacturers use includes the stainless steel 304, 316 and 316L.

viii. The connection types may vary according to the manufacturer but include DOE, thread and SOE 222/226.

ix. You can use it in different applications such as high molecular polymers, hydraulic oil, hot gas, and water treatment plants.

4) Stainless Steel wedge wire filters

Stainless steel wedge wire filters have filter cartridges with wires in the shape of a wedge.

The elements of the wedge shape are important for different and challenging filtering applications.

In most cases, the features that make it one of the best types of stainless steel filter cartridges are as follows:

i. It has a wide range of the wedge wire screens which has slot widths from 50 microns or 0.05 mm. it also has an open area ranging between 2% to 40% providing filtration and separations solutions for many industries.

ii. It has a continuous slot or aperture which provides a wide area that guarantees low-pressure drops. At this point, it guarantees the user low tendencies to clog or blind.

iii. It has precise slot widths, especially with the looped wedge wires. You can use it in starching of screens in the extraction of corn starch.

iv. Due to the numerous number of welds and wire winding close together, the wedge wire devices are very strong. They are very important and durable stainless steel filters, especially in waste management applications.

v. The triangular wire and continuous aperture section will ensure two contact points for the particles. This helps in the minimization of the risk of clogging and blinding.

The advantages of using the stainless steel wedge wire filters include:

i. It provides optimum strength of the structure for the heavy loads

ii. It has very minimal blinding and plugging

iii. It is capable of withstanding the high pulsating pressure

iv. It is corrosion resistant in comparison to other types of filters

v. You can use it in high-temperature conditions without affecting the structure

vi. It is durable and you can use it for a longer period by just cleaning and reusing.

vii. It allows a very high rate of flow and has low-pressure drops

viii. You can use it in sterile applications such as the food industry.

The stainless steel wedge wire filters offer maximum effectiveness and efficiency in fluid/solid separation.

It is suitable for separation, filtration, and straining of the fluids that pass through it.

You can use it in the pulp and pare, petrochemical, chemical, plastic extraction, coatings, sealant/adhesive filtration among other applications.

5) Stainless steel filter baskets

The stainless steel filter baskets filters are suitable for the filtration of gasses and liquids.

It consists of a filter housing which is either cast iron or stainless steel that contain the stainless steel filter elements.

The shape of the basket differs and you can either find double, single or multiple baskets.

Stainless steel basket filter element

The stainless steel filter baskets were originally very useful in the filtration of cold brew systems.

They are the replacements for the bag filters and have multiple layers of stainless steel in uniform bond.

The diffusion bond increases the strength, resistance to corrosion and the life of the basket.

The one-piece construction of the stainless steel filter basket is very easy to handle as the basket becomes the filter media.

One-piece construction also eliminates the need for a perforated filter basket or bag for the purpose of filtration.

The main features of the stainless steel filter basket include:

i. Manufacturers use the 304 or 316 material for construction of the stainless steel filter baskets.

ii. It has different micron ratings depending on the application but the most common one is 6 microns

iii. It also has a range of absolute microns between 10 and 150 microns

iv. Manufacturers use welding construction to ensure longer life of the basket.

v. It is easy to clean and has configurations for additional end rings that fit the housing of other liquid bags.

vi. You can make a custom design with the help of your manufacturer to fit your needs.

vii. The design of the filter will allow large flows in different industrial applications.

How to Clean Stainless Steel Filter Cartridge

The stainless steel filter cartridge is one of the most durable devices industries use in the filtration of fluids.

The durability of the stainless steel filter cartridge depends on how you clean the device.

There is a wide range of stainless steel filter cartridges available and the cleaning methods may also vary.

In this guide, we will go through the process of cleaning the sintered stainless steel mesh filters.

You can use the process of cleaning the sintered stainless steel mesh in cleaning other types of filter cartridges.

The method of cleaning may, however, vary in some types of stainless steel filter cartridges.

The sintered stainless steel filter cartridge is available in three main forms which include:

i. Sintered mesh filter elements

ii. Sintered felt filter elements

iii. Sintered metal powder filter elements

It is the type of stainless steel filter cartridge that many industries use thus more suitable for cleaning demonstration.

Before cleaning, there are a few elements that you need to take care of and that includes safety.

Make sure you put on protective clothing and gloves to protect you from the dangerous chemical spills.

Apart from that, you need to prepare the following items that will assist you in cleaning:

i. Baking furnace filters on the excess impurities of grease in continuous temperature of 380 degrees centigrade.

ii. The NC ultrasonic machine for cleaning

iii. Spray equipment that you can easily adjust

iv. A cleaning tank where you can heat the filters.

A powerful cleaning agent and a highly efficient water base agent.

It should be free of chloride ions that might cause corrosion of the stainless steel.

The water for cleaning should be deep, and clean under the 5 millimicrons filtration equipment.

The chloride content of the water should be below 20mg per litre of water.

Gas that would assist in blowing the dust through the 5 millimicrons filtering equipment.

After securing all the cleaning equipment, the first step will be checking the differential pressure.

Make sure that the pressure is very low to avoid any accidents that may occur when you dismantle the cartridge.

You should also check the surface of the filter cartridge and ensure everything is okay before removing the filter cartridge.

Put the stainless steel filter cartridge in a nitrogen protection furnace and heat it to a temperature of 380 degrees.

The heating should continue for two hours as it filters out the dirt and the impurities sticking to the cartridge.

Remove the filter and allow it to cool to desired temperatures.

Place the filter in the ultrasonic cleaning slot of the cleaning machine.

The slot should have a strong liquid for cleaning inside and then heat it to 80 degrees for an hour.

In this part, the cavitation on the filter and the cleaning liquid will easily penetrate the filter from every corner.

The dirt will disappear gradually after taking it through these processes.

You can use the hanging piece method of detecting corrosion in the cleaning tank.

In case of any, you will use the cleaning agent to get rid of the corrosion conditions.

You can use the water to rinse the filter cartridge as much as possible to get rid of the residues.

After that blow the filters to dry the water from the cartridge for 20 seconds.

You can also dry the stainless steel wire mesh into the oven at a temperature of 50 degrees Celsius.

To check if there are any impurities on the stainless steel filter cartridge, you can use a magnifying glass.

The magnifying glass should be 30 times more powerful to help in the identification of any impurities.

If you find nothing, then the stainless steel filter cartridge is clean and should be reinstalled.

Replacing Stainless Steel Filter Cartridge

The purpose of a stainless steel filter cartridge is to trap impurities in the fluids that flow through them.

Continuous entrapment of the impurities will increase the burden on the filter cartridge and may slow the efficacy.

The relief to the clogging burden is to remove the stainless steel filter cartridge and clean it properly.

The process of clogging and cleaning can continue up to a point where you cannot clean it anymore.

This process of cleaning is possible but the cartridge may not be as effective as it should be.

The only option you have is to remove the old stainless steel filter cartridge and replace with a new one.

The incidents when you will have to replace the stainless steel filter cartridge are very few.

You will replace it after a long period of use and the efficacy is on a low level.

Apart from that, it is prone to damage and you will need to replace it when some parts are damaged.

The process of replacing the stainless steel filter cartridge is straight forward but you need to be careful.

Make sure that you have the protective gear on to avoid any injuries from the device or its contents.

Apart from that, you will need to gather all the tools that you need to assist you in replacing the cartridge.

Make sure you shut down the whole process so that nothing will come through for filtration during the replacement process.

Look at the pressure gauge and make sure that the pressure is at minimal or shut down completely.

Pressure gauge

Looking at the pressure system will also give you a clue that it is time to replace the filter cartridge.

Using the right appliances, such as a wrench carefully remove the stainless steel filter cartridge from the system.

After that check the adjacent joining parts of the system and see if they are in a good condition.

You can either clean the joining parts or replace them altogether with the filter cartridge.

After that, you can now bring in the new stainless steel filter cartridge and place it at the right point.

The new stainless steel filter cartridge has to be of the same size as the one you are replacing.

It will make everything easy and they will fit into the system easily.

Make sure that the replacement is standard and the system is tight and in the right place.

Check that everything is in order to avoid any accidents that may occur in the future during the process of filtration.

Applications of the Stainless Steel Filter Cartridge

There are many applications where you will use the stainless steel filter cartridge in the filtration of fluids.

Most of the applications are industrial as they involve the high temperature and pressure systems.

You are about to know more about some of the major applications in the following guide.

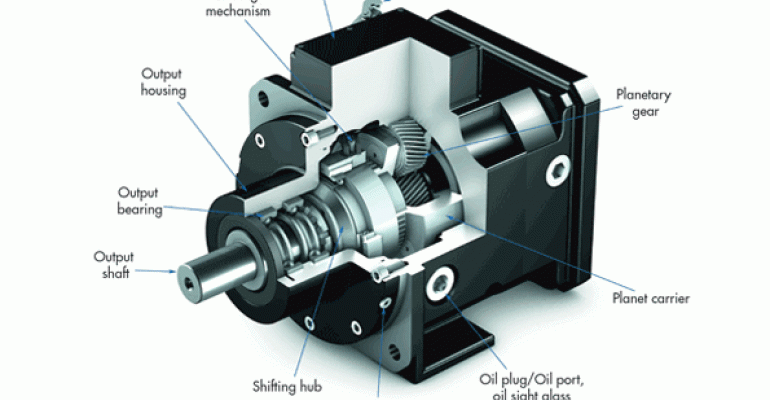

a) Gearbox and bearing lube oil filtration

The systems in a vehicle’s gearbox require oil or lubricants to help in reducing friction on the moving parts.

The lubricants should be soft and clean to avoid any damages that impurities may cause to the gearbox.

The lubricants will reduce wear and tear in the gearbox thus reducing the aging of the system.

Gearbox

Apart from the gearbox of the vehicle, the lubricant is useful in other gearboxes in other industrial applications.

It is available in applications such as:

i. Industrial equipment gearboxes and turbine gearboxes

ii. Locomotive gearboxes and pinion gears

iii. Planetary gear drives, roller bearings, and reduction drives

The stainless steel filter cartridge is an integral part of these systems to help in cleaning the oil or lubricant.

The oil might have contaminations from abrasions on the moving parts which may be dangerous to the normal functions.

The filter will help in getting rid of the impurities making the system to be flawless in operation.

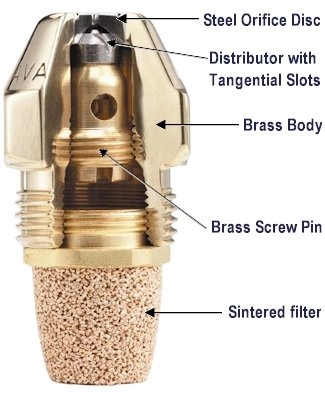

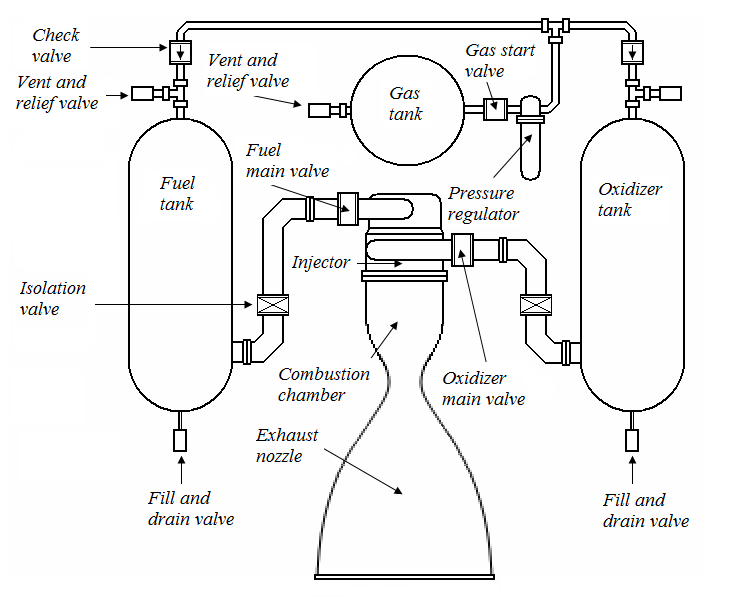

b) Fuel nozzle protection in oil burners

It is also important in the fuel nozzle protection of the oil burners and improves the efficiency of the system.

The oil burners are important especially in commercial, marine and industrial applications for heating of water.

In different industries, you will use the oil burners are responsible for heat generation, boiling water and generation of steam.

Oil burner nozzle

An oil burner is a type of mechanical device that will burn a liquid or a gas to flames under control.

The boilers need a fuel source which can either be oil or gas and converts the heat into steam.

Fuel comes from the storage tank and passes through the preheater and into the filter before going to the valve.

As the fuel goes through the filter, it undergoes a cleaning process that gets rid of the impurities.

The filter, in this case, is often the stainless steel filter cartridge which is able to operate in such conditions.

The impurities in the fuel may originate from any place including the original crude oil.

It is important to protect the fuel nozzles of the oil burners to maintain the efficiency of the boiler.

The contaminants in the fuel may alter the surface finish on the nozzle thus changing the spray pattern.

It may also alter the size of the nozzle thus changing the droplet size of the fuel and altering the entire system.

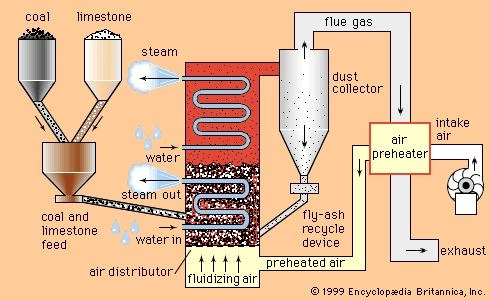

c) Fluidized bed combustion

Fuel particles are often in a suspension of hot bubbling fluidity beds of particulate materials and ash.

Fluidized bed combustion

At this point, it receives hot gas air or oxygen that will assist in the gasification or combustion.

The whole process promotes chemical reactions and rapid transfer of heat within the bed of the combustion bed.

The system is very sensitive and any interruptions from impurities may alter the chemical process.

Normally, the stainless steel filter makes it more effective by eliminating the impurities from the system.

The system is fully functional even if it is working at very high temperatures and pressure.

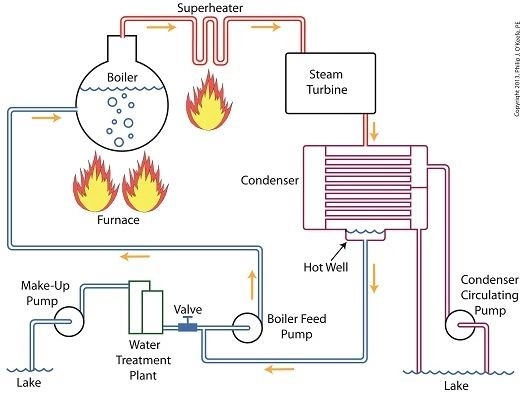

d) Condensate water

The filtration of condensate water is one of the key points the system of the power plants.

A reliable and stable condensate water system is very important as it:

i. Protects the safe running of the steam and boiler turbine

ii. Extends the circle of resin regeneration

iii. Reduce the starting time of the system

Condensate water plant

In the operation of the whole unit, the main impurities in the system are iron and silicone.

The iron can corrode and affect the effective movement and safety of the whole system.

It can also melt and condense in the water at high temperatures so it is important to remove it.

e) Water treatment

Water is very important and can have contaminations by rust, dust, algae, decaying sediments, chemicals, and organic matter.

Wastewater treatment plant

To prevent the components from creating any problems with the health of the user, you will have to treat.

This possible by passing it through the stainless steel filtration cartridges in large scale ensuring the user are healthy.

f) Seal protection

The stainless steel filter cartridge is an important part of the industrial system and assists in protecting seals.

The seals of the industrial equipment are always rotating and any form of impurities may cause breakdown of the system.

Stainless steel filter cartridge – Photo courtesy: ECVV

The filter can, therefore, help by getting rid of the impurities that may reach the rotating parts of the system.

You can use it to protect the seals of the rotating equipment such as refiners and pumps.

g) Pressurized gases

The stainless steel filter cartridge protects the equipment from water, dirt, oil and other impurities in compressed air.

The filter is able to remove the impurities from the air effectively even under very high pressure with a 99.9% success rate.

Pressurized gas system

As the air passes through the filter, the impurities remain on the filter cartridge making the air that passes through clean.

FilSon Filters Stainless Steel Filter Cartridge Solution

FilSon is one of the companies that specialize in the manufacture of the stainless steel filter cartridge in China.

It has a wealth of experience in the design, manufacture, and supply of the stainless steel filter cartridge.

It has the means and capability of producing custom stainless steel filter cartridge for your industrial applications.

It has a team of able engineers with long years of service and experience that are always ready to help.

The team of designers and engineers work together to come up with new ideas and innovations for the device.

The teams can also help you get a custom design that is functional and can last a longer service period.

With 15 years of experience in the manufacturing industry, FilSon takes every detail very seriously.

It has been the main reason for the quality materials that they have been producing.

Thus, it gives special attention to the design details and makes sure that the device is able t perform exceptionally well.

You are at liberty of visiting the factory in China to view the different types of stainless steel cartridges available.

The company is willing to send samples to your destination to allow you to check the quality of the device.

It also offers free advice on maintenance of the device and how you can clean and replace the filter cartridge.

Apart from that, FilSon is expanding its arms and can serve the huge demand for the stainless steel filter cartridge.

It has a customer care service that is available for you to contact and discuss your preferences.

No matter the location of your industry, FilSon is able to supply the stainless steel filter cartridge all over the world.

Conclusion

The confusion and the doubts in your mind are fading away and you are now sure of a proper filter.

The stainless steel filter cartridge is the best option for your industrial needs especially in the high temperature and pressure operations.

Get your stainless steel filter cartridge as soon as possible and forget about the high cost of maintenance.