Custom Hastelloy Filter Serving Your Application

Filson Hastelloy filter is versatile for a wide range of industrial applications, from food processing to oil & gas refining. Generally, the filter is made of different grades of Hastelloy, including Hastelloy B-3, Hastelloy C-22, Hastelloy C-276 and more.

Since Hastelloy is a nickel-based alloy with numerous superior properties, Filson Hastelloy filter is endowed with good physical and chemical advantages. And due to its excellent corrosion resistance and thermal stability, Hastelloy filter is popular in aviation business and chemical field.

Filson, as one of the most professional Hastelloy filter manufacturers in China, is committed to exploring the benefits of Hastelloy and bringing the best filter for our customers all over the world.

If you don’t know where to buy quality Hastelloy filters or still don’t know how to choose a proper Hastelloy filter for your application, please feel free to contact Filson today and our specialists will help a lot.

Filson Hastelloy Filter

Why Choose Filson Hastelloy Filter

Filson is known as an expert in filtration field, providing perfect solutions for your challenging projects of either gas filtration or liquid filtration. Among all our metal and alloy filters, Hastelloy filter always comes to the first place for its outstanding corrosion resistance.

During the past 20 years, Filson has accumulated rich experience in Hastelloy filter designing and manufacturing. We select the raw material strictly complying with the international standards, and under the support of advanced technologies, Filson Hastelloy filter is always engineered to fit your specific application needs.

Filson: Your Reliable Hastelloy Filter Supplier in China

Filson Hastelloy filter has a long application history in nuclear power industry and strong acid industry thanks to its great corrosion and temperature resistance. And through the course of continuous use, the components have been upgraded and developed for enhanced capability.

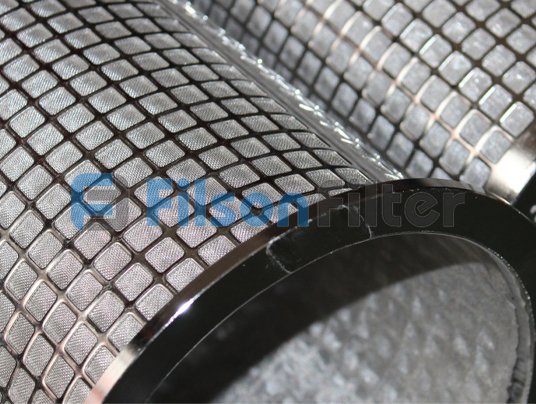

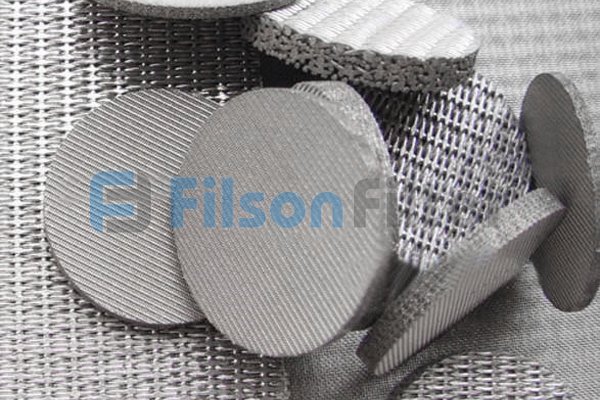

Filson supplies Hastelloy filter in a lot of forms, including Hastelloy wire mesh, Hastelloy sintered disc and Hastelloy filter cartridge, even for filter housing, we can provide you one made of Hastelloy.

Generally, Filson Hastelloy filter has excellent resistance to most corrosive media in both oxidizing and reducing atmosphere. Also it is resistant to pitting, crevice corrosion and stress cracking corrosion.

You may ask why choose this Hastelloy to form the filter instead of other metals or alloys. That’s because Hastelloy is much more stronger than any others. Same as Monel filter, Filson Hastelloy filter also uses a nickel-based raw material. There are some differences between them. View the following comparison and find the most suitable material:

Monel:

- The mechanical properties of Monel are comparable to those of alloy steel, and the tensile strength is relatively high and can be about 30% higher than that of Hastelloy.

- In addition, the material is non-magnetic, high in strength, good in ductility and weldability.

- Monel has good corrosion resistance and conventional processes (hot rolling, forging, annealing, etc.) have little effect on it.

- Monel filter can be used in certain applications where require non-magnetic and resistant media to strong reducing corrosion.

Hastelloy:

- Hastelloy has been widely used in some very harsh industrial environments due to its good corrosion and high temperature resistance.

- After years of upgrading, there are many product grades ( C-276, C-2, C-2000, B-2, B-3, G-30 ).

- Strong reducing corrosive environments and serious oxidizing environments will not have a great impact on Hastelloy.

- Due to the better performance, the price of Hastelloy has been much more expensive than Monel alloy.

Hastelloy has a very stable austenitic matrix organization and contains a large amount of alloy element Ni, which is easy to be welded and secondary cold processed. Filson can offer you the quality Hastelloy wire mesh or multi-layer sintered Hastelloy disc for you to process, or just deliver the finished filter to you.

Filson also manufactures Hastelloy perforated sheet. As one of our best selling products, it is customized in different hole sizes, pitches, sheet sizes and thickness according to customers’ requirements.

Among all grades of Hastelloy, C-276 is the most commonly used grade to fabricate Filson Hastelloy filter. It is one of several materials that are resistant to corrosion by moist chlorine, hypochlorite and chlorine dioxide solutions. Also, it has significant resistance to highly concentrated chloride salt solutions, such as ferric chloride and copper chloride.

Filson carries full capabilities to manufacture Hastelloy filter for your industry. And from pre-sale to after-sale, Filson promises to offer the most professional and responsible service to eliminate any of your doubts and problems.

Except for Hastelloy filter, Filson also possesses amazing products, such as Monel filter, Titanium filter and Nickel filter. Contact us today and get the satisfactory device for you business:

Phone: +86-157 3695 8886

Email: sales@filsonfilters.com

Filson Hastelloy Filter Function:

- Replace other metals and alloys in some certain environments

- Remove solid particles in highly corrosive chemical liquids

- Filter seawater and serve other marine industries

- Offer excellent performance under harsh conditions

- Prolong the life of expensive components in the system

- Guarantee the high working efficiency for considerable profits

Filson Hastelloy Filter Feature:

- Wide filtration accuracy for both fine and coarse particles removal

- Good mechanical strength to withstand high pressure up to 350Mpa

- High temperature resistance up to 1090℃

- Various Hastelloy grade options to fit different industrial applications

- Custom Hastelloy filter types for customer to choose

- Outstanding filtration performance under high corrosion environments

- Good resistance to oxidizing and moderate reducing corrosion

Filson Hastelloy Filter Specification:

- Construction material: Hastelloy C-276, Hastelloy C-2, Hastelloy C-22, Hastelloy B-2

- Filtration accuracy: 1 – 300 micron

- Operating temperature: 650 – 1040℃, up to 1090℃

- Pressure resistance: Max. 350MPa

- Filter form: mesh, sheet, disc, rod, tube, cartridge

Note: specifications listed above are for reference only, product should be engineered based on actual needs, please consult our factory for more details.

Filson Hastelloy Filter Application:

- Petrochemical industry

- Oil and gas refinery project

- Chemical industry

- Water / wastewater resources management

- Pharmaceutical industry

- Food and beverage plant

- Ballast water management

- Seawater filtration applications

- Chlorination devices

- Pesticide processing

Filson Hastelloy Filter FAQ:

Filson Hastelloy filter is an industrial device used to filter, separate and purify all kinds of gases and liquids in a filtration system to obtain the clean fluid which is required for the following operation processes.

Hastelloy filter is a premier choice for most applications for its high resistance to corrosion. It is possible for you to choose different grades of Hastelloy to form the filter and fulfill the various demanding tasks.

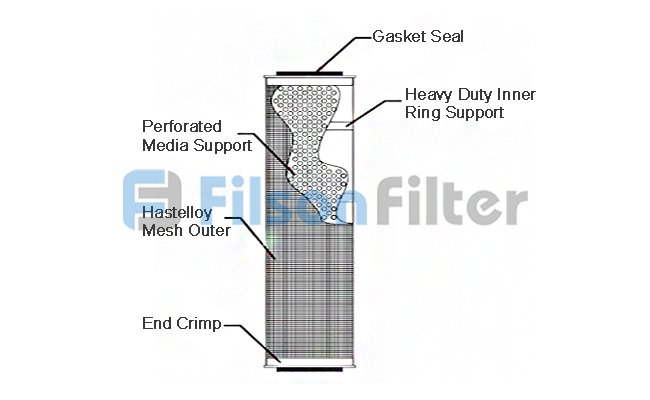

Filson introduces a full series of Hastelloy filter for your application needs, from the simple filter element to the complex filter assembly and even the outside shell which we call a filter housing can be designed and supplied to you.

The types of Hastelloy filter that Filson supplies including:

- Sintered Hastelloy wire mesh

- Sintered Hastelloy filter disc

- Hastelloy sintered filter

- Hastelloy gas filter

- Hastelloy basket strainer

- Hastelloy basket for the strainer

- Hastelloy filter cartridge

- Hastelloy filter housing

……

Filson is able to provide you all kinds of Hastelloy filters to comply with your different situations. We can deliver the finished filter for direct use or ship the semi-finished product for you to secondary processing into the product you want.

To some extent, it is.

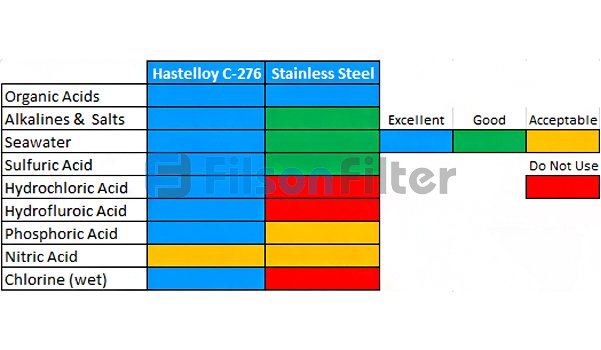

Hastelloy and stainless steel are two kinds of alloys which contain metals as the major component and nonmetals as a minor component. The two alloys are both resistant to corrosion, however, due to the special composition with more nickel in it, Hastelloy is better than stainless steel.

Hastelloy features:

- Nickel-based alloy which is called a superalloy

- Composed of nickel, chromium and molybdenum

- High temperature resistance up to 1090℃

- Excellent corrosion resistance in both oxidizing and reducing atmosphere

- High stress resistance

- Easy to be welded and fabricated

- Resistant to stress cracking corrosion

- Suitable for chemical processing, aerospace and pharmaceutical industry

Stainless steel features:

- An alloy of steel with a high chromium content

- High corrosion resistance

- Excellent performance in acid environments

- Available in forms of sheet, plate, tube and wire

- Outstanding tensile strength

- Composed of iron, chromium and carbon

- Suitable for architecture, pulp and paper, chemical processing, food and beverage

In brief, Hastelloy is a more expensive alloy comparing to stainless steel. And when you are dealing with an extremely corrosive problem and stainless steel is not regarded as the suitable material for the process, then Hastelloy can be the best alternative.

At present, Hastelloy is mainly divided into three series: B, C and G. It is mainly used for strong corrosive occasions where iron-based Cr-Ni or Cr-Ni-Mo stainless steel and non-metallic materials cannot be used.

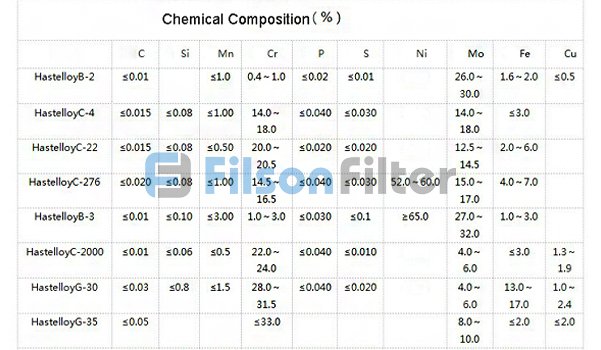

There are some common grades of Hastelloy, see the properties below:

- Hastelloy B-2 is a nickel-molybdenum alloy with excellent corrosion resistance in reducing environments.

- Hastelloy B-3 is an upgraded version of B-2 with excellent resistance to hydrochloric acid at any temperature and concentration.

- Hastelloy C-4 has good thermal stability and great toughness and corrosion resistance under high temperature of 650 – 1040℃.

- Hastelloy C-22 has better uniform corrosion resistance than C-4 and C-276 in oxidizing media and provides excellent localized corrosion resistance.

- Hastelloy C-276 has good resistance to oxidizing and moderate reducing corrosion and outstanding stress corrosion resistance.

- Hastelloy C-2000 is the most versatile corrosion resistant alloy in both oxidizing and reducing environments.

- Hastelloy G-30 is a nickel-based alloy with high chromium content that performs well in phosphoric acid and other strong oxidizing acid mixtures.

- Hastelloy G-35 is an upgraded version of G-30 with better corrosion resistance and thermal stability.

In today’s market, the most frequently used grades of Hastelloy are B-2, C-22, C-276 and C-4. With different composition, the material features vary from one to another. In order to enhance the efficiency of the final product, you are recommended to choose the right raw material. Contact Filson today and know more about the differences.

To keep the efficiency of your Hastelloy filter, you’d better to clean and wash the filter after a period of using. The correct cleaning method can help you recover the effectiveness, however, if applying the wrong way, the filter would be damaged.

1. Blowback and backwash flushing

This is the common and simplest cleaning method for almost all filters. In order to achieve the purpose, the method relies on a reverse flow of liquid or gas to force particles out of the media structure.

For those deeply embedded contaminants, multiple times of the repeated operation is required.

2. Soak and flush

Chemical soaking is the usual cleaning method for Hastelloy filter by dipping the filter in a detergent solution, generally acid solutions. Through the process, the contaminants will be loosened, removed or dissolved. It’s suitable for dealing with metal oxides like ferro rust.

3. Ultrasonic washing

Ultrasonic cleaning is the most effective procedure for deeply embedded particles. And a better results can be gained using with chemical solvents.

4. Hydro blasting

Hydro blasting is a technique which is usually used to replace other cleaning methods if the particles have grossly adhered to the media surface. It won’t reach deeply to the internal media structure, but it’s enough for the cleaning of common filters.

You can use one of these methods to clean you Hastelloy filter, or you can combine them together to realize a higher efficiency to handle a seriously clogged product. If you have any doubt, just consult our professional specialists at any time.