Your Premier Monel Filter Choice for High-Corrosion Application.

Filson Monel filter is a kind of nickel alloy composed of nickel ( 52% – 67% ), copper and other metals including iron and manganese. For different industries, like chemicals and pharmaceuticals, we provide different types and sizes of Monel filters for better performance.

Typically, Filson Monel filter is used to protect downstream equipments from being polluted and damaged by the particulate matters, at the same time, the device separates substance existing in the target fluids to realize its filtration function.

Filson, as a professional expert in Monel filter manufacturing, is able to assist you in any filtration project. It is possible that we firstly customize a sample for your system to let you check the quality and efficiency, so that we can establish a deep cooperation.

Filson Monel filter is the ideal choice for applications with harsh conditions, providing amazing resistance to high corrosion and temperature. With excellent chemical and physical properties, our Monel filter will never let you disappointed.

Filson Monel Filter

Why Choose Filson Monel Filter

- Quality product assurance

All Filson Monel filters are engineered with best quality materials according to the international standards to make sure the safe and efficient operation. Also, before leaving our factory, these products will undergo a series of rigorous tests and checks.

- Reasonable filter pricing

According to processing technologies and labor costs, the price of Monel filters may vary from one manufacturer to another and most of them are expensive. However, Filson is always here to offer the most suitable and reasonable price for you.

- Fast and safe delivery

After placing an order, the Monel filter will be put into production. For different situations and requirements, it may take different production time. All the products will be packed and delivered directly from our factory to save time.

Your Dependable Monel Filter Manufacturer and Supplier in China

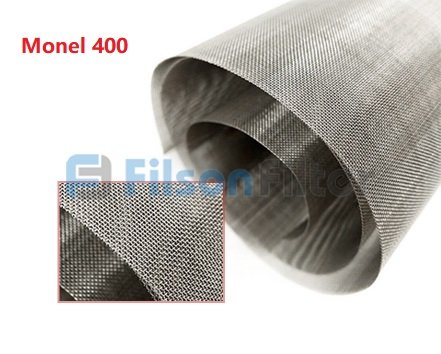

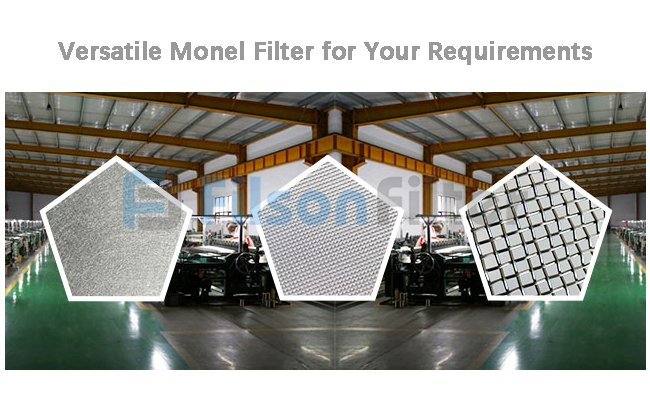

Filson possesses a full range of Monel filters with different forms and structures to satisfy your special requirements. You can choose the proper product from Monel 400 wire mesh, sintered Monel wire mesh, Monel filter cartridge, Monel reactor…

Filson Monel filter is constructed by Monel 400, Monel K-500, Monel 401, Monel 404, Monel R405 and other grades monel alloys. Thanks to the certified raw material, the filter is endowed with metallic properties, while more superior than metals.

In different situations, Filson Monel filter has different functions. In some applications, it is used to stop the large foreign matter passing through. And in some other cases, it works to protect the downstream devices.

As one of the best manufacturers in China, Filson customizes Monel filters for your specific application needs. Just send us your clear requirements or specifications, our experienced engineering team will come up with a perfect solution for you.

Filson Monel filter is featured with excellent properties that you can find it among all industries:

1. Unique combination of toughness and corrosion resistance

Because of the highly resistant to corrosion, Filson Monel product is widely used in chemical and other industries. For example, it is used in the manufacturing of heaters, heat exchangers, evaporators, distillation kettles, distillation towers, etc.

2. High strength and good oxidation resistance

Filson provides Monel alloy in various forms including mesh, sheet, disc, rod and tube. All these products are strong enough to work under high temperature, so it can also be used in the heat treatment industry.

3. Easy to be welded and formed

With great weldability, Filson Monel alloys can fit any special equipment needs. It also has good resistance to high pressure water and is therefore also used in light water reactor nuclear power plants.

Filson fabricates a complete Monel filtration equipment from filter element to filter housing. If you need, you can import Monel wire mesh, Monel filter cartridge, sintered Monel wire mesh or the whole device from Filson.

As an active supplier in fighting against COVID-19, Filson will try our best to run the business and export best Monel filter for our customers around the world. The safety of your each order will be guaranteed by those strict quality checks and disinfection works, so just feel free to use the products.

If you are confused about Filson Monel filter, or do you still need more information? Filson is here for help at any time. Call at 86 – 157 3695 8886 or directly send an email to sales@filsonfilters.com, we will contact you immediately as soon as we receive your message.

Filson Monel Filter Function:

- Stop the foreign matters in filtration and separation applications

- Purify and filter liquids and gases

- Control the distribution of the air flow

- Increase the heat transfer efficiency

- Protect the equipments downstream the system

- Withstand high corrosion and high temperature

- Replace other metals or alloys in some harsh or specific conditions

Filson Monel Filter Feature:

- Powerful raw material for high corrosion and temperature resistance

- Good strength and durability for long time use

- High filtration efficiency for stable filtering performance

- Excellent weldability for cutting, punching and stretching

- Available to be used in high pressure environments

- Low coefficient of thermal expansion

- Suitable for high alkali and high acid conditions

Filson Monel Filter Specification:

- Raw material: Monel 400, Monel K-500, Monel 401, Monel 404, Monel R405

- Filtration rating: 1 – 100 micron

- Operating temperature: up to 1200°C

- Mesh wire diameter: 0.03 – 8.00mm ( usually 0.20 – 0.25mm )

- Filter shape: mesh, sheet, disc, rod, tube, cartridge

Note: specifications listed above are for reference only, product should be engineered based on actual needs, please consult Filson for more details.

Filson Monel Filter Application:

- Petrochemical and chemical industry

- Pharmaceutical industry

- Sea water applications

- Shipbuilding industry

- Automotive industry

- Food and beverage

- Metallurgic industry

- Aviation industry

- Water treatment

- Environmental protection

Monel Filter: The Ultimate FAQs Guide

In this guide, you’re going to learn everything you should look for when buying Monel filter.

It covers components, available grades, composition, classification criteria and replacement requirements.

So, before you invest in new Monel filters, read this guide.

A Monel filter is a filter which is primarily constructed using Monel.

You can use a Monel filter which has both the filter cartridge and the filter housing made from Monel or only either of the two parts of the filter constructed using Monel.

However, you can have only the most sensitive components constructed using Monel when the filter is working in ales sensitive environment.

The rest of the parts may constitute stainless steel or any other suitable material like polypropylene to lower the filter cost given that Monel is very expensive.

Some filters also have customized designs constructed from fabricated Monel and stainless steel or other suitable material.

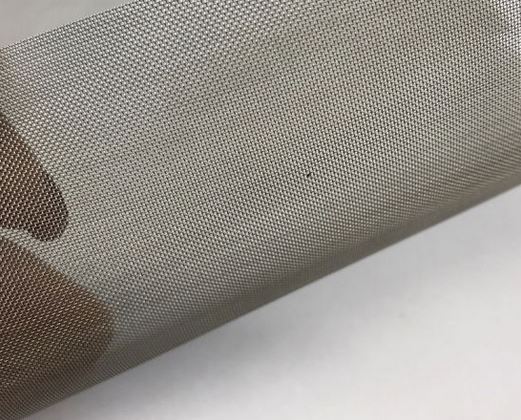

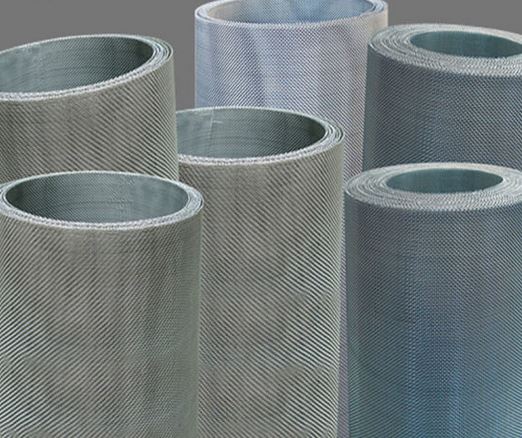

Monel wire mesh filter

Just like any other filter, a Monel filter has all the parts of a characteristic of a standard filter.

A standard Monel filter should possess the following key components:

Filter housing: The housing has a bowl and head. It houses the filter cartridge, ports and the differential pressure gauge.

Ports: These include the inlet and outlet ports which feeds in the contaminated fluids and releases clean process fluid.

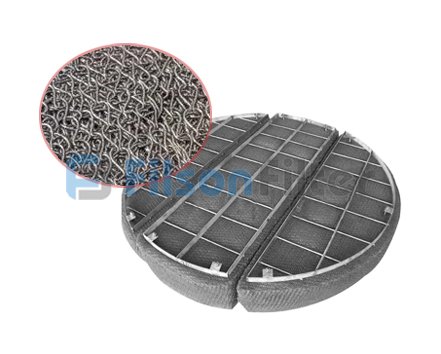

Filter cartridge: The filter cartridge is constructed using diverse grades of Monel wire mesh.

Depending on the application, a Monel filter cartridge can have only one wire mesh or multiple layers of wire mesh.

The support core and endcaps can be constructed using stainless steel or other types of material.

The filter cartridge is responsible for removing dirt from the fluid flow.

Pressure relieve valve: A pressure relief valve is usually located on the housing head and you will use it to release excess pressure from the housing during refill.

Drains: The drain is fundamental for removing liquid found in the bowl.

You can have your Monel filter fitted with automatic drains or manual drains.

You can also use the drains to draw a sample for the fluid for testing.

Differential pressure gauge: This device is optional. It is constructed from other materials since it does not come into direct contact with the fluid.

The gauge measures the pressure differentials across the filter element and signals when the cartridges are due for replacement.

You can use visual appearance to identify Monel filter though it may be challenging for an untrained eye.

Similarly, surface treatments may affect the natural appearance of Monel which has a slight greenish tint.

However, you do not have to do this since the manufacturers usually assign a unique serial number to each filter housing and element.

The number helps in tracing the filter back to the type of raw material used to manufacture it up to point of delivery thus ensuring that the material specifications are very correct.

The process of selecting the correct housing follows a similar procedure as selecting housing for any other metal filter.

The correct filter housing is mandatory to achieve satisfactory filtration using Monel filters.

When selecting a Monel filter housing, you have to consider the following factors:

- Compatibility with process fluid and contaminants.

- The operating temperature and pressure

- The desired housing design and configuration

- The size and placement of the ports

- The size of housing

You can use a Monel filter in a wide range of applications.

You can use these filter in processes that involve filtering liquid to liquid, liquid to solid, gas to liquid and gas to solid.

Such applications may involve removing oil, contaminated or salty water, fertilizers, chemicals, food, steam, gas, hydrocarbon, solvents, air, steam etc.

However, Monel has superior resistance to chemicals and better yield strength when compared to most of the standard stainless steel.

The high yield strength also makes Monel alloys extremely resistant to heat.

These types of filters are common in marine/sea water-related industries, hydrocarbons and chemical industries.

The ability to withstand heat also makes them suitable for use in thermal and electronic industries.

Some of the most common applications that use Monel type filter include:

- Processing seawater

- Processing hydrocarbons and chemicals

- Processing freshwater and gasoline

- De-aerating heaters

- Processing crude petroleum stills

- Thermal industries

- Steam processing

- Electronics

Monel filter

The feature of a Monel filter will depend on the grade of Monel you use to construct the filter.

However, nearly all common grades of Monel possess the following features:

- Anti-acid

- Anti-alkali

- Heat tolerant

- Anti-corrosion

- Resistant to high temperatures

- Resistant to wear and tear

- Excellent hardiness

- Superior tensile strength

- Durable and long-lasting

- Resistant to stress corrosion cracking

- Resistant to salty water

Monel is a Trade name comprising a group of nickel alloys.

Usually, Monel comprises of copper and nickel although you can add varying proportions of other elements to manufacture different grades of Monel.

The proportion of Nickel can vary from 52 to 67% but where the proportion of copper exceeds that of Nickel, then the material is known as cupronickel.

The chemical composition of Monel alloys differs from one grade to the other.

For instance, you can add trace elements of aluminium and titanium to manufacture Monel K-500 which have similar levels of resistance but greater strength than Monel 400.

On the other hand, Monel alloy 400 comprise similar proportions of copper and nickel that exist naturally on earth mines.

Monel filters are modelled and fabricated to offer reliable and efficient filtration solutions under very demanding and corrosive conditions.

Using Monel filters has the following key advantages:

- Monel filters are easy to produce, use, maintain and service.

- Long service life compared to other metal filters

- Highly resistant to physical and chemical corrosion

- Excellent mechanical strength, stability and durability

- Can withstand very high temperatures and heat

- Can withstand the high capacity flow

- Easy to clean

- Easy to customize the filters to meet your specific needs

- Very stable under acidic, alkaline and saline conditions

- It can withstand very high pressure and flow rates

- It is very resistant to wear and tear

There are several grades of Monel alloys which comprise varying proportions of Nickel, copper and other trace elements.

The variation influences the specific mechanical and chemical properties and hence their function.

The different grades of Monel alloys are designated with numbers and letters.

You can select the most appropriate alloys from the following grades of Monel.

· Monel Alloy 400

It is the most commonly used grade of Monel and comprises 63% nickel and 23% copper.

You can manufacture this type off Monel alloy through solid solution annealing though you cannot heat treat it after production.

Alloy 400 is very strong and has a high resistance to steam and seawater, even at very high temperatures.

The chemical composition of the alloy includes nickel, copper, and trace elements of sulfur, carbon, manganese, iron and silicon.

The material is also resistant to alkalis which makes it conducive for applications that work under reducing conditions.

It is also very resistant to brackish waters even under rapid flow rates.

It has shown excellent resistance to cracks and corrosive stress on freshwater as well.

This alloy exhibits superior performance in a wide range of temperatures from cryogenic to high temperatures.

One of the most attractive traits about this alloy is the good ductility which makes it easy to work with.

· Monel Alloy 401

The grade type is specifically manufactured for use in electrical and electronic applications, bimetal contacts and wire-wound resistors.

Other applications include marine engineering, gasoline and freshwater tanks, crude petroleum stills, industrial heat exchangers, etc.

You can readily weld this Monel alloy autogenously into thin sections.

You can use the common gas-tungsten-arc welding procedure or achieve a satisfactory result from using resistance welding.

You can either cold or hot work the alloy as desired.

However, you should do cold working using a soft die and standard tooling to achieve superior finishing.

Following the cold working, you can anneal alloy 401 at 760°C for one hour to recover.

· Monel Alloy 404

Similarly, Alloy 404 is best suited for electronic devices and electrical applications because it is strong, resistant to corrosion, has low permeability, low curie temperature, and good brazing properties.

You can also consider this grade of Monel for applications involving chemical processing equipment, gasoline tanks, heat exchangers etc.

You can also manufacture Monel alloy 404 in the form of a coil (strip, ribbon, foil) or wire (flat, square, round or profile).

You can weld the superalloy material either through using submerged-arc, gas metal-arc, gas-tungsten arc, and shield metal-arc welding.

You anneal Monel 404 at 760°C and harden it through cold working.

It responds well to hot working capacity and does not respond to any heat treatment except for annealing.

You should perform cold working on the material using standard tooling and use soft die material to reduce galling problems and produce good finishing.

· Monel Alloy R-405

This alloy has high strength and toughness with superior resistance to a wide range of substances such as sulfuric and hydrofluoric acids, alkalis, brackish water and seawater.

It has shown superior resistance to alkali, neutral and acidic salts.

It also has very good resistance to chloride ions stress corrosive cracking but has poor resistance to acids in the presence of oxidizing salts.

It has excellent mechanical strength and machinability over a wide range of temperature.

You can use this material in a wide range of application though it is highly recommended for automatic screw machine stock.

You can join the alloy through standard brazing, welding, and soldering techniques.

Alloy 405 chemical composition resembles that of Monel 400 with the addition of sulfur from 0.024 max to 0.025 -0.060%.

The addition of sulfur improves the machinability of the alloy and acts as a chip breaker during machining.

You can fabricate, heat treat and pickle this material just like you would Monel 400.

· Monel 450

This grade of Monel is of the 70-30 type and comes with superior weld-ability compared to other grades of Monel.

It has excellent fatigue strength, higher thermal conductivity, it can provide a very high mechanical strength over a wide range of temperatures.

Its hardiness and strength can increase at subzero temperatures with only a slight impact resistance or ductility impairment.

It is resistant to a wide range of media including acids, alkalis and seawater.

They are also very resistant to biofouling in seawater, corrosion, organic compounds, neutral solutions etc.

· Monel K-500

This grade of Monel is manufactured through the addition of aluminium and titanium to enhance strength and hardiness.

It also has the corrosive capabilities of Monel 400 though it can stress-corrode crack under an age-hardened condition in particular environments.

It is very resistant to a sour gas environment.

Monel K500 is suitable for operation at cryptogenic temperatures up to very high temperatures.

These properties make it suitable for the construction of filters that operate under very high temperatures and in very corrosive environments.

However, you have to do machining before precipitation hardening because it has low machinability.

This grade of Monel also forms a gamma prime with ageing which slows down the rate of corrosion with time because the layer acts as a boundary between the alloy and corrosive agent.

The material hardens through heat treatment which makes cold working and machining very difficult.

It has almost triple the yield and tensile strength delivered by Monel 400.

Monel K500 filter

Both Monel and stainless steel are superalloys.

However, stainless steel filter is an iron alloy while Monel is a Nickel-copper alloy.

Monel filters are more expensive than stainless steel filters though they also come with superior resistance to corrosion.

In terms of appearance, the two metals have a very distinct physical appearance.

Whereas Monel has a slight greenish tint, stainless steel is silvery and can be shiny when buffed.

Stainless steel filter

The service life of Monel filters will depend on so many factors.

When the environment is conducive, then the filter housing constructed using Monel 400 or Monel K500 will last for years.

The service life of the Monel filter elements is also very durable.

In most cases, you will be able to clean and reuse the elements a couple of times before you can replace them.

The duration will depend on the dirt holding capacity of the cartridge and the frequency of cleaning.

Yes.

You can construct any type of filter using Monel as long as your process application operates under very high temperatures and in corrosive environments.

Typically, you can make the following type of filter elements using Monel alloys.

- Particulate Monel filters

- Coalescing Monel filters

- Filter separators

- Strainers

- Natural gas filters

- Fuel gas filters etc.

The main limiting factor against using Monel filter is the cost of operation.

Monel filters are way too expensive compared to stainless steel filters and other standard types of filter.

Therefore, it will only make sense to use Monel filter under conditions that the operation won’t support a cheaper alternative.

Secondly, just like any other superalloy, Monel will only remain effective against galvanic corrosion when you protect it from damaging agents.

Specifically, Monel is very sensitive to oxidizing agents or under oxidizing conditions.

These conditions will accelerate the rate of corrosion exuberantly in the presence of acids.

The price of Monel filters significantly fluctuates depending on numerous factors.

Availability and demand of Monel is a major determinant of the cost of Monel filters.

Other factors include the size, type, grade, application, micron rating etc.

A small Monel screen can cost as low as $ 2 apiece when bought in wholesale.

You can also buy the Monel wire cloth or screens as plates or in square meters.

You can use standardized testing procedures used for testing the effectiveness and quality of other metal filters.

Depending on your application, you can conduct a DOP or Multi-pass test to determine the effectiveness of the filter in removing the contaminants.

You can also subject the Monel filter to maximum operating temperatures or challenging it with corrosive agents before installation.

The performance of the filter will vary depending on the type of Monel filter you are using.

Generally, most filters are designed for continuous use but if the process fluid stagnates in the filter elements, then bacteria can grow inside the housing.

The bacteria may affect the quality of your end products.

It depends on the level of contamination and nature of your application, you might only need to flush it or clean it before initiating normal filtration.

However, you should always examine the quality of a porous filter element to ensure it is still efficient and safe to use.

This is because complete dehydration can affect the filtration efficiency of the filter in some cases.

You should follow the instructions provided by the manufacturer when replacing the Monel filter cartridge.

Change the filter cartridges when they reach the recommended change-out pressure drop.

Usually, this pressure drop varies from 7 to 15 PSI.

You can wash and reuse the filter cartridges as instructed by the manufacturer.

However, you should note that cleaning the cartridge only removes between 80-90% of the dirt.

Consequently, the efficiency of the filter will decrease with time.

Depending on the instructions of the manufacturer, you can clean your cartridges up to 5 times before replacing it with a new filter element.

Beyond the fifth cleaning, the cost, and frequency of cleaning the cartridge increases and negatively impact on the efficiency and profits.

The properties of Monel filters which suit them to operate under demanding conditions also make them less prone to damages.

However, you have scheduled regular maintenance programs to facilitate easy and smooth operations.

The most critical maintenance practice is to observe the change-out pressure and replace the filter cartridges as required.

Installing a differential pressure gauge with a preset alarm will help you achieve timely element change-out.

Alternatively, you can consider using a Monel filter that can self-clean to reduce downtime and change-out costs.

You should consider the following precautions to avoid damaging your Monel filter.

- Ensure that you protect the filter from environmental factors which can discolour and deteriorate the filter.

- Avoid leaving stagnant salty water in the filter for long to avoid pitting

- Avoid using the following compounds as they are very corrosive to Monel:

- A mixture of water and either sulfur dioxide and nitric oxides

- Concentrated hypochlorites, nitrous and nitric acids, ferric sulfates, ferric chlorides, cupric chlorides, acidic and alkaline oxidizing salts, stannic chloride, silver nitrate, and mercuric chloride

- Sulfurous acids may or may not corrode the Monel filter depending on the environmental conditions.

- Exposing Monel filters in moist conditions to aerated hydrofluoric acid can cause stress corrosion cracking.

- Avoid using metal fasteners constructed from zinc, iron and aluminium as they easily corrode when it comes into contact with Monel and under severe environmental conditions.

With this information, am sure you can choose an appropriate Monel filter.

In case you have any questions about Monel filters, contact FilSon Filters now.