Stainless Steel Sintered Filter Cartridge

Having more than 20 years experience on making filter cartridge, Filson can provide you stainless steel sintered filter cartridge with high temperature and corrosion resistance as well as high filtration efficiency.

- Various raw materials like 304, 316, 904L, 310S

- High temperature and corrosion resistance

- Customized size available

- High filtration efficiency and micron rating

- Quick and safe delivery

What is Stainless Steel Sintered Filter Cartridge

Filson stainless steel sintered filter cartridge is a filter element, which has stainless steel as the core element through a sintering process. Stainless steel sintered filter cartridge, similar as stainless steel filter cartridge, mainly consists of filter tube, end caps and O-ring.

Filson always uses 100% stainless steel to fabricate stainless steel sintered filter cartridge, and it can withstand high temperature and corrosion as well as having good mechanical strength. Being regarded as an ideal filtration part to eliminate impurities, stainless steel sintered filter cartridge can be widely used in gas, liquid or solids filtration.

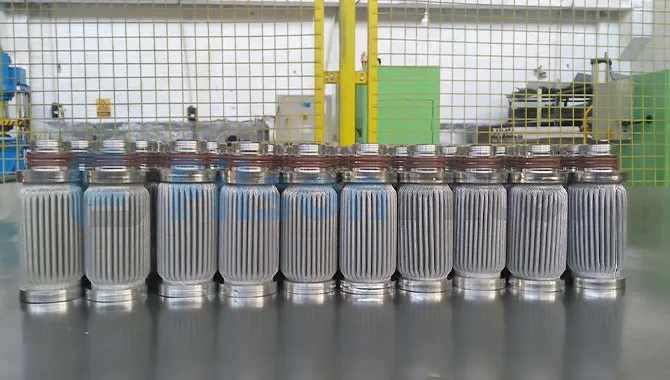

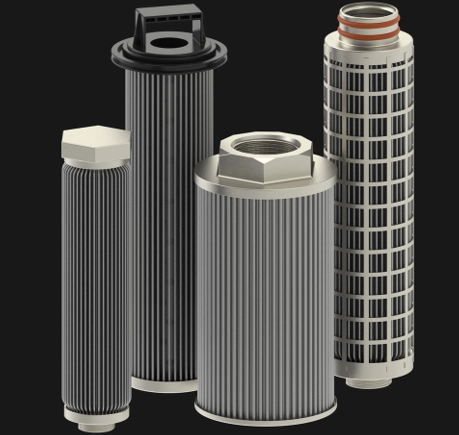

Stainless steel sintered filter cartridge has various categories, including pleated sintered filter cartridge, sintered candle filter, sintered dust collector filter bags, sintered flame screen and stainless steel sintered mesh filter.

Stainless Steel Sintered Filter Cartridge Series

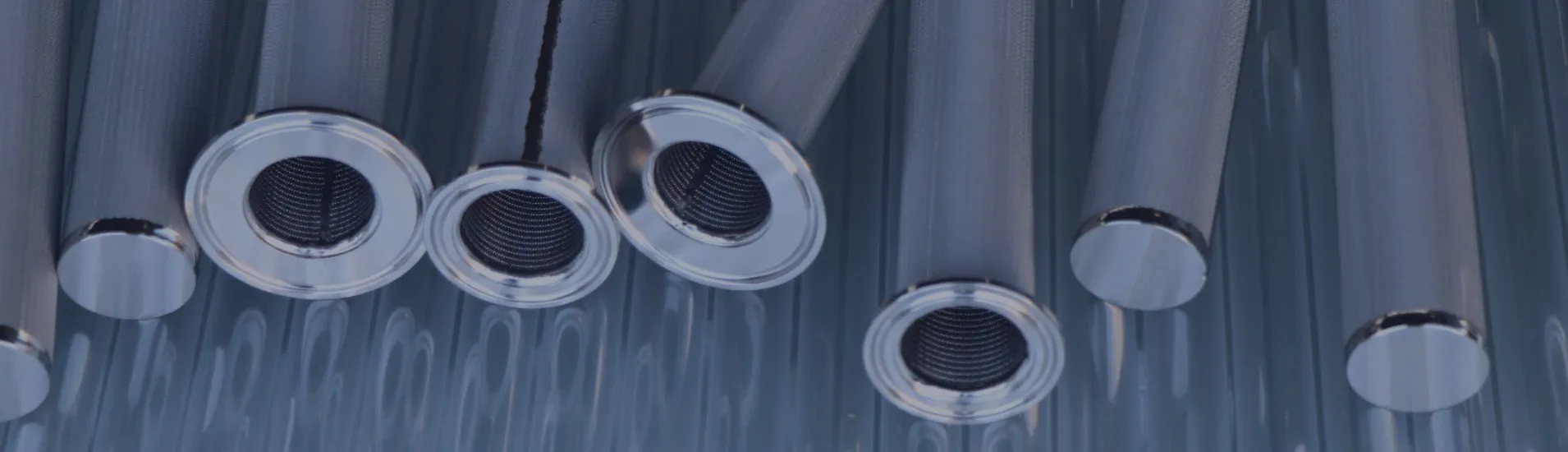

Having a pleated structure, Filson pleated sintered filter cartridge has 3 times dirt-holding capacity than common cartridge like powder filter. The porosity of pleated sintered filter cartridge can reach 90%, and the filtration efficiency is as high as 99.99%.

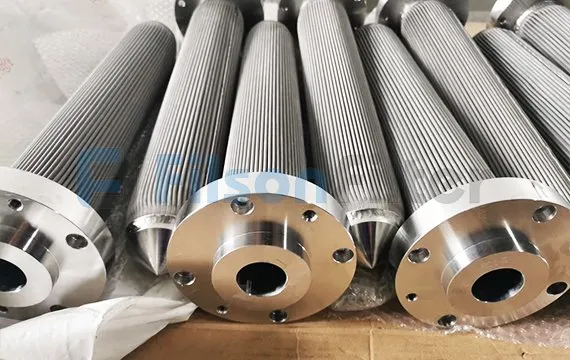

Filson usually fabricates sintered candle filter with stainless steel, including SS fiber felt, SS sintered mesh and SS powder. The filtration efficiency of sintered candle mesh can even reach 99.9% at 0.2 micron filtration rating.

Filson sintered dust collector filter bags are made of high-quality stainless steel 304, 316L through a sintering process, which can work normally under high thermal and corrosion condition. And it can be used in gas filtration to eliminate dust with micron up to 200 micron.

Sintered metal flame arrestor, is an important part in gas flow control to stop flame. Utilizing stainless steel or other alloys, Filson sintered metal flame arrestor can withstand high temperature up to 760℃.

Having 5 to 8 layers, stainless steel sintered mesh filter generally has larger filtration area than conventional filter. As an critical filter in many industries, stainless steel sintered mesh filter has high filtration rating up to 250 micron.

Stainless Steel Sintered Filter Cartridge Benefits

Utilizing standard stainless steel materials like SS 304, 316, Filson steel sintered filter cartridge has high temperature tolerance up to 816℃. And it can also operate normally under harsh environment, like corrosion and acid condition.

You just need to do several steps to install stainless steel sintered filter cartridge: place filter cartridge in the housing and fastening, connect pipes and allow liquids in, close bleeder valve, turn on the pump and finally open the bleeder valve to let liquids pour out.

Filson can make stainless steel sintered filter cartridge with a wide filtration rating from 0.2 micron to 200 micron. And its filtration efficiency can reach 99.99%.

Stainless steel sintered filter cartridge is easy to be cleaned through blowback or backflush system, ultrasonic cleaning or chemical cleaning methods like solvents.

Stainless Steel Sintered Filter Cartridge Advantages

Filson always uses 100% stainless steel to manufacture stainless steel sintered filter cartridge. Through a sintering process, our cartridge can be used in high temperature up to 816℃ and high pressure environment, like steam filtration and high temperature liquids and gases.

If you choose 904L as main material, stainless steel sintered filter cartridge can also resist high corrosion. Therefore, our filter cartridge can be applied in catalyst recovery or other corrosive places.

The filtration efficiency of stainless steel sintered filter cartridge ranges from 60% to 99.99%, and the porosity can reach 90%. You can use Filson stainless steel sintered filter cartridge in various filtration industries, such as water treatment and gas – liquid separation.

Stainless Steel Sintered Filter Cartridge Features

- Excellent chemical property to fit in almost all kinds of liquids, gas or solids.

- Overall welded construction to lessen liquid consumption

- High operating temperature up to 816℃

- Good corrosion resistance

- Allowable to be reused through various cleaning methods

- Longer lifespan up to 2 years

- Wide filtration rating ranging from 0.2 micron to 200 micron

- High filtration efficiency up to 99.99%

- Wide and high porosity up to 90%, large filtration surface area

- Reliable quality in accordance with ISO certification

Choose Stainless Steel Sintered Filter Cartridge

As one of the professional stainless steel sintered filter cartridge manufacturers in China, Filson can offer you reliable products in accordance with ISO certification. What’s more, to guarantee quality, each cartridge will be conducted bubble point test.

The designed filtration rating of stainless steel sintered filter cartridge is between 0.2 micron to 200 micron. So our filter cartridge can capture most impurities in liquids. And like sintered mesh filter cartridge, the filtration area is up to 1000cm2 per 500mm length.

In addition, Filson can provide you OEM service on stainless steel sintered filter cartridge manufacturing. We can offer you customized porosity, filtration rating or other specifications according to your requirements.

If you need sintered metal filters of other materials, we can also meet your needs. Whether sintered titanium filter, sintered nickel filter or other alloys, Filson can always ensure that they have reliable quality and excellent property.

Want to learn more details about stainless steel sintered filter cartridge or other Filson sintered filters, give us a call at +86-157 3695 8886 or send an email at sales@filsonfilters.com, we will respond with a perfect product for you.

The general parameters of Filson stainless steel sintered filter cartridge are as following. You can choose from them or just send us your unique specifications.

- Raw Material: stainless steel 304, 304L, 316, 316L, 904L

- Working Temperature: -200℃ to 816℃

- Operating Pressure Differential: up to 4 bar

- Flow Rate: 25 to 30 rpm per 10’’ length

- Filtration Efficiency: 60% – 99.99%

- Porosity: up to 90%

- Filtration Rating: from 0.2 to 200 micron

- Outside Diameter: 64mm

- Inner Diameter: 28mm

- Common Length: 5’’, 10’’, 20’’, 30’’, 40’’

- Surface Area: up to 1000cm2 per 500mm length

- O-ring Material: Silicone, EPDM, Viton, PTFE

- Connector: DOE, Code, Thread, Flange, SOE, 222, 226

Due to its unique characteristics, Filson stainless steel sintered filter cartridge can be widely used in following fields:

- Aerospace

- Metallurgy

- Petroleum

- Food and beverage

- Chemical industry

- Pharmaceutical industry

- Gas&liquid filtration

- Solid catalyst recovery

- Oil refining process

- Gas – liquid separation

- Power generation

- Water treatment

Stainless Steel Sintered Filter Cartridge Related Products

Stainless Steel Sintered Filter Cartridge: The Ultimate FAQ Guide

Here are important facts you need to know before choosing stainless steel sintered filter cartridge.

Whether you want to learn about the design, material type, working principle or construction, you will find all information right here.

Keep reading to learn more.

Stainless steel filter cartridge

This is a filter element that has stainless steel as the core element.

It can remove physical impurities through physical means by preventing them from passing through the pores.

However, the fluid is allowed to pass through.

The filter cartridge has a housing that gives it physical protection from damage.

Besides the physical dirt, it also possible to remove chemical impurity using the filter element.

From the market, you can get filter elements with different micron ratings. Therefore, you would have a different application of the filter elements.

Due to the very low micron rating, you would be able to filter very small impurities like; yeast and bacteria sediments.

The filter element can give you a longer service life.

You may need to replace it when the pressure difference is too high, the efficiency level is low, or when damaged.

Having the right protective clothes and tools needed, you should ensure the whole system is shut down and the pressure is too low before the onset of replacing.

Sintered mesh filter

Both filter elements have a lot of similarities as below.

- They are both made using the sintering process

- Also, they both have high resistance to temperature, pressure, corrosion, and oxidation.

- Besides, they are made from stainless steel hence they derive similar benefits from using stainless steel

- They need housing for protection and mechanical strength

- These filters are made of single or multilayers with precise pores for effective filtration.

The filter element is made of stainless steel.

Stainless steel material you are likely to use include; SS 304, SS 316, & SS 316 L.

Several wire meshes are sintered together in a vacuum under mechanical pressure through cold isostatic pressing.

This increases its porosity and stability.

The wire meshes are rolled into a cylinder.

Also, the cylindrical filter can either be pleated or plain. This further increases its filtration area.

The two ends are seamed together through welding.

Besides, the shaping into cylindrical form is done to increase the roundness and flatness of the filter element.

Cylindrical shaping also increases its mechanical strength. Additionally, a courser material is added to prevent it from being destroyed.

You could test the integrity of the filter element through a bubble point test.

Through the test, you can verify that the pore sizes are uniform and of the required size, no openings are found at the joint or seems, and no media migration occurs.

The features of the filter element are the key determinants of its working efficiency level. Features are also helpful in improving the quality of the device.

The features of the element are highly influenced by the design, material used, dimensions of the stainless steel, micron rating, seal configuration, working conditions, method of construction, filtration area, and type of the end.

Other features are as listed below;

- It is of quality enabling you to reuse the filter element.

- It has consistent pore sizes enabling you to have the consistent filter rating desired.

- Stainless steel has chemical resistance. Therefore, you could use it in filtering corrosive fluids.

- The filter element is easy to clean. This will allow you to use the filter element for a long time saving you on cost.

- Besides, the filter element has a high flow rate of 25 or 30 rpm per 10″ length

- It can withstand high temperatures of up to 400° F. therefore, you could utilize it in a heating process.

- Besides, it can withstand high-pressure operations (50 ΔP). Therefore you could utilize it in pumps.

- The courser element added and then shaping it into cylindrical form increases its mechanical strength in comparison to sheet filter counterparts.

It has a high dirt holding capacity. This capacity is further increased by the housing

It has high mechanical strength enabling it to withstand very high pressure without destruction

Besides, this filter has uniform pore sizes increasing its filtration efficiency

Moreover, it can withstand very high temperatures in comparison to some filter elements

Also, it is easy to clean increasing its service life

You can find it in different sizes.

Therefore, you may find that which suits your application.

The pore structure is firm which prevent the backflow of the impurities into the filtered fluid therefore, you are guaranteed of efficient filtration of the process fluid.

Having been made from stainless steel, it resists corrosion. Therefore, you could use it in corrosive fluids

It allows back flushing of the fluid so that you do not leave any fluid on the filter

The filter element is manufactured through an expensive process making it costly.

Also, the clogging limits its filtration efficiency

You could use the Stainless Steel Sintered Filter Cartridge infiltration of liquids, gas, or solids. The most specific industrial use of the Stainless Steel Sintered Filter Cartridge include;

Sintered filter cartridge

- Sound attenuation like in aerospace, metallurgy, petroleum, and food industries

- You could also use it in sound attenuation in disabling a bomb

- Gas distribution in a fluidized bed

- Machinery industry, you could use it in fine filtration of hydraulic oil and lubrication oil.

- Chemical industry, you could use it in polymer filtration.

- Pharmaceutical industry, you could use it during washing and drying.

- Food and beverage industry, you could use it in treating water and filtering gas.

They come in different sizes.

You can find one as small as the head of a pin or as large as a 55-gallon drum

There are several factors you might need to consider when designing the filter element. Otherwise, your filter element may not be efficient infiltration.

Some of the design considerations include;

· The Filtration Rate

It is dependent on pore sizes. The bigger the pore sizes the lower the filtration rate you will achieve and vice versa.

The specific pore sizes prevent the passing of particles beyond the specific pore sizes.

You could use an absolute or nominal micron rating.

The absolute micron rating is more specific with a filtration rate of 99%.

Nominal micron rating is less efficient at 60%.

· Pressure Drop

Pressure drop is the difference in pressure between the inlet and outlet of the filter element. There is usually a loss of pressure between the two sides of the filter element.

You should have a specification on the maximum pressure drop of the filter element that best suits your application.

· Temperature Range

Different applications will have different temperature ranges. It may be to the extreme on both ends.

Therefore, your filter element should be applied in the right temperature applications otherwise it may fail.

· Mechanical Strength

The application may expose the filter element to forces that may damage it.

Therefore, the filter element of your choice should be strong enough to resist damage.

· Filtration Area

The design should allow for enough room for filtration.

Smaller filtration are would make the filter element less efficient.

Hence the reason why the filter area is either cylindrical or plain.

The main alloys of steel that are likely to make your filter element include; 304, 304L, 316, 316L, 904L

Each of the alloy has differential characteristics as discussed below;

· Stainless steel 304SS

It has increased resistant to oxidation at high temperatures.

Also, it has high resistance to corrosion

It is malleable into different shapes and sizes through welding, cutting and shaping

Besies, it is also non-magnetic in annealed conditions.

Therefore, you could utilize this alloy in many applications.

· Stainless Steel 304L

It has lesser carbon concentration in comparison to 304SS.

This makes it easier to weld easily. It also has got chromium ≥ 18% and nickel ≥8%.

It is non-magnetic with high resistance to corrosion and oxidation.

· Stainless Steel 316 SS

It has increased resistance to corrosion on and pitting. This is made possible due to presence of molybdenum.

Though it has similar traits as stainless steel 304, you may not opt for it in some conditions.

However, you would probably opt for it in industrial chemical manufacture of corrosive chemicals.

It is the most second utilized alloy in comparison to stainless steel 304.

· Stainless Steel 316L

This alloy has got reduced concentration level of carbon in comparison to stainless steel 316. However, you would still benefit from a similar trait as with stainless steel.

It also has higher weldability in comparison to stainless steel 316 SS.

You benefit from sintering by;

- Ability to form different shapes of the filter element

- You can get a precise dimension of the filter element

- The process is repeatable and reliable in mass production

- The interconnected porosity can be filled with oil to obtain a self-lubricating filter element

- It is possible to obtain unique and isotropic material

- The production process of the material support the green technology since there is no wastage and energy efficiency

- The surface finish is excellent; smooth and flat

- Internal micro porosity result in 5%to 25% weight reduction

Stainless steel filter cartridge

The filter element works by creation of a physical barrier between the process fluid and the impurity.

Besides, the process fluid passes from the outside to the inside.

The outer layer is course trapping the larger impurities whereas the inner layer are finer trapping micron size impurities.

Also, the process fluid passes the filter element through high pressure. Through adhesion, the impurities stick together to form a large mass.

Cartridge filter housing

You should choose the housing for the filter element according to;

- The application parameters

- Filter element precision

- The design of the filter element

Yes, you can use either of the procedures below;

- Blowback is done for gas filters

- Backflush for liquid applications

- Ultrasonic cleaning to remove inert dirt

- You could also remove solvents to dissolve dirt e.g. water, acid,

The cleaning steps include;

You should first make sure that the differential pressure is too low to cause an accident.

Put the filter element in a nitrogen furnace and heat it to 380 degrees for 2 hours

After cooling, place the element in a strong liquid and heat it to 80 degrees for 1hr.

In case of corrosion, use a cleaning agent.

You should rinse with much water until all the residues have been removed.

Blow-dry the element to remove all the water for 20 seconds or use a an oven at 50 degrees

You should use a magnifying glass to check how clean the filter element is. The magnifying glass should be 30 times stronger.

If clean, reinstall the filter element.

Yes, they are very durable.

Stainless steel filter cartridge can last up to 2 years if utilized in the right condition.

Yes, because it is corrosion-resistant.

Some of the micron rating you could choose from include;

- 5micron rating -Most ideal in fine filtrations applications.

- 10 micron rating – This is ideal in filtration requiring medium filtrations.

- 50 micron rating – This rating is intended for pre-filtration. It is therefore used in trapping large particles or sediments before they enter the filtration element

Your filter design will be dependent on applications that would otherwise destroy polypropylene.

Such applications include;

- High pressure

- High temperature

- Chemicals that would destroy polypropylene

You should ensure that the filter element is clean. Having done that, installation should be easy as below.

- Place the filter element into the housing and fasten

- Connect the right inlet and outlet pipes and allow water in

- Close the bleeder valve

- Turn on the pump

- Open the bleeder valve and allow the excess water to pour out then close it

The pressure rating is usually specific depending on their application and the type of material used in its making.

However, the manufacturer will always indicate it to you.

The sealing configuration is the key determinant of how then sealing will be done.

Therefore, before you decide on how to seal, you need to be aware of the sealing configurations.

You cannot afford to compromise on the seal since it will have a great impact on the integrity of the seal.

Since the sealing process involves a heat process, you should leave enough allowance of the material that will be melted together to form a seal.

Therefore, you need to specify the dimensions of the Stainless Steel Sintered Filter Cartridge having put the seal into consideration.

That is during the making of the filter element.

Otherwise, you risk having a leaking filter element.

The filtration area is the surface area around the filter element where filtration takes place.

Remember, the bigger the filtration area the more the surface area for the filtration of the process fluid.

Also, the more the filtration area the higher the filtration efficiency.

A small filtration area would reduce the efficiency of your filter element.

Among the design chosen for the filter cartridge, a pleated design is the most ideal.

It creates more filtration area giving you an increased efficiency infiltration.

The diameter of the filter element also has an impact on the efficiency of the filter element.

A bigger diameter provides a bigger surface area for filtration and increased efficiency of the filter element.

Therefore, if you have an opportunity to specify the type of filter element you want from your manufacturer, you should be sure to have a high surface area.

The flow rate of the process fluid at a given pressure is also increased by having a high filtration area.

Therefore, if you want a more reliable filter element it should be of high filtration area

End configuration of stainless steel sintered filter cartridge

The end type is a representation of the type and the number of openings found in a filter element.

Most of the filter element you will find, has a double opening.

Being more specific, the type of openings you are likely to find are;

- Double open end with grommet type of seal

- Single open end with a female NPT connection

- Single open end with the male NPT connection

- Single open end with grommet type seal

- Single open end with the 222-O -ring

The end type also varies on size.

Therefore, as you choose the end type, it should be compatible with your application.

In the manufacturing arena, there are different types of filter elements.

You should therefore be able to choose a filter element that best suits your application.

Some of the filter elements that you can choose from include;

- Stainless steel mesh filter cartridge

- Stainless steel pleated filter cartridge

- Stainless steel wedge wire filters

Let’s explore these filters:

1) Stainless Steel Mesh Filter Cartridge

This filter element is composed of a mesh wire filter.

Also, the mesh wire filter should be of high quality.

Besides, the wire mesh is formed through high temperature and pressure.

The formed wire mesh is then taken into drawing to provision.

Some of the features characterized by the filter element include;

- The wire mesh is made with precision making it uniform.

- It has a high filtration rate giving you increased accuracy to your precision

- Also, it has a very high resistance to high temperatures. Therefore, you can utilize them at high temperatures.

- It has a high resistance to pressure making it ideal to use in conditions with high pressure.

- Moreover, it has got resistance to corrosion making it ideal to use in applications utilizing chemicals and acids without getting damaged.

You will find it is highly utilized by the oil industries, chemical fiber, and electroplating industries.

The oil industry will mostly use it in removing mud, the chemical fiber industry will use it as a strainer whereas the electroplating industry will use it in acid pickling.

The filter element is made of different materials other than stainless steel which include; brass wire and nickel.

Its wire has got two diameters which can either be weft or warp.

This type of filter is weaved using different styles.

Some of the weaving you may find include; twill weave, double wire dutch weave, dutch weave, and plain weave.

2) Stainless Steel Pleated Filter Cartridge

Pleated filter cartridge has got stainless steel fiber as the main material.

However, you may also find wire mesh being used.

Stainless steel 304 and 316 are the main materials used.

Some of the benefits you may derive from using this filter element include;

- The pleating design increases the filtration surface area increasing the filtration rate

- The filter elements increase its porosity

- Besides its high filtration area, it also has got high dirt holding capacity

- You will find it easy to clean through using ultra cleaning or chemical cleaning

- It has got a wide micron range of 3 to 200 micron

- It has a low-pressure drop

- You may have the flexibility of using it in different applications which include; hot gas, high molecular polymers, water treatment plants, and hydraulic oil

3) Stainless Steel Wedge Wire Filters

The filter wires are wedge-shaped making them ideal for your use in challenging applications.

Its continuous aperture provides a large surface area guaranteeing you of low-pressure drop or tendencies to clog.

The precise slot makes wedge filter ideal for you to use in starch extraction

Besides, the increased number of its welds and winding wires makes it strong and long-lasting. Therefore, it doesn’t only save you on maintenance cost and replacement but also it is useful in waste management.

These filter element has increased capacity for effective fluid/ solid separation. You could also utilize it in the straining of fluids.

Other applications include; pulp and pare, plastic extraction, adhesive filtration, petrochemical, and chemical extraction.

Other benefits include;

- Mechanical strength

- Minimized blinding and plugging

- Resistant to pressure

- Corrosion-resistant

- High temperature resistant

- Long service life

- Low-pressure drop

- High flow rate

- Useable in sterile conditions

They both have the same processing method by sintering several layers of wire mesh. Therefore, they have similar features. However, the plate is made of more layers of the wire meshes (2 to 10)

Some of the features include:

Sintered porous stainless steel filter

- Stainless steel 316 is used but other alloys are also used Monel and Hastalloy

- It has insertion capability

- It is possible to customize their porosity level

Both filter elements are made through a sintering process with single or multiple layers.

The main difference is on both is on the design one as a disc and the other as a cartridge.

However, you will experience similar benefits on mechanical strength, low-pressure drop, inherent stainless steel qualities, and resistance to high pressure and temperature.

Whether to go for stainless steel filter disc or filter cartridge will depend on your application requirements.

Sintered stainless steel filter disc

Sintered stainless steel filter cartridge

The sintered filter element is superior by;

- The sintering process makes it rigid to destruction unlike fabric and synthetic media which easily get destroyed.

- Sintering leaves it with uniform pores sizes for specific micron rating unlike the non-sintered elements

- Sintered element is more permeable

- Sintering enables multi-layering unlike fabric and synthetic media. Hence stronger

- Sintering enables the element to be malleable into different design unlike fabric and synthetic media

Depending on your specific needs are requirements, FilSon Filters offers a range of stainless steel sintered filter cartridges.

Contact us now for all your stainless steel sintered filter cartridge.