Your Professional Manufacturer of Metal Filter Cartridge in China

Filson is a leading brand in China that manufacturers the best quality metal filter cartridge at competitive prices.

- Wide filtration rating ranging from 0.1 micron to 200 micron

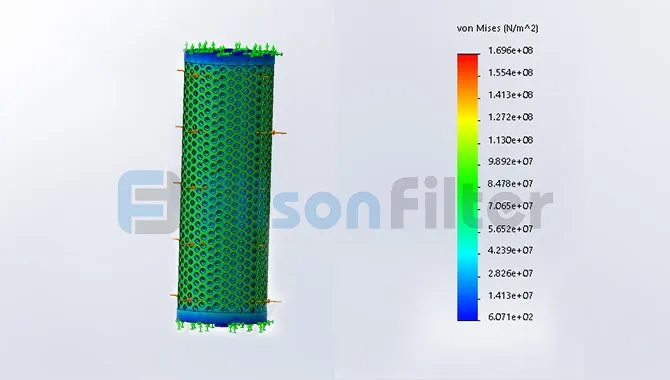

- High mechanical strength, absolute rated for reliable performance

- High temperature resistance and excellent corrosion resistance

- Large dirt retention capacity, easy to install and clean

In accordance with ISO 9001: 2015 quality certification

What is Metal Filter Cartridge?

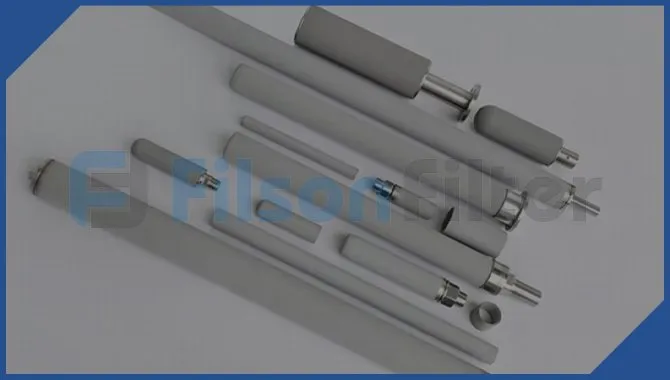

Metal filter cartridge, also called metal filter element, is a core part for industrial filtration applications.

To achieve process purification and requirements, metal filter cartridge is specially designed to provide clean fluid for downstream equipment and protect them from wear and tear.

Metal filter cartridge is mainly used to remove coarse to fine harmful impurities from water, oil, steam, or air/gas medium. The micron rating of metal filter cartridge ranges from 0.1 to 200 micron.

Whether the flow pattern is from outside to inside, or from inside to outside, dirt particles were retained on the surface, and allow clean fluid flow out.

The construction material of metal filter cartridge could be standard 304 or 316L stainless steel, special alloy titanium, nickel, Hastelloy, Monel, Inconel, etc. Its sealing materials are available in NBR, EPDM, silicone, Viton, and others.

Metal filter cartridge is widely used in food and beverage industry, chemical industry, petroleum industry, pharmaceutical industry and so on.

Metal Filter Cartridge Types by Material

Stainless steel filter cartridge is available in multiple shapes such as cylindrical, candle, pleated, basket and more to adapt to different applications. It is your optimal solution for liquid and gases filtration with efficient particle removal capability.

Monel filter cartridge, also called sintered Monel filter, is a hollow cylinder composed of cylinder body, end cup, and sealing gasket. The filter element is made of high quality Monel mesh woven or sintered together to achieve high filtration purpose.

Titanium filter cartridge is designed for a variety of applications including corrosive liquids and gases, high viscosity solutions, process steam, high temperature liquids and gases and catalyst recovery. It features excellent corrosion resistance.

Compared to plain stainless steel filter, Hastelloy filter has better corrosion resistance, and higher mechanical strength. It is popular in aviation business and commercial fields. Hastelloy grades including Hastelloy B-3, hastelloy C-22, Hastelloy C-276 and more.

Nickel filter can be applied as a filter media, chemical catalyst carrier, and electromagnetic shielding materials. With excellent properties, sintered nickel filter has become one of the ideal electrode material options to make hydrogen-nickel batteries.

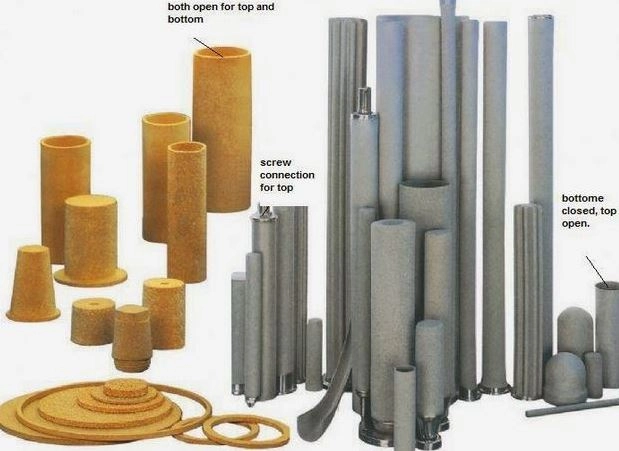

Porous metal filters are mainly made of metal powder with different particle sizes, to help meet various requirements of permeability. Regular materials of porous metal filters include stainless steel powder, bronze powder, titanium powder, inconel powder.

Metal Filter Cartridge In Stainless Steel (5)

Porous Metal Filter Cartridge Types (4)

Metal Filter Cartridge Features

There are numerous kinds of metal filter cartridges available, such as sintered metal filters, pleated SS filter cartridge, porous metal filters, SS wire mesh filters.

Whether coarse filtration or fine filtration, we always meet your requirements. The filtration accuracy of metal filter cartridge is between 0.1micron and 200micron.

To withstand harsh conditions, we utilize high quality materials to build metal filter cartridges. They shows superior thermal and pressure resistance.

Most metal filter cartridges are washable and reusable, you can replace them after a long term use. This extends their life service and saves costs.

What Kind of Applications Use Metal Filter Cartridge?

Metal filter cartridges have served a wide range of industry. They are typically used in food and beverage industry, chemical industry, petroleum industry, etc

- Used in applications which need high permeability and flow rates

- Suitable for high flow rates while keeping large dirt holding capacity

- Used for steam, air and liquid filtration with large filtration area

- Applied in catalyst retention and recovery, gas filtration, liquid filtration

How Long Can Metal Filter Cartridges Last?

The service life of metal filter cartridges depends on many complex factors.

Metal filter cartridges can take several months or even years before you replace them with new one. This mainly depends on the applications and cleaning efficiency.

It also depends on other important factors such as frequency of use, operating conditions of the cartridge, size, level of the fluid contamination, etc.

Though cleaning saves costs, you should note that you can only restore the cleanliness of the filter to about 80%-90% of its initial condition. After about 5 cleaning cycles, you should consider acquiring a new filter cartridge.

Benefits of Using Metal Filter Cartridge

Metal filter cartridge is optimized to achieve optimal filtration performance and minimum costs. It offers numerous advantages:

- They extend service life of equipment by preventing critical components from wear

- They permit excellent distribution of flow with high porosity

- They can support up to 20 times more flow rates(pleated design) compared to normal filter cartridges

- Anti-corrosion: they are suitable for corrosive fluids and chemicals

- Suitable for diverse designs: they can achieve efficient surface filtration through the buildup of cake as well as excellent depth filtration

Send us your drawing and specifications, we will quote for you immediately.

Why Choose Filson Metal Filter Cartridge?

Filson is committed to provide customers with high quality metal filter cartridge. We have been manufacturing metal filter cartridges over two decades. We accept OEM&ODM specifications to suit our clients specific needs.

Equipped with skillful workers, we utilize advanced equipment to build metal filter cartridge through vacuum sintering technology. We has the confidence to offer first-class service for customers. We assure short lead time. Order now, ship now!

Our metal filter cartridges exhibit superior filtration performance even under harsh environments. We can custom your metal filter cartridge with competitive prices. If you have any requirements, please feel free to contact us, we will respond you immediately.

More details to be known by the following ways:

Phone: +86-157 3695 8886

Email: sales@filsonfilters.com

- Construction material: 304, 316L or 904L stainless steel, titanium, nickel, Hastelloy, Monel, Inconel and other special alloys

- Length: 10 inch, 20 inch, 30 inch, 40 inch or tailor-made

- Filtration accuracy: 0.1-200 micron

- Working temperature range: 480℃ upon material

- Working pressure range: 5 bar

- Filtering medium: air, gas, steam, corrosive liquid, water, etc

- Seal material: Viton, silicone, NBR, EPDM, etc

- Food and beverage industry

- Pharmaceutical industry

- Petroleum industry

- Chemical industry

- Water treatment

- Power generation

- Paper and pulp industry

- Metallurgy industry

- Gallery

Metal Filter Cartridge Related Products

Metal Filter Cartridge: The Ultimate FAQs Guide

I know you’re looking for highly efficient and durable metal filter cartridge.

Or, you would like to find a metal filter cartridge manufacturer in China.

In today’s guide, I will make the two processes simple for you by answering every question you have been asking.

Let’s get started.

It is a cartridge constructed using a metallic material from a single or multiple metal alloys.

Metal filter cartridges are fundamental in dynamic applications as primary protective filters.

Metal filter cartridge

There are three main types of metallic filter cartridges.

The choice of a particular type of filter cartridge depends on the filtration requirements.

Below are some of the common types of metal filter cartridges:

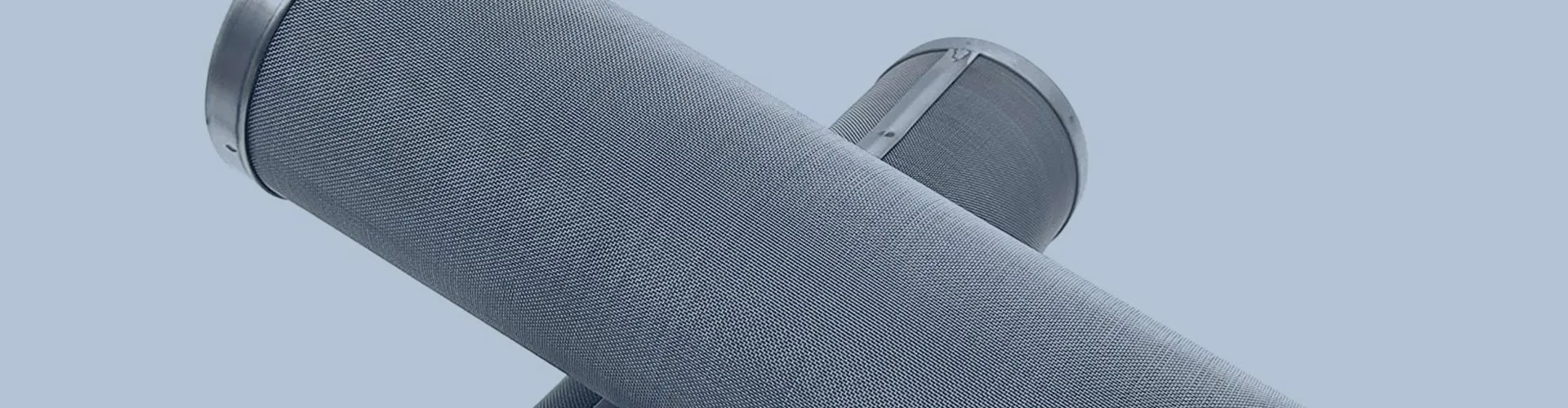

· Woven Wire Mesh

This type of media removes particulate contaminants on the surface of the media.

The process resembles a woven piece of cloth and a loom.

Woven wire mesh filters have an absolute micron rating because it has a precise aperture size that depends on the type of weave selected.

The micron rating for woven wire mesh filters can range from 10 to 300 microns.

Wire mesh filter cartridge

The majority of woven wire mesh filters are constructed using stainless steel, carbon steel, galvanized steel, and aluminum.

You can also make them using copper, brass, titanium, Inconel, nickel, and other assorted alloys.

· Random Metal Fiber/Metal Felt filter cartridges

You can construct this type of cartridge using a thin filament of nonwoven metal fiber.

The type cartridge is a depth filter element that removes particulate contaminants by trapping them within its depth.

The cartridge is composed of multiple layers of individual metal fiber strands pressed, heated, and bound together.

The metal felt material generated are porous and ideal for highly corrosive, high pressure, high radioactive, and viscous applications.

Although it is more expensive than wire mesh, sintered metal, and nonmetallic materials, it offers more benefits compared to the others.

Metal fiber filter cartridge

For instance, it has up to 80% more porosity, higher dirt holding capacity, and can support up to 20 times higher flow rates compared to other types of filters.

Just like woven wire mesh media, you can construct it using diverse types of materials but stainless steel 316/316L are some of the best materials.

They can protect from particles measuring 100 microns down to 1-micron.

Ideally, these types of filter cartridges provide top-notch filtration for particles below the 60-micron rating.

· Sintered Metal Filter Elements

Just like metal felt filter cartridges, these type of cartridges also removes contaminants through depth retention.

Sintered metal filter cartridge

The cartridges comprise of tiny metal spheres that have been subjected to pressing, heating, and bonding.

These cartridges are suited for low flow systems, particularly in gas filtration.

Filtering viscous fluid or hydraulic fluids will raise the pressure drop across the elements.

The micron rating of the cartridge depends on process control that defines its filtration efficiency.

The cartridges are available from 0.2 microns to up to 1000 microns.

You can use diverse construction materials to make this type of filter cartridge though stainless steel 316/316L has shown more efficiency.

The primary advantage of using sintered metal filters is their ability to withstand high temperatures.

You can use them in applications with temperatures as high as 650°C.

They are also very stable under the alkali and acidic environments.

Compared to other types of metal filters, they have excellent mechanical and compressive strength.

Metal filter cartridges are suitable for applications that operate under harsh environmental conditions.

Such processes require robust materials to meet the needs of harsh environments with extreme conditions.

They are appropriate for applications with high differential and operating pressure, fluids requiring special compatibility needs, and extreme temperatures.

Metal filter cartridges are vital in numerous industries such as Food and beverage, pharmaceutical, metallurgy, chemical, petrochemical, recycling of catalysts, and environmental protection.

They are also critical in the manufacture of dyes, paints, cement, paper, and pulps.

Some of the applications that use metal filter cartridges include:

- Crossflow filtration

- Natural gas filtration

- Fuel gas filtration

- Polymer filtration

- Aerosol applications

- Separation of gas and liquids

- Medical equipment

- Oil filtration

- O. pre-filtration

- Filtration of hot gases

- Hydraulic oil filtration

- Fuel and amp filtration etc.

The two main designs of metal filter cartridges include:

· Pleated Metal Filter Cartridge

Pleated cartridges have increased surface area for filtration that translates into maximum on-stream processing and increased dirt holding capacity.

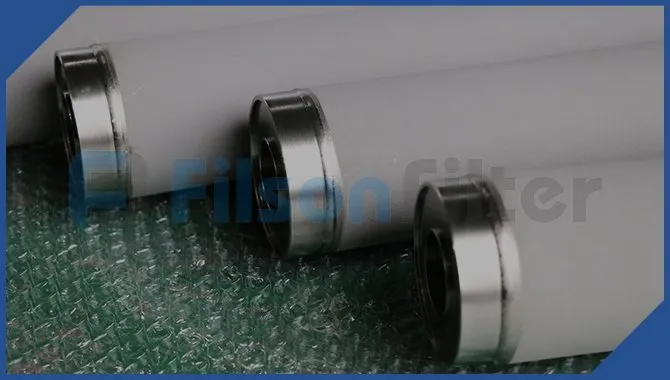

· Cylindrical Metal Filter Cartridge

Cylindrical metal filters can work with any type of process application.

There robust construction, uniform pore size, and self-supporting core eliminate the need for more support hardware.

This design has a smooth finishing which is suitable for self-cleaning mechanisms.

You can get variations from single to multi-layered cylindrical design structures.

There are diverse types of materials that you can use to construct metal filter cartridges.

The most commonly used material is stainless steel 300 series (Classes 304 and 316).

Other types of metal materials include but not limited to Monel, aluminum, titanium, Inconel, and zirconium.

A state of art metal filter cartridge should possess the following characteristics:

- Higher dirt holding capacity

- Low-pressure drop

- Stable pore size

- High mechanical strength

- Higher permeability

- Increased resistance to temperature

- Noncorrosive

- Automatic cleaning through bac flushing

- Zero migration of media

- Customizable for different applications

- Can withstand a high differential pressure

- Increased throughput

Metal filter cartridges offer numerous filtration advantages compared to standard filter cartridges.

They possess the following key benefits:

Metal filter cartridge

- They have extended service life because of their high dirt holding capacity

- They also have very high porosity that supports excellent distribution of flow and extended lifetime on-stream.

It can support up to 20 times more flow rates compared to normal filter cartridges.

- Resistant to corrosion and heat: Depending on the type of metal you use, most metal filter cartridges are very resistant to heat and corrosion.

Stainless steel is particularly the most suitable to use for corrosive fluids and chemicals.

You can also get special alloys that are more suitable and compatible with your process fluids.

- Suitable for diverse designs: You can achieve efficient surface filtration through the buildup of cake as well as excellent depth filtration.

- Excellent mechanical strength: Most metals are very hardy and resistant to breakage.

When the metal cartridges are further subjected to sintering, the process produces a high strength fiber media as a result of a strong fiber bond.

The metal cartridges can withstand very high differential pressure and thermal shock when supported with a strong inner core.

- Availability of diverse alloys: You can select from the broad range of metals and appropriate alloys to construct your elements.

The majority of the alloys are hardy, wieldable, easy to chemically clean, resistant to thermal shock, and have low thermal expansion.

- Reusable: You can clean and reuse metallic filter cartridges.

An appropriate cleaning method will maximize the service life of the cartridge and significantly reduce the cost of production.

- Durable: Steel is strong and durable. Hence, it can last for several months or years without breakage and collapsing.

- Lower cost of production: Reusing the filter cartridges will lower the production cost and help you save money that you would otherwise use on purchasing disposable filter cartridges.

Also, you will have a reduced downtime and element replacement cost because of the high dirt holding capacity and extended service life for the cartridge.

Sintering is a heat treatment that combines small metal particles through heating below the melting point.

It increases the structural integrity and strength of the material.

The process blends fine metal powder material then presses them into desired complex shapes.

The material is then compressed and heated in a furnace with controlled temperatures to facilitate material bonding.

Sintering is fundamental in processing metals with very high melting points.

Yes.

Constructing a filter cartridge using sintered metal possesses multiple benefits compared to non-sintered metal.

In fact, today sintered metal filters are suitable for applications that require high efficiency.

Sintered metal filter

You can use one or a mixture of the several methods recommended by the product manufacturer to clean the metal filter cartridges.

You can use either of the methods below to clean the cartridges.

The cleaning method may also differ depending on the type of filter medium.

· Ultrasonic Cleaning

This type of cleaning requires a special device that uses ultrasonic waves to remove particles out of the medium surface.

The waves generate create numerous but small vacuum bubbles that burst when subjected to excess pressure and remove the dirt.

This type of cleaning is the most effective in removing particles that are deeply embedded when used together with a suitable detergent.

Ensure that your transducers are producing at least 60 watts for every gallon of fluids in the ultrasonic bath.

Depending on the level and type of your metal filter cartridge, you may achieve efficient cleaning between 20 and 60 minutes.

Also, reverse the ultrasonic waves to normal filtration direction to achieve optimal results.

· Automatic Cleaning

You can use either blowback or backwash flushing.

These are some of the simplest cleaning methods that you can easily use under intense production routine.

In the case of backwash flushing, a filtered fluid is reverse flushed at high pressure to remove loosely embedded particles from the surface of the metallic cartridges.

In the case of blowback, the system uses a blast of clean air/gas to remove any embedded particles in the cartridge.

Where the particles are deeply embedded, you have to direct multiple blowbacks for effective cleaning.

Using gas to remove particles over a liquid also creates turbulence which helps dislodge more particles as the liquid-gas mixture moves through the medium.

· High Temperature

Furnace cleaning is most suitable for contaminants such as a polymer.

The process involves burning out biological and organic compounds which do not leave behind ash residues.

In the case of ash leftovers, then you have to remove the ash with an additional cleaning method.

· Hydro Blasting

This type of cleaning is more suitable where the contaminants are attached to the surface of the medium.

The method uses a pressure water blast to remove impurities from high-energy impaction.

Usually, the pressurized water does not deeply penetrate the medium but acts on surface embedded particles.

· Soak and Flash

The technique uses detergents to soak the filter cartridge which loosens the particles and enables you to flush them out using pressurized clean water.

The method is suitable for both small batches in the lab as well as process filters.

· Circulation Flow

The cleaning technique is more suited for contaminants which must be dissolved out.

The method uses a cleaning system that pumps and circulates the cleaning solution/solvents through the cartridge until the cartridge is free from all impurities.

You have to filter out the dislodged impurities from the cleaning fluid before rerunning it through the medium again.

For efficient cleaning, you have to circulate the solution in a reverse direction to the normal filtration flow.

You should note that the efficiency of cleaning a metal filter cartridge is not easy to predict and mainly depend on three factors. They include:

· Filter Rating

Removing dirt from lower-rated cartridges is very difficult and will, therefore, result in less efficient cleaning compared to higher micron ratings.

· Operating Pressure

Metal filter cartridges that operate under high pressure have more firmly embedded dirt which is not easy to remove.

· Type of Particles

Some types of impurities such are fibers are more difficult to get rid of compared to others such as cube-type particles.

The procedure and intensity of cleaning stainless steel depending on the industry of interest.

While in some applications you can just simply blow the surface using compressed air, in others you have to carefully consider the solvent to use to avoid trace elements.

You should clean the stainless steel filter cartridges to avoid product contamination and downstream corrosion.

There are several materials and solutions you can use to clean stainless steel filter cartridges.

You should match the cleaning agent to the contaminants.

You can use nonpolar solutions to remove hydrocarbons and polar solvents to reactivate contaminants before removing them.

You can also use polar protic solvents to do general cleaning and remove diverse types of contaminants from a wide range of applications.

Ensure that you select the least aggressive but most effective solution for cleaning the filter cartridges.

Some of the best solutions include:

- Filtered de-ionized water

- Isopropyl alcohol

- Acetone

- Octagon oxygen cleaning compound

- Pentane and hexane

- Dichloromethane etc.

- Dawn liquid detergent

- Ammonia

- High purity hydrocarbon solvents

- Mild sonication

- Methylene chloride

- Oakite 31 or Sonicor #103 to remove grease

Take extra cautioned when cleaning the stainless steel cartridges using acids because it may deteriorate welded joints if you don’t apply and rinse appropriately.

As a rule of thumb, ensure that you follow all the safety precautions as outlined and approved by the manufacturers, company, or industry standards.

You should also take note of the local in-country, region, or state regulations where applicable.

You have to use different methods to construct different types and designs of the metal filter cartridge.

For instance, when constructing a sintered metal cartridge, you will sinter the composite fiber together with the wire mesh in a vacuum.

Roll the sintered material into matts with diverse thicknesses.

You can use the mats to construct metal cartridges designed as tubes, pleated, plain, single or multilayered structures.

The principle of operation employed by metal filter cartridges is similar to that used by other types of filters.

For woven wire mesh metal filters, they retain all the dirt which have a larger diameter than the pore size of the mesh and therefore have an absolute rating.

Melt felt filters and sintered metal filters are depth filter cartridges that remove particles as the fluid passes through the depth of the filter.

Depending on the type of the filter, the direction of flow can be formed inside to outside or from outside to inside.

Generally, particulate metal filters flow from outside to inside while coalescing metal filters flow from inside to outside.

Both types of filters remove particulate contaminants through four main mechanisms:

- Impaction: The removal of large size contaminants which hit and stick on the media

- Interception: These mechanisms remove midsize particles, that is, particles between 0.1 to 1 microns. These contaminants are suspended in the fluid stream and drive into the medium through turbulent flow then stick on them.

- Diffusion: The mechanism helps in removing smaller particles below 0.1 microns. The particle’s motion in the fluid stream is facilitated through Brownian motion.

The random movement increases the probability of particles hitting and sticking on the medium surface.

Metal filter cartridge

You can test the quality of metal filter cartridges by conducting several tests to ensure that it meets all the standards of your application.

You can conduct a Multipass test to validate the performance of the filter.

The test specifications are outlined under ISO 16889:2008 guidelines.

You can also consider the requirements of the regional standards like ASTM F 795 -88 which also provide guidelines on procedures of testing metal filter cartridges.

You can also conduct a bubble Point test to confirm the integrity of the filter.

The other important test that you can perform include:

- DOP test

- NaCI test

- LASE test

- ANSI/CAGI test

- Flow test

- Dirt loading test

- Contaminated pressure test

Some of the common problems associated with metallic filter cartridges include:

· Corrosion

Corrosive process fluids attack the cartridges causing damages and cartridge failure in the process.

Corrosion affects the both function of the filter and the quality of the finished product.

· Surface Reactivity

This problem arises when catalytic activity and /or chemical adsorption occurs as a result of the reaction between the filter substrate and the medium.

Chemical adsorption will result in product quality problems and analytical test problems.

· Filter Occlusion

Though not specific to metal filters only, pore occlusion and restriction to fluid flow as dirt particles build up in the filtration medium.

The blockage of medium pores will reduce the filtration efficiency and hence demand cartridge replacement or cleaning.

Though identifying the above challenges associated with metal filter cartridges is critical, finding an appropriate solution is more difficult, costly, and time-consuming.

SS Filter cartridge

Some of the common practices you followed to avoid or rectify some of the above problems include:

- Using automatic cleaning systems such as back flash or reheat.

- Timely replacement or cleaning of the filter cartridges

- Using a construction material that is compatible with the chemical properties of your process fluid.

- Using inert material for the construction of the cartridges.

Though the above measures are effective, they are expensive and increase the production cost.

Alternatively, you can use Chemical Vapor Deposition (CVD) which is cheaper and more effective.

Chemical Vapor Deposition is a coating method that prevents fouling and corrosion to the surface of any metallic filter cartridge.

The process enables the penetration of coating vapor to enter and coat the internal surfaces of the medium.

Also, the coating layer is usually very thin and enables the medium to work without extra pressure build-ups.

You can use assorted types of amorphous disposition to provide a physical barrier and prevent acid and base resistance.

Ensure that the coating material selected can withstand the maximum temperatures in your application.

Similarly, the inert nature of the coating material makes it an excellent anti-adsorption material, reducing problems with analytical failures and product contamination.

The antifouling capabilities are a result of the low energy surface properties of the coat.

The filtrates fail to readily adhere to the coated surface compared to a bare metal surface.

When you install an automatic self-cleaning mechanism such as back-pulse and back-flush protocols then you can dramatically extend the lifespan of the filter cartridges.

Metal filter cartridges can take several months if not years before you replace them with new once depending on the application and efficiency of cleaning.

The lifespan of the filter cartridge will also depend on other factors like the frequency of use, operating conditions of the cartridge, size, level of fluid contamination, etc.

Though cleaning saves costs, you should note that you can only restore the cleanliness of the filter to about 80-90% of its initial condition.

After about 5 cleaning cycles, you should consider acquiring a new filter cartridge because the cleaning cost might not be profitable to the service life of the filter.

Metal filter cartridges have more benefits than standard cartridges constructed from other materials.

Though the initial purchasing cost may be high, the cost of ownership will be lower due to reuse in the long run compared to other types of cartridges.

One outstanding advantage of the metal filter cartridge is its ability to maintain efficient filtration capacity under extreme working conditions.

They will maintain very strong mechanical strength under very high temperatures and pressure unlike other types of materials that may disintegrate under such conditions.

You can select from a very wide range of metal alloys which are highly resistant to corrosion unlike the other type of materials.

Metal filter cartridges are probably the easiest to maintain given that they do not require a lot of special care.

The most crucial care is cleaning the cartridges when the change out pressure has reached.

After cleaning the cartridges, you should evaluate to see the effectiveness of cleaning.

You can achieve this by conducting airflow, leak, and/or bubble point test then compare the results to data acquired from a clean cartridge.

The airflow test will give you the pressure differential between the inlet and outlet of the cartridge.

An effective cleaning will give less than a 15% increase compared to a clean element.

If the pressure differential is higher, then you should consider performing a second cleaning.

You can also weigh the filter as a measure of cleaning.

When the weight of a cleaned cartridge is similar to that of a new one, then it indicates that the cleaning was successful.

However, lower weight than the new one would indicate possible corrosion while a higher weight is a symptom of the presence of contaminants.

The cost of a metal filter will vary greatly to the cost of material metal used in its construction.

For example, stainless steel is more expensive than carbon steel.

Therefore, a stainless steel cartridge with a similar specification will cost more compared to a carbon steel cartridge.

Metal filter cartridge

Metal filter cartridges have different filtration efficiency at varying micron ratings.

Generally, a good metal filter cartridge should have between 95 and 99.98% filtration efficiency.

In short, once you consider everything mentioned in this guide, it will be easier to choose a suitable metal filter cartridge.

You can contact FilSon for all your metal filter cartridge replacement.